Electronic component mounting system and electronic component mounting method

一种电子元件安装、电子元件的技术,应用在用电元件组装印刷电路、电气元件、电气元件等方向,能够解决不能有效地执行安装位置修正、焊料位置信息不能被利用等问题

Active Publication Date: 2008-11-26

PANASONIC CORP

View PDF1 Cites 35 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

For this reason, solder position information acquired by a print inspection device may not be available, and thus mounting position correction may not be effectively performed during component mounting

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

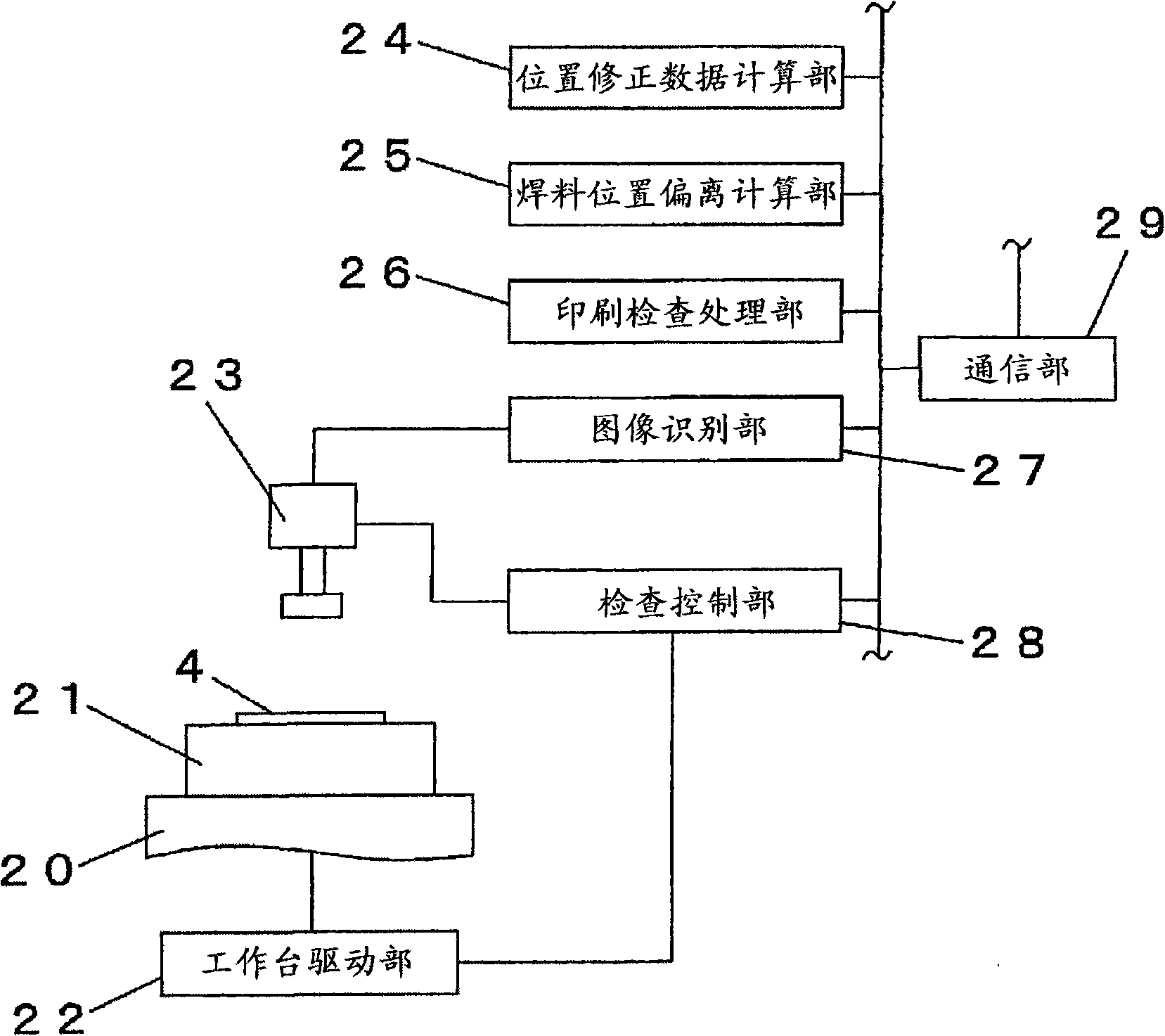

In electronic component mounting for a plurality of individual substrates held on a carrier, solder position deviation data is calculated for each individual substrate based on a mark position recognition result on a carrier after solder printing, a solder position recognition result, and electrode position information indicating the position of an electrode on each individual substrate, an operation of calculating position correction data, which is used to correct the positional deviation to mount electronic components at proper positions, is performed for each individual substrate based on the calculated solder position deviation data and the calculated position correction data is feed-forwarded to an electronic component mounting apparatus, and an electronic component mounting operation of a component mounting mechanism is controlled based on the mark position recognition result and the position correction data.

Description

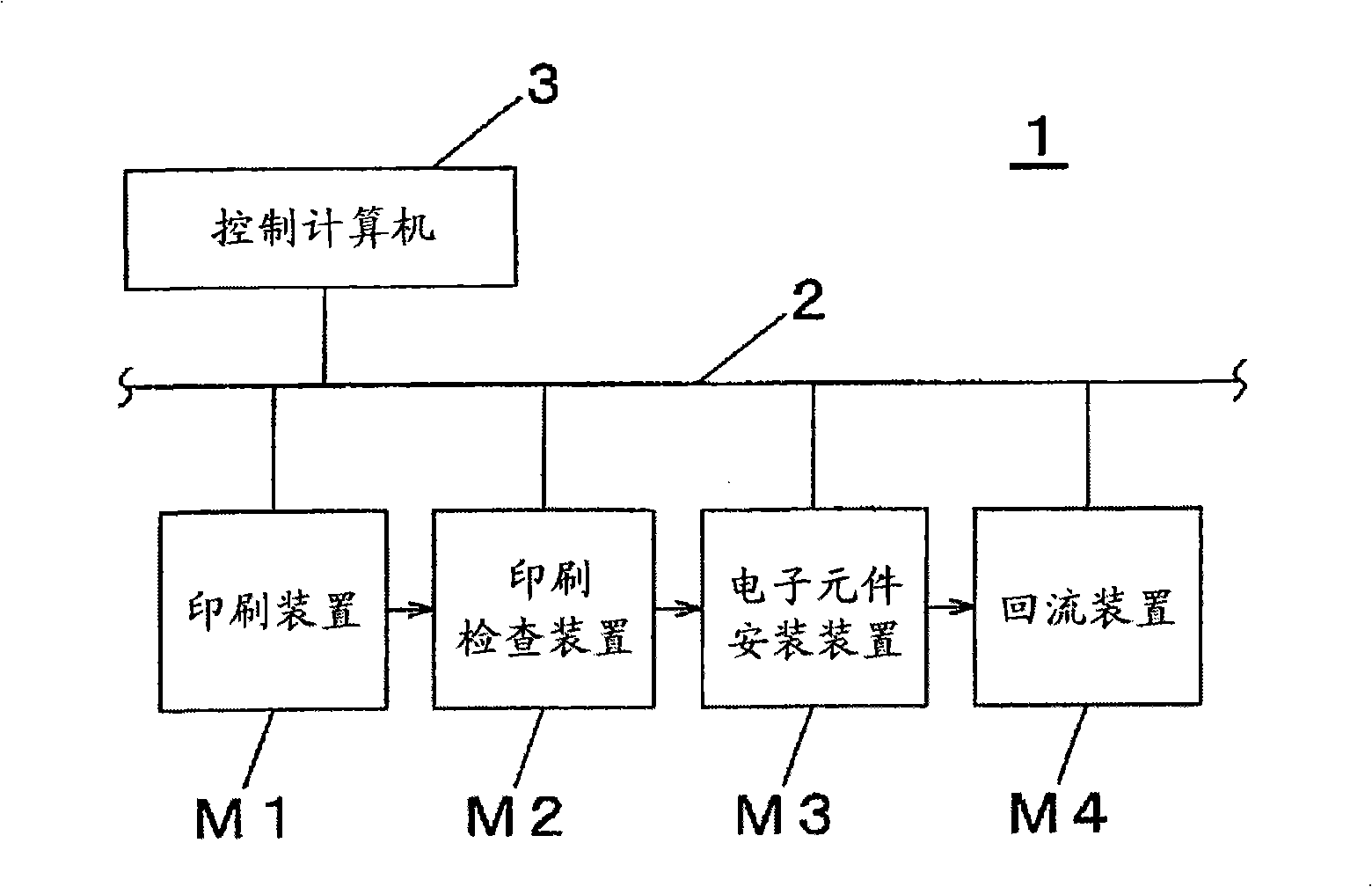

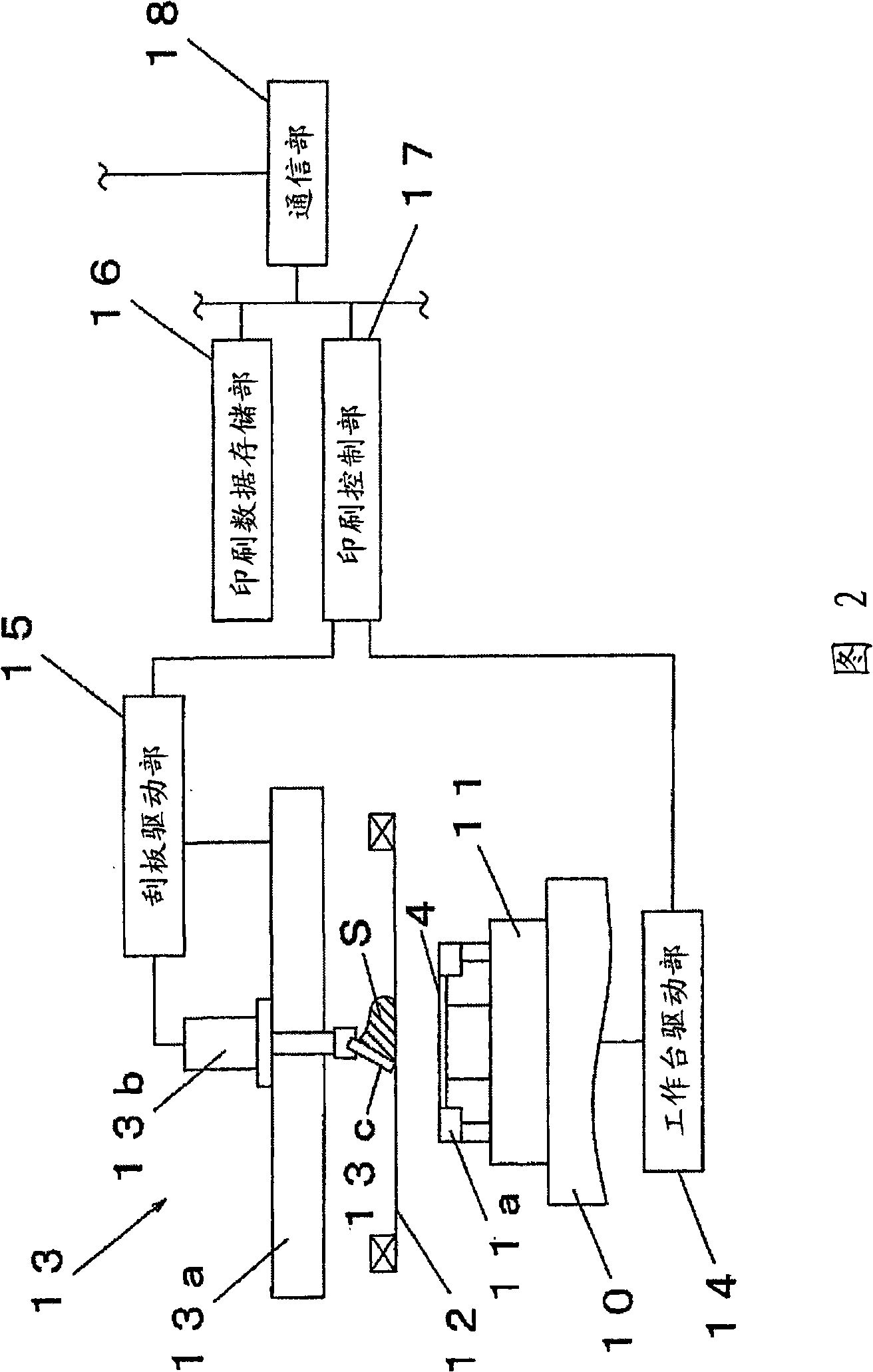

Electronic component mounting system and electronic component mounting method Technical field The present invention relates to an electronic component mounting system and an electronic component mounting method, which mounts electronic components on a plurality of individual substrates held in a carrier by soldering, thereby manufacturing a single-chip mounting board. Background technique An electronic component mounting system is formed by connecting multiple devices for mounting electronic components, such as a solder printing device, an electronic component mounting device, and a reflow device. The electronic component mounting system mounts electronic components on a substrate by soldering to manufacture and mount board. In order to perform high-reliability quality control in such an electronic component mounting system, a technique is known which provides a function of automatically judging whether the component mounting operation has been performed correctly by providing a...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): H01L21/60H01L21/66H01L21/68H05K3/34H05K13/04

CPCH05K2203/0545H01L24/83H01L24/81H01L2224/81801H05K2201/09918H01L2224/83801H01L2223/54426H01L2224/81121H05K3/1216H05K3/3484H01L23/544H01L2224/83121H05K1/0269H05K3/0097H05K2203/0165H05K2203/166H05K3/303H01L2924/01068H01L2223/54473H05K3/3485Y10T29/49131Y10T29/49144Y10T29/49179Y10T29/53174Y10T29/53178Y10T29/53191Y02P70/50H01L2924/3512H01L2924/00

Inventor 井上雅文菊次郁男木原正宏

Owner PANASONIC CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com