Control method of sewing machine

A control method and technology for sewing machines, which can be applied to control devices for sewing machines, sewing machine components, sewing machines, etc., can solve problems such as cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

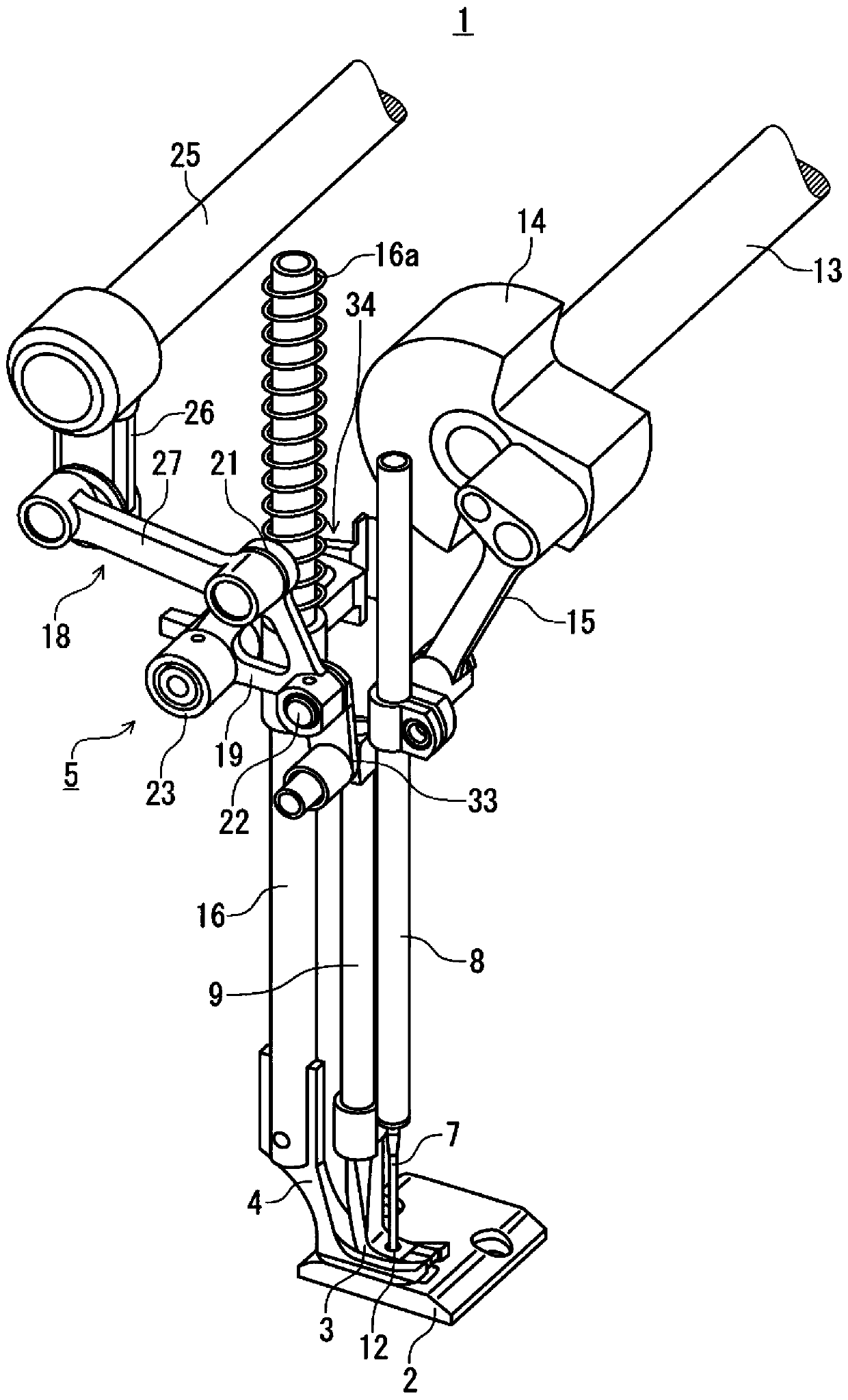

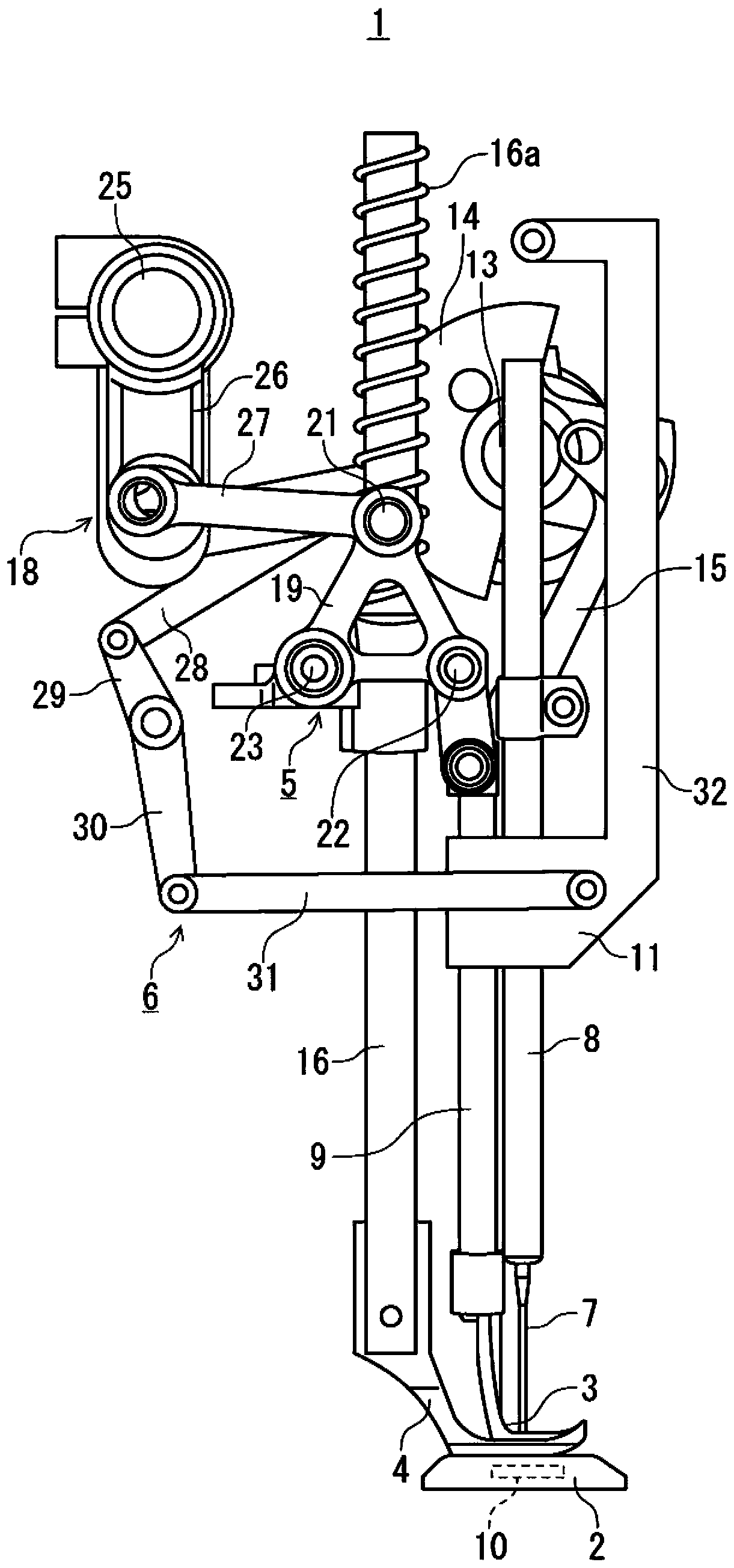

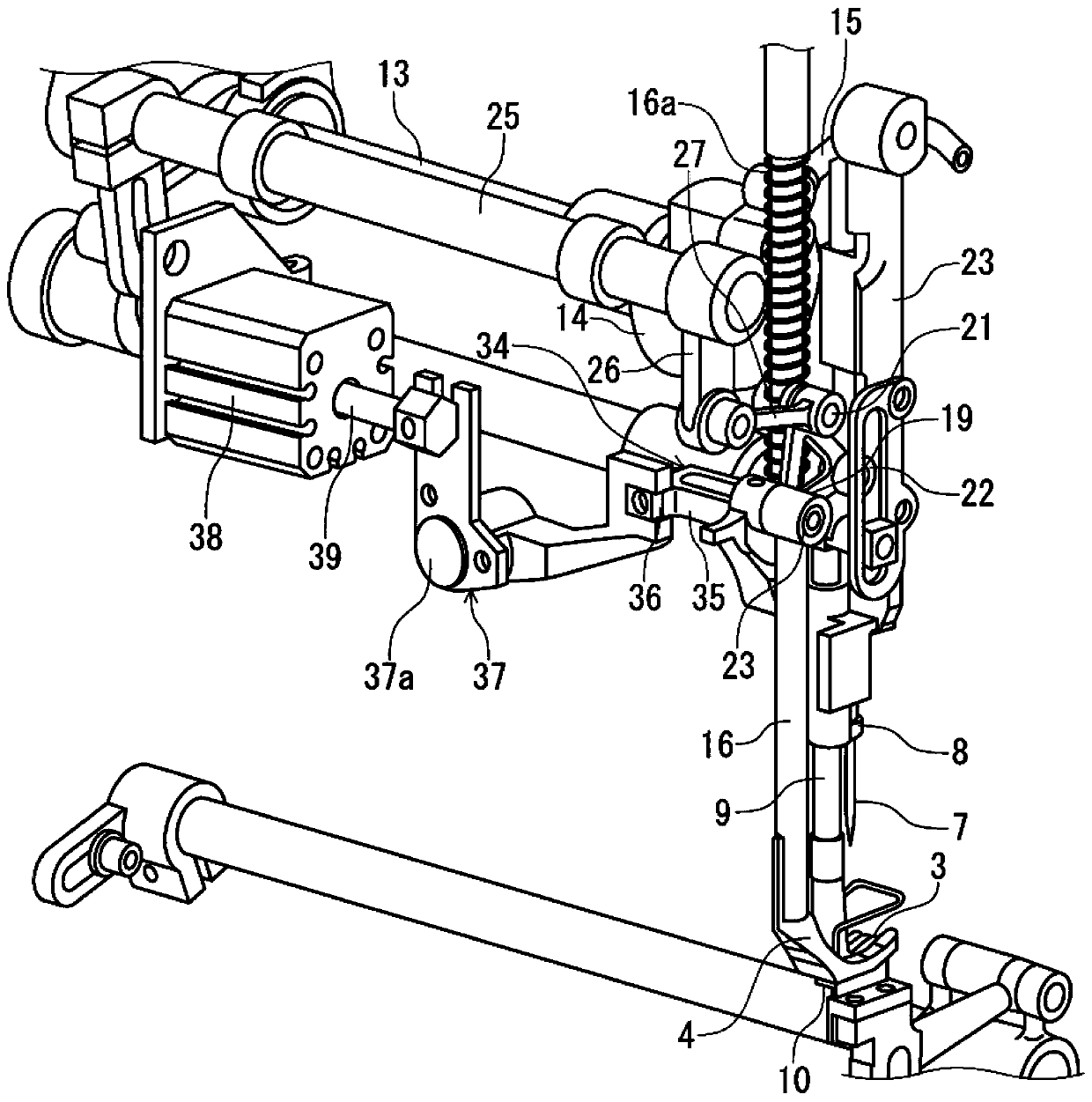

[0045] Next, an embodiment of the control method of the present invention will be described using a sewing machine capable of realizing the control method of the sewing machine.

[0046] Such as Figure 1 ~ Figure 3 As shown, the sewing machine 1 has: an upper feed foot 3, which moves in a predetermined direction, that is, the feed direction of the sewn object W, in a state of contacting the object to be sewn W on the needle plate 2 from above to feed the object to be sewn. The sewing product W is conveyed; the presser foot 4 presses the sewing product W toward the needle plate 2 from above; the first action mechanism 5 makes the upper feed foot 3 and the presser foot 4 move up and down in opposite phases. and the second action mechanism 6, which makes the upper feed foot 3 reciprocate in the horizontal direction (feed direction).

[0047] The upper feed leg 3 is supported by a support bar 9 extending in the up and down direction so as to be in the length direction of the nee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com