Push structure of forming device lower knife

A technology for cold-formed forming machines and rolling parts, applied in forming tools, metal processing equipment, manufacturing tools, etc., can solve the problem that the lower tool seat plate has a large impact on the machine tool, the stability and reliability of the forming machine are not high, and the frictional resistance is small. and other problems, to achieve the effect of high stability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

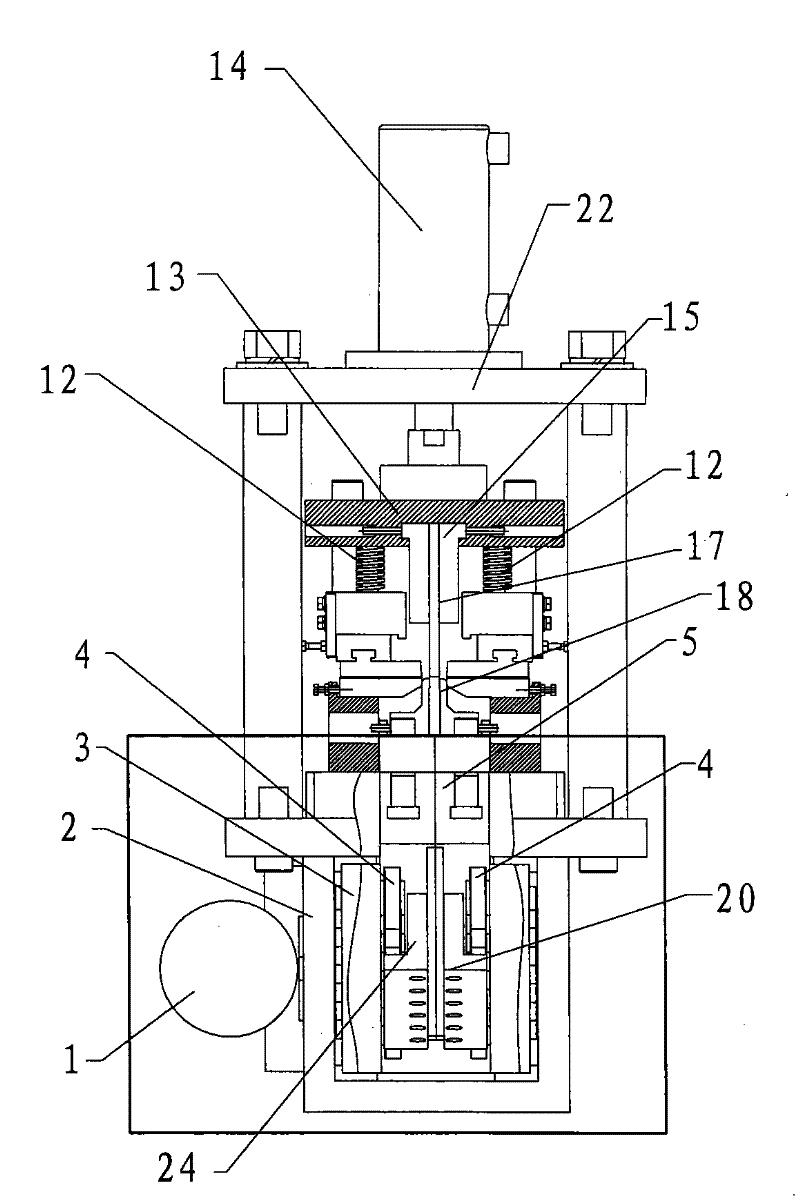

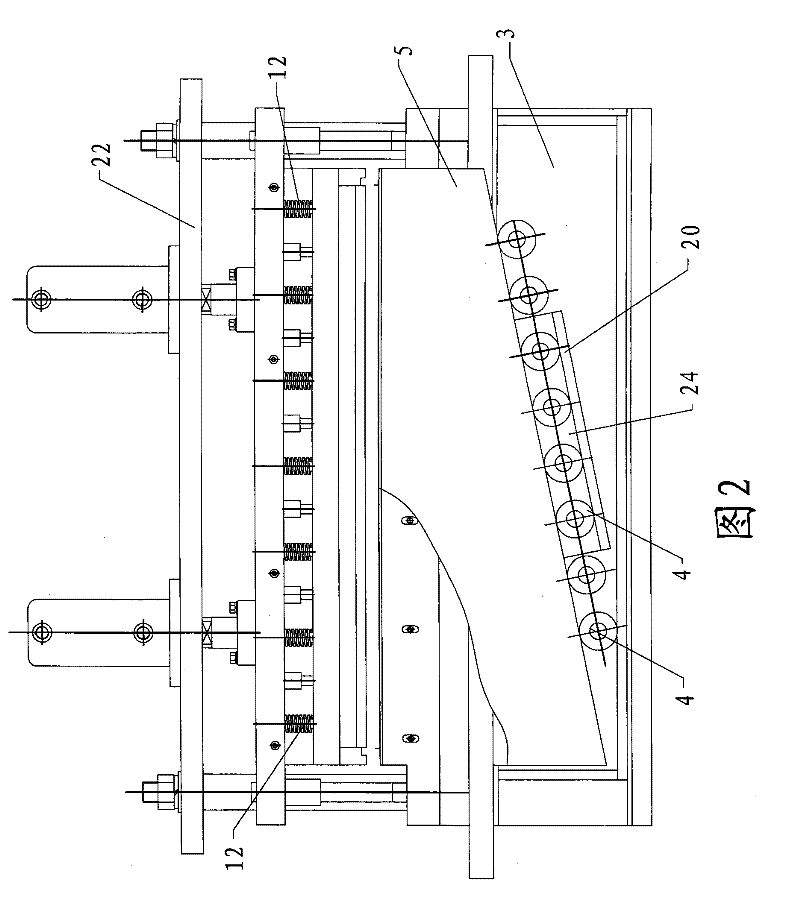

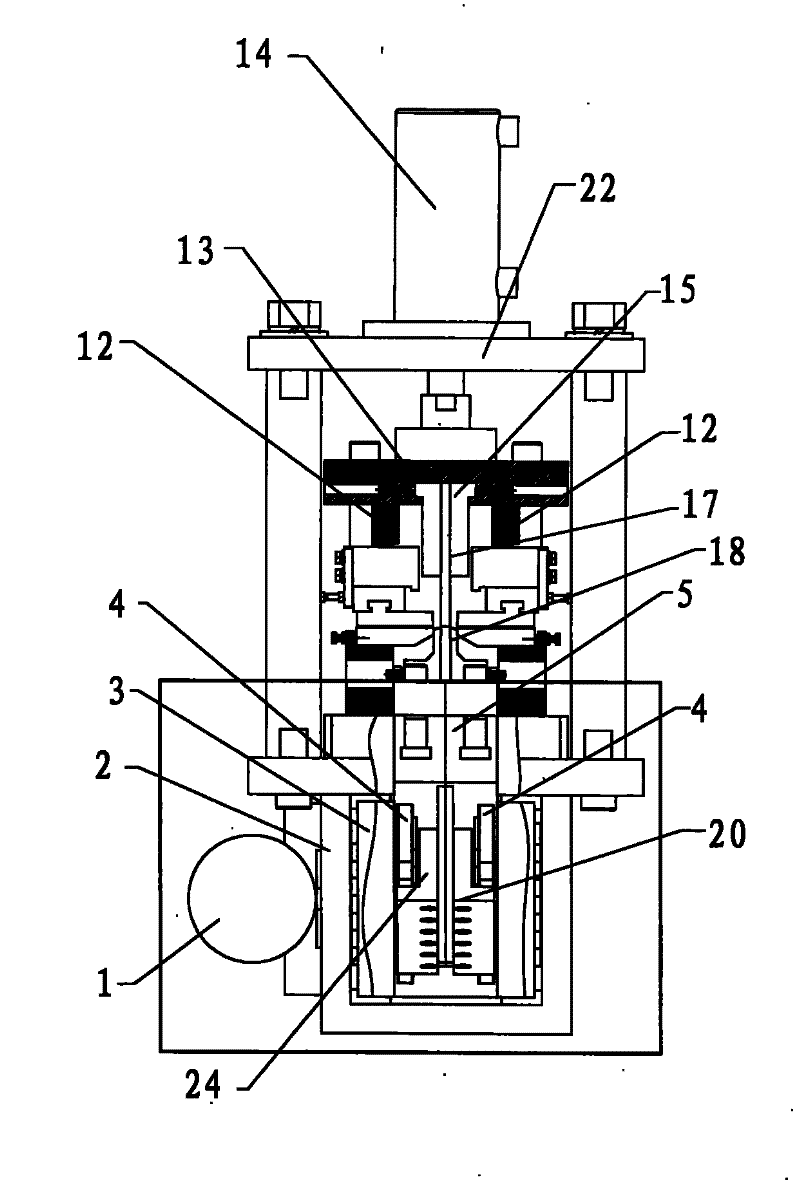

[0009] The specific structure and working principle of the present invention will be further described below in conjunction with the accompanying drawings.

[0010] See attached figure 1 As shown in and 2, a push structure for the lower knife of a cold roll forming machine is used to control the upward shearing and downward return of the lower knife, including a moving box 3 that moves back and forth in the horizontal plane, and in the vertical direction The lower knife seat plate 5 that moves back and forth and is driven by the moving box 3, the top of the moving box 3 and the bottom of the lower knife seat plate 5 have guide slopes, the lower knife A lower knife 18 is installed on the seat plate 5, and a plurality of rolling elements 4 for reducing friction are rotatably provided on the guide slope of the moving box 3, at least part of the rolling elements 4 and the guide of the lower knife seat plate 5 The inclined surfaces are in contact with each other, and rolling occur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com