Sewing machine

A sewing machine and sewing needle technology, applied in the direction of sewing machine components, sewing equipment, sewing machine ring mechanism, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

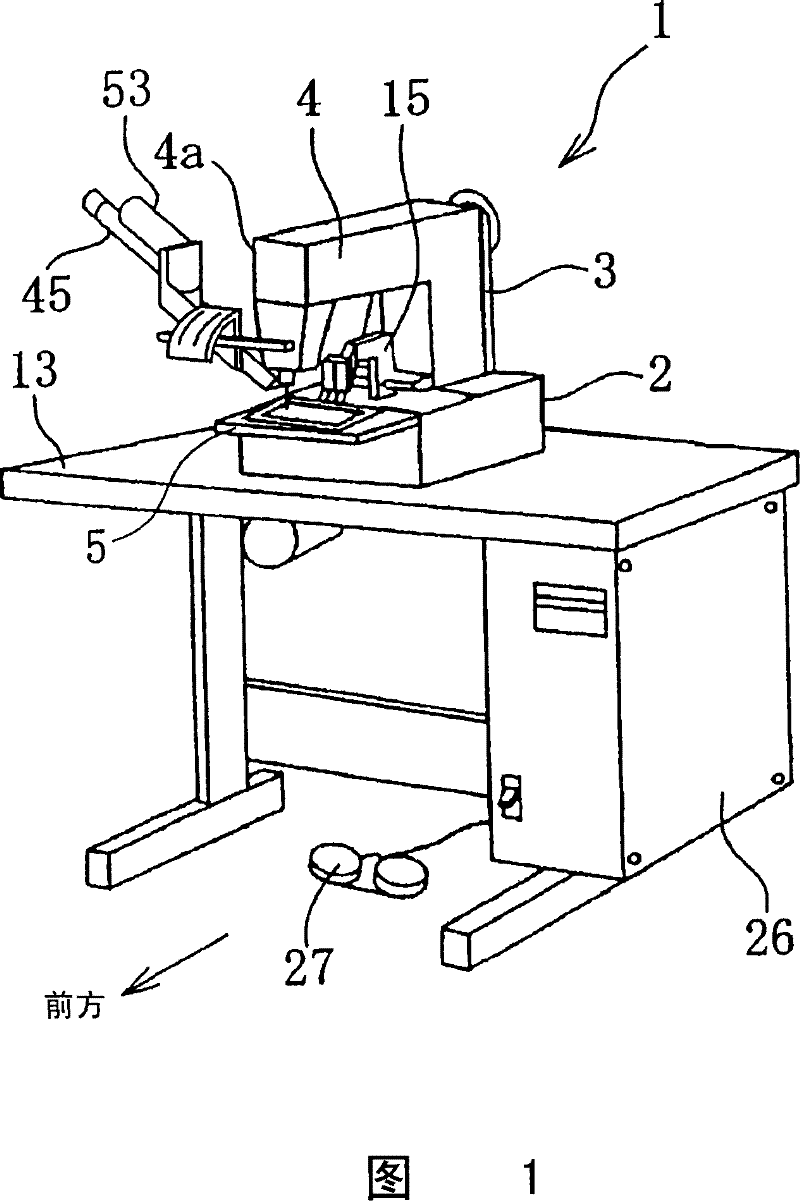

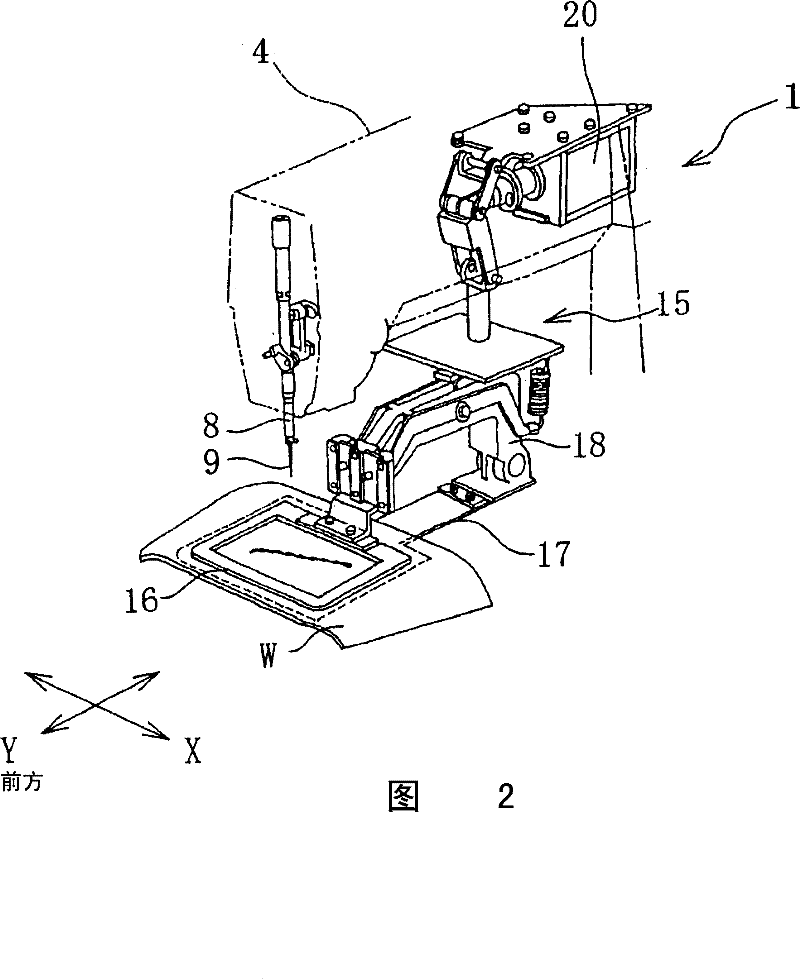

[0049] Such as figure 1 As shown, the sewing machine 1 has on the workbench 13: a bottom plate 2 as the sewing machine body; a column portion 3 continuous with the bottom plate 2; The bottom plate part 2 has a needle plate 5 and a cloth presser 15 on the upper part. The needle plate 5 has a needle hole 5a through which the sewing needle 9 can pass (refer to Figure 5 ). The bottom plate portion 2, the column portion 3 and the machine arm portion 4 constitute a sewing machine frame. exist figure 1 In FIG. 1 , the side of the column portion 3 is defined as the rear of the sewing machine 1 , and the side of the clamp plate 16 described later is defined as the front of the sewing machine 1 .

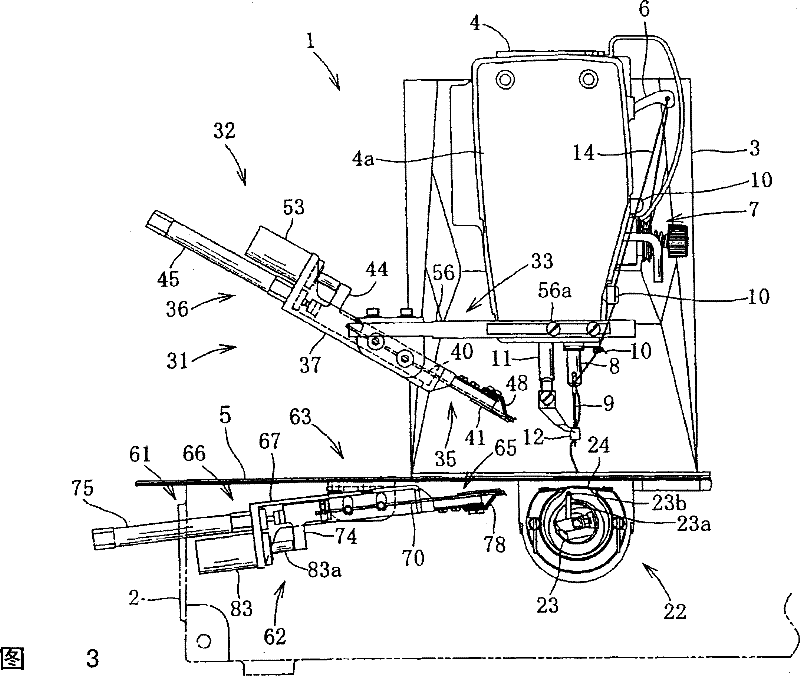

[0050] The arm portion 4 has a main shaft (not shown) extending in the front-rear direction. A needle bar 8 and a thread take-up lever 6 that reciprocate up and down are provided on the machine arm 4 (refer to image 3 ). A sewing needle 9 is installed at the lower end of the needle b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com