Optical lens component

A technology of optical lenses and components, applied in optical components, optics, instruments, etc., to eliminate primary aberrations, reduce weight, and reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below through specific embodiments and in conjunction with the accompanying drawings.

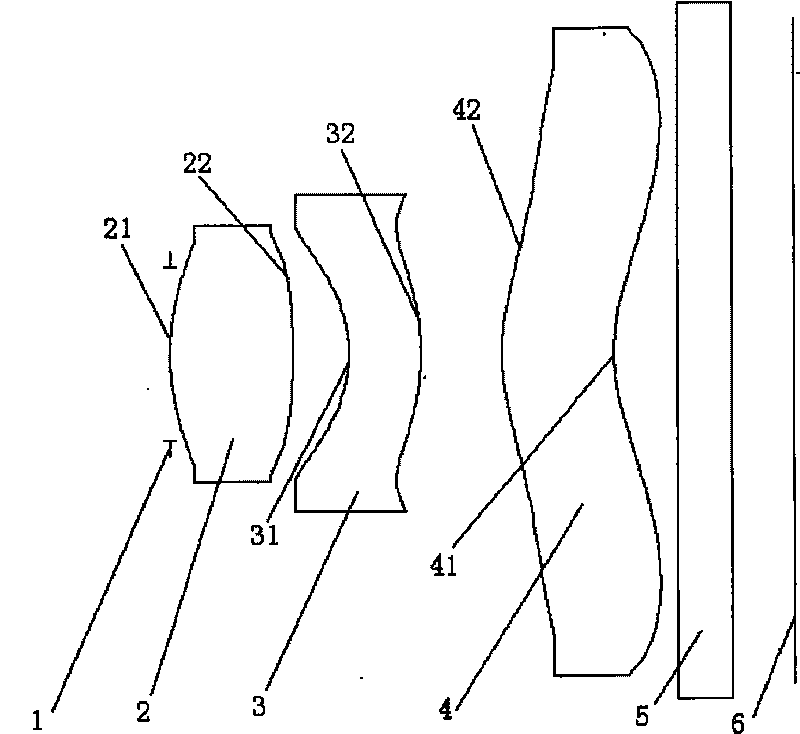

[0027] like figure 1 As shown, the optical lens assembly of the present invention includes a fixed diaphragm 1, a group of lenses and a glass filter 5, and the group of lenses includes a coaxial plastic first lens 2 and a second lens arranged in sequence from the object direction image side 3 and the third lens 4, the optical lens assembly forms an image on the imaging surface 6, the fixed diaphragm 1 is located in front of the first lens 2 and close to the object side, and the filter 5 is located between the imaging surface 6 and the third lens 4.

[0028] The first lens 2 has a first surface 21 close to the object side and a second surface 22 close to the image side, both of the first surface 21 and the second surface 22 are convex. The second lens 3 has a third surface 31 close to the object side and a fourth surface 32 cl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| optical path length | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap