sewing machine

A sewing machine and motor technology, which is applied to sewing machine components, sewing equipment, sewing machine control devices, etc., can solve the problems of lightening and incapable of fully realizing the burden of operators, and achieves suppression of confusion and reduction of confusion and burden of stitch formation. lightening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] [Structure of sewing machine]

[0050] Next, a sewing machine 10 as an embodiment of the present invention will be described with reference to the drawings.

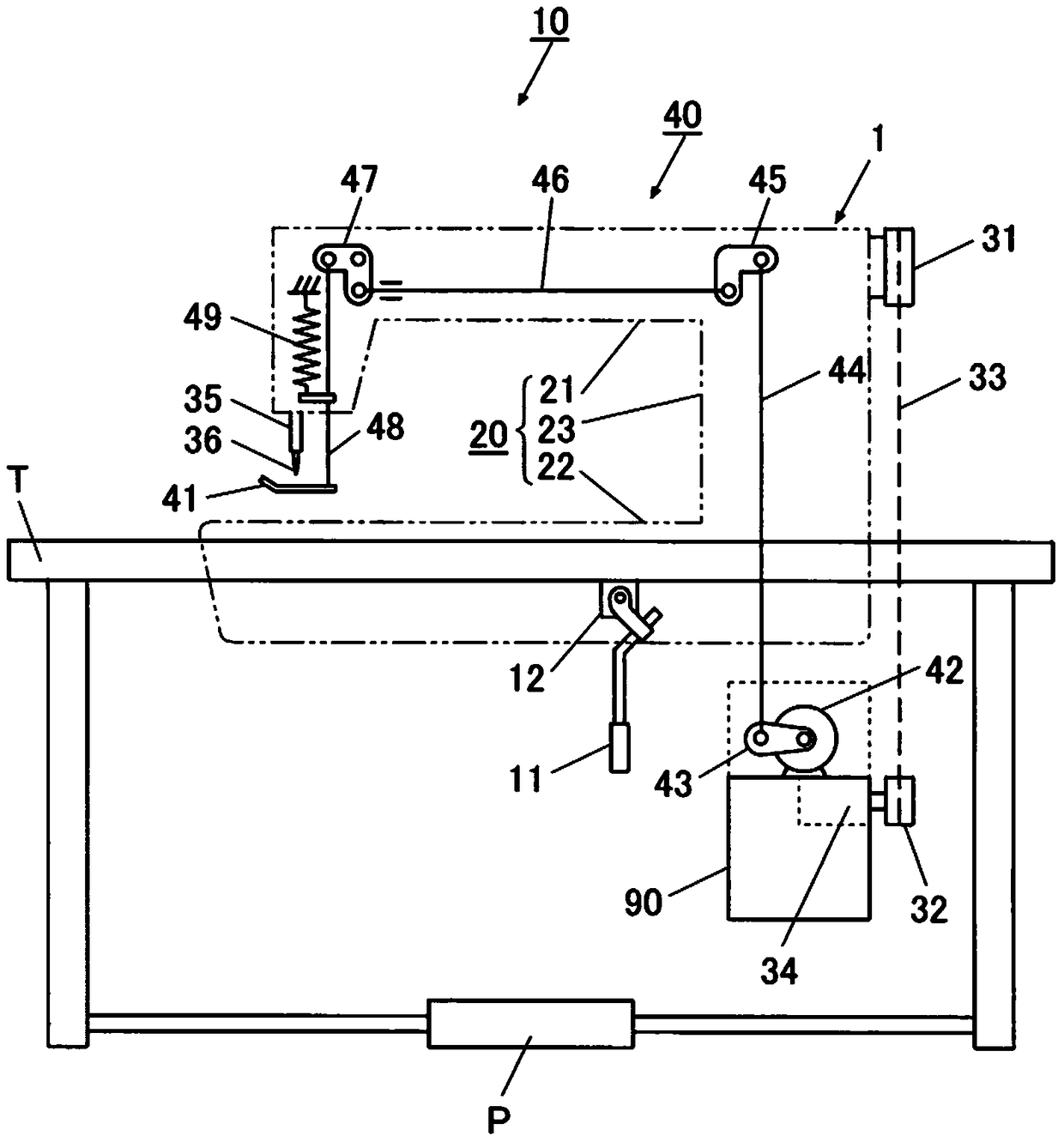

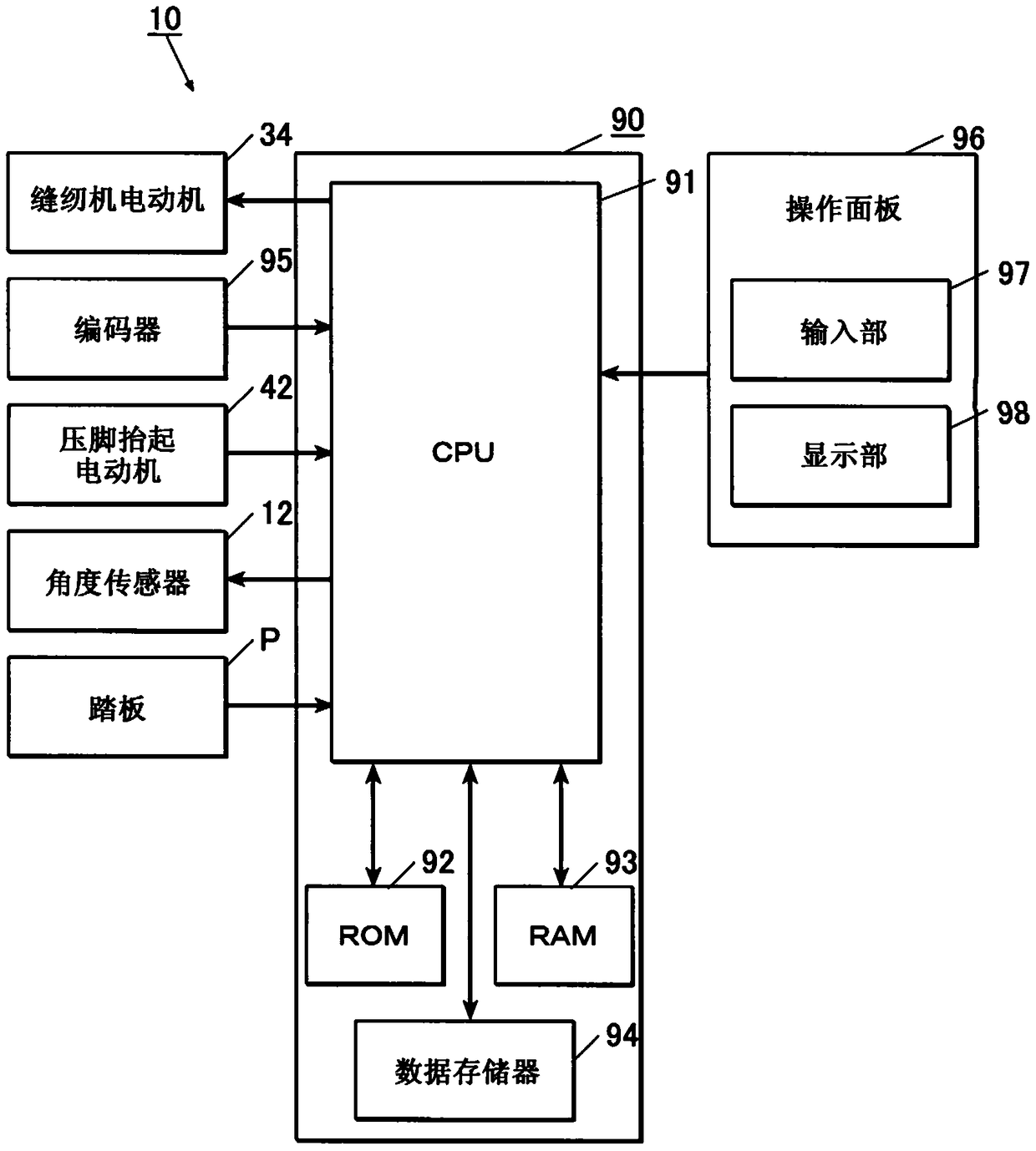

[0051] sewing machine 10 as figure 1 As shown, there are: a sewing machine main body 1, which is provided on the sewing machine table T; ; and the control unit 90, which centrally controls each part of the sewing machine.

[0052] Sewing machine body 1 such as figure 1 A sewing machine frame 20 having a substantially U-shaped outer shape when viewed from the side is shown. The sewing machine frame 20 has: a sewing machine arm part 21 which forms the upper part of the sewing machine main body 1 and extends in the left-right direction; a sewing machine base part 22 which forms the lower part of the sewing machine main body 1 and extends in the left-right direction; and a longitudinal body part 23 which The sewing machine arm portion 21 is connected to the sewing machine base portion 22 .

[0053] This sewing ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com