Thin spring hinge mechanism of glasses temple

A spring hinge and temple technology, applied in the directions of glasses/safety glasses, glasses/goggles, optics, etc., can solve the problems of wear of the peripheral part of the pivot of the hinge, complicated assembly of the glasses frame, loosening of the fixing screws, etc. The effect of hinge shake suppression, high fashion and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

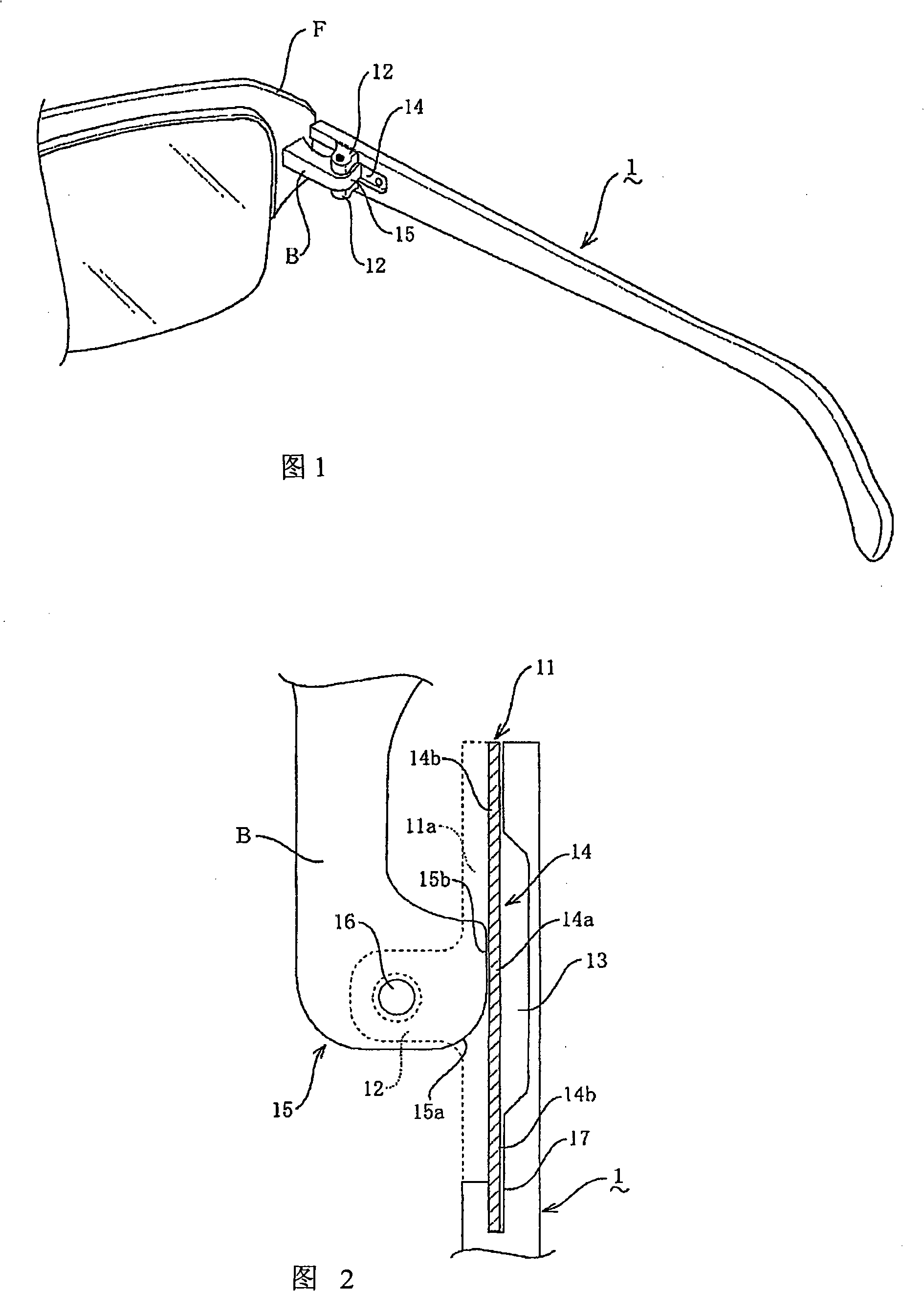

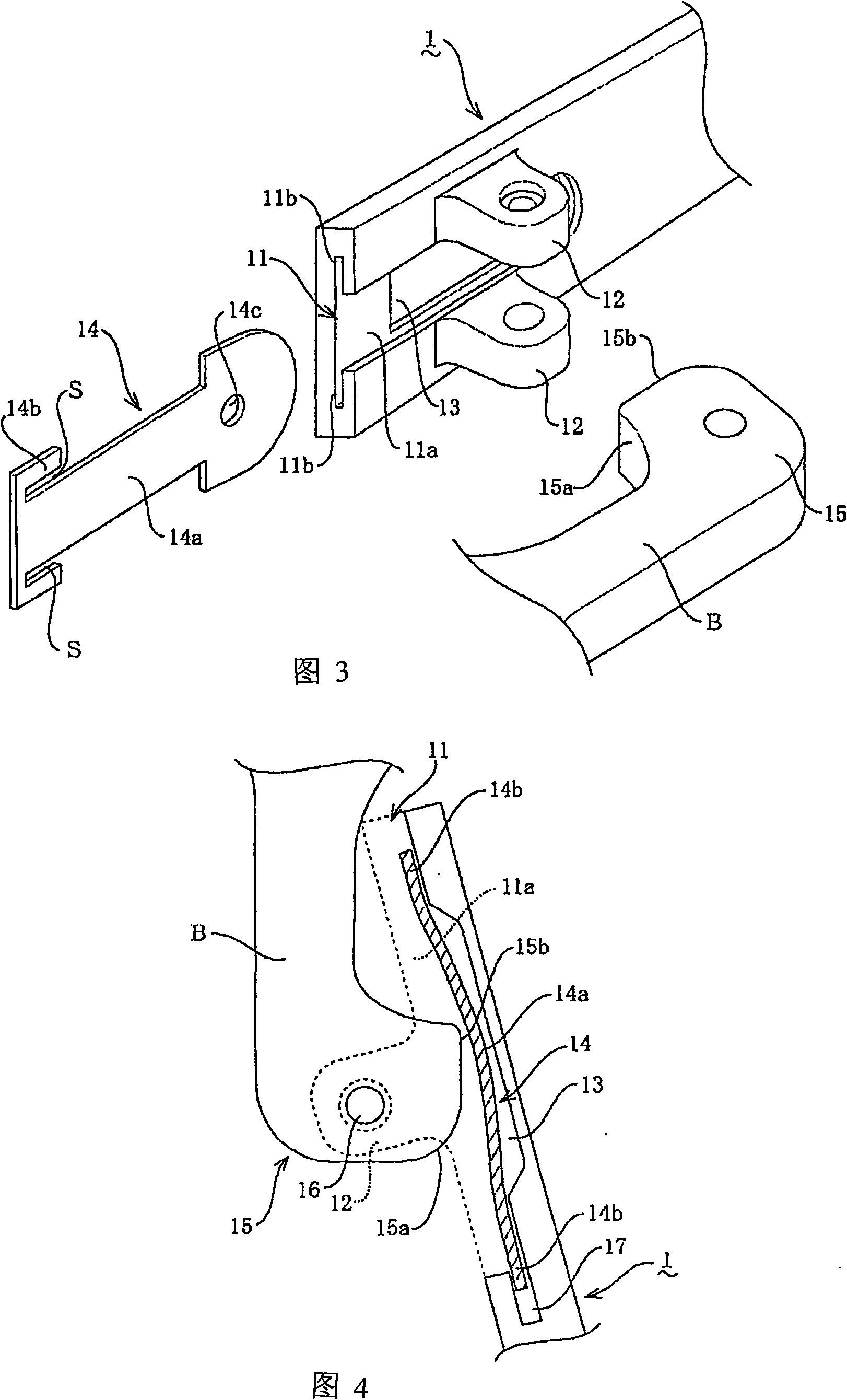

[0025] Referring to FIGS. 1 to 4, an insertion groove 11 having an opening 11a on the inner surface side is provided at the front end of a band-shaped metal temple 1, and the opening of the insertion groove 11 is sandwiched between the upper and lower sides of the temple. The opposite of 11a is provided with a butterfly piece 12 (see Fig. 1, Fig. 2). On the outer surface side of the inner wall of the insertion groove 11 of the temple 1, a relief hole 13 is formed at the position corresponding to the butterfly piece 12, and a sheet-shaped leaf spring 14 is installed in the insertion groove 11b of the insertion groove 11 (see FIG. 3 ). In this embodiment, the material of the leaf spring 14 is SK steel which is cheap and easy to form. Of course, stainless steel which is not easy to rust, copper alloys such as beryllium copper, titanium alloys, etc. can also be used.

[0026] Between the two butterfly pieces 12 of the temple 1, a rotating butterfly piece 15 is inserted, and the r...

Embodiment 2

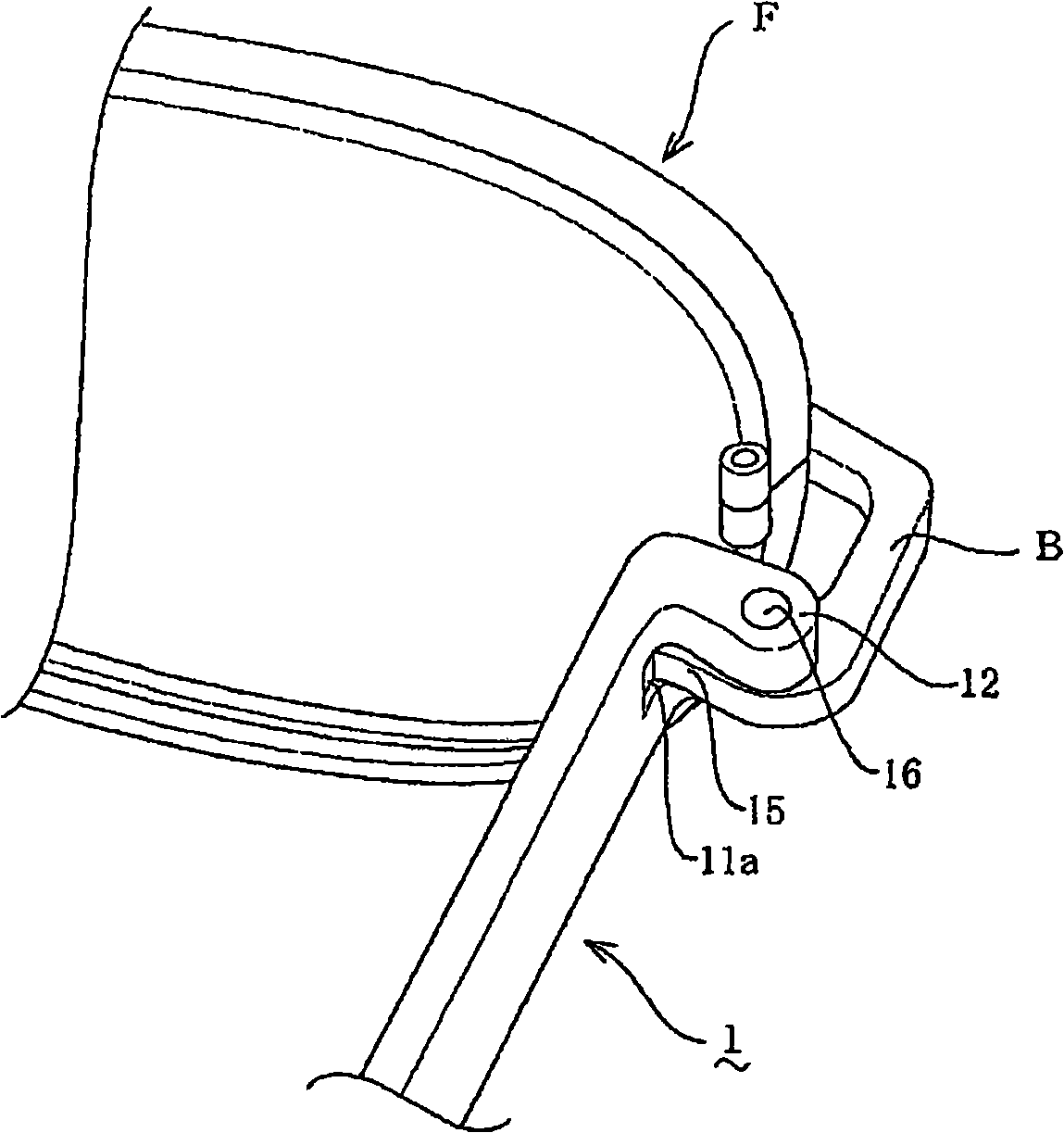

[0033] see Figure 5 ~ Figure 7 , the same as Embodiment 1, the difference is that in this embodiment, the insertion tunnel 11 having the opening 11a is provided on the outer surface side of the temple 1, between the butterfly pieces 12 that are provided sandwiching the opening 11a , insert the rotating butterfly 15 formed on the rear end of the bracket B connected with the side end of the front frame F and perform hinge connection, by means of this, when the temple 1 is opened to the outside, the protrusion of the rotating butterfly 15 The curved portion 15b bends the leaf spring 14 inwardly, and can impart a rebound force to the opening and closing operation of the temple 1 (see Figure 5 , Figure 6a, Figure 6b).

[0034] And in the present embodiment, the inner side of the temple 1 is punched to form a relief hole 13, because the deformation of the leaf spring 14 is not limited by the thickness of the temple 1, so the leaf spring 14 can be bent beyond the thickness of the t...

Embodiment 3

[0037] see Figure 8 , Fig. 9, the same as Embodiment 1, the difference is that in this embodiment, a temple 1 made of plastic is used, and the middle area part has a bending part 14d in the insertion groove 11 of the temple 1. With this structure, when the temple 1 is opened to the outside, the convex portion 15b of the rotating disc 15 presses the bending portion 14d to make it bend. With this, the deformed bending portion can be utilized. The elastic action of 14d exerts a force on the temple 1 (refer to Figure 8 and Figure 9a , Figure 9b ). Moreover, the temple 1 without the leaf spring 14 can be made thinner. In addition, when the leaf spring 14 is deformed, no local load is applied to the insertion groove 11. Therefore, even a plastic temple with relatively low rigidity There is no deformation, and there is no problem in using it.

[0038] Cutouts 17 are formed at the front and rear of the insertion groove 11 of the temple 1 , and the leaf spring 14 is tightly fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com