Method and apparatus for improving main rotor yoke fatigue life

A technology for rotors and rotorcraft, which is applied to rotorcraft, transportation and packaging, motor vehicles, etc., and can solve problems such as increased yoke life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

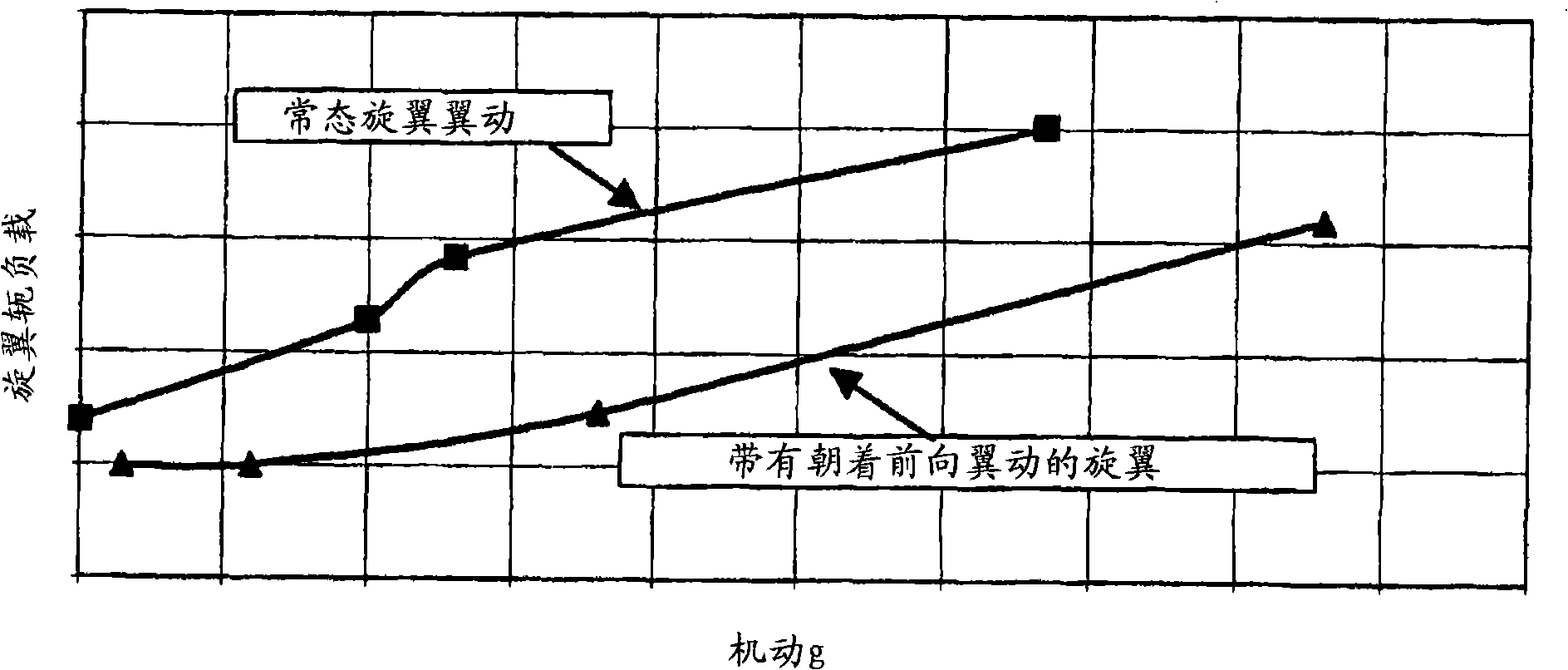

[0017] Efficient and reliable measurements of rotor wing motion are understandably difficult to accomplish. However, it is known that rotor motion consists of two components. The first component is the thrust coefficient C of the rotor T and a function of the advance speed ratio μ. C T is a function of the collective control position of the rotor, and μ is a function of the helicopter's flight speed (airspeed). The second wing motion component is a function of the cyclic control input to the rotor, primarily the longitudinal cycle. Therefore, the total rotor motion can be accurately estimated using the longitudinal period input, the collective position, and the measured (true) flight speed. Advantageously, these three parameters are readily available parameters that are measured in most rotorcraft.

[0018] In one embodiment, sensors or encoders are used to measure the longitudinal period and collective control positions. In addition, the flight speed sensor can be used ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com