Air damper

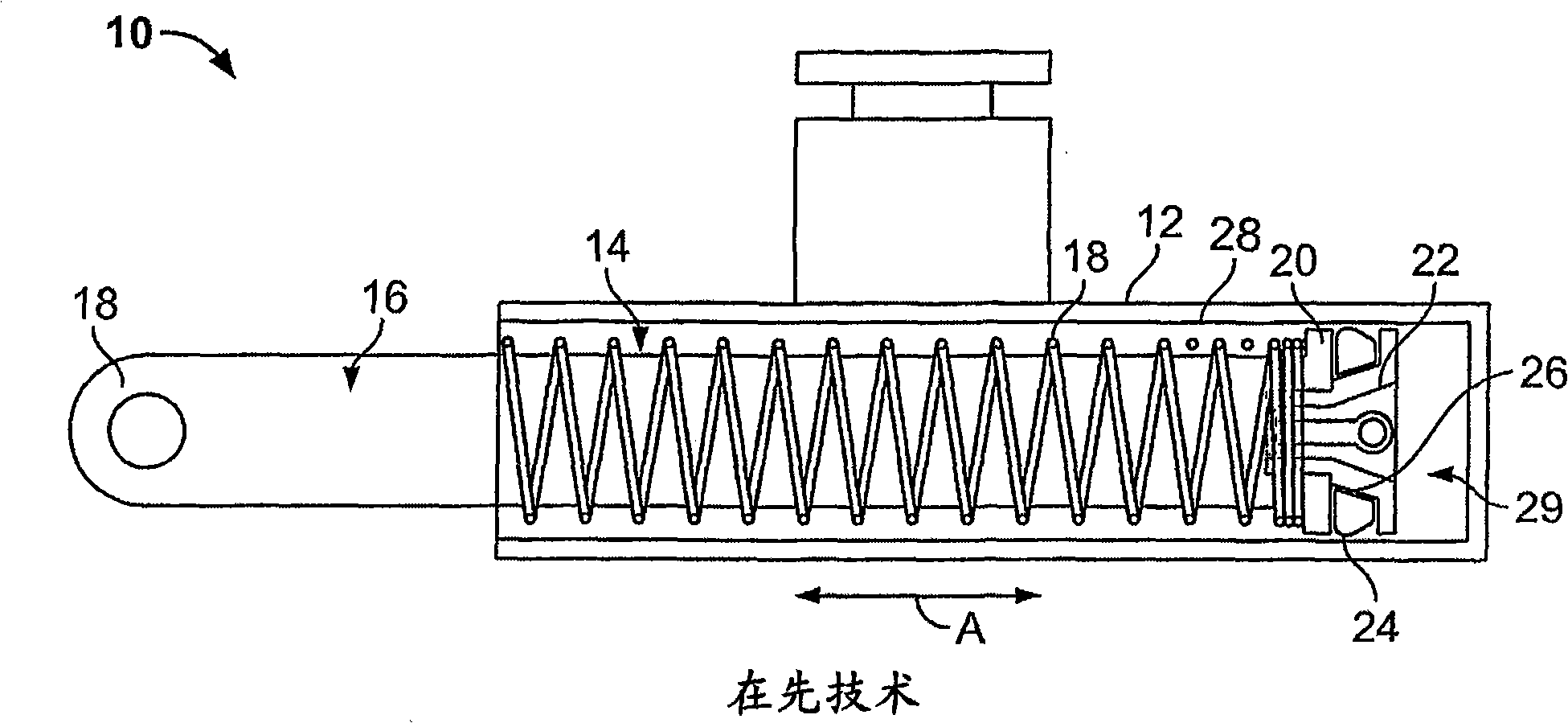

A technology of air damping and lining, used in gas shock absorbers, shock absorbers, shock absorbers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

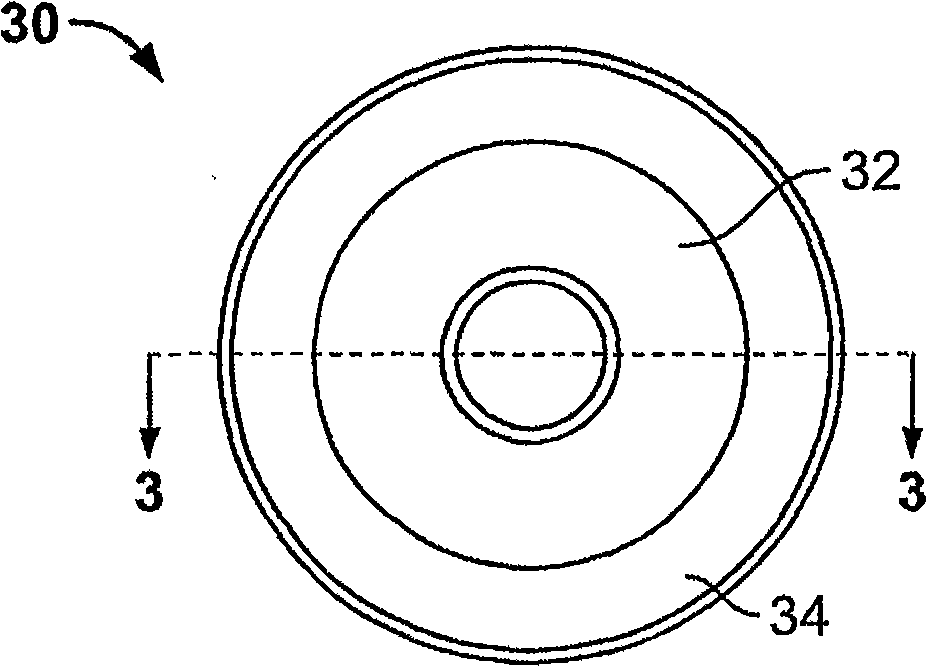

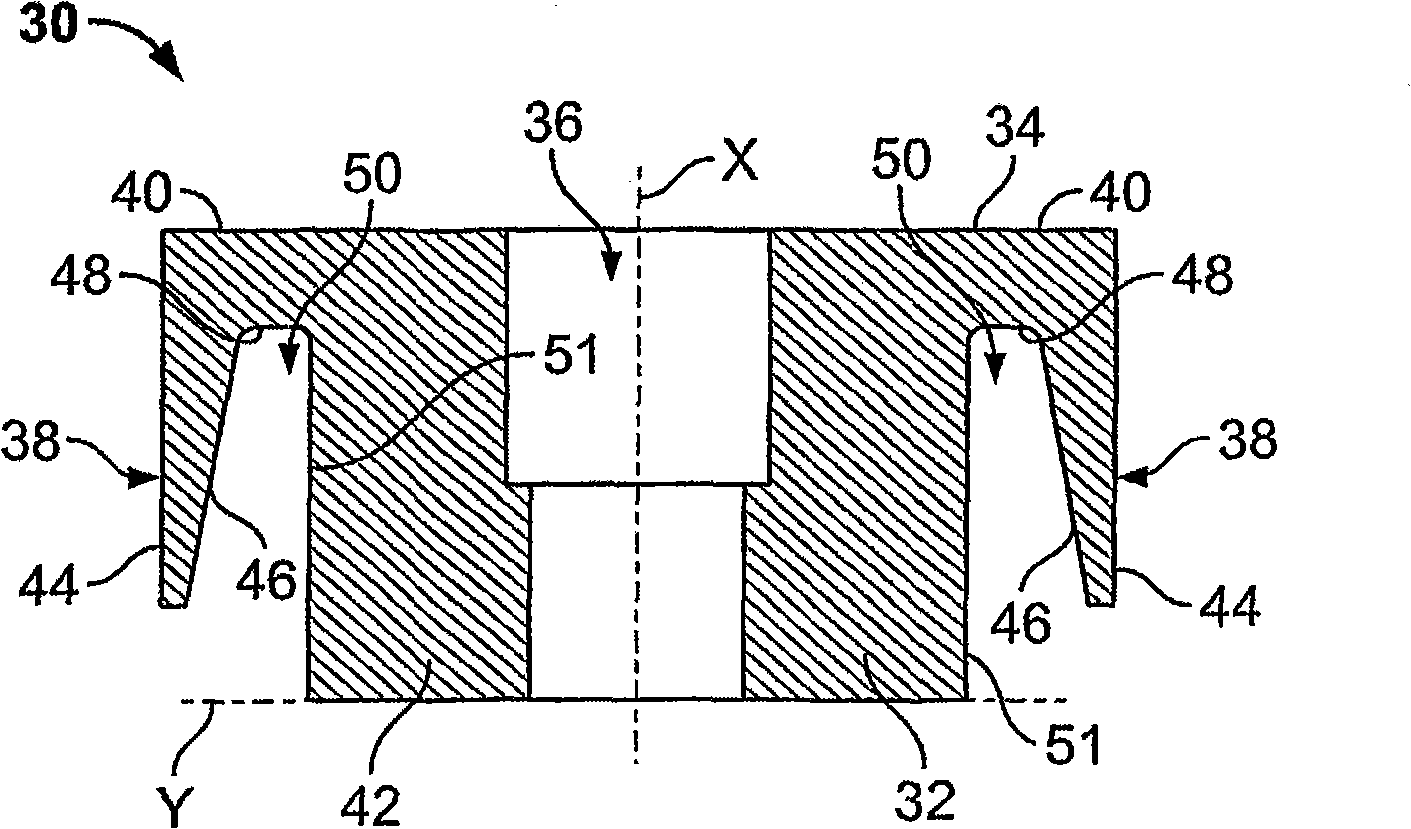

[0024] figure 2 A top plan view of a gasket cap (or piston tip) 30 according to one embodiment of the invention is illustrated. Gasket cap 30 includes a main cylinder or post 32 integrally connected to a circumferential ledge 34 extending around main cylinder 32 . Gasket cap 30 may or may not include holes (not shown) configured to control fluid leakage.

[0025] The liner cap 30 may be formed from a polyolefin, such as a resin-based polyolefin or a thermoplastic. Typically, polyolefin materials may contain oils or other fillers. Resins may, for example, be further classified as polyethylene or polypropylene from a group of materials. Such materials are further subdivided into Low Density Polyethylene (LDPE), Linear Low Density Polyethylene (LLDPE), Medium Density Polyethylene (MDPE), High Density Polyethylene (HDPE), High Molecular Weight Polyethylene and Ultra High Molecular Weight Polyethylene Polyethylene (HMWPE and UHMWPE), homopolypropylene, random copolymer polypro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com