Mounting and dismounting method for gantry crane

A gantry crane, assembly and disassembly technology, applied in cranes, trolley cranes, transportation and packaging, etc., can solve the problem that gantry cranes cannot be installed and disassembled, and achieve less mechanical equipment, good economy, and improved utilization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

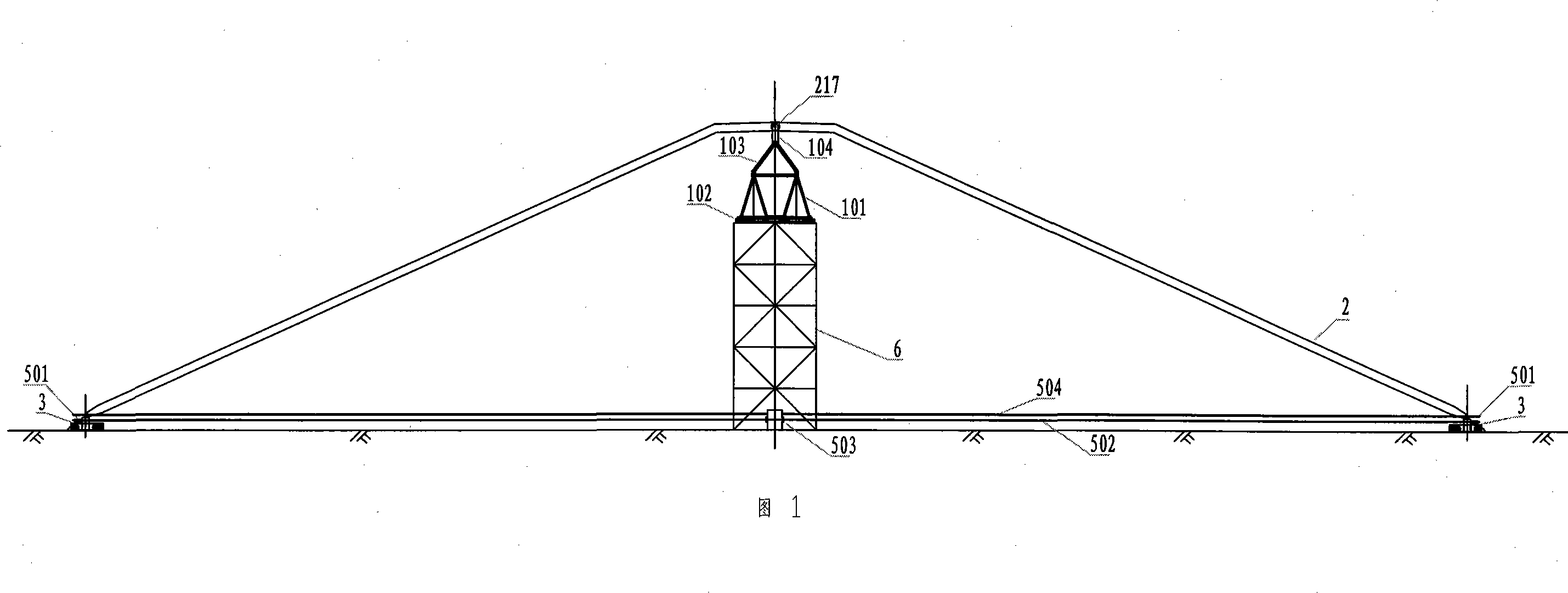

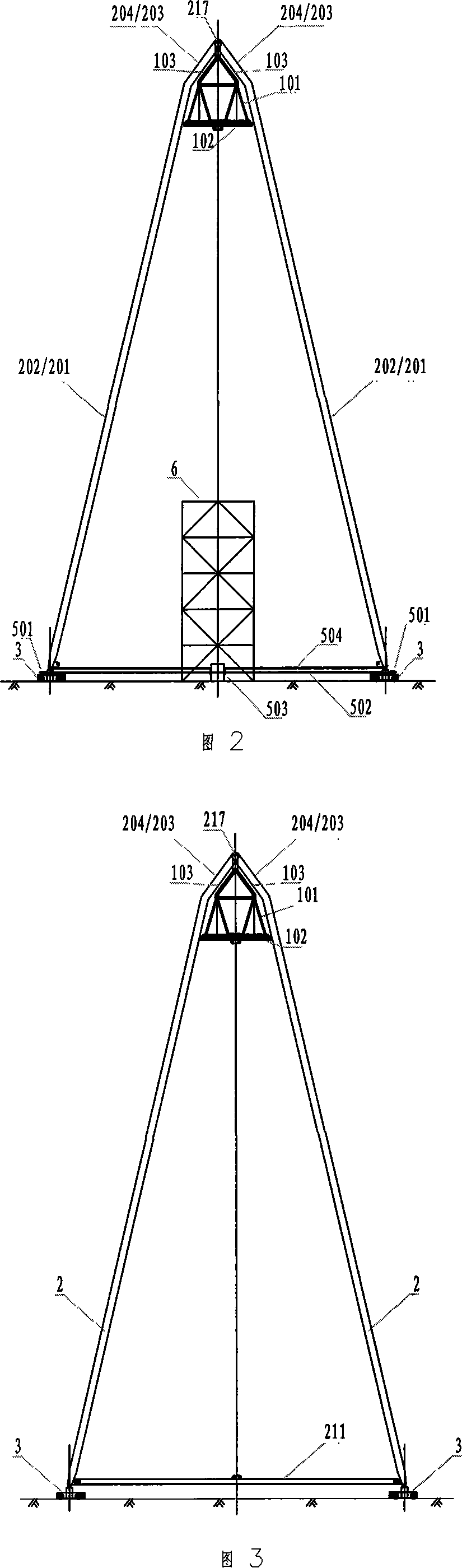

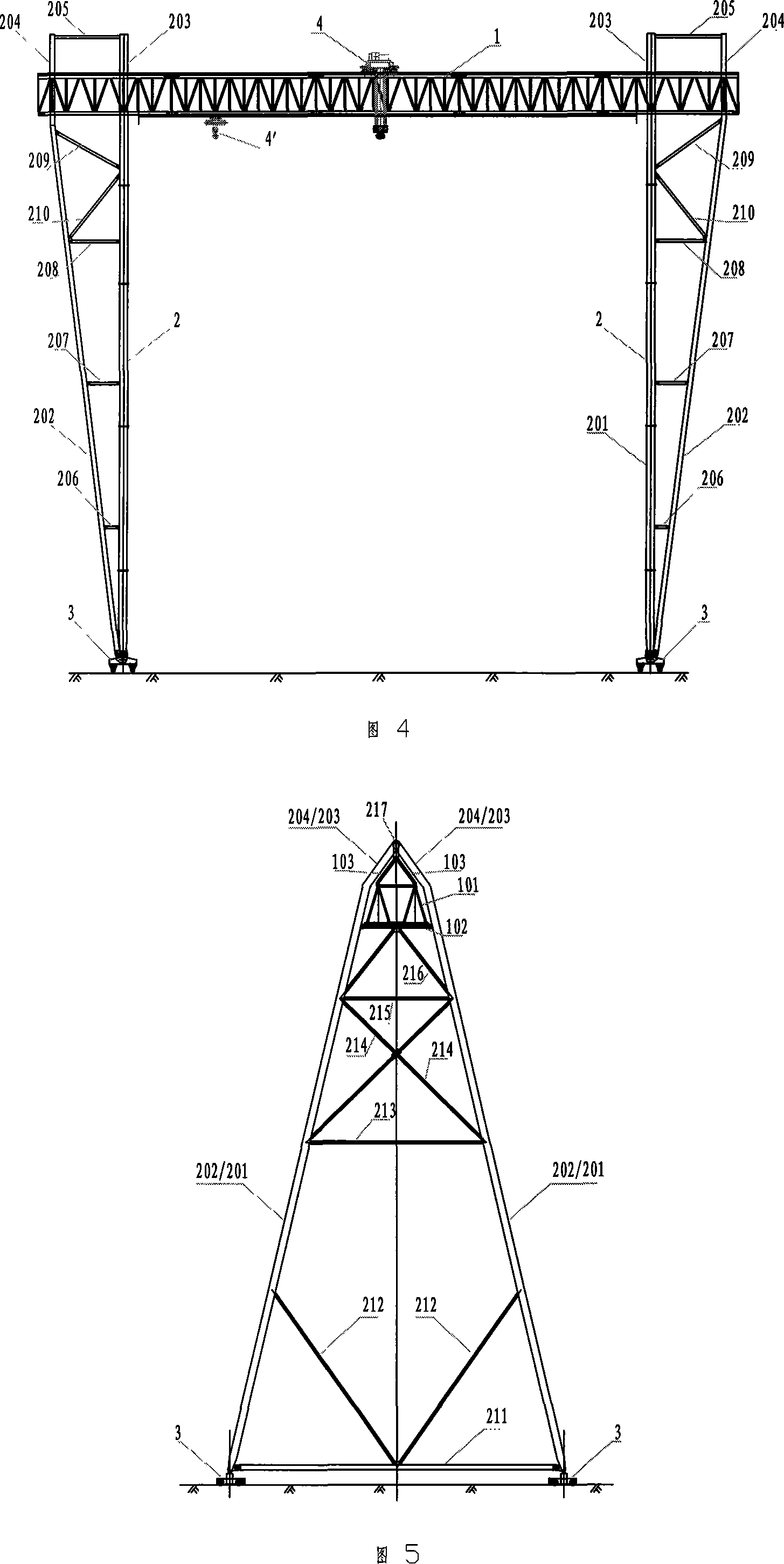

[0022] As shown in Figures 1 and 2, first assemble the main beam 101 on the bracket 6, and at the same time assemble the supporting leg distribution beam 102 under the main beam with the main beam 101. On the ground, two groups of each leg are assembled into two identical stringers, and each stringer is composed of a main leg 201, an auxiliary leg 202, a bending part of the main leg 203, and a bending part of the auxiliary leg 204. The two trusses of each supporting leg share the connecting pin 217, and the lower end of each truss of the supporting leg is hinged with the traveling cart 3, and the traveling cart 3 is temporarily fixed to the ground track. The assembled main girder is suspended below the connecting pin shaft 217 of the supporting legs through the connecting suspension plates 103 and 104 . The height of the bracket 6 used to assemble the main girder 1 should be adjusted according to the specific conditions of the door machine, and different materials and structur...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap