Patents

Literature

37 results about "Device Knife" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

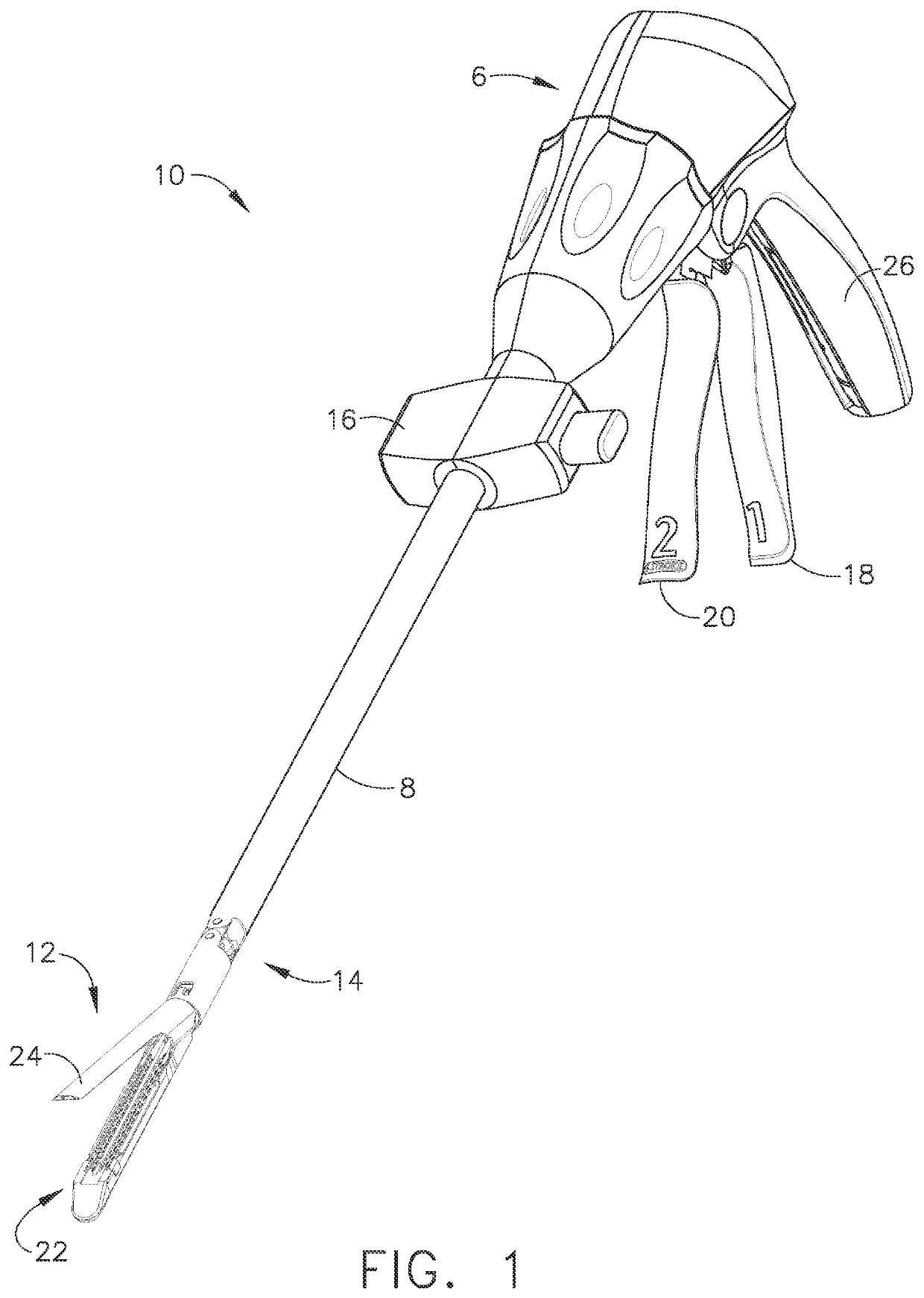

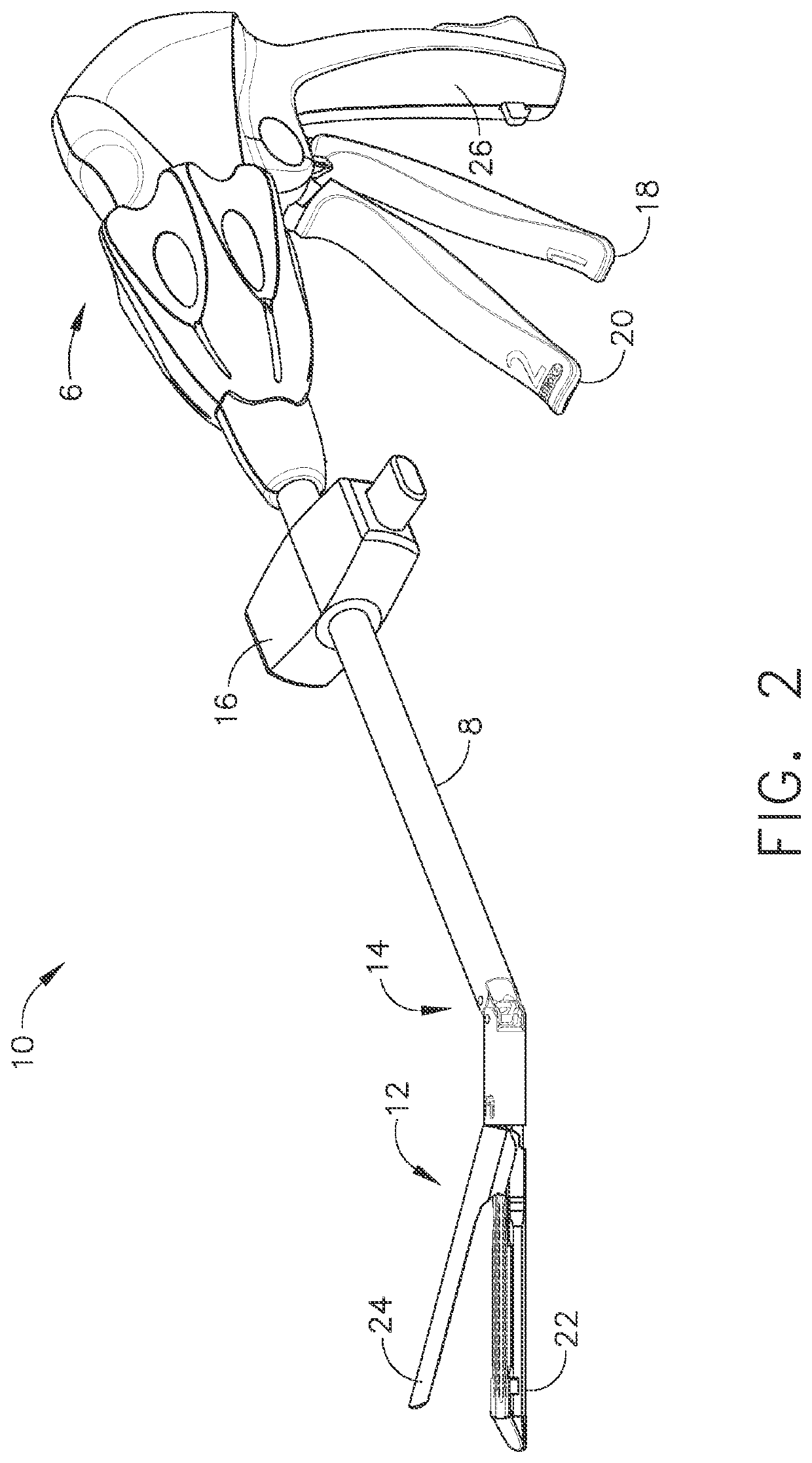

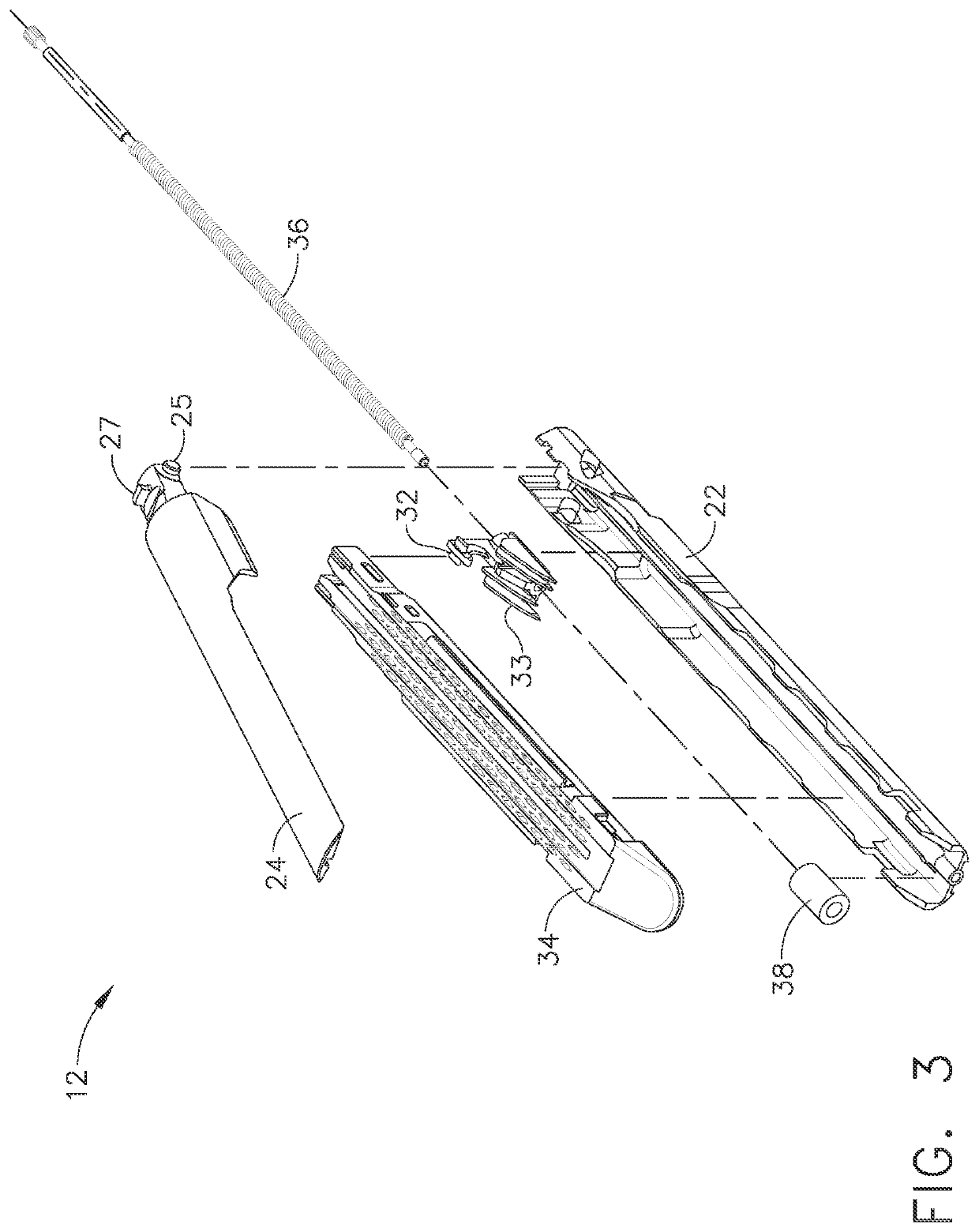

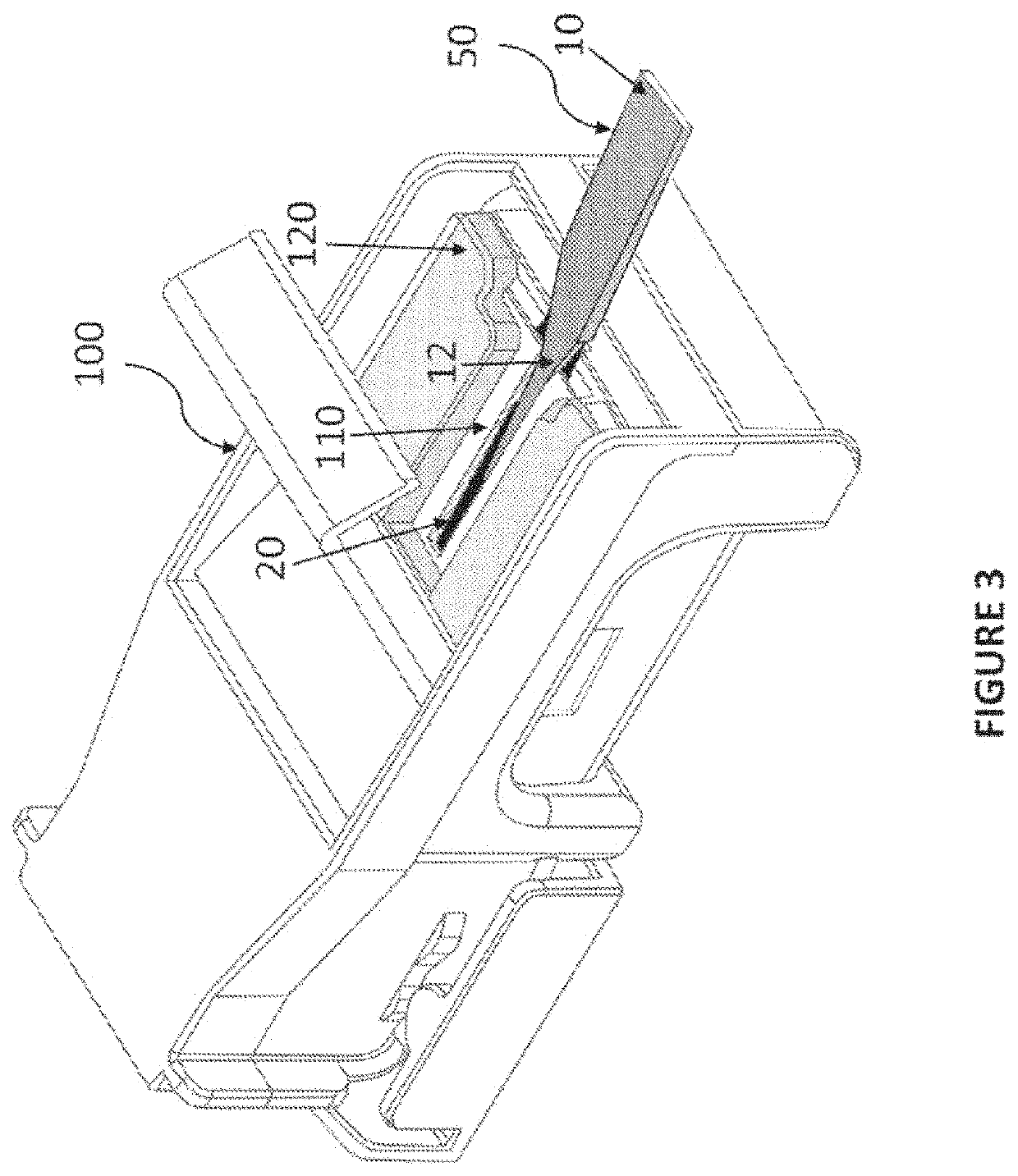

Surgical instrument assembly

Owner:CILAG GMBH INT

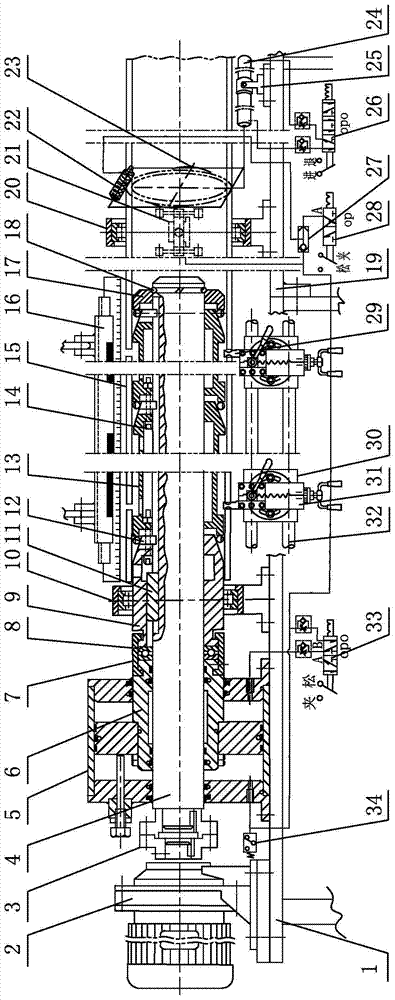

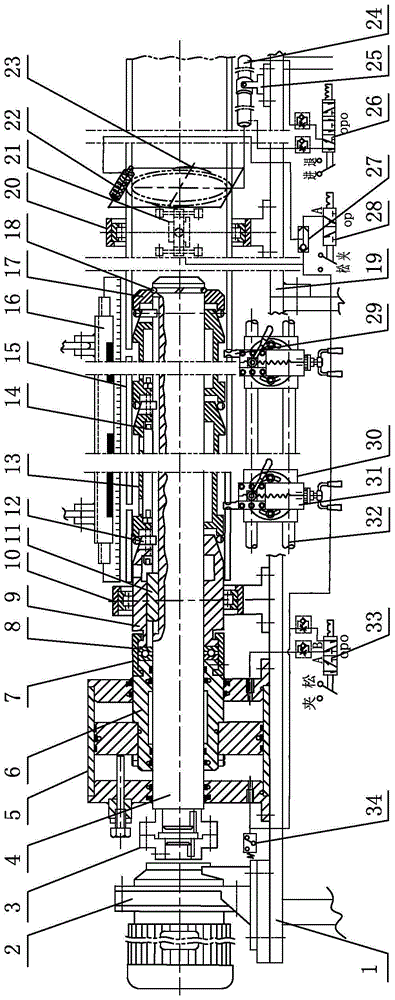

Cutting-off and chamfering integrated turning tool and one-step clamping, cutting-off and chamfering pipe cutter

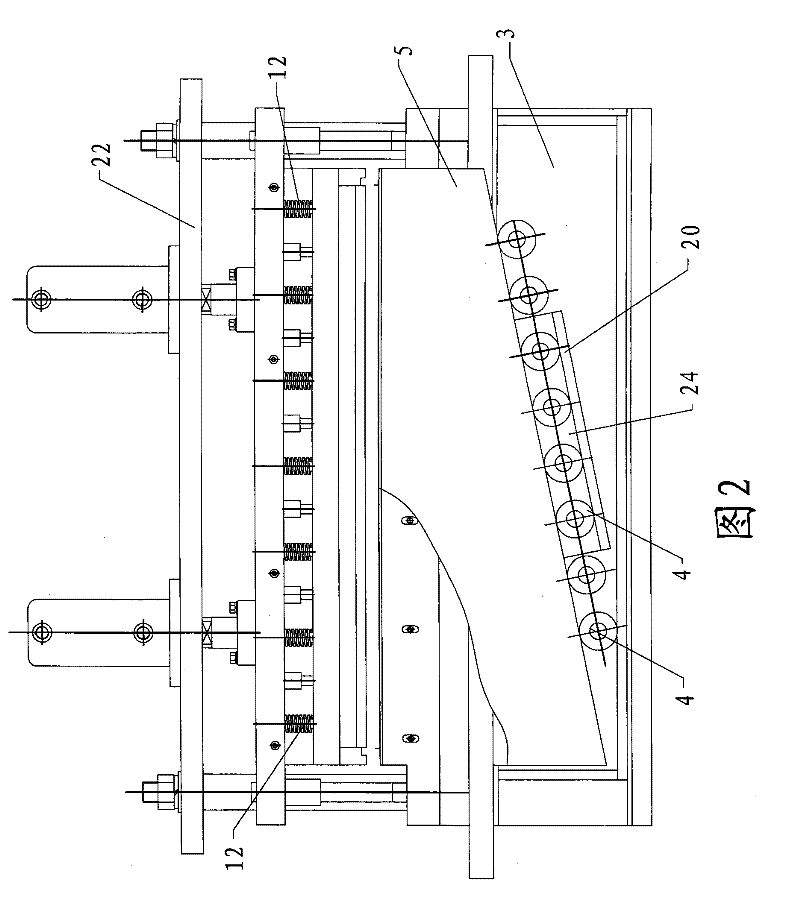

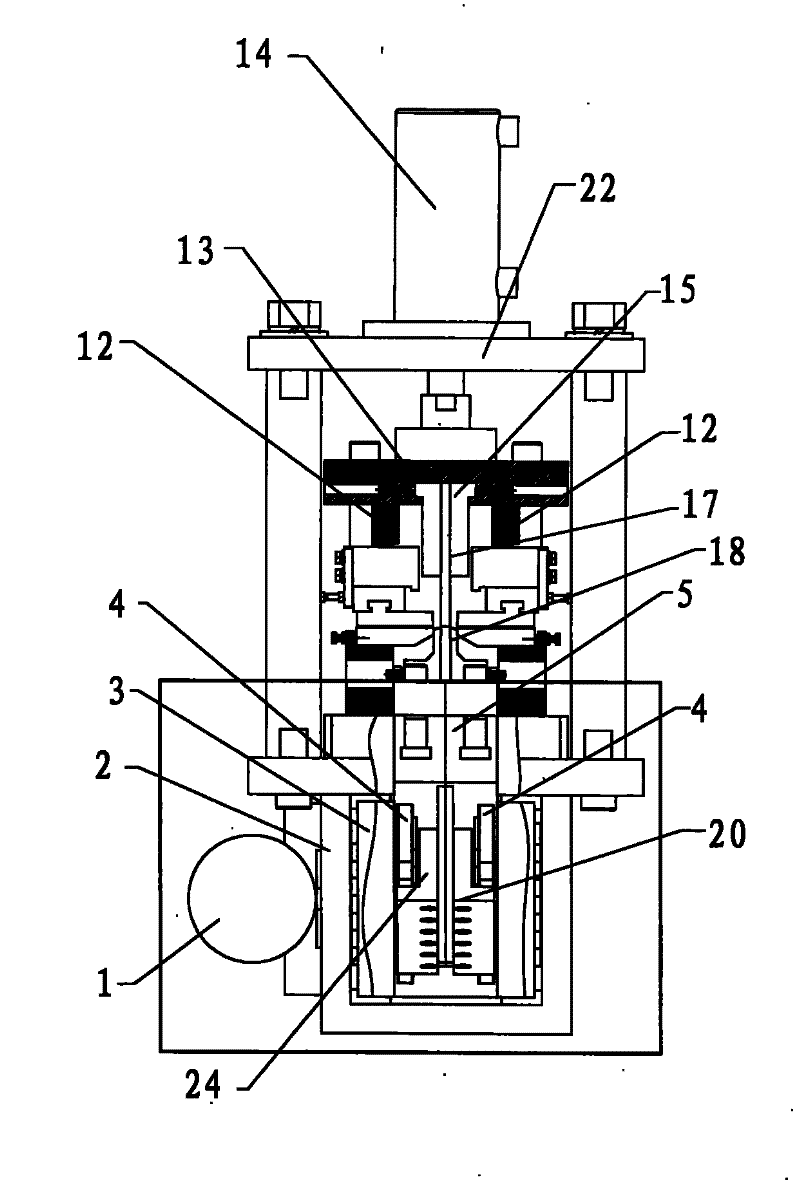

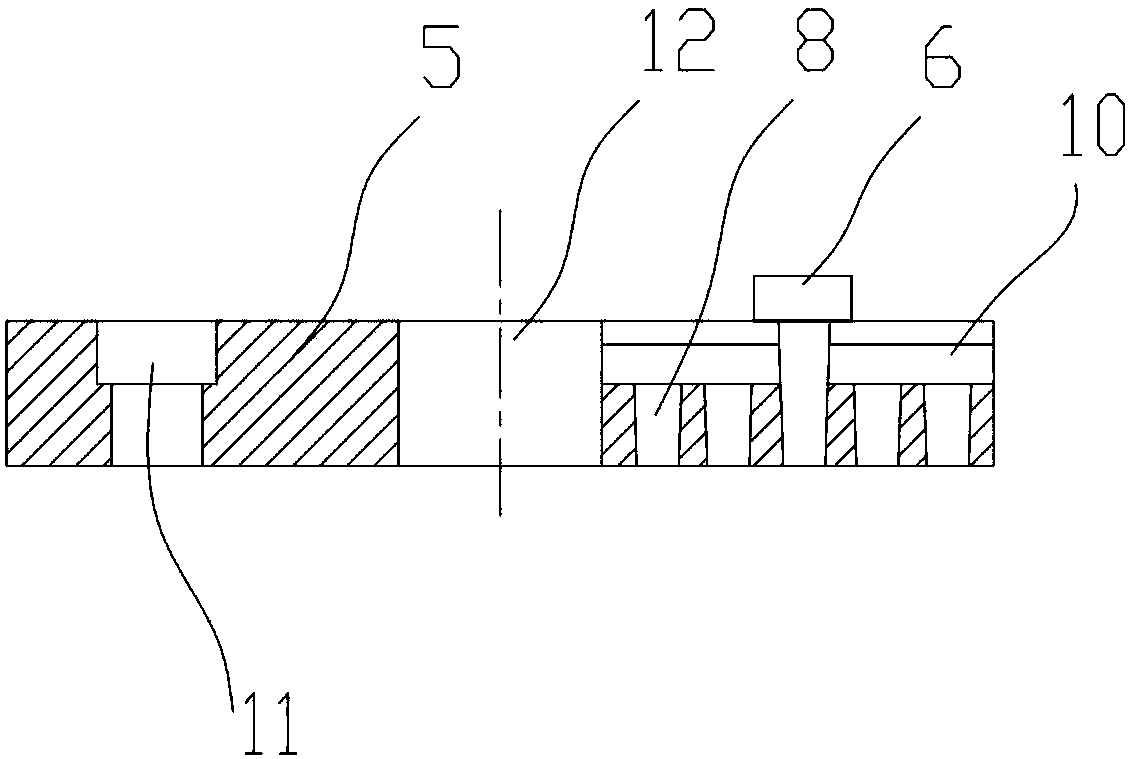

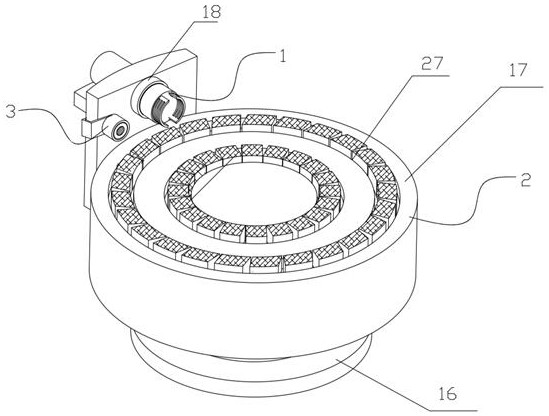

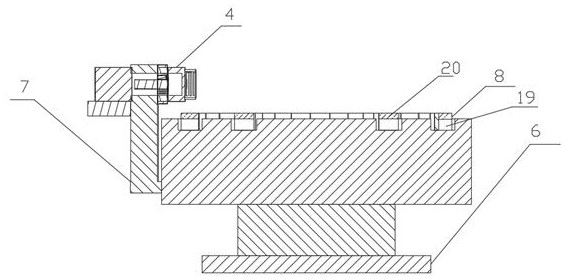

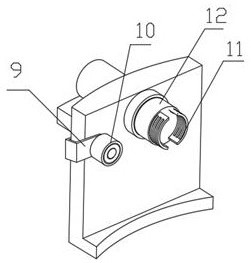

InactiveCN103480872AStable structureFlexible operationAuxillary equipmentTurning toolsTool bitThrust bearing

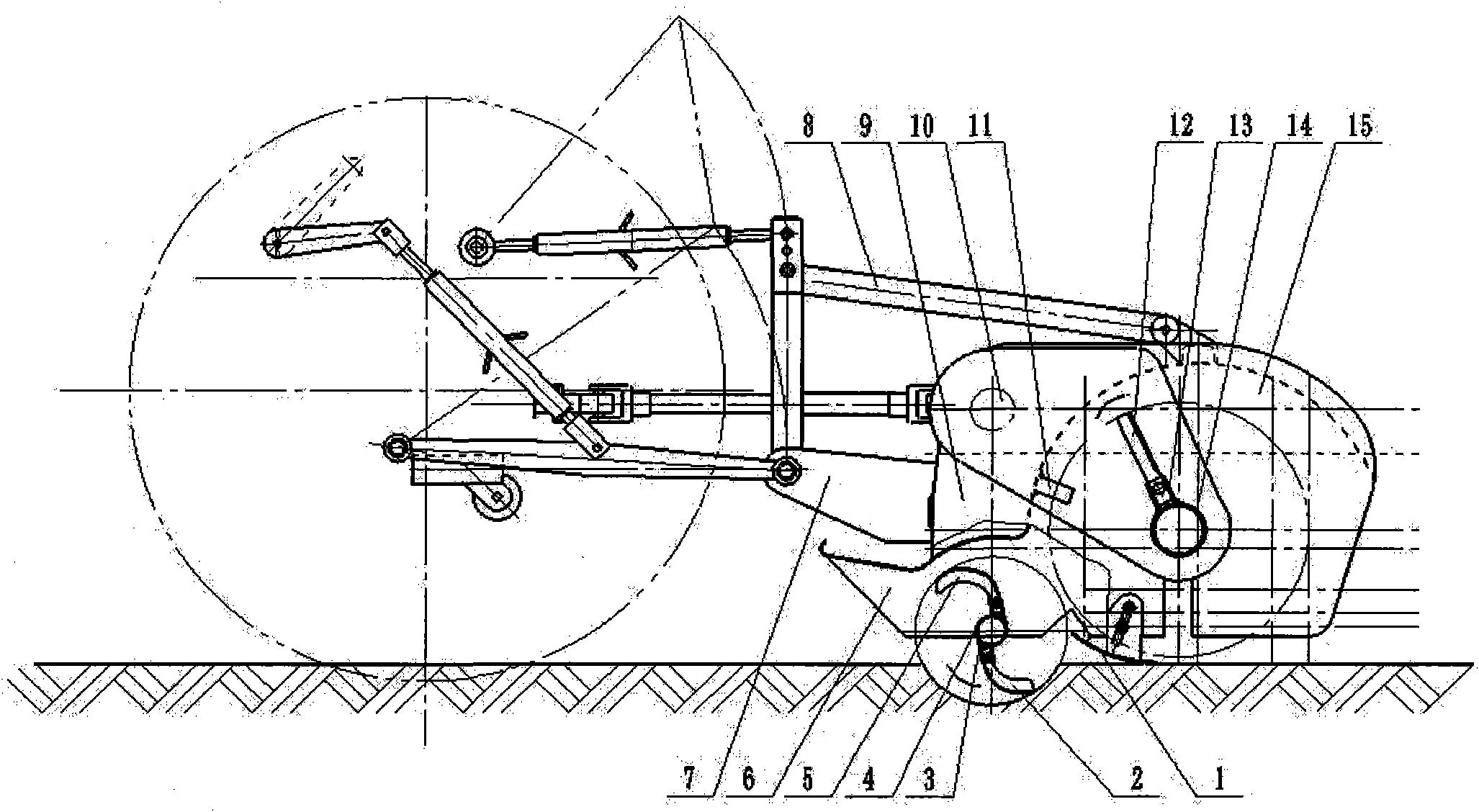

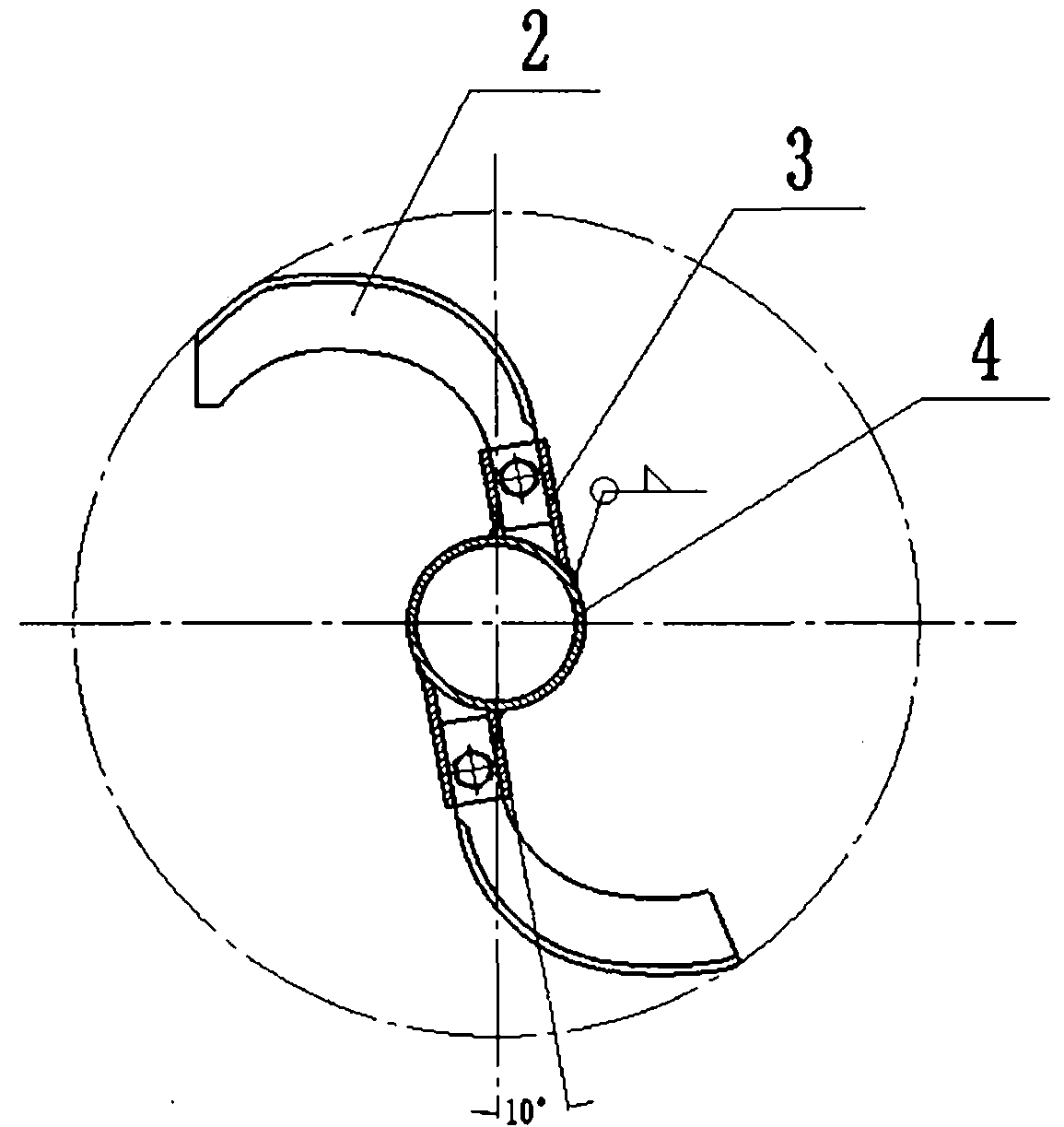

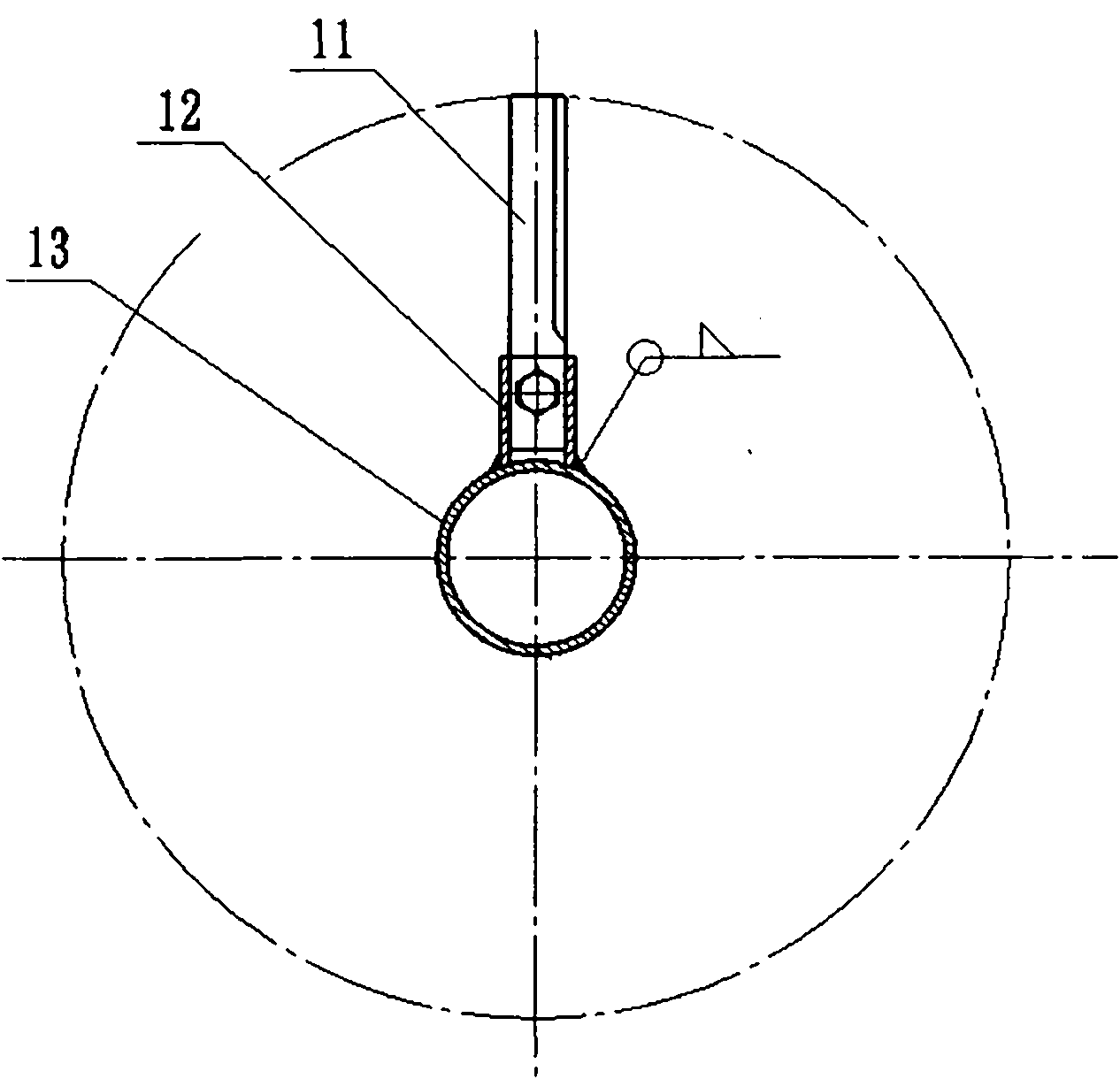

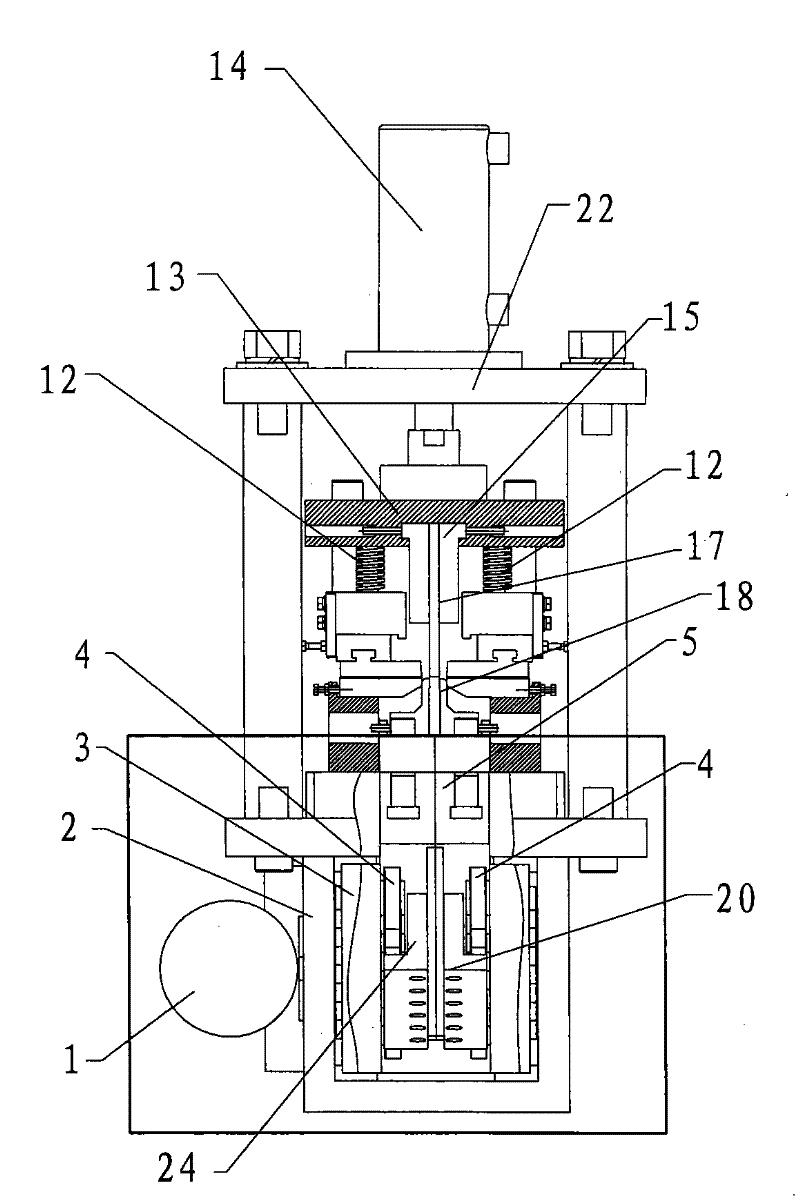

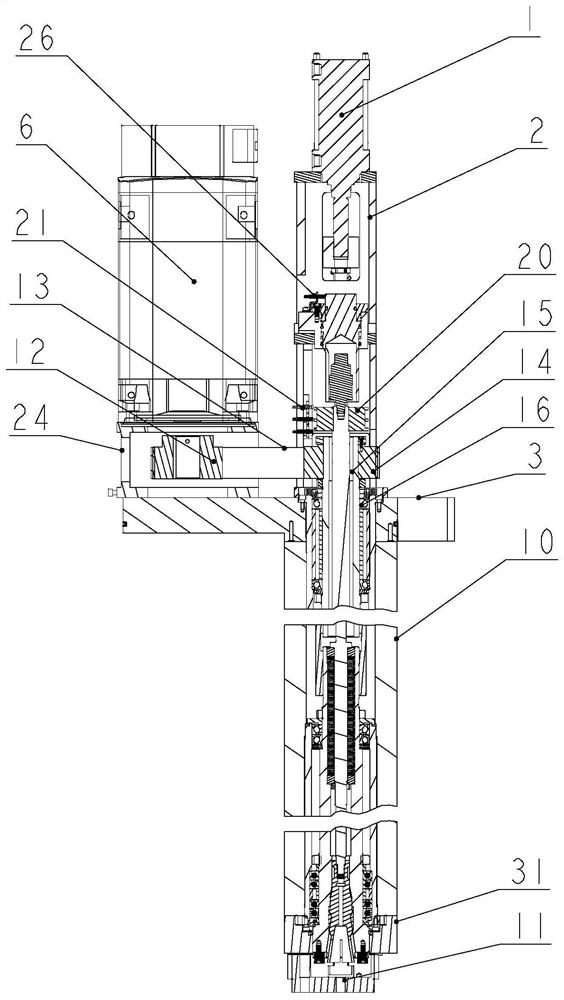

The invention relates to a cutting-off and chamfering integrated turning tool and a one-step clamping, cutting-off and chamfering pipe cutter and belongs to pipe machining equipment. A main cutting edge is arranged on a front tool surface of the front of a tool handle, and two V-shaped grooves are symmetrically arranged in two auxiliary cutting edges, so that both cutting-off and chamfering can be performed, the operation is flexible, and exchanging of different turning tools during chamfering are avoided. The cutting-off and chamfering integrated turning tool is used by the pipe cutter, a thrust bearing, a tapered wedge thrust pipe and a plurality of tapered wedge pipes which are mounted on a cylindrical shaft successively are connected together, and a rotary feed pipe is clamped firmly by outward expansion of C-shaped rings under thrust of a clamping air cylinder piston and tapered heads. By means of the cutting-off and chamfering integrated turning tool mounted on a sliding shaft lathe tool rest, within the range of clearance grooves of the tapered wedge pipes, during feed pipe cutting-off tool withdrawn, and on a device, during once clamp of the inner diameter of a thin-wall round pipe, a plurality of feed pipes can be cut off by setting the length, and chamfering is performed on inner and outer edges of two end faces of notches.

Owner:柳燕明

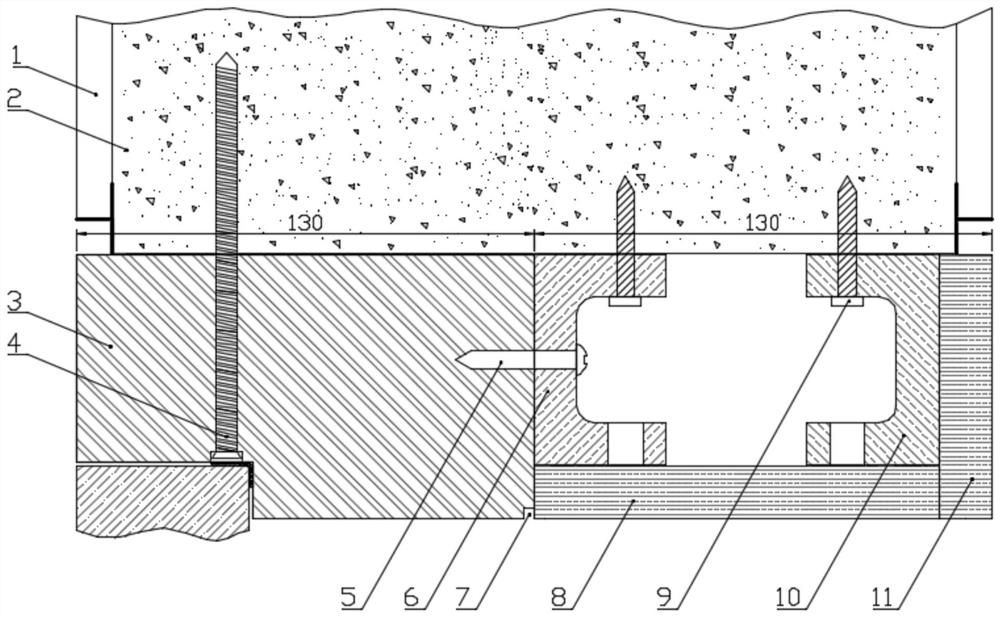

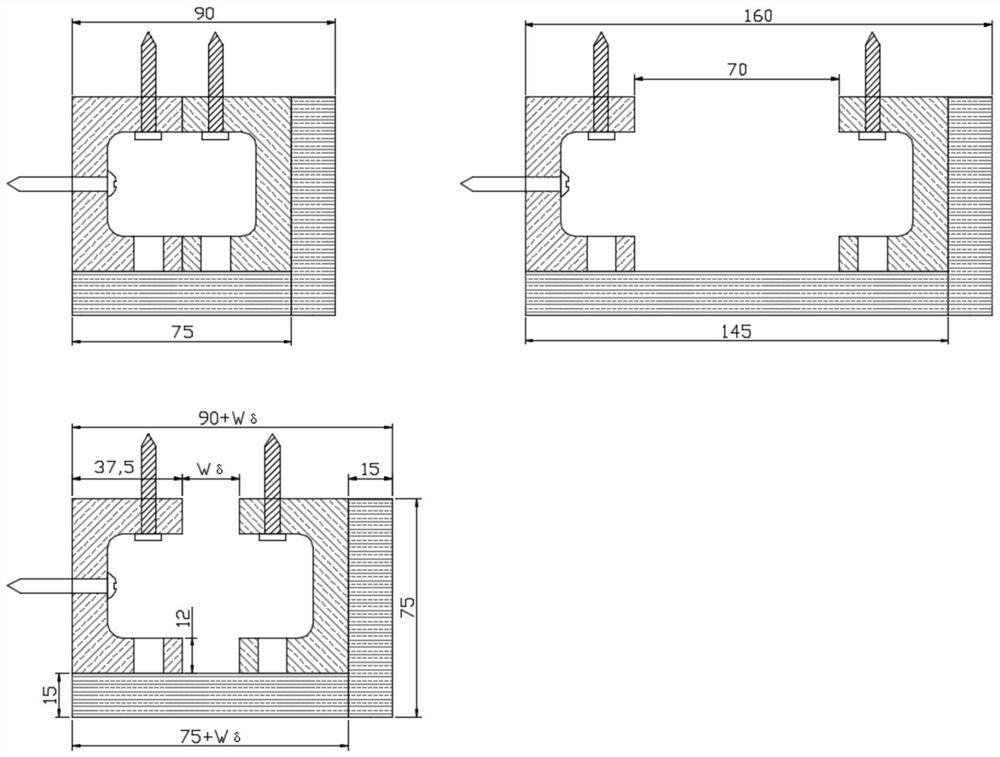

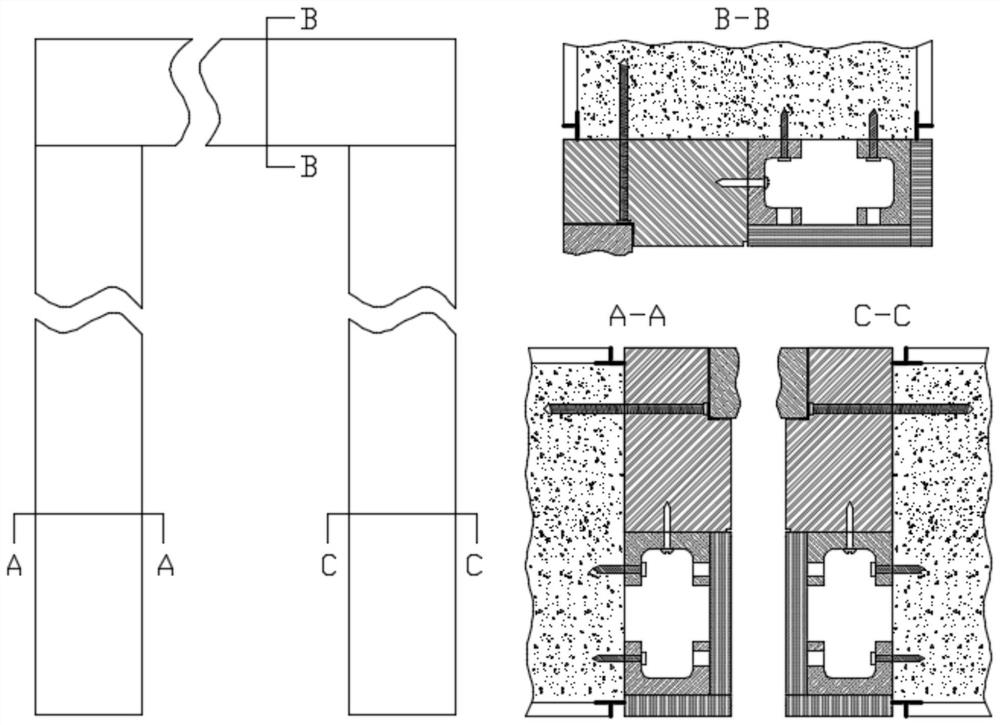

Door-knife door-lock device for elevator door

A door knife door lock device for an elevator car, comprising a door knife device and a door lock device, the door knife device and the door lock device are fixed on the door knife bottom plate, and the door knife bottom plate is fixed on the door machine hanging plate of the elevator car, The lock seat is fixed on the seat plate, and its technical points are: the upper connecting plate sleeve is fixed on the upper connecting plate of the door knife device, and the rear side of the upper connecting plate is connected to the transmission device; the hinge belt of the lock body shaft fixed on the door knife bottom plate The lock body of the lock hook and the contact of the moving door switch, the limit frame with the limit bolt is also fixed on the seat plate, and the door knife bottom plate between the upper connecting plate and the limit bolt of the door knife device is hinged with a concave The shifting frame of slot, bump ear and torsion spring is arranged on the door knife base plate and the door knife is parallel to the strike plate hinged successively by the shaft and the connecting plate, and the lock body cover is fixed on the outward lock body of the strike plate. The present invention has reasonable structural design, safe use, and convenient installation. When the car door is locked, except professionals who can open it with a manual unlocking device on the outside, no one can open it from the outside under normal conditions.

Owner:SHENYANG YUANDA INTELLECTUAL IND GRP CO LTD

Stubble collecting and returning machine

The invention relates to the technical field of agricultural machinery and provides a stubble collecting and returning machine. The machine comprises a gear box, a tripod, a stander, a stubble collecting device knife pivot, a stubble collecting device knife bed, a stubble collecting knife, a stubble chopping knife, a returning device knife pivot, a returning knife bed, a returning knife, a fixed knife, a case and a copying sliding plate, wherein the gear box is mounted on the stander; the tripod is mounted on the stander by a suspension loop; the stubble collecting device knife pivot is horizontally mounted on the stander; the stubble collecting device knife bed is welded on the stubble collecting device knife pivot according to helix arrangement for mounting the stubble collecting knife and the stubble chopping knife; the returning device knife pivot is horizontally mounted on the stander; the returning knife bed is welded on the returning device knife pivot according to helix arrangement for mounting the returning knife; the case is mounted outside the returning device; the fixed knife is welded at the inner side of the front of the case; and the copying sliding plate is mounted on the case. When the machine works, the stubble collecting device collects the stubbles and throws the stubbles together with the straws into the returning device and the returning device crushes and returns the stubbles and the straws, thus realizing that the machine and the tools enter into the field once and carry out straw stubble collecting and returning operations simultaneously.

Owner:SHANDONG UNIV OF TECH

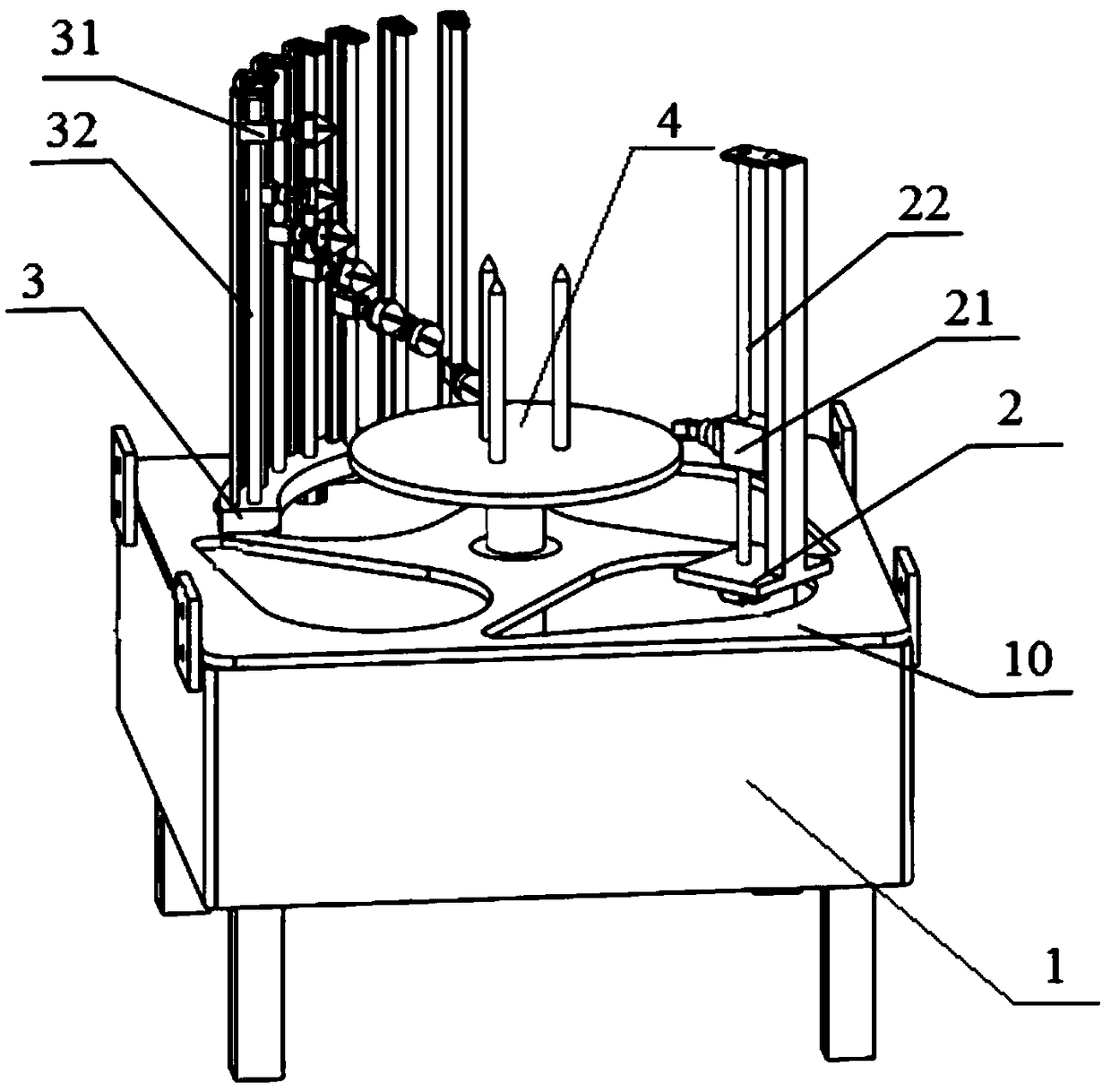

Fruit peeling and de-pitting integrated machine

The invention relates to the technical field of peeling machinery and discloses a fruit peeling and de-pitting integrated machine. The integrated machine comprises a peeling box provided with a fruitplacement opening, a peeling device arranged in the inner cavity of the peeling box, a de-pitting device and a rotatable worktable. The worktable is used for a to-be-processed fruit to be placed and is arranged between the peeling device and the de-pitting device. The peeling device comprises a peeler close to the fruit, a first lifting device driving the peeler to move vertically, an adjustable peeling knife head and a first telescopic part meshed with the fruit. The de-pitting device comprises a de-pitting knife assembly, wherein the de-pitting device knife assembly comprises a rotatable de-pitting device knife close to the fruit, a second lifting device driving the corresponding de-pitting knife to move vertically and a second telescopic part meshed with the fruit. The fruit peeling andde-pitting integrated machine integrates peeling and de-pitting functions and is simple in operation and capable of saving time and effort.

Owner:WUHAN UNIV OF SCI & TECH

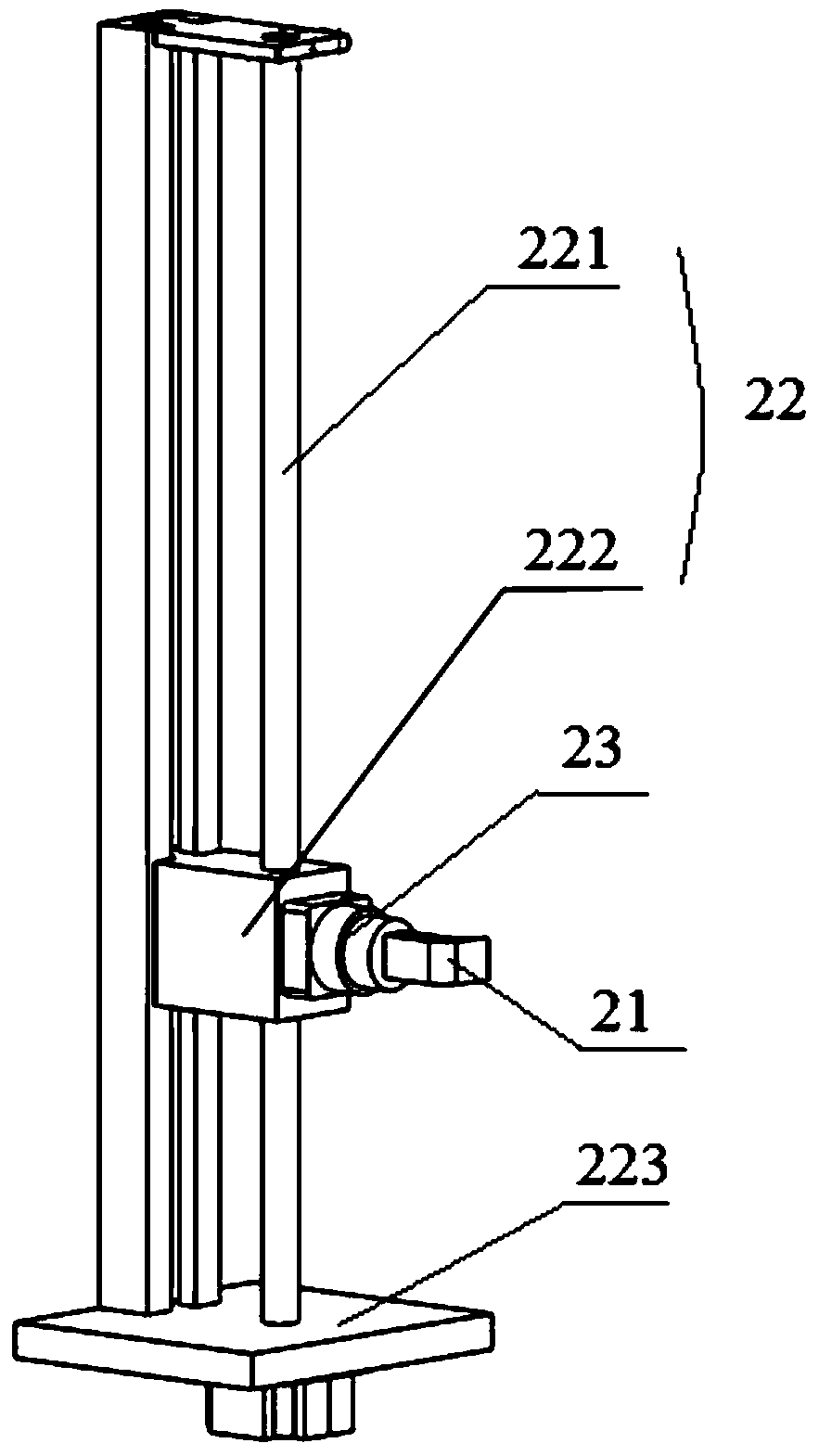

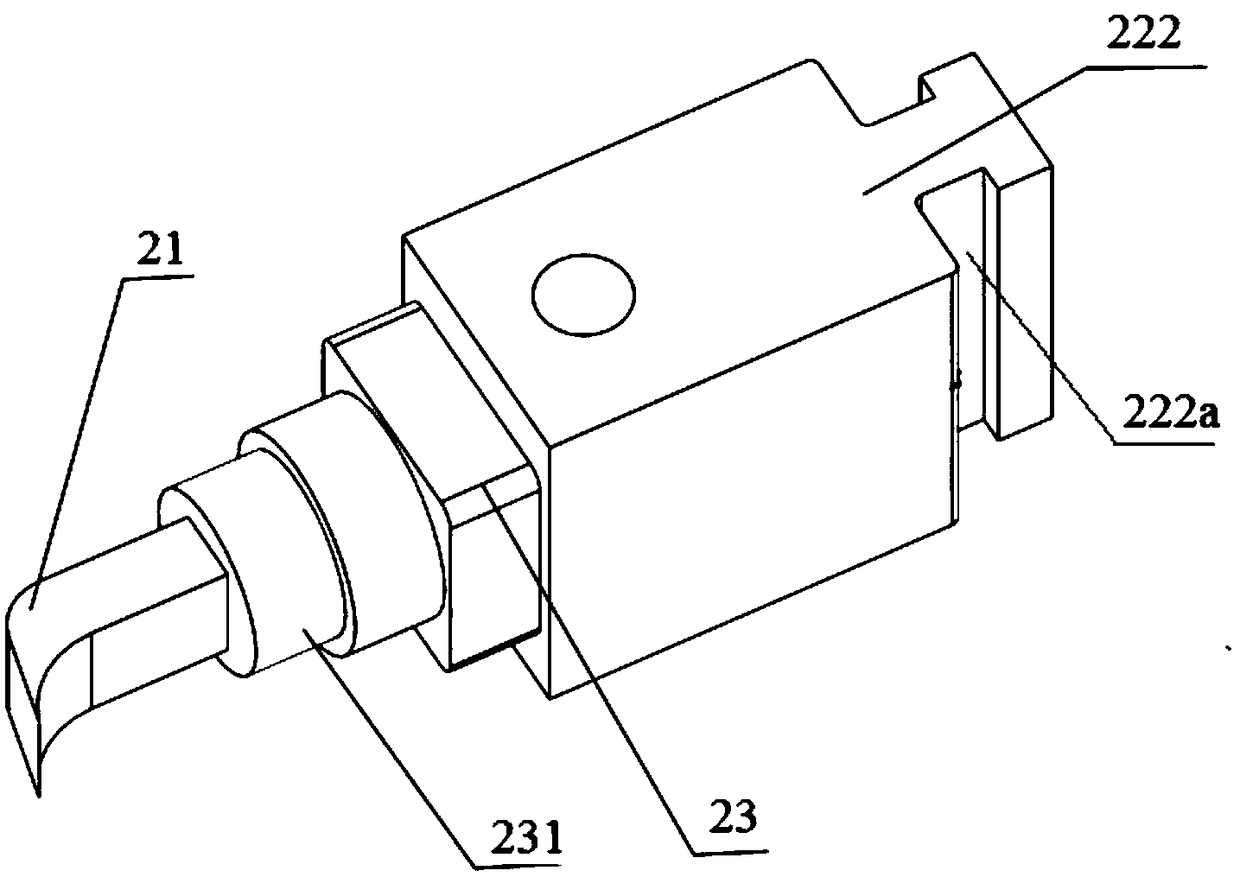

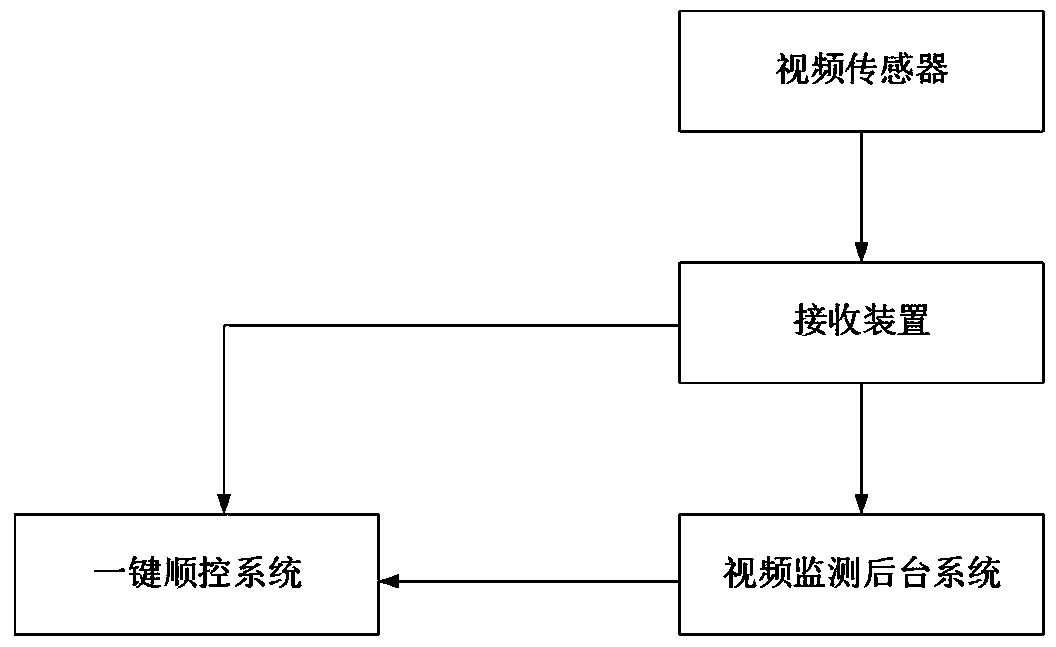

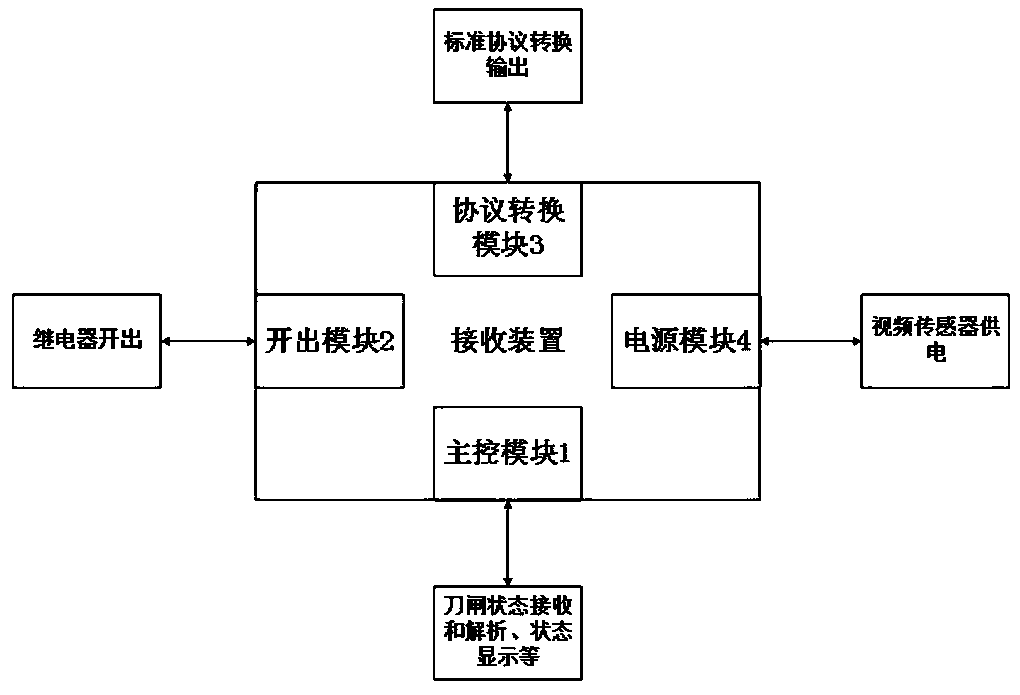

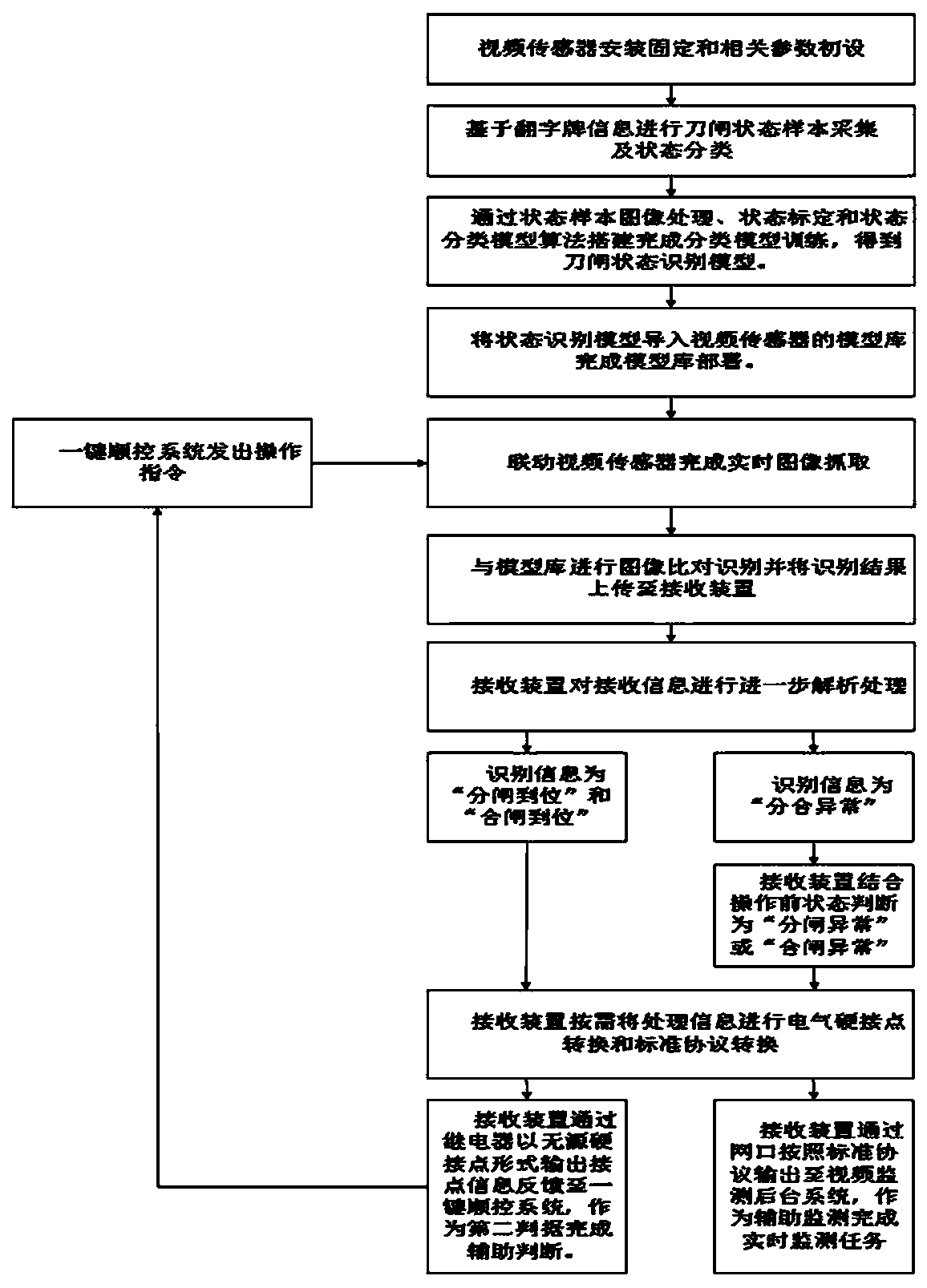

Real-time monitoring system and method for GIS equipment knife switch opening and closing state confirmation

PendingCN111600386ASolve the auxiliary judgment of the separation and closing stateRealize double confirmationCircuit arrangementsClosed circuit television systemsVideo monitoringVideo sensors

The invention discloses a real-time monitoring system and method for GIS equipment knife switch opening and closing state confirmation. The monitoring system comprises a video sensor, a receiving device and a video monitoring background system, wherein the video sensor is installed on a nearby bracket of a knife switch control mechanism and is used for carrying out real-time image acquisition andreal-time result processing on a word turning board on a control mechanism box so as to achieve auxiliary judgment of the on-off state of a knife switch in GIS, the receiving device is connected withthe video sensor and the video monitoring background system, and the receiving device receives an identification result of the video sensor on the word turning plate board and performs further video analysis to obtain the state of the knife switch. According to the invention, auxiliary judgment of the on-off state of the switch contact inside the knife switch can be realized, and double confirmation of the knife switch state in one-key sequential control operation is realized.

Owner:SHANDONG ELECTRICAL ENG & EQUIP GRP

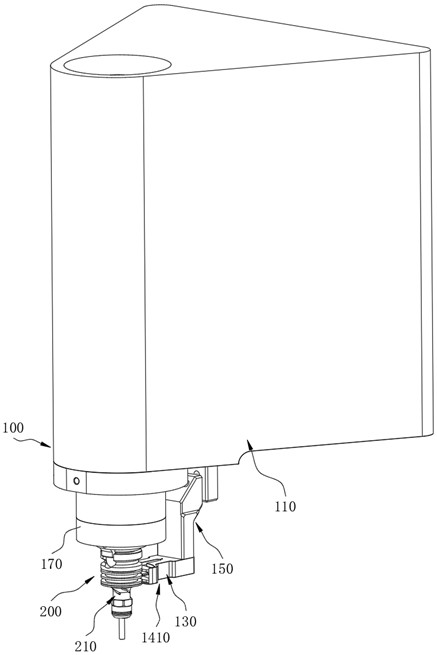

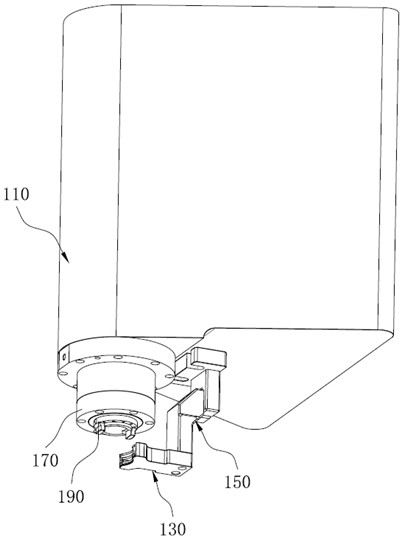

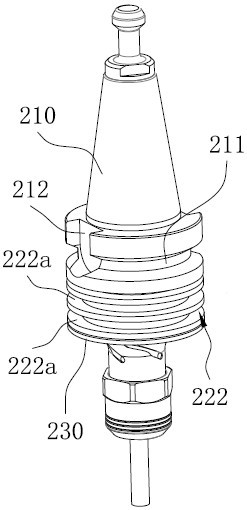

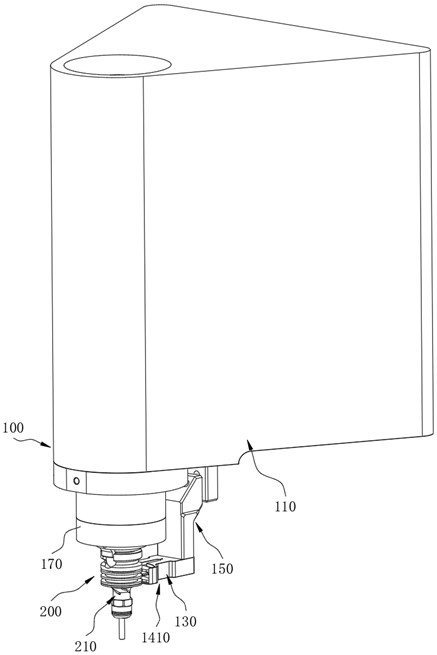

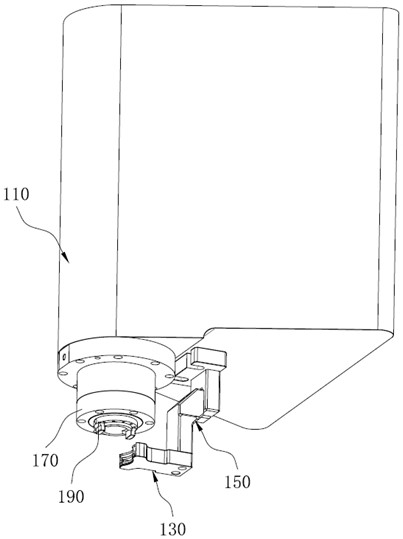

Ultrasonic main shaft, ultrasonic knife handle and ultrasonic machining equipment

ActiveCN112317781ARealize wireless transmissionRealize automatic tool changeTurning machine accessoriesLarge fixed membersRotational axisTransmitter coil

Owner:CONPROFE MACHINE TOOLS CO LTD +1

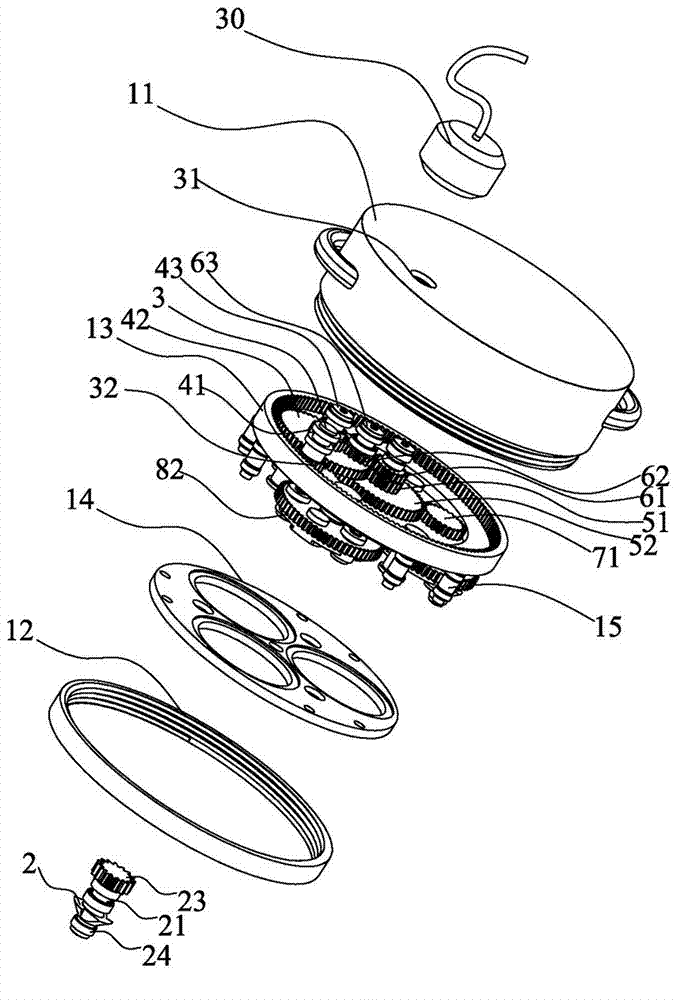

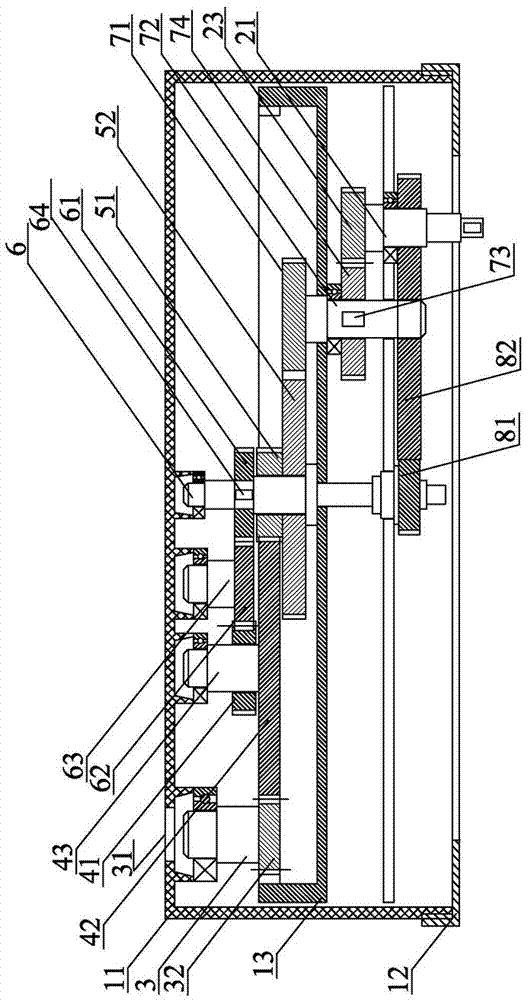

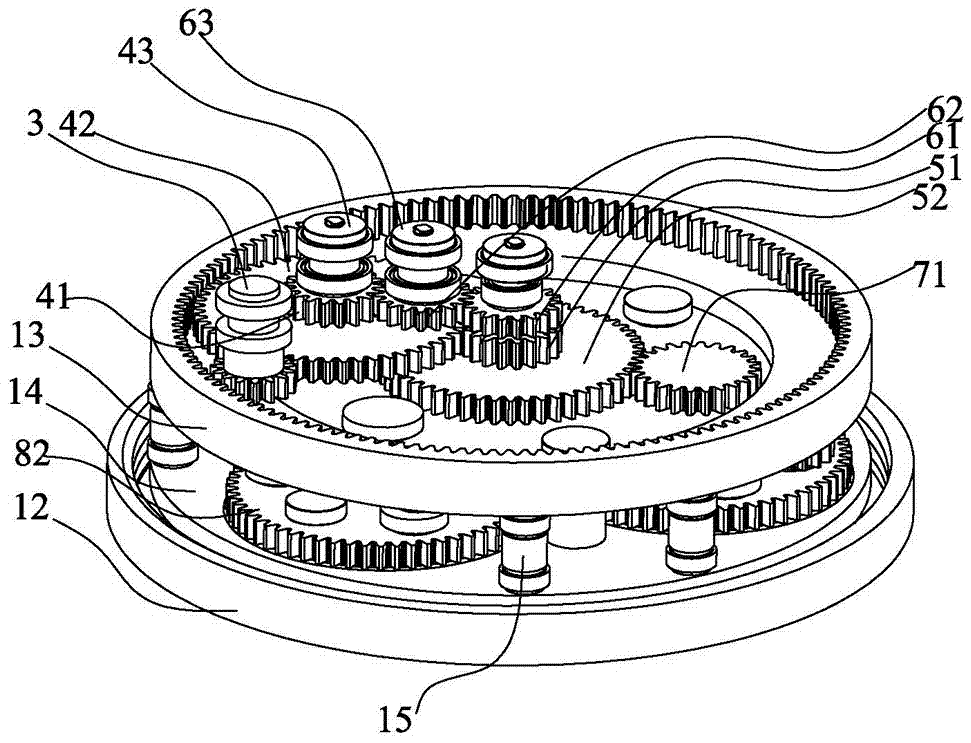

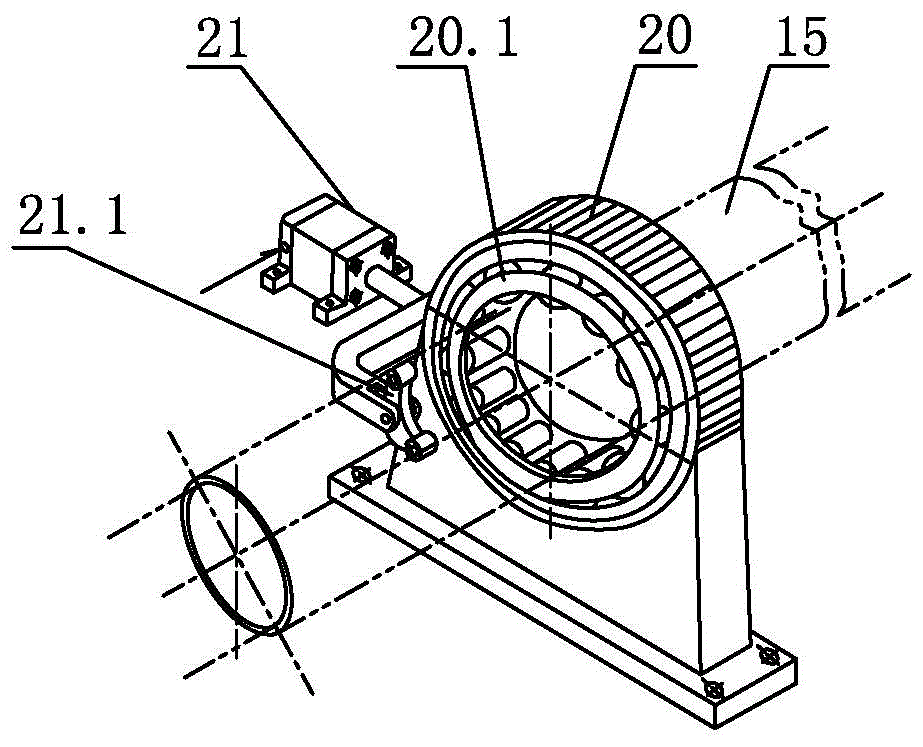

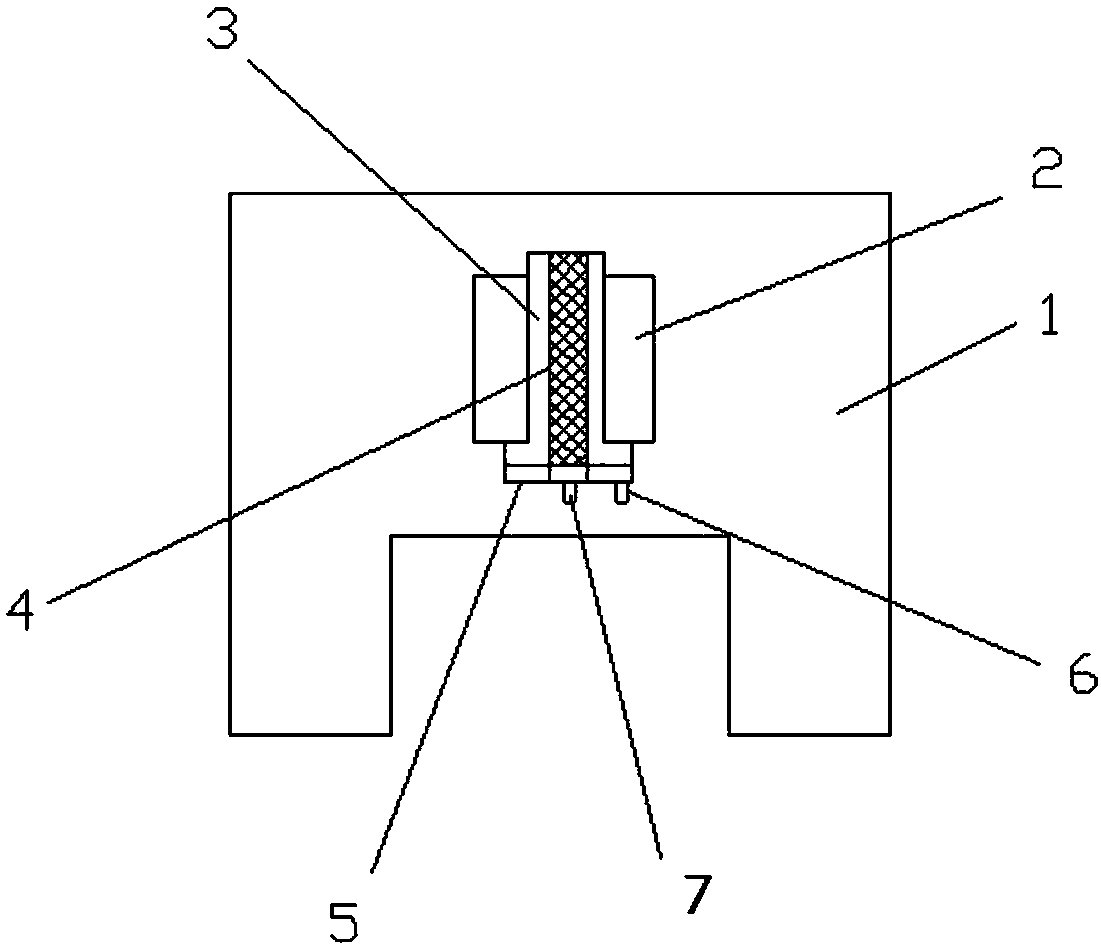

Self-aligning chamfering processing mode and equipment

ActiveCN107442866ARealize multiple utilizationSimplify alignment workFeeding apparatusLarge fixed membersGear wheelEngineering

The invention discloses self-aligning chamfering processing equipment and a corresponding processing mode. The self-aligning chamfering processing equipment comprises a main body, a power source, a cutter and a transmission gear set, wherein the cutter is fixedly mounted on one end of a cutter rotary shaft, the cutter rotary shaft is spinningly mounted on the transmission gear set, the transmission gear set is assembled in the main body, the power source drives the cutter rotary shaft and the cutter to rotate at high speed through the transmission gear set, and the cutter rotary shaft and the cutter can revolve around the center of an inner hole to be processed and the revolution radius is variable, a distance between the cutter of the equipment and the center of the inner hole to be processed can be adjusted automatically, so that the equipment can be better applied to the processing requirements of chamfering with different internal diameters, a cutter changing process is avoided and the production efficiency is improved.

Owner:XIAMEN UNIV OF TECH

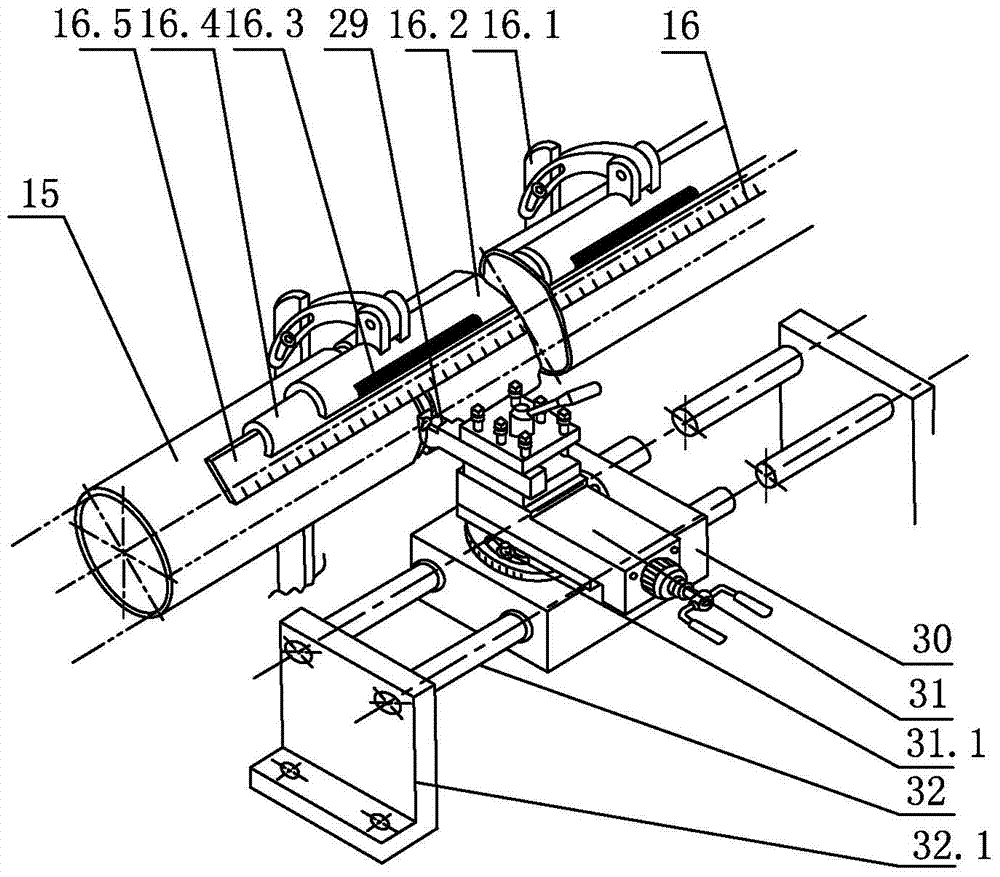

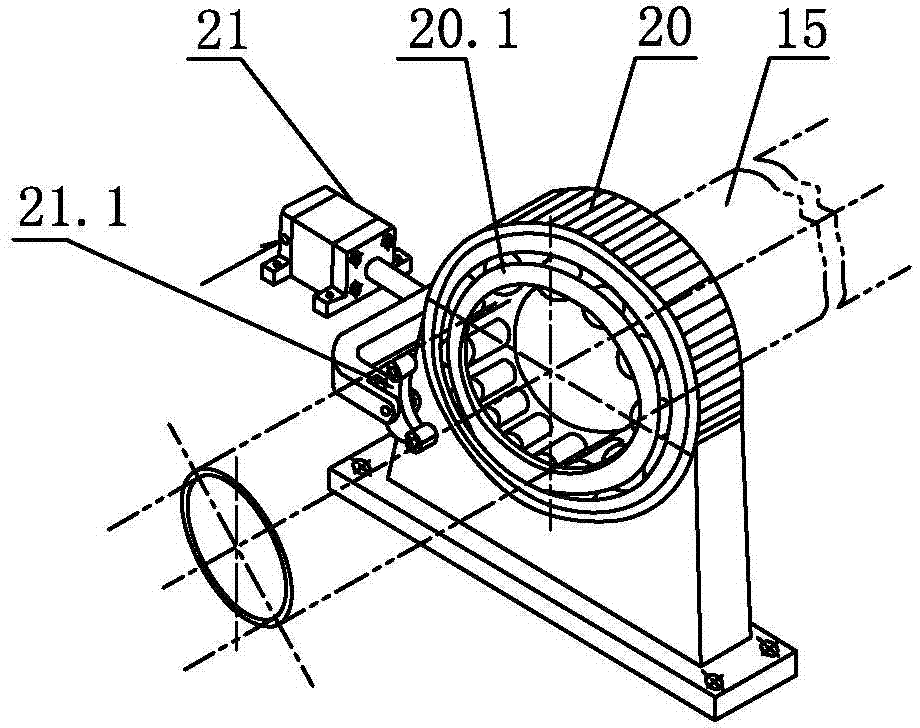

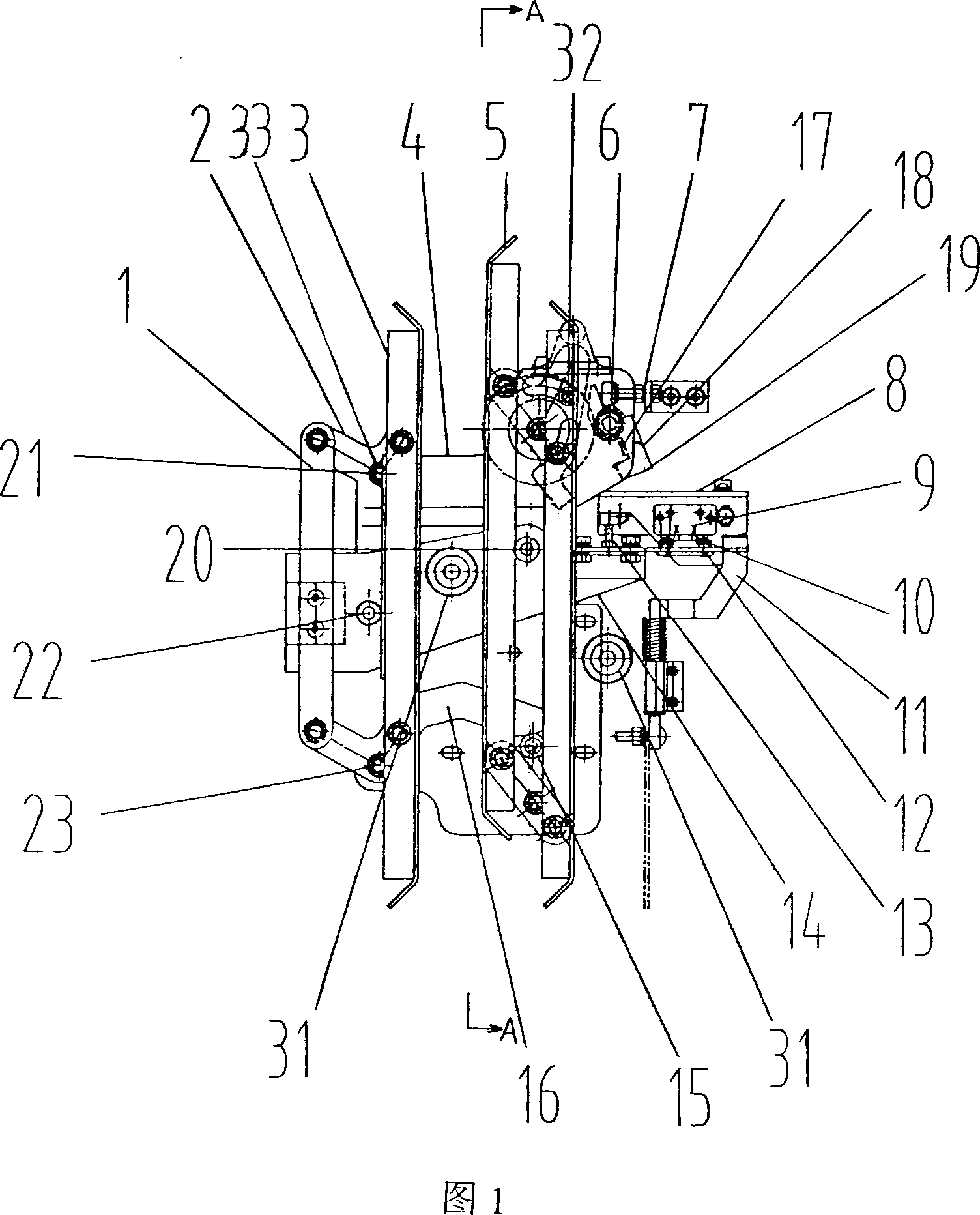

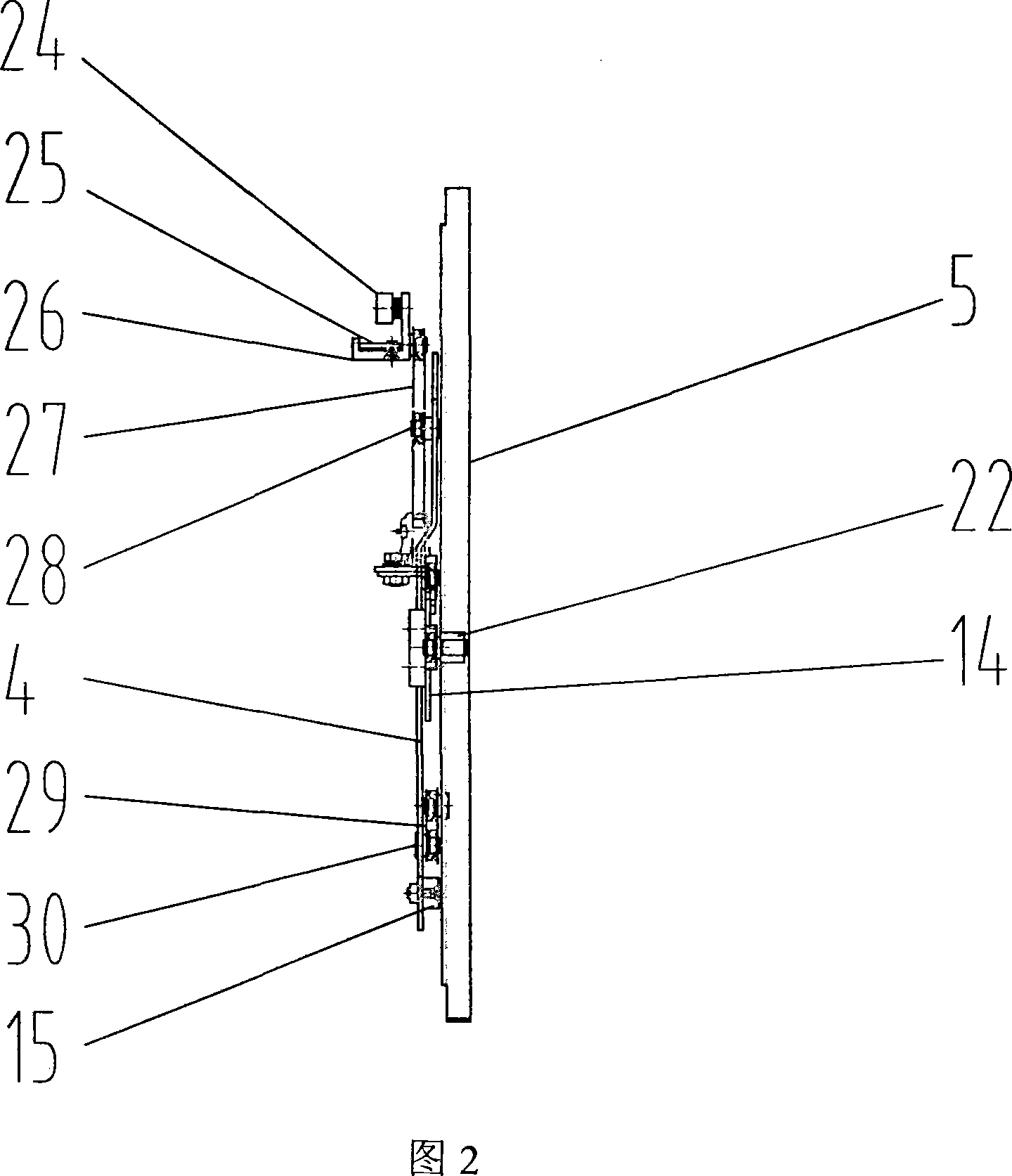

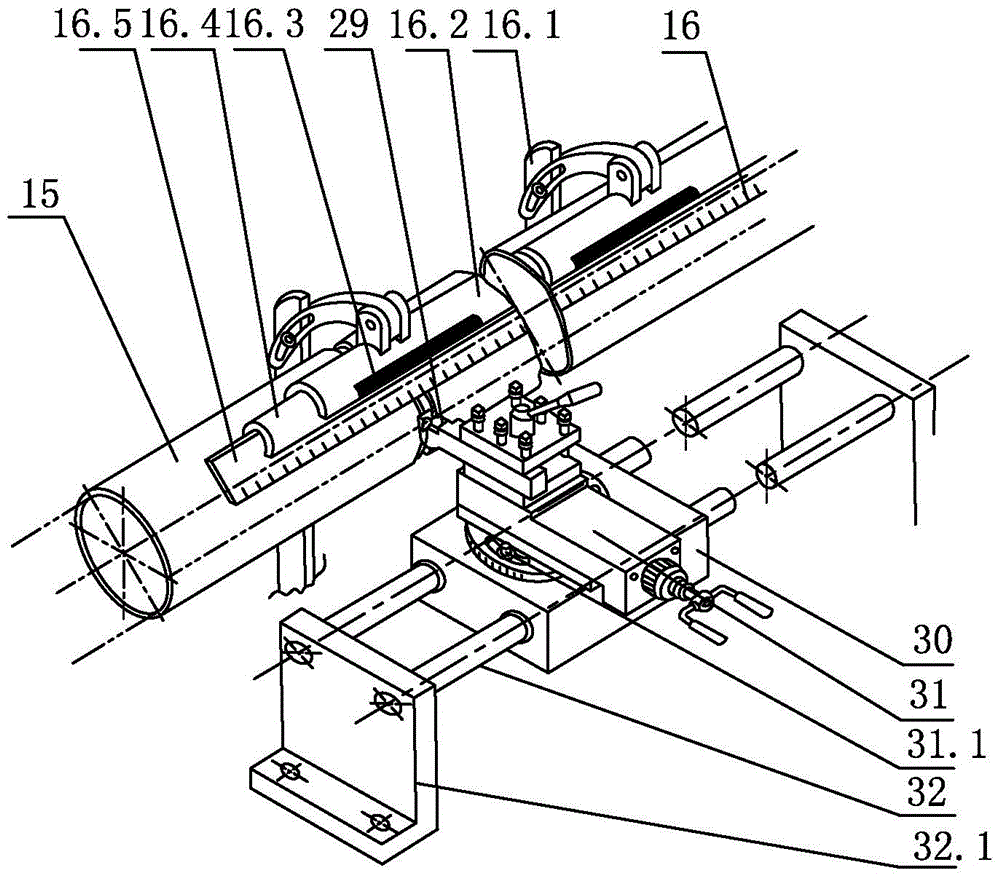

Cutting and chamfering integrated turning tool and pipe cutting machine with one clamping and chamfering at the same time

InactiveCN103480872BStable structureEasy to useAuxillary equipmentTurning toolsClassical mechanicsThrust bearing

The invention relates to a cutting-off and chamfering integrated turning tool and a one-step clamping, cutting-off and chamfering pipe cutter and belongs to pipe machining equipment. A main cutting edge is arranged on a front tool surface of the front of a tool handle, and two V-shaped grooves are symmetrically arranged in two auxiliary cutting edges, so that both cutting-off and chamfering can be performed, the operation is flexible, and exchanging of different turning tools during chamfering are avoided. The cutting-off and chamfering integrated turning tool is used by the pipe cutter, a thrust bearing, a tapered wedge thrust pipe and a plurality of tapered wedge pipes which are mounted on a cylindrical shaft successively are connected together, and a rotary feed pipe is clamped firmly by outward expansion of C-shaped rings under thrust of a clamping air cylinder piston and tapered heads. By means of the cutting-off and chamfering integrated turning tool mounted on a sliding shaft lathe tool rest, within the range of clearance grooves of the tapered wedge pipes, during feed pipe cutting-off tool withdrawn, and on a device, during once clamp of the inner diameter of a thin-wall round pipe, a plurality of feed pipes can be cut off by setting the length, and chamfering is performed on inner and outer edges of two end faces of notches.

Owner:柳燕明

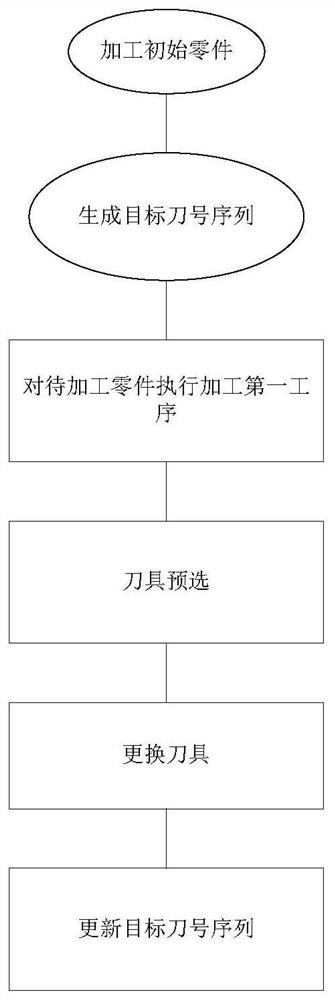

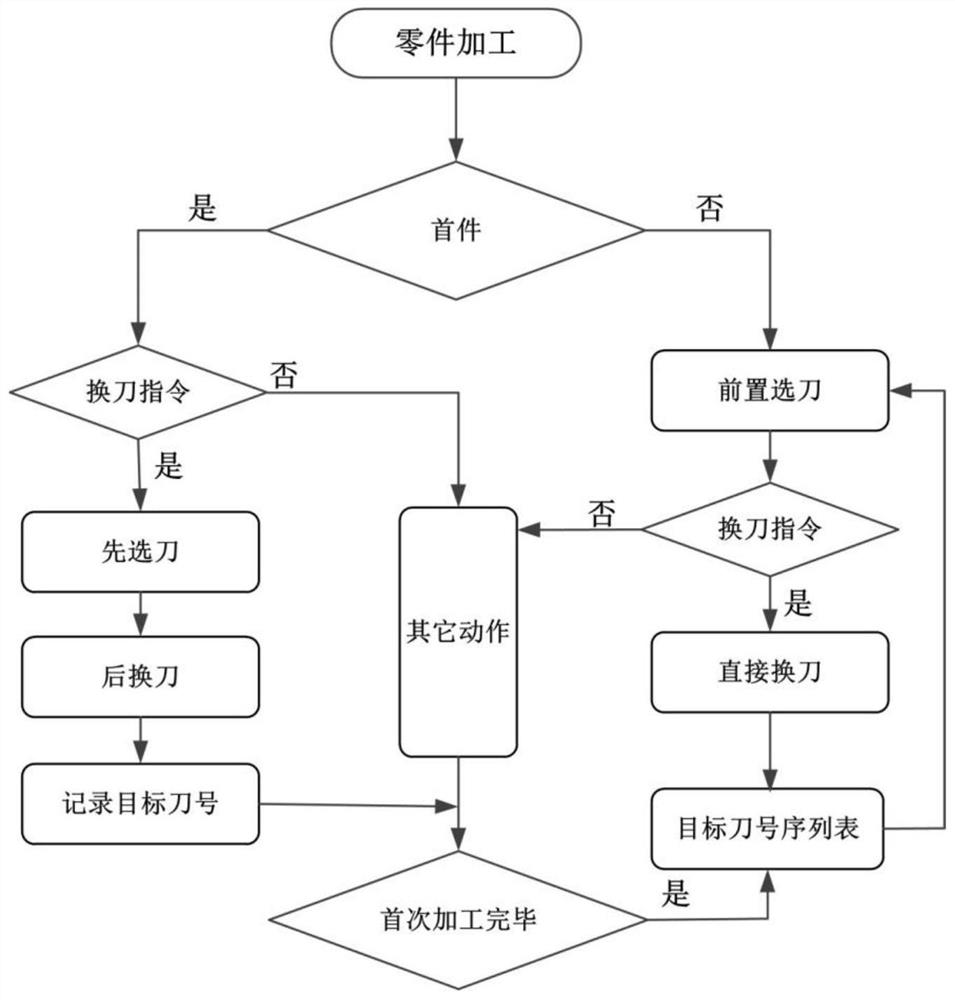

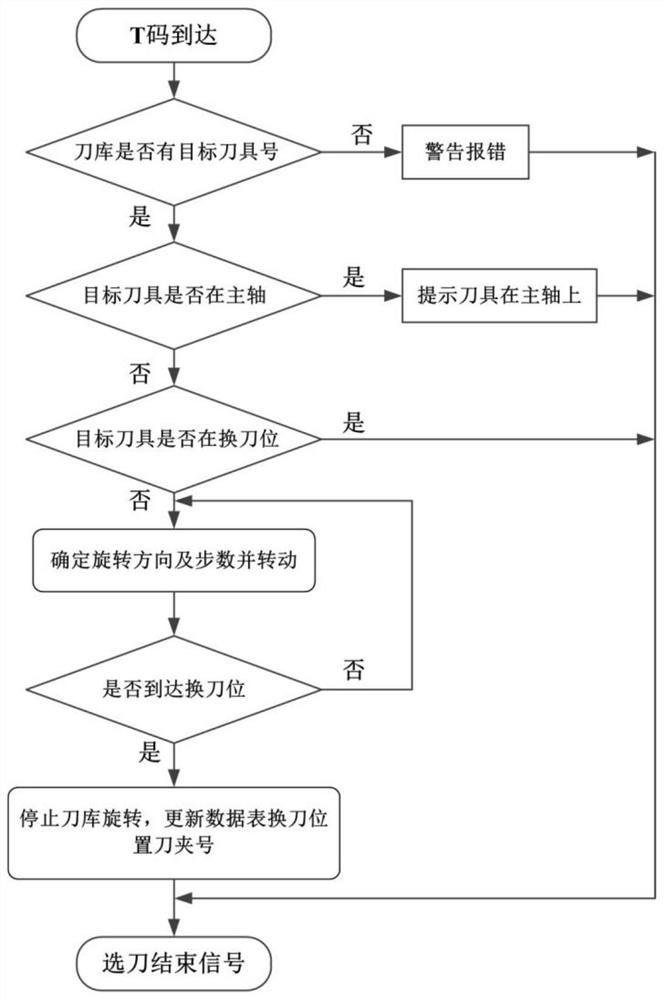

Tool magazine control method and machining equipment

PendingCN113579818ASave tool selection timeAvoid occupyingPositioning apparatusMetal-working holdersProcess engineeringMachining process

The invention provides a tool magazine control method and machining equipment, and the tool magazine control method comprises the steps: machining an initial part, and recording the model of a tool required by each machining process in the machining process of the initial part, so as to generate a target tool number sequence; the processing procedures comprise a plurality of processing procedures which are sequentially arranged according to a processing sequence; according to the target tool number sequence, tools corresponding to all the machining procedures are selected; and when the part to be machined is machined, according to the target cutter number sequence, pre-selecting the target cutter required by the next machining procedure, so that after the current machining procedure is completed, replacing the pre-selected target cutter on the machining main shaft. The problem that in machining equipment in the prior art, the tool changing time accounts for a large proportion of the whole machining duration is solved.

Owner:GREE ELECTRIC APPLIANCES INC

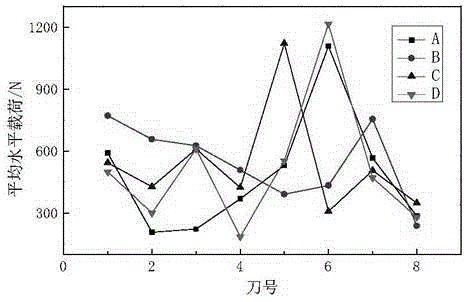

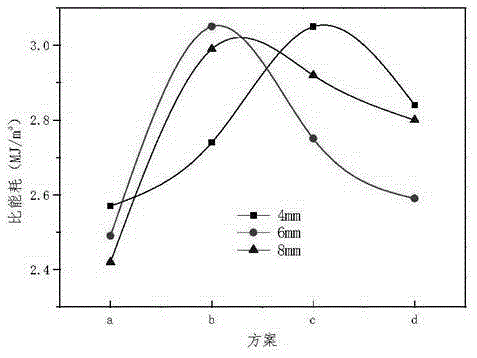

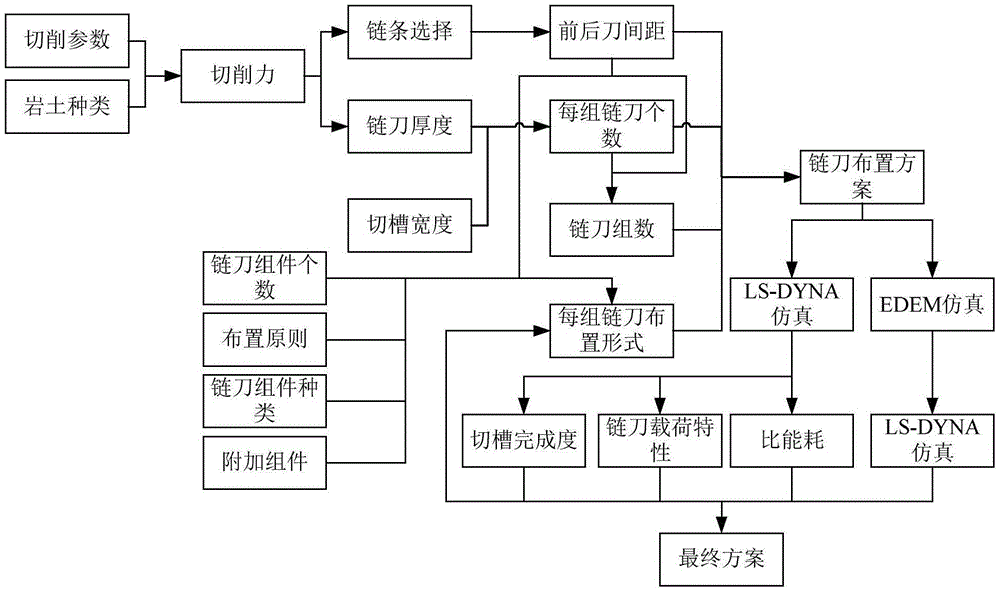

Cutter arrangement method of tunnel groove precutting equipment

The invention provides a chain cutter arrangement method of tunnel groove precutting equipment. Firstly, relevant parameters of chain cutter arrangement are determined, the relevant parameters comprise the front and rear cutter interval of chain cutters, the chain cutter group number, the number of chain cutters in each group, and the arrangement mode of each set of chain cutters, the arrangement mode of each set of chain cutters comprises the number of chain cutter assemblies in each group, and the arrangement principle of each group of chain cutters in the chain direction, the varieties of the chain cutter assemblies and additional assemblies. Then a groove precutting equipment chain cutter arrangement model is established, and finally the groove precutting equipment chain cutter arrangement model is evaluated through multi-module numerical simulation analysis according to groove precutting equipment chain cutter arrangement evaluation indexes. The evaluation indexes comprise the groove cutting completion degree, the chain cutter stress uniformity, the cutting specific energy consumption and the deslagging performance. Multi-module numerical simulation comprises LS-DYNA single-group chain cutter rock breaking simulation and EDEM single-group chain cutter deslagging simulation. It is guaranteed that the groove precutting equipment efficiently and accurately excavates cutting grooves through the determined arrangement positions of the chain cutters on cutter beams of the groove precutting equipment.

Owner:CENT SOUTH UNIV

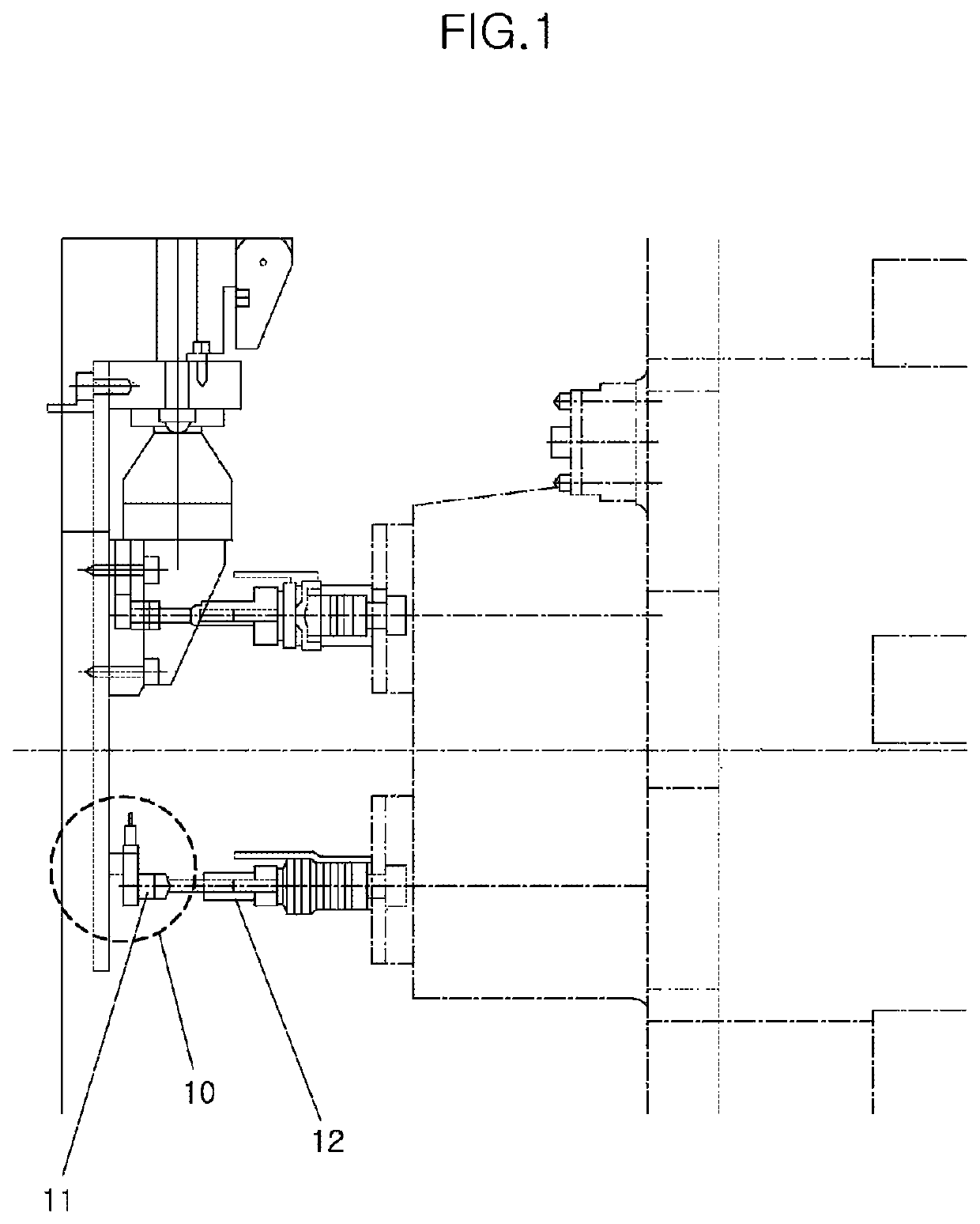

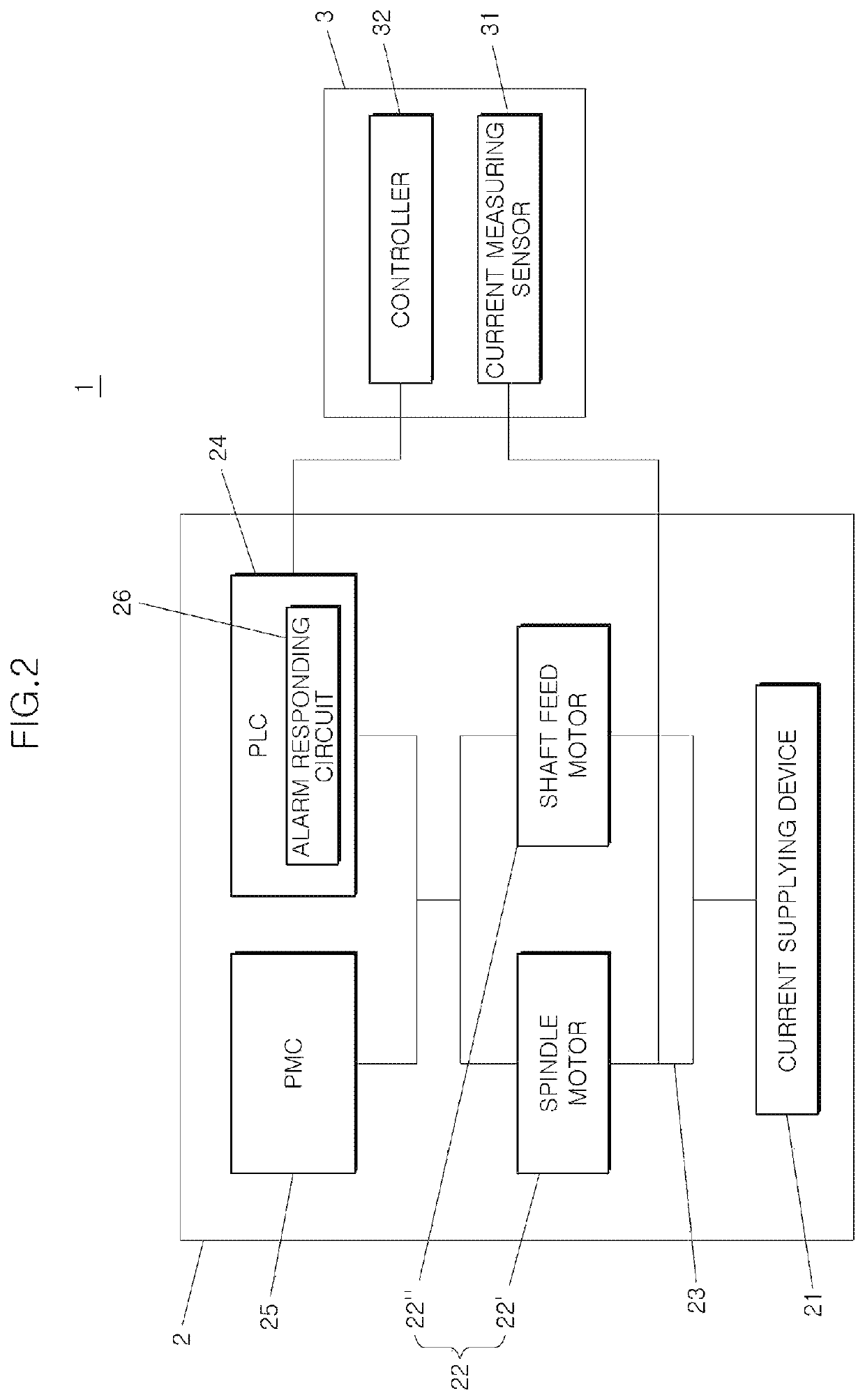

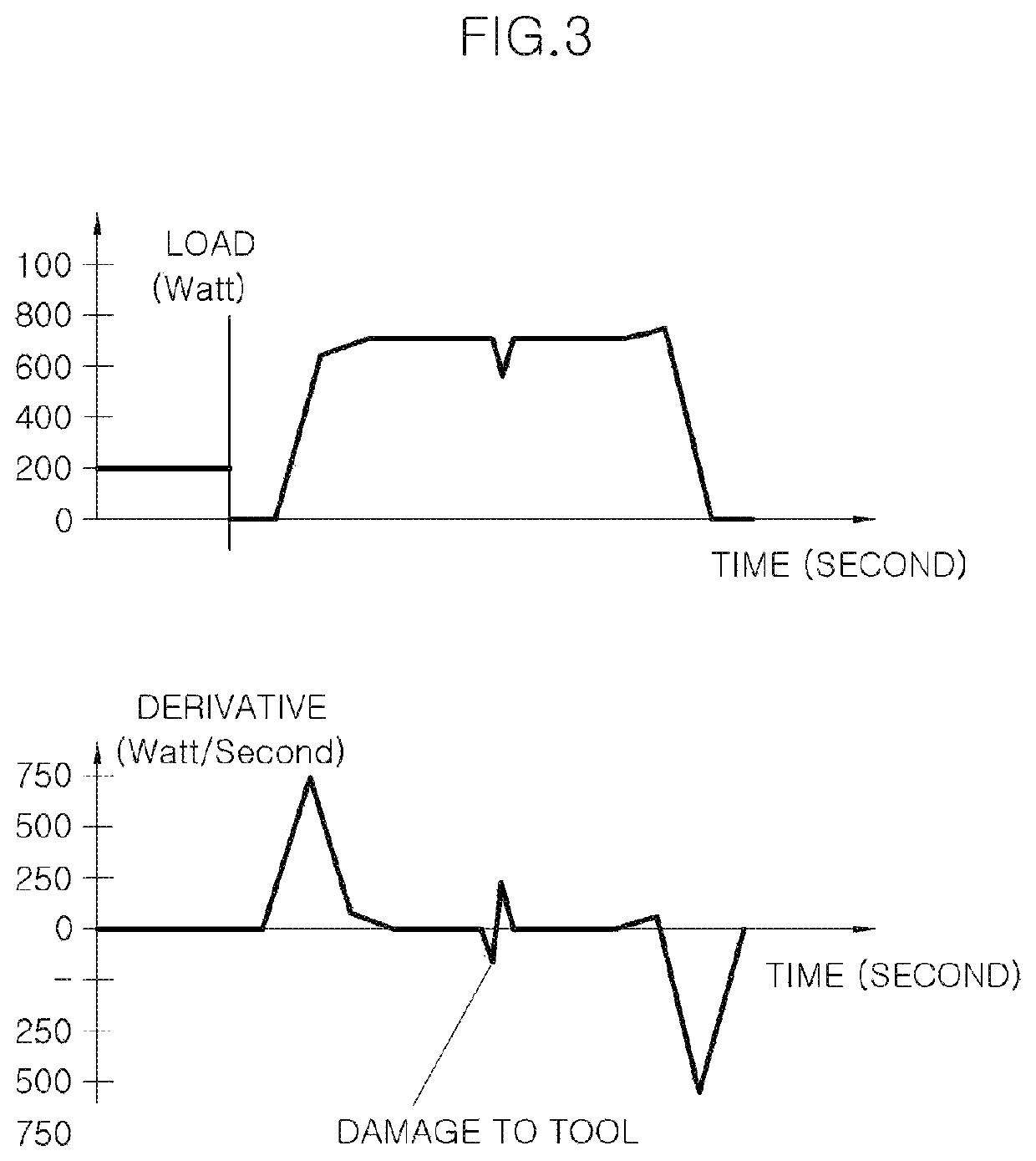

System and method for detecting damaged tool of multi-axis head machining equipment

ActiveUS10589395B2Avoid damageIncrease productivityProgramme controlMeasurement/indication equipmentsMachiningDamage detection

A system for detecting a damaged tool of multi-axis head machining equipment includes multi-axis head machining equipment, and a damaged tool detecting device connected to the multi-axis head machining equipment to detect a damaged tool, the damaged tool detecting device being configured to measure a current and a current change amount of the multi-axis head machining equipment to monitor a machining load, and a derivative and machining energy of the machining load, so as to detect whether there is an abnormality in a plurality of tools mounted on a multi-axis head during machining.

Owner:HYUNDAI MOTOR CO LTD +1

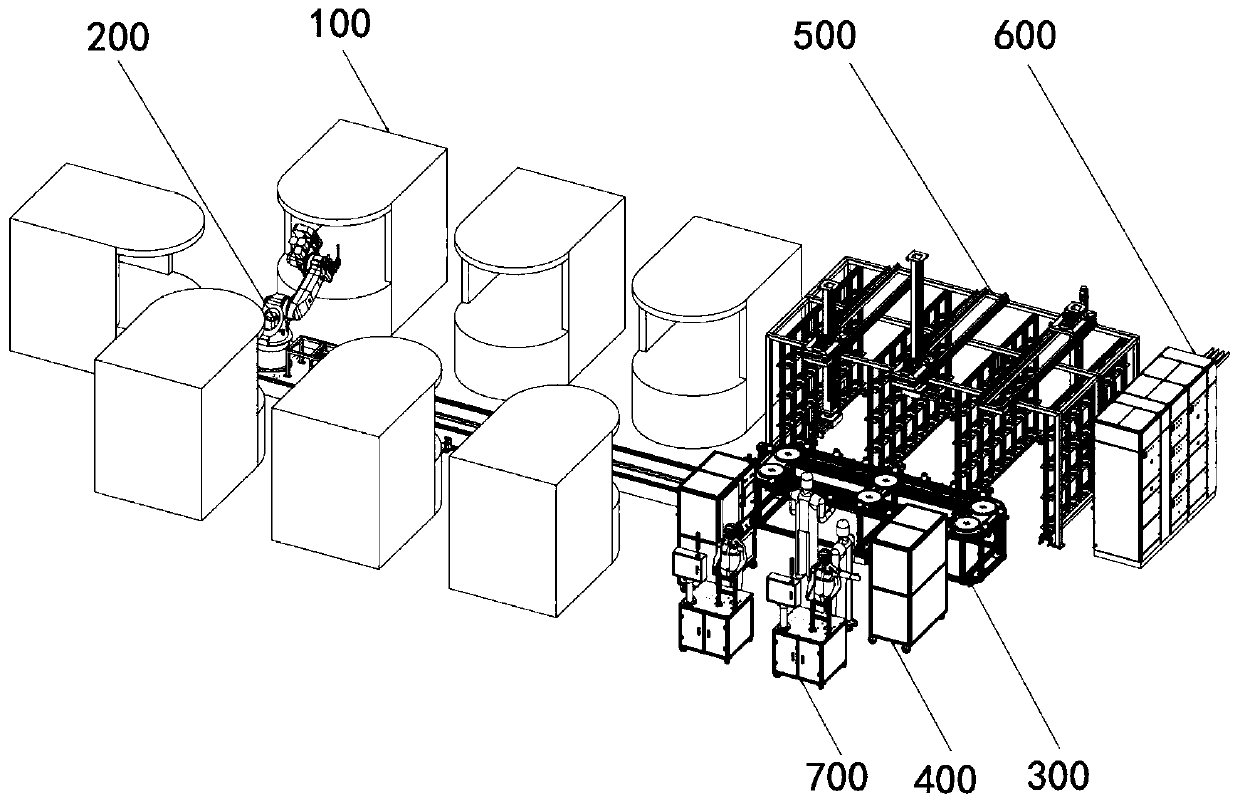

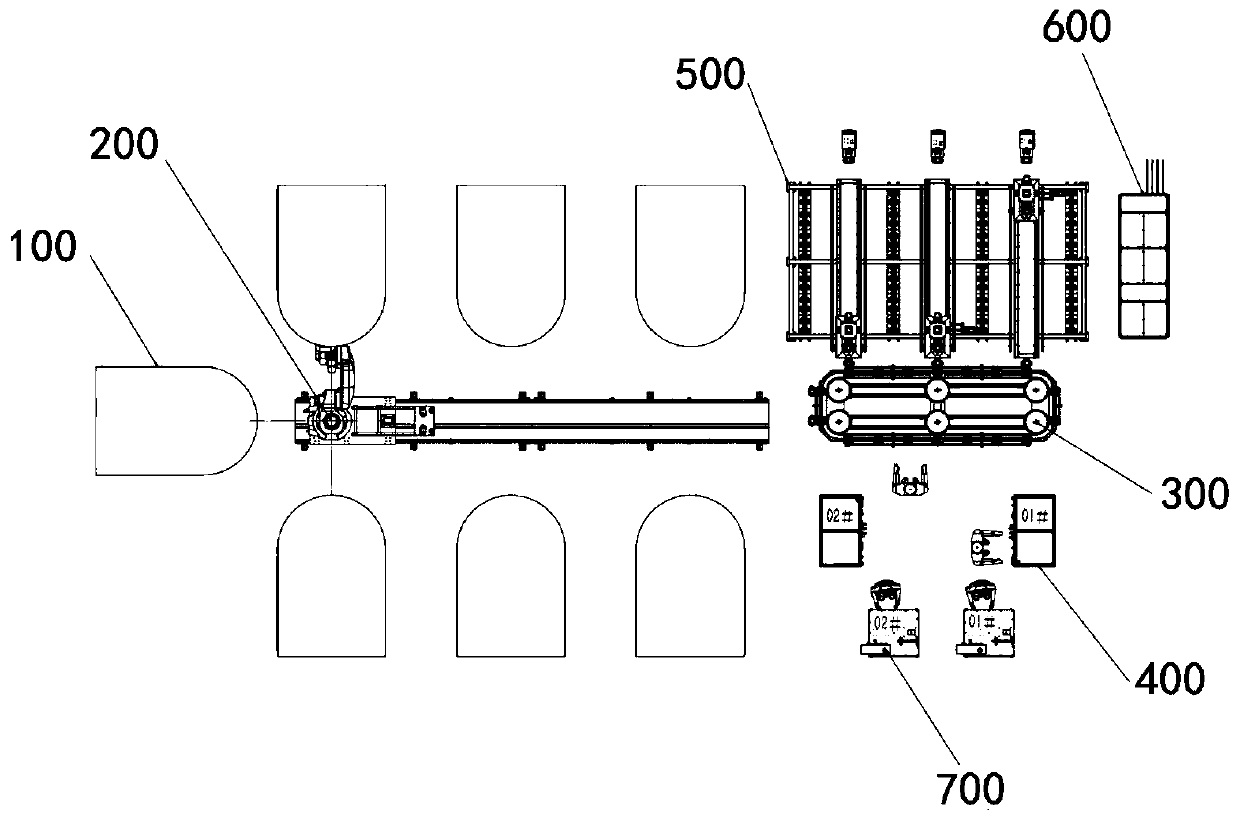

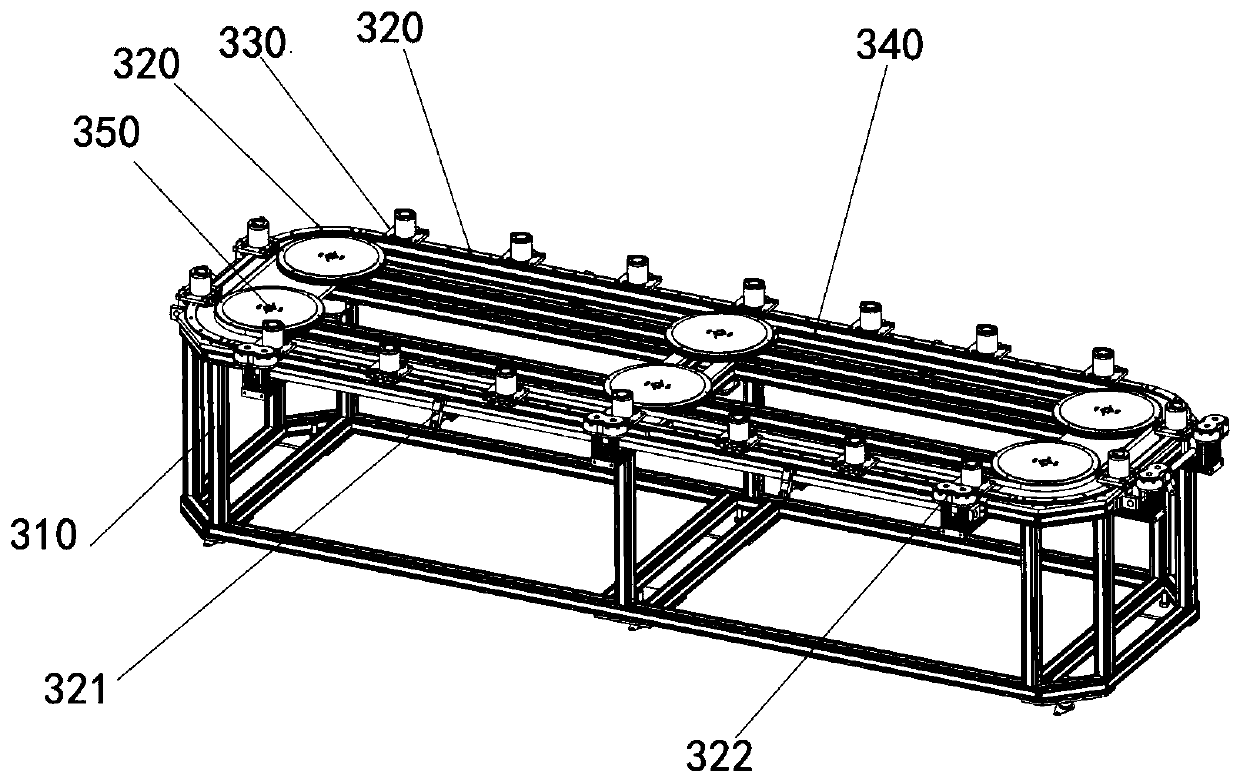

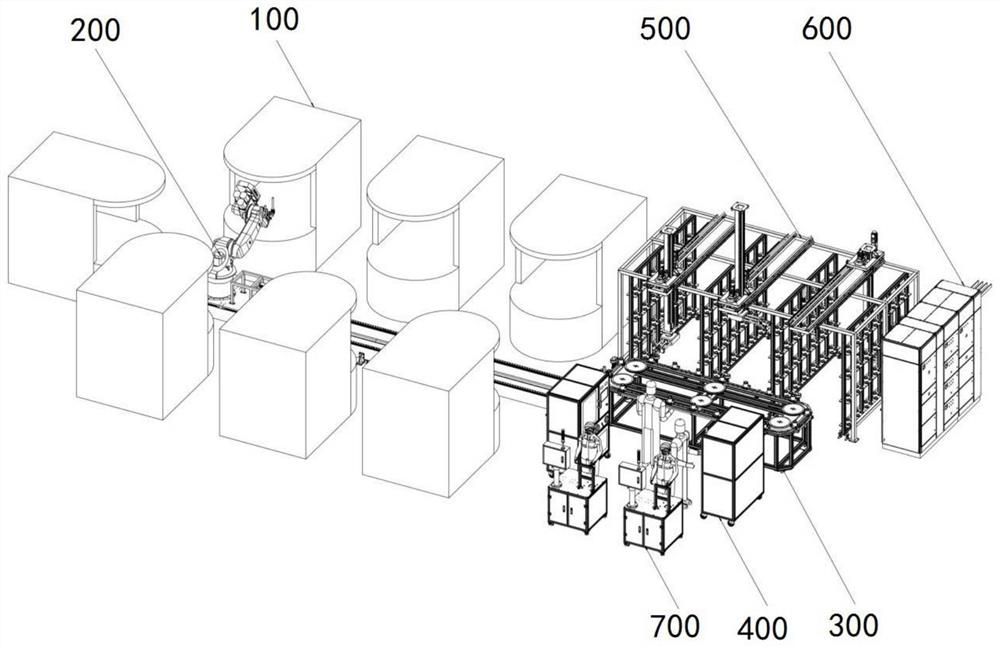

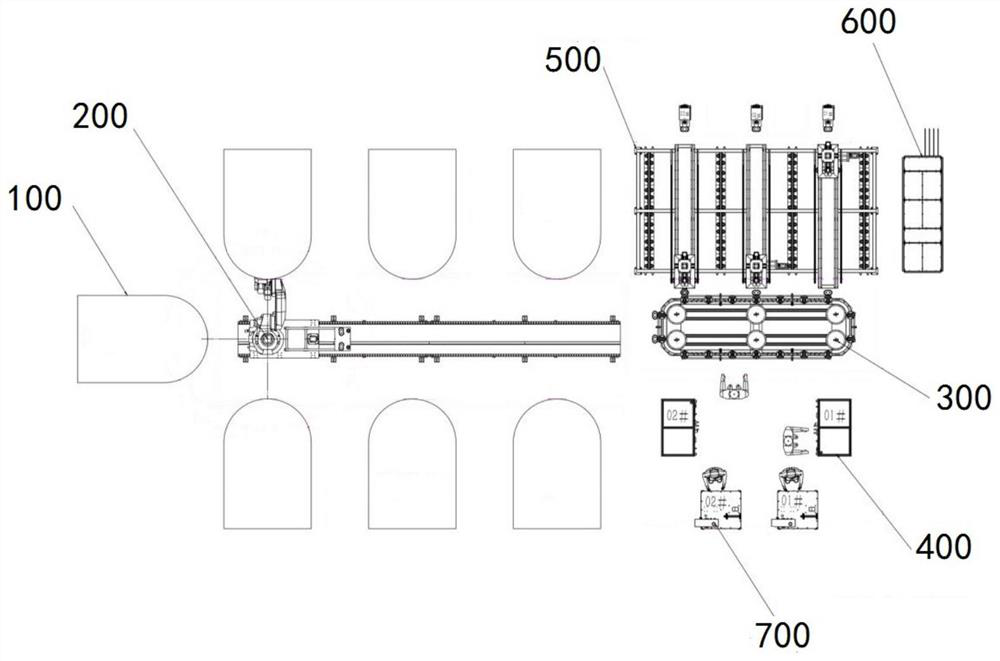

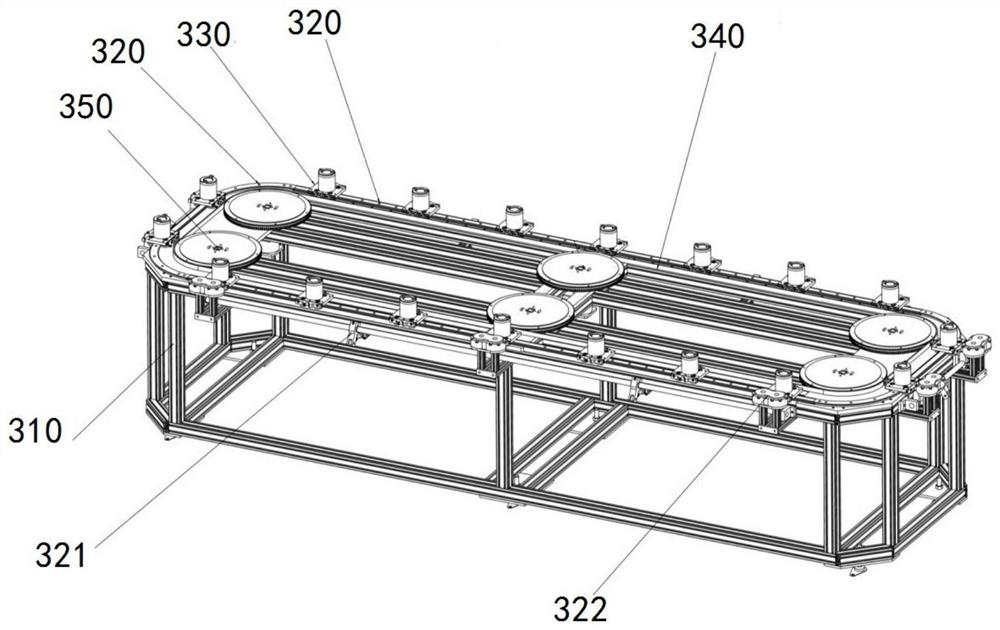

Production line for automatic cutter feeding and discharging of knife sharpener and use method thereof

ActiveCN111571319AFix imperfectionsRealize full automationGrinding feed controlOther manufacturing equipments/toolsProduction lineKnife sharpener

The invention provides a production line for automatic cutter feeding and discharging of a knife sharpener and a use method thereof. The production line for automatic cutter feeding and discharging ofthe knife sharpener comprises knife sharpeners, a robot working unit, a cutter loader, a cutter detection device, a tool stereo garage and a digital management system, wherein the robot working unitis arranged adjacent to the cutter loader, the plurality of knife sharpeners are arranged around the robot working unit, the cutter detection device is arranged on one side of the cutter loader, the tool stereo garage is arranged on the opposite other side, and the knife sharpeners, the robot working unit, the cutter detection device and the tool stereo garage are all in communication connection with the digital management system. According to the production line for automatic cutter feeding and discharging of the knife sharpener, the problem that an existing knife sharpening and repairing system production line is not perfect is solved, the knife sharpening and repairing system is perfected, whole-process automation of feeding and discharging is realized, and the purposes of digital management and monitoring of the knife sharpening and repairing system are achieved.

Owner:厦门奇达智能科技股份有限公司

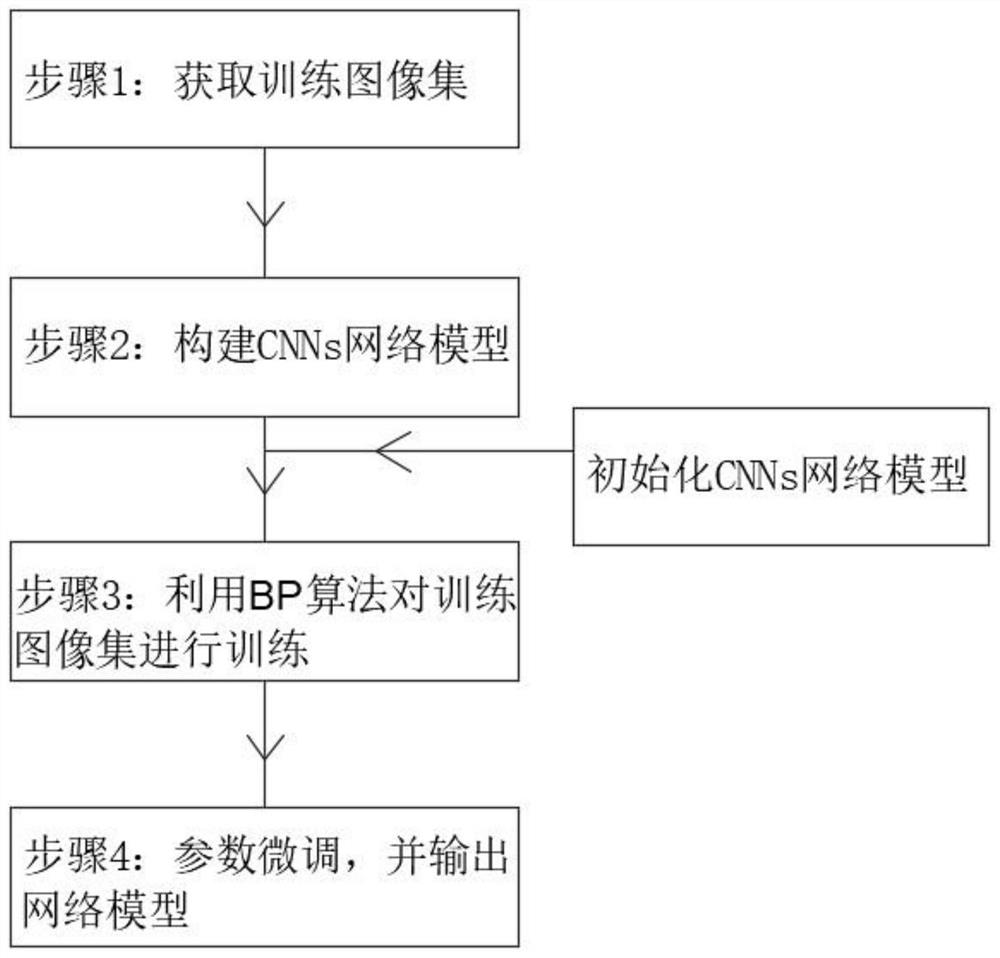

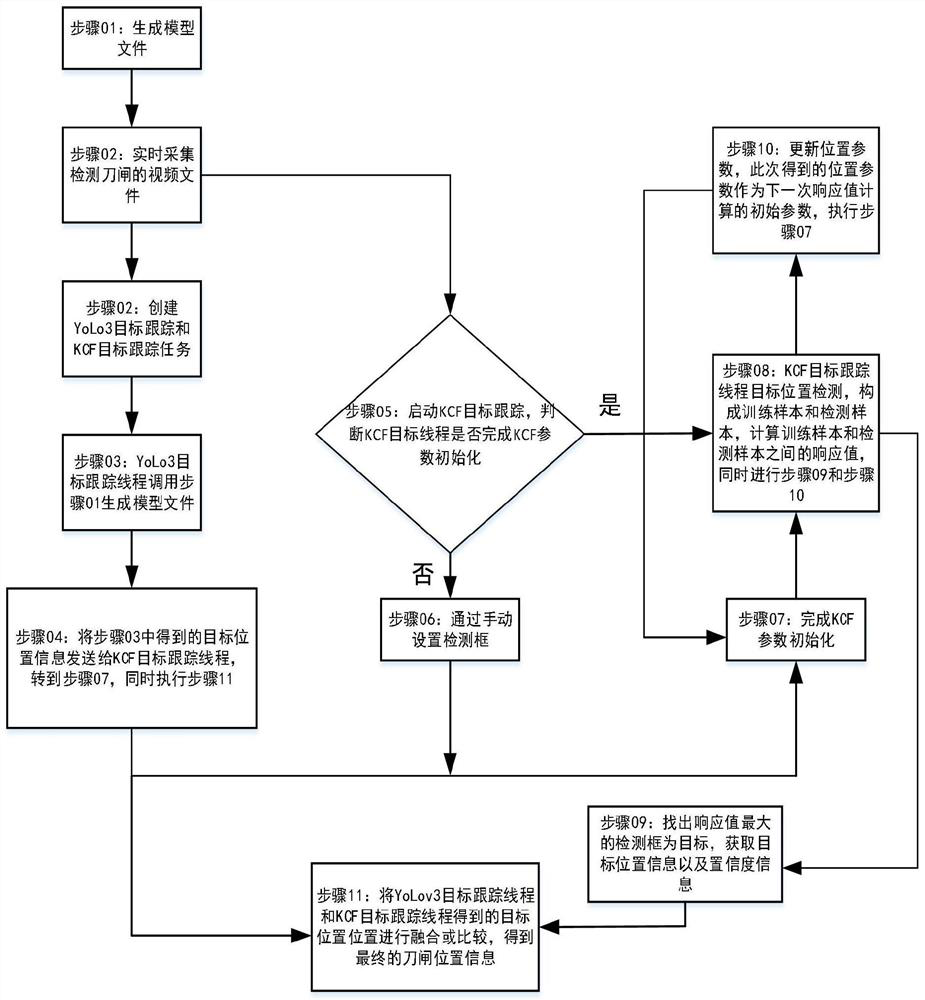

Visual judgment method for opening and closing of disconnecting link body of GIS equipment

PendingCN114693974ASolve the problem of target interferenceImprove the accuracy of state recognitionCharacter and pattern recognitionNeural architecturesStochastic gradient descentSigmoid activation function

The invention belongs to the technical field of intelligent detection, and particularly relates to a GIS equipment knife switch body opening and closing visual judgment method, which comprises knife switch body static state identification and knife switch body motion state identification, and is characterized in that knife switch body static state identification is realized through a knife switch body state identification method based on improved deep learning; knife switch body motion state identification is realized through a method based on combination of a YOLOv3 deep learning target detection network and a KCF target tracking algorithm, in the knife switch body state identification method based on improved deep learning, Gaussian distribution is used to carry out random initialization on CNNs weight values, so that feature dimensions are reduced, overfitting is avoided, and the identification accuracy of the knife switch body state identification method based on improved deep learning is improved. A traditional sigmoid activation function is abandoned in an activation function in the BP algorithm, a ReLU activation function is adopted, gradient diffusion in the training process of the image set is avoided, and therefore the convergence speed of the stochastic gradient descent method is increased.

Owner:国网山西省电力公司超高压变电分公司

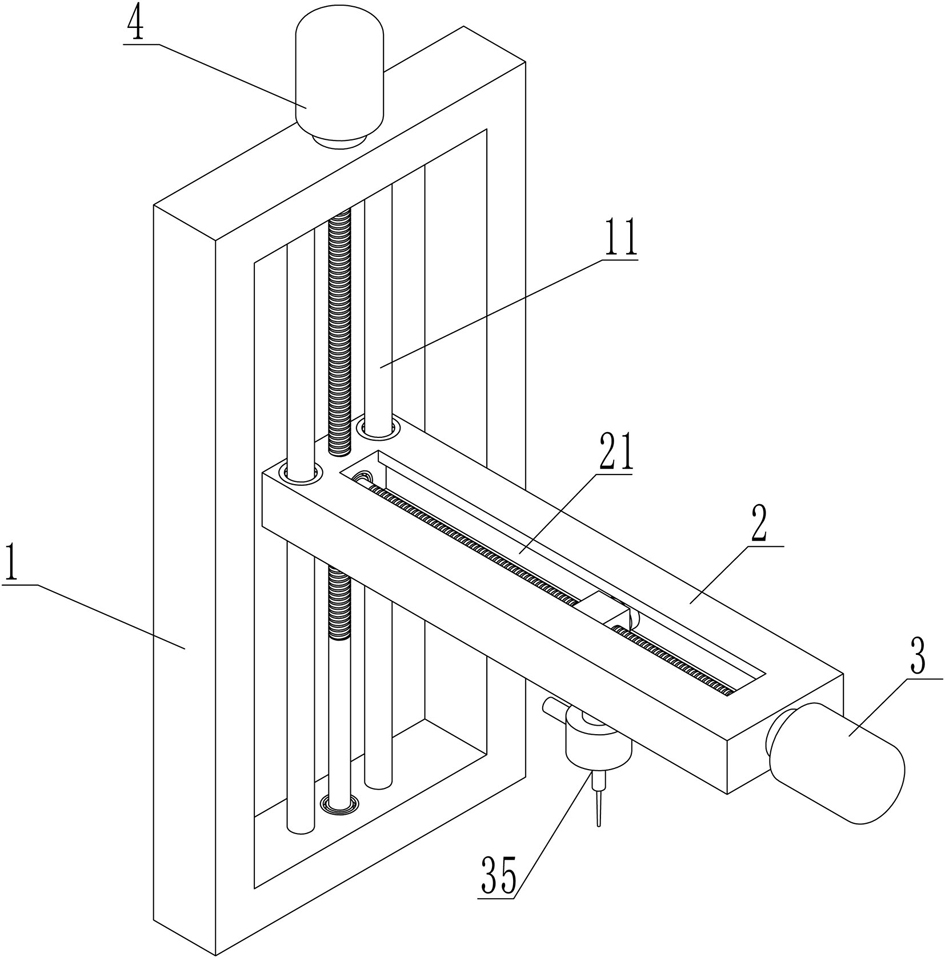

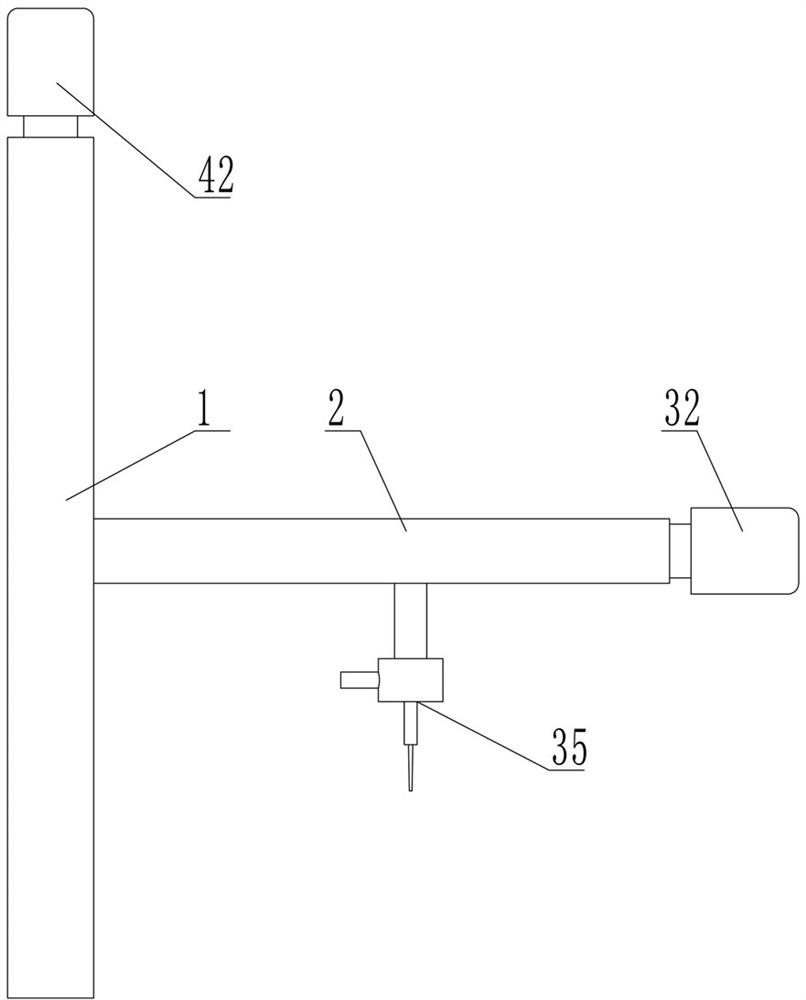

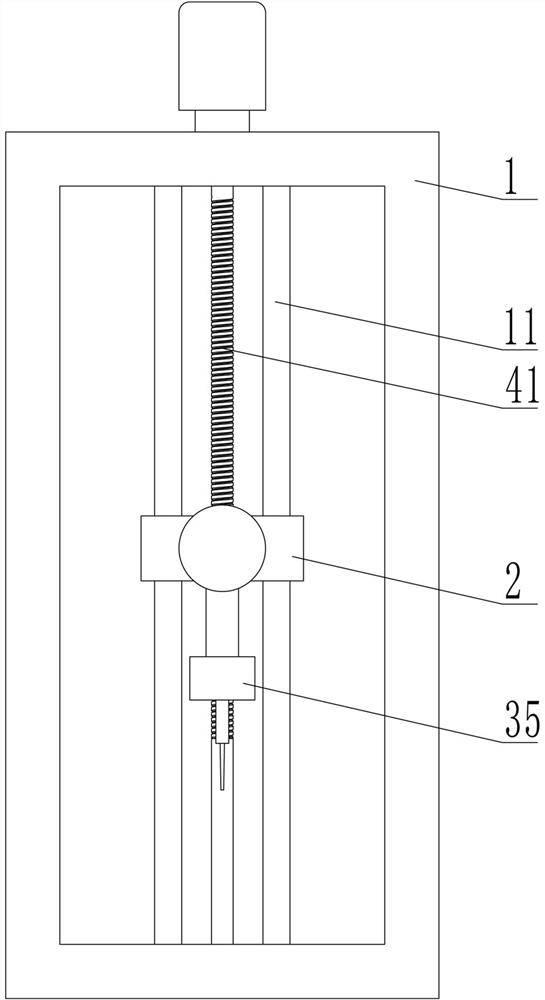

Water cutting knife nozzle and driving device for driving water cutting knife nozzle

PendingCN112643792AImprove efficiencySimple structureMetal working apparatusWater flowElectric machinery

The invention discloses a water cutting knife nozzle and a driving device for driving the water cutting knife nozzle. The device comprises a support frame, a knife rest, a knife adjusting mechanism and a knife rest adjusting mechanism, wherein one end of the knife rest is in sliding fit with a positioning rod of the support frame, and the knife rest is laterally perpendicular to the support frame; a horizontal lead screw of the knife adjusting mechanism penetrates through the knife rest to be matched with a knife holder; a vertical lead screw of the knife rest adjusting mechanism penetrates through the support frame to be matched with the knife rest; a servo motor drives the horizontal lead screw to rotate to drive the knife holder to linearly move horizontally; and a stepping motor drives the vertical lead screw to rotate to drive the knife rest to ascend and descend. According to the water cutting knife nozzle and the driving device for driving the water cutting knife nozzle, the problems that when a knife of original water flow cutting equipment is adjusted, the initial cutting point and height are not accurately adjusted through manual movement and the labor intensity is high are solved; and the water cutting knife nozzle has the advantages of being simple in structure, capable of accurately positioning the initial cutting point and cutting height of a water cutting knife, free of manual movement of the knife, low in labor intensity, high in efficiency and easy and convenient to operate.

Owner:阎文忠

A wear test and prediction method of a tunneling equipment tool in a soft soil environment

InactiveCN108387473BTest for wearReduce workloadUsing optical meansInvestigating abrasion/wear resistanceOptimal testAgricultural engineering

The invention a method for testing and predicating the wearing of an excavating device cutter in a soft soil environment. The method simulates the actual working condition of engineering through a test technique, and predicts the wearing of the cutter in the actual engineering. The method can be used to scientifically and effectively test the wearing condition of the excavating device cutter in the soft soil environment, the onsite inspection and maintenance of the cutter are guided through the test of the wearing of the cutter, and the actual wearing amount of the cutter is calculated to determine the replacing cycle of the cutter, so inspection and maintenance personnel has no need to frequently enter a pressure chamber in the engineering and detect, the workload is reduced, and the excavating engineering process is improved; and the method fully considers the characteristics of the influences of the soft soil on the wearing of the cutter, and the optimal test running time is determined through preliminary test to make the test result scientific and close to the actual working condition, so the error of the test is reduced to well guide the engineering practice.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD +1

Push structure of forming device lower knife

Owner:SUZHOU JINTONG MACHINERY MFG

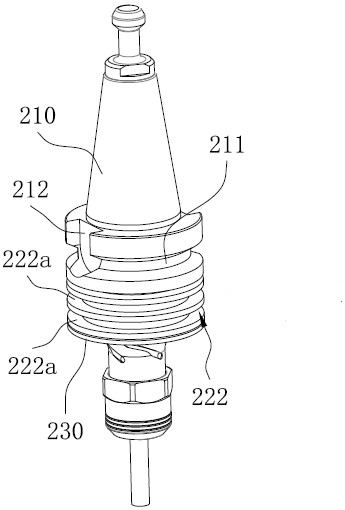

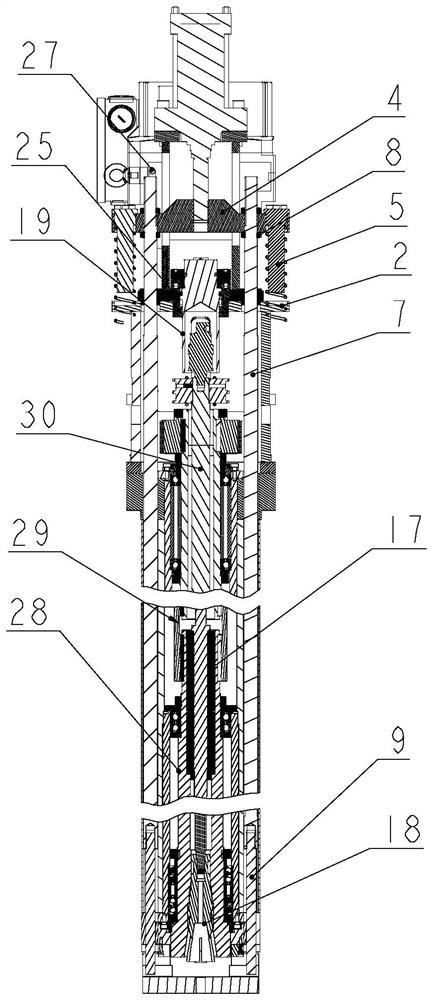

Ultrasonic spindle, ultrasonic tool holder and ultrasonic processing equipment

ActiveCN112317781BRealize wireless transmissionRealize automatic tool changeTurning machine accessoriesLarge fixed membersTransmitter coilRotational axis

The present invention relates to the technical field of ultrasonic processing, in particular to an ultrasonic spindle, an ultrasonic tool handle and ultrasonic processing equipment, including a spindle housing; There are installation holes; the launching frame is arranged on the front side of the spindle housing. The launching frame includes a launching part, which is in the shape of a non-full circle around the outer circumference of the rotating shaft assembly. An annular first accommodation tank; an ultrasonic wireless transmitting unit, which is arranged in the first accommodation tank, and the ultrasonic wireless transmitting unit includes a transmitting coil and a transmitting ferrite. By replacing the traditional full-ring wireless transmitting device with a non-full-circular ultrasonic wireless transmitting unit, after the ultrasonic tool handle is installed on the ultrasonic spindle, it is possible to leave a space for the tool holder on the tool holder body , so that the tool magazine can be used for automatic tool change, and the versatility of the equipment tool magazine can be improved.

Owner:CONPROFE MACHINE TOOLS CO LTD +1

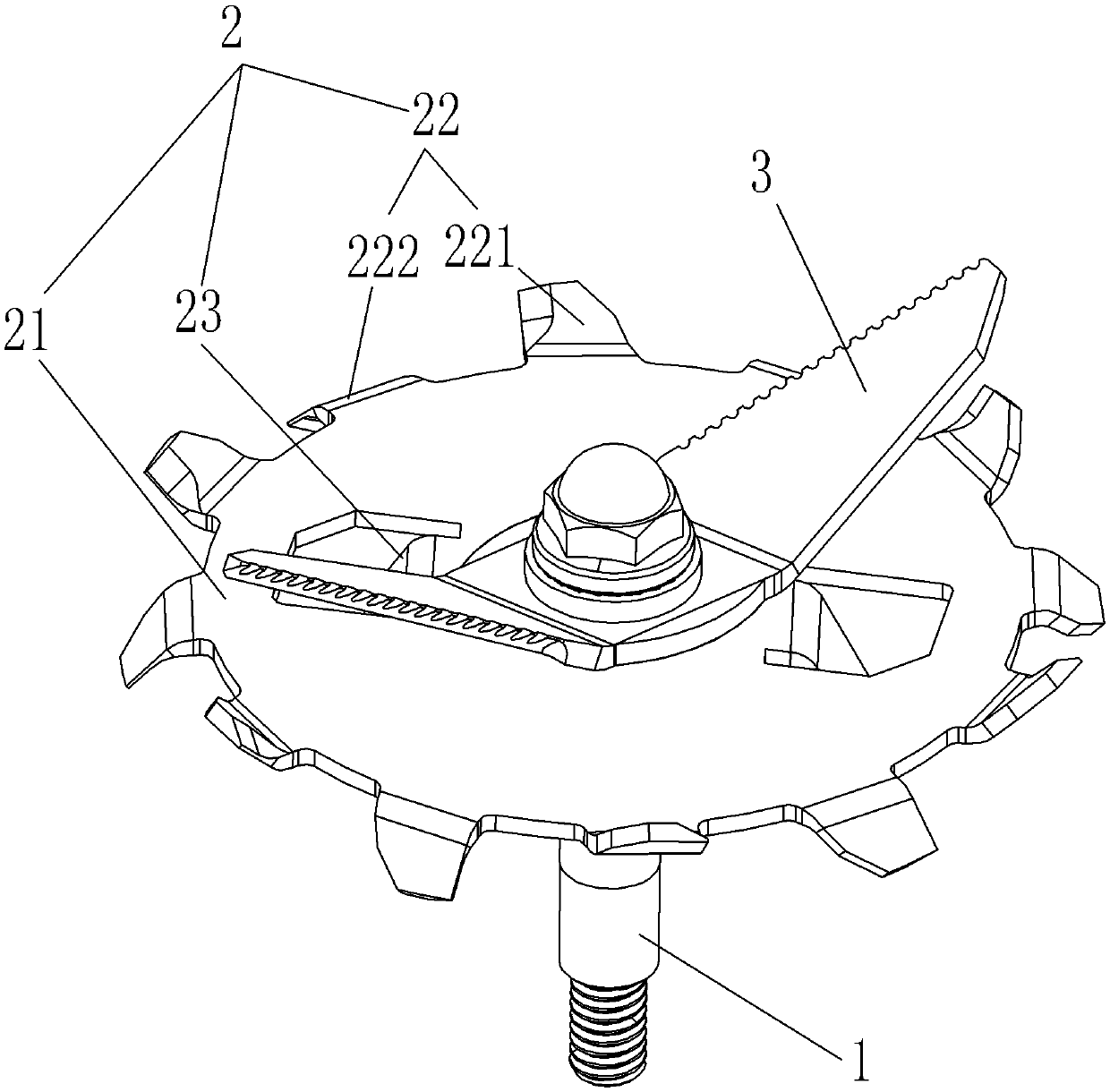

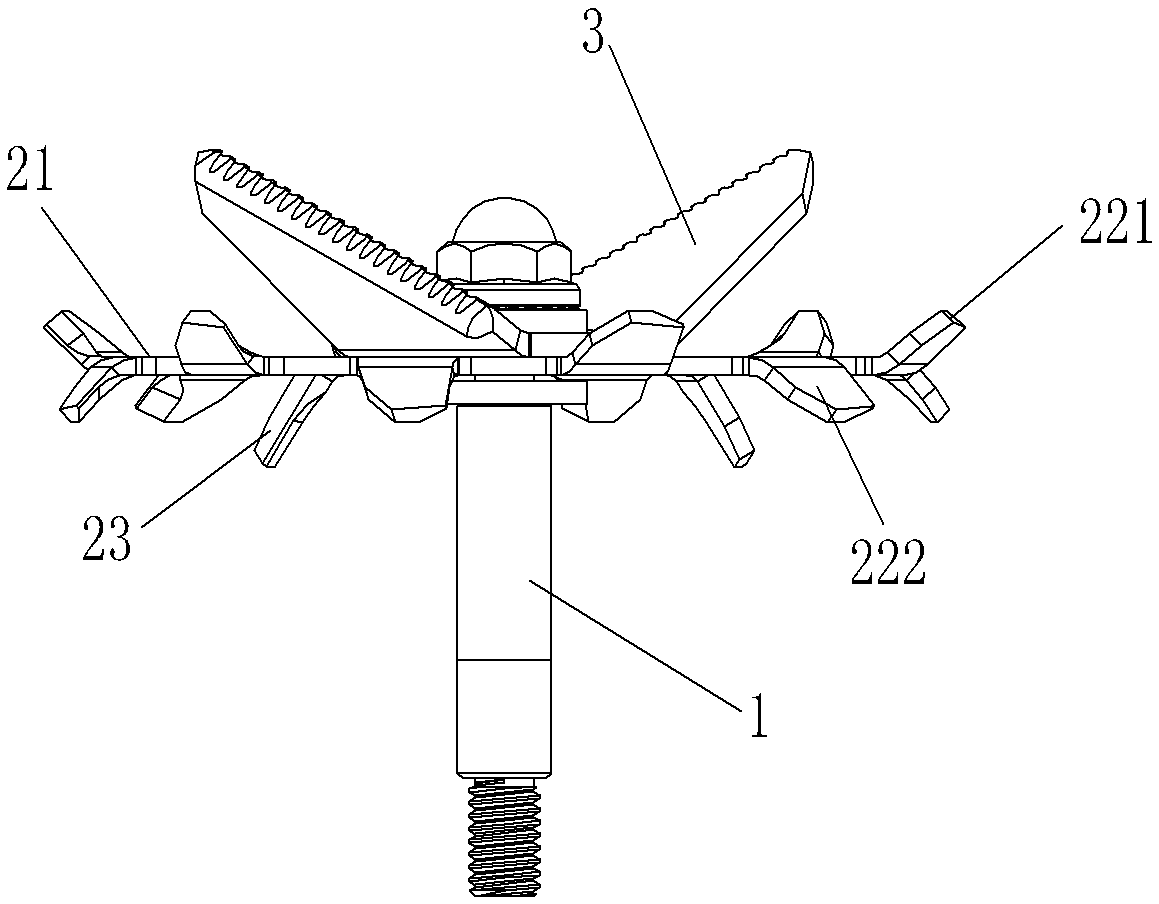

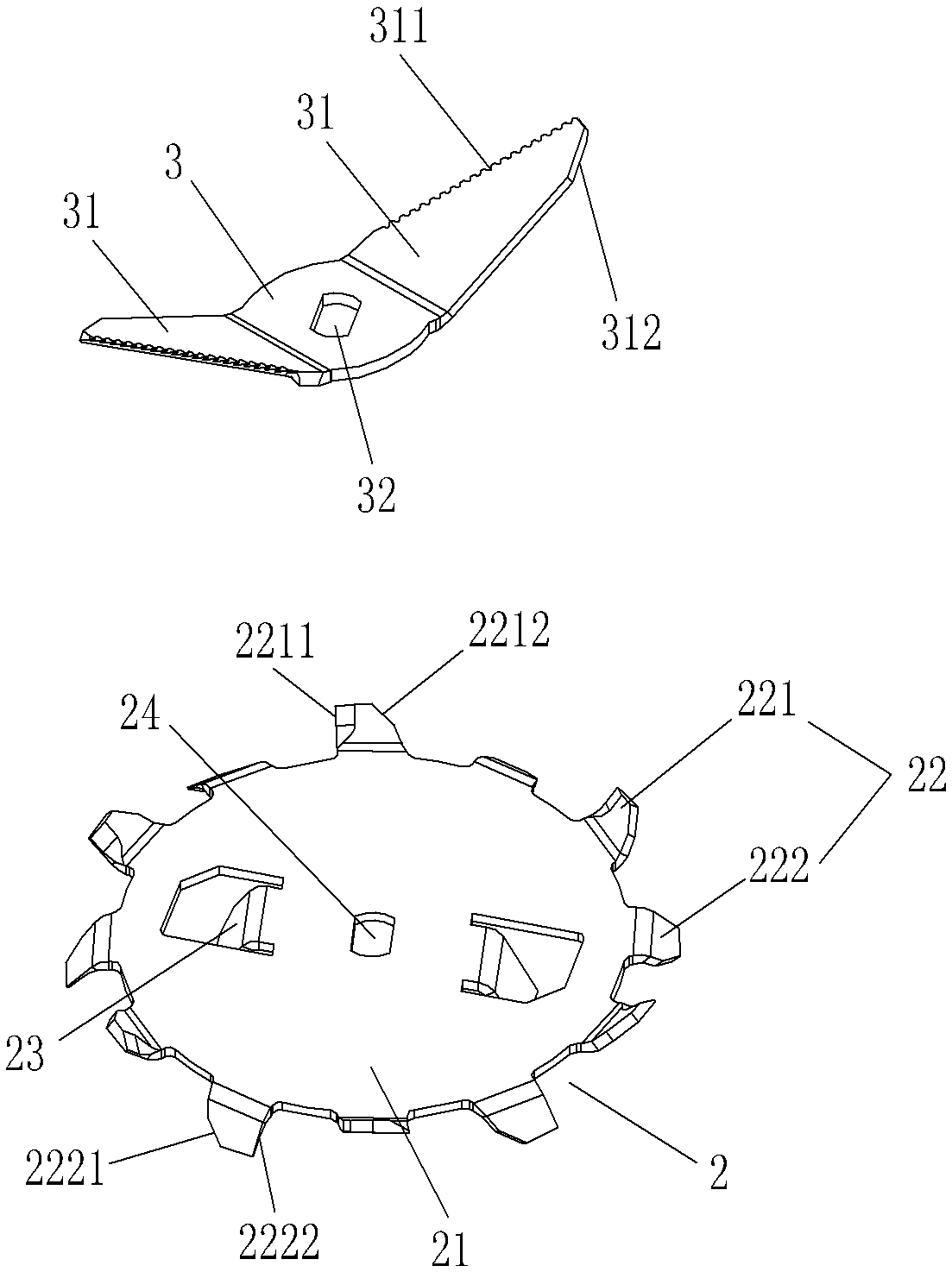

Food processor and knife component for same

The invention discloses a food processor and a knife component for the same. The knife component comprises a knife shaft and a knife blade mounted on the knife shaft, the knife blade comprises an upper knife blade fixed on the knife shaft in a sleeving manner and a disc knife, the disc knife comprises a round body, a plurality of knife teeth which are uniformly distributed and warp upward and downward extend outward at the outer edge of the round body, and a lower knife blade is arranged on the round body. Acting force generated by the upper knife blade and upper knife teeth can offset that generated by the lower knife blade and lower knife teeth, so that the knife component is highly balanced when rotating at a high speed and the food processor is avoided causing sever vibration and high noise. In addition, the upper knife blade, the upper knife teeth, the lower knife teeth and the lower knife blade are positioned in different planes respectively, so that the knife component has four stirring tracks when running, thereby being capable of fully crushing food materials in the different stirring tracks, and the knife component has the advantages of high crushing efficiency and uniformity in crushing.

Owner:HOME CULTURE APPLIANCES SHENZHEN

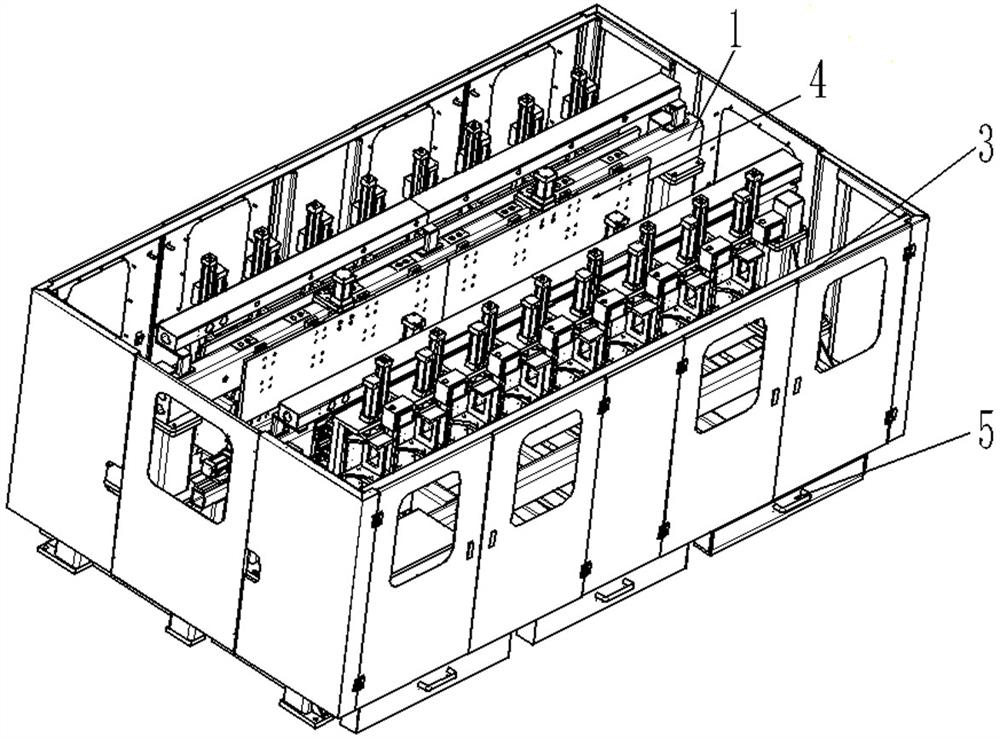

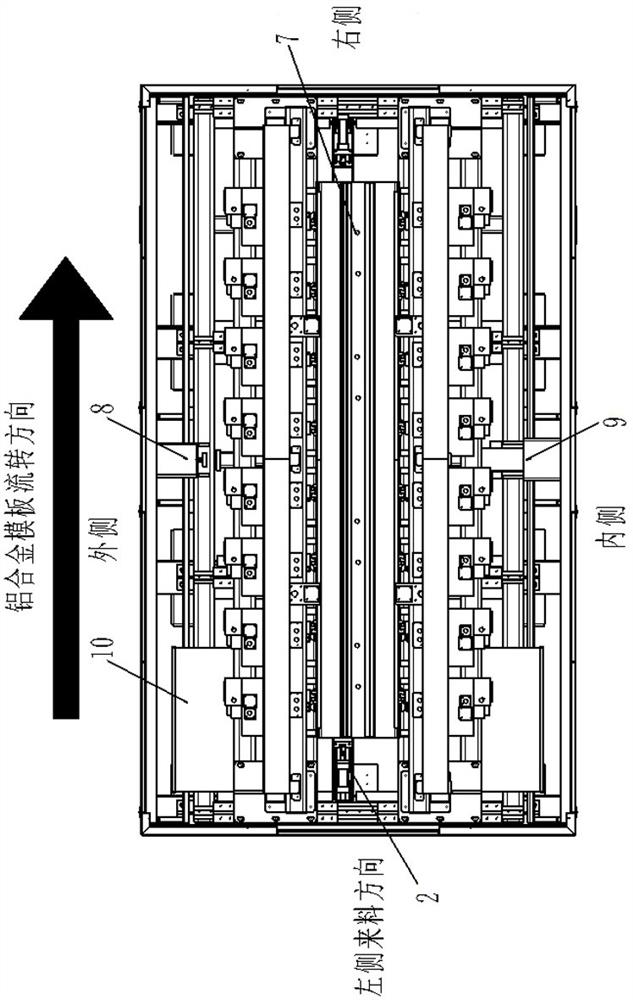

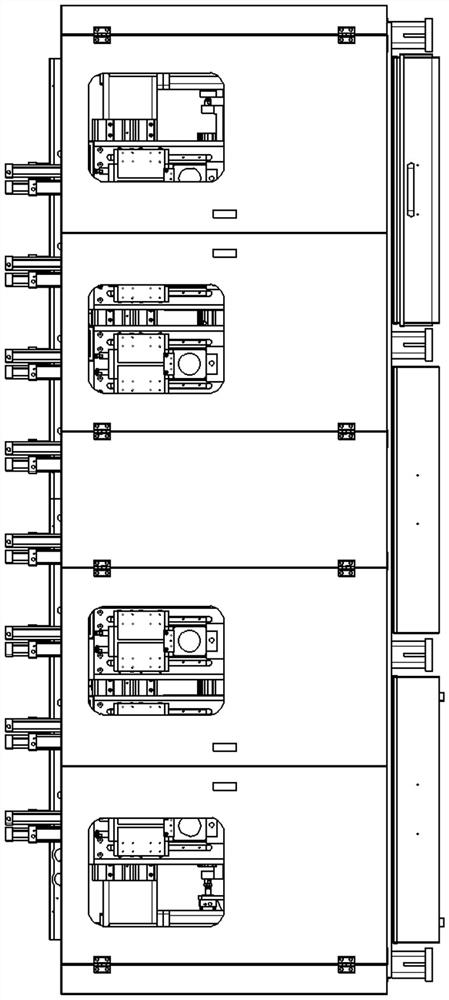

Aluminum template numerical control slot milling machine

InactiveCN114083034ASolve the problem of split designSolve the problem that the feeding is not in placeWork clamping meansFeeding apparatusNumerical controlTool bit

The invention discloses an aluminum template numerical control slot milling machine, and relates to the field of modern equipment manufacturing. The aluminum template numerical control slot milling machine comprises a protective cover frame; feeding mechanisms are symmetrically arranged on the front side and the rear side of an inner cavity of the protective cover frame, wherein one is an outer side transverse moving feeding mechanism, and the other is an inner side transverse moving feeding mechanism; pressing mechanisms are arranged at the upper ends of the sides, close to each other, of the two feeding mechanisms, and aluminum scrap collecting devices are arranged on the front side and the rear side of the bottom of the protective cover frame correspondingly; the left ends of the sides, away from each other, of the outer side transverse moving feeding mechanism and the inner side transverse moving feeding mechanism are each provided with a power distribution cabinet; a clamping unit is arranged between the two sets of feeding mechanisms, and groove milling mechanisms are arranged on the sides, away from each other, of the two sets of feeding mechanisms. The problem of split type design of a tool bit structure and a pressing mechanism of the equipment is solved, so that the groove milling is more stable, and the problems that the conditions that feeding is not in place and pause easily occur when the feeding mechanism moves, so that steps exist when the aluminum template is subjected to groove milling, and the smoothness cannot meet the technical requirements are solved.

Owner:山西建投建筑产业有限公司 +2

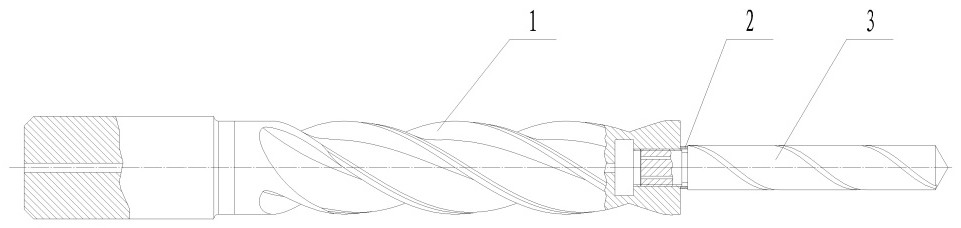

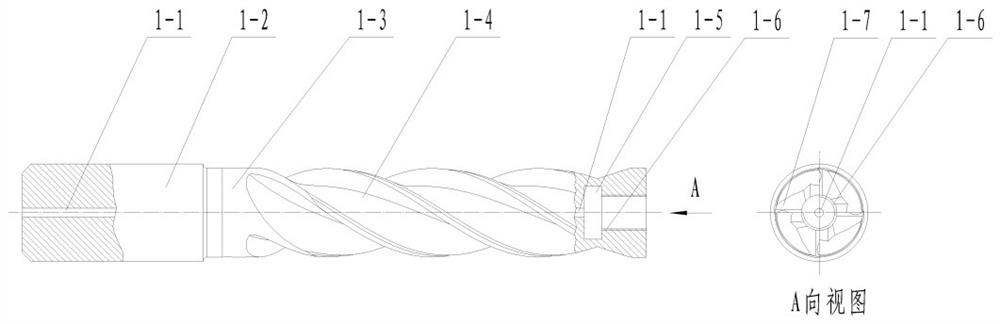

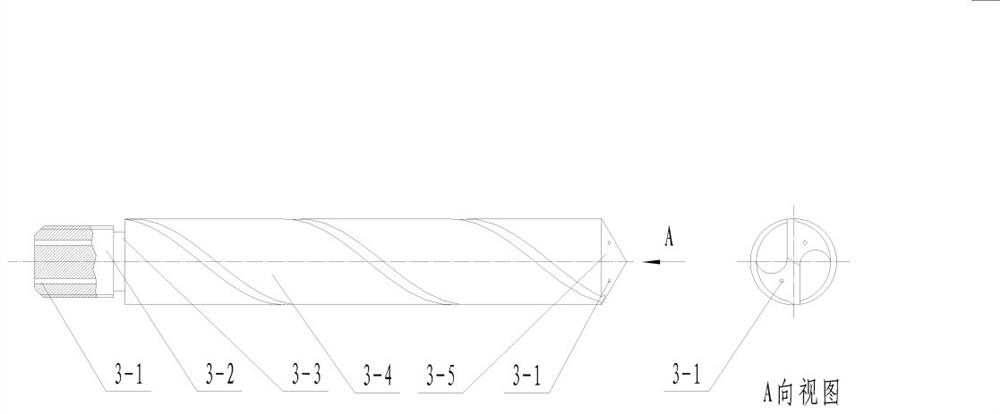

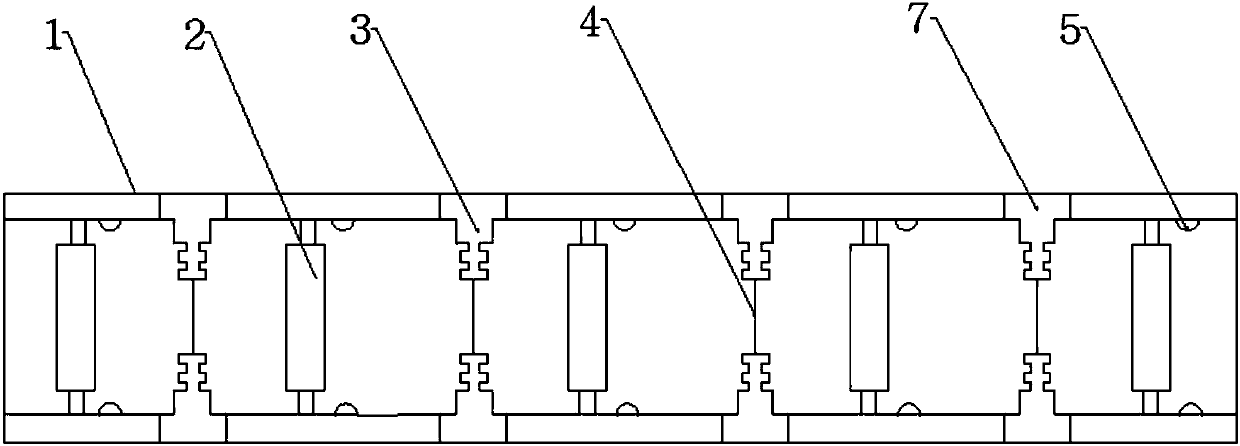

Combined tool with cooling function for machining stepped holes

InactiveCN113547154AImprove cooling effectTransportation and packagingStepped drillsMilling cutterCooling effect

The invention belongs to metal cutting tools, and particularly relates to a combined tool for machining stepped holes. The combined tool comprises a milling cutter (1) with an inner cooling hole, an adjusting shaft sleeve (2) and a twist drill (3) with an inner cooling hole. The milling cutter (1) with the inner cooling hole is in threaded fit with the twist drill (3) with the inner cooling hole, the stepped holes of different types and sizes are machined, the investment of equipment and tools for machining the stepped holes is reduced, machining procedures and auxiliary working hours are reduced, the inner cooling holes are formed, cutting fluid flows in the tool, and the cooling effect of the tool is improved.

Owner:LIAONING TECHNICAL UNIVERSITY

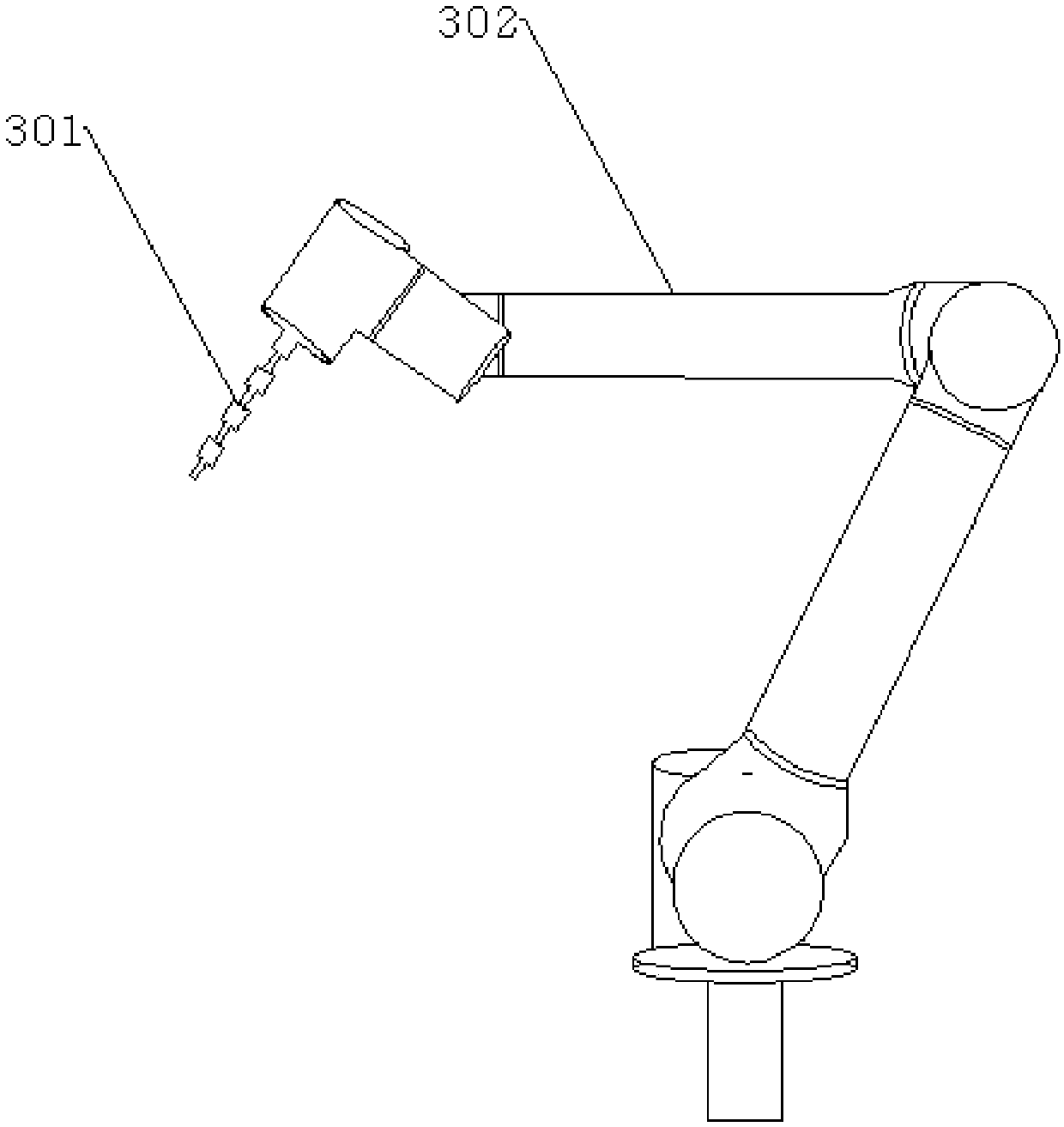

A production line for automatic loading and unloading of sharpening machine tools and using method thereof

ActiveCN111571319BFix imperfectionsRealize full automationGrinding feed controlOther manufacturing equipments/toolsMachineWork unit

The invention provides a production line for automatic loading and unloading of knives of a sharpener and a method of use thereof, which includes a production line for automatic loading and unloading of knives of a sharpener, including a sharpener, a robot working unit, a tool loader, Tool testing equipment, tool stereoscopic warehouse, digital management system, the robot work unit is set adjacent to the tool loader; several knife sharpeners are set around the robot work unit; tool testing equipment is set on one side of the tool loader and on the opposite side There is a three-dimensional tool library; the knife grinder, robot work unit, tool testing equipment, and tool three-dimensional library are all connected to the digital management system by communication. The invention provides a production line for automatic loading and unloading of sharpener knives, which solves the problem that the production line of the existing knife sharpening and repairing system is not perfect; it improves the knife sharpening and repairing system, realizes the full automation of loading and unloading, and achieves It realizes the purpose of digital management and monitoring of the knife sharpening repair system.

Owner:厦门奇达智能科技股份有限公司

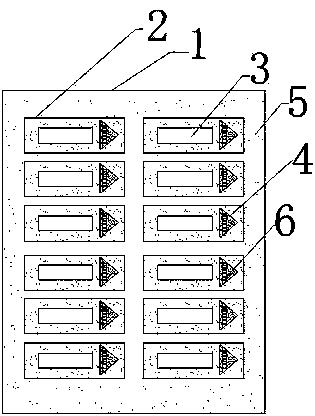

Template device knife for drilling bits

The invention relates to a template device knife for drilling bits. The template device knife comprises a template, wherein a plurality of rectangular cutting knives for cutting package paper of the drilling bits are parallelly inserted into the template, a rectangular hole is formed in each rectangular cutting knife, one side of each rectangular hole is provided with a triangular cutter in each rectangular cutting knife, the outer sides of each rectangular cutting knife and each triangular cutter are respectively wrapped by a filler, 6-8 teeth are arranged in the center of each triangular cutter, the filler is sponge or foam, and the thickness of each rectangular hole is larger than the thickness of the package paper of the drilling bits. The template device knife is simple in structure, and can be operated manually or mechanically, the cutting speed is high, 20-30 pieces of cutting paper can be cut at a time, the cutting is precise, the cutting precision is high, and the safety of working staff is ensured.

Owner:JIANGSU TIANGONG PRECISION TOOLS CO LTD

Automatic gypsum line cutting device

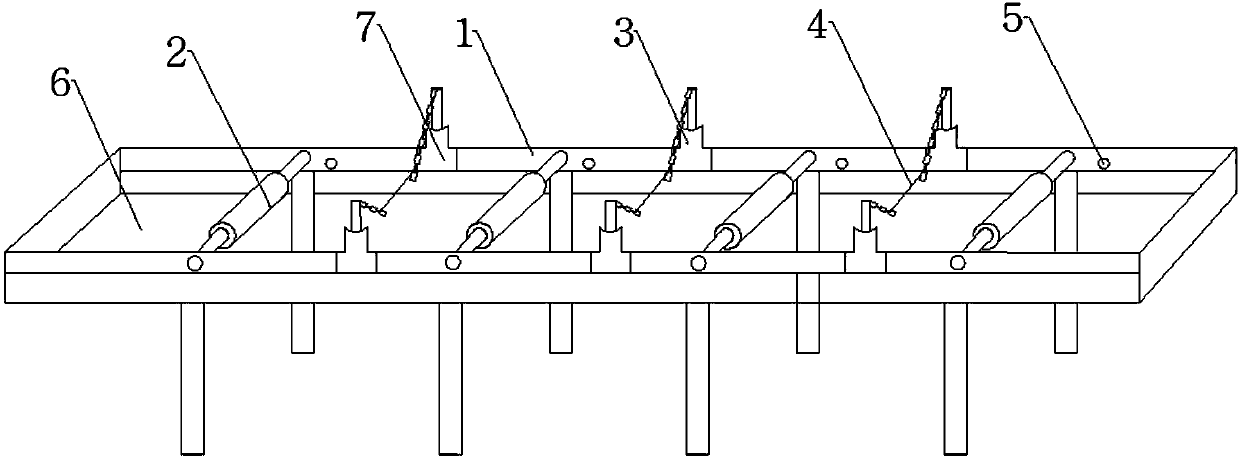

PendingCN107685396ACutting stabilityImprove cutting efficiencyWorking accessoriesManipulatorWire cuttingEngineering

The invention discloses an automatic gypsum line cutting device and relates to the field of gypsum line automatic cutting devices. The automatic gypsum line cutting device comprises a working platform, a transmission device, a cutting device and a control device, the transmission device, the cutting device and the control device are arranged on the working platform, the transmission device comprises conveying rollers, a conveying belt and a motor, the cutting device comprises manipulators, a mounting seat and an emery line, the conveying rollers are equidistantly arranged on two sides of the working platform and movably connected with the conveying belt, and the motor is connected with the conveying belt; the mounting seat is arranged between the conveying rollers, the manipulators are mounted on the mounting seat, the emery line is connected with the manipulator on the other side through the manipulator on one side, and the manipulators are electrically connected with the control device. The problem that existing gypsum line cutting equipment is high in knife damaging speed, low in cutting stability and incapable of automatically cutting gypsum lines different in length, and the automatic gypsum line cutting device has the advantages that cutting efficiency of the gypsum line cutting device is improved, and the gypsum lines different in length can be cut automatically.

Owner:峨眉山市万晟新材料科技有限公司

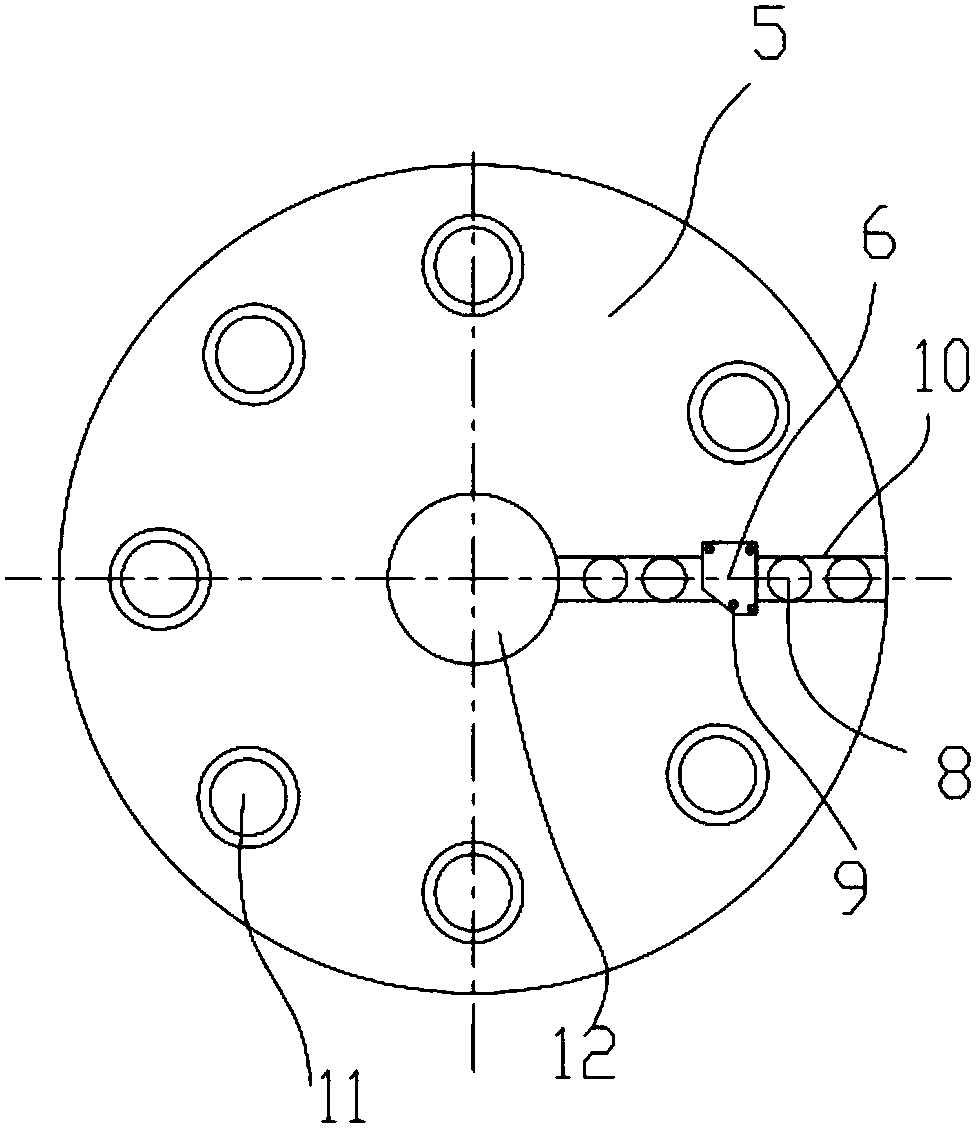

Turning-milling complex eccentric cutter handle

PendingCN107695752AQuality improvementImprove rigidityPositioning apparatusMetal-working holdersMilling cutterStructural engineering

The invention discloses a turning-milling complex eccentric cutter handle, which comprises a machine tool bed, a main shaft box, a main shaft, a main shaft axis, a cutter handle and a cutter. The mainshaft box is arranged in the machine tool bed; the main shaft axis is arranged in the center of the main shaft box; the main shaft is arranged on an external circular surface of the main shaft axis in a sleeving way; the cutter handle is fixedly connected to the bottom part of the main shaft; the center of the cutter handle is positioned in the main shaft axis; the cutter is eccentrically connected to the outer side of the circle center of the bottom part of the cutter handle; a flange plate end face of the cutter tightly fits a connecting end face of the main shaft in a seamless way; the cutter handle is fixedly connected onto the main shaft; the cutter is arranged and fixed to a radial slot, and an eccentric position of the cutter in the radial slot can be adjusted, so that the rigidityof the cutter is improved, meanwhile, errors easily occur during a cutter process are eliminated, and the surface of a produced workpiece is smoother; the turning-milling complex eccentric cutter handle is provided with a milling cutter handle avoidance site, so that a milling cutter handle can be used simultaneously in a noninterference way; and the integrated design structure is simple, the functionality is good, and the quality of products is greatly improved through the equipment.

Owner:广东钶锐锶数控技术股份有限公司

Cutter polishing and cleaning equipment

ActiveCN114147550AAvoid cloggingImprove the winding effectOther manufacturing equipments/toolsGrinding work supportsPolishingSmart manufacturing

The invention relates to the technical field of intelligent manufacturing equipment, in particular to cutter polishing and cleaning equipment which comprises a cutter clamping seat, a grinding seat and a fan, the cutter clamping seat is arranged on the upper side of the grinding seat and matched with the grinding seat, and the fan is arranged on one side of the grinding seat and matched with the grinding seat; the cutter clamping seat comprises a clamping head and a rotating seat, the rotating seat is arranged on the inner side of the grinding seat, the rotating seat is rotationally matched with the grinding seat, the clamping head is arranged on the upper side of the rotating seat, and the clamping head is fixedly connected with the rotating seat. And therefore, the safety of the cutter polishing process is effectively improved, and the situation that a user is injured is avoided.

Owner:重庆市大足区光头刀具有限公司

Tool locking ram structure of turning and milling composite equipment

ActiveCN113752047AReduce the number of clampingImprove machining accuracyOther manufacturing equipments/toolsPositioning apparatusMilling cutterMachine tool

The invention discloses a tool locking ram structure of turning and milling composite equipment, and belongs to the technical field of machine tool cutter component devices. The problems that due to the fact that an existing part is clamped many times, the working procedure is troublesome, time is consumed in the replacement process, and the machining quality and precision of the part cannot be guaranteed are solved. The tool locking ram structure comprises a turning tool loosening and tightening mechanism, a milling cutter loosening and tightening mechanism, a main shaft rotating mechanism and a ram. The tool locking ram structure has the advantages of being compact in structure, reliable in operation and the like, and solves one core problem of turning and milling combination of a machine tool. When applied to a machine tool, the turning and milling combination can be realized, the part clamping frequency is reduced, and the part machining precision is greatly improved. The tool locking ram structure can be used in cooperation with a tool magazine, tool loading and unloading automation is achieved, and the automation degree of equipment is further improved. In this way, due to the automation of tool replacement, the production auxiliary time is shortened, and the production efficiency can be obviously improved.

Owner:浙江日发精密机床有限公司

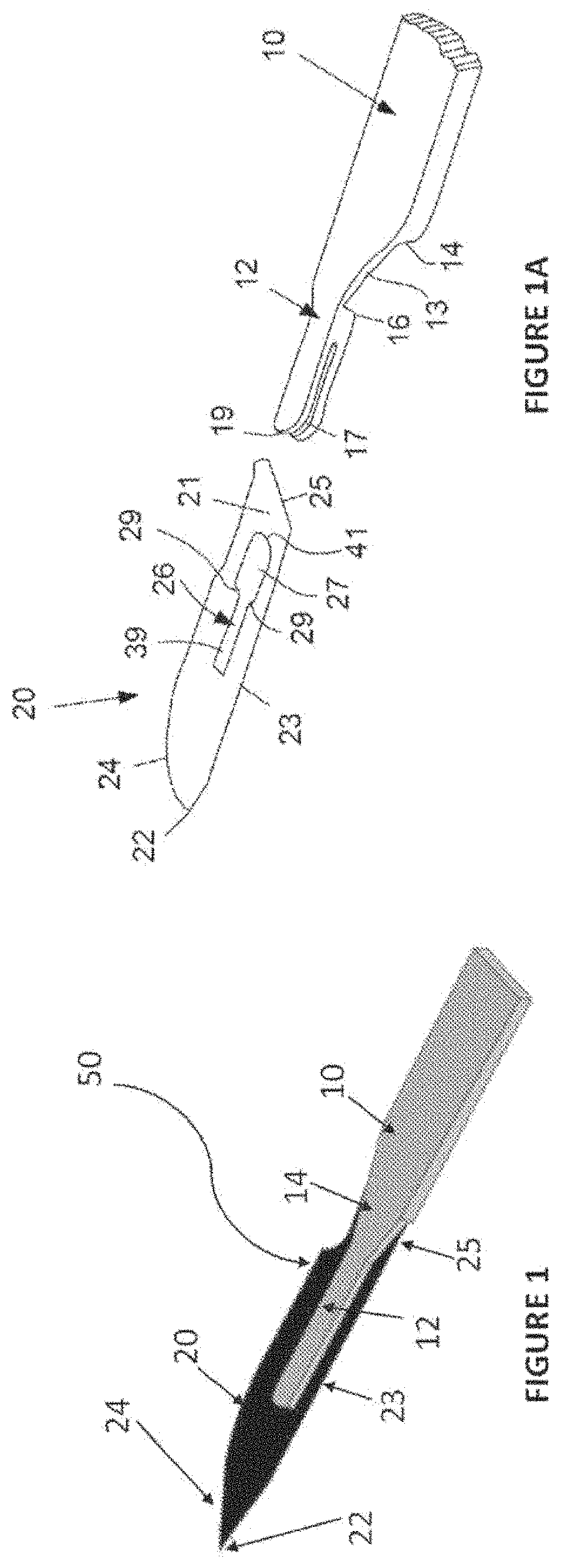

Apparatus for detaching surgical blades

An apparatus for detaching a blade from a scalpel handle is provided. The blade has a cutting portion and a heel portion and is removably mounted on a tang of the scalpel handle. The apparatus has a flexible blade detachment member with a stepped portion for engaging the heel of the blade as the handle is withdrawn and a leading angled portion. A backing member is provided with the detachment member being arranged adjacent the backing member so that during use the detachment member flexes in only one direction, away from the mounting tang in response to force applied by the handle to the leading angled portion thereby causing the blade and the handle to be separated and detached relative to each other. Upon withdrawing the tang from the opening, the stepped portion engages the heel of the blade resulting in detachment of the blade from the tang.

Owner:AUNEX PTY LTD

Modular bamboo door frame and assembling method

PendingCN112267787AReduce configurationReduce investmentFrame fasteningWindow/door framesStructural engineeringIndustrial engineering

The invention discloses a modular bamboo door frame and an assembling method, and relates to the technical field of bamboo door frames. The modular bamboo door frame comprises a standard door frame module, an adjustable inner support and an L-shaped plate, the standard door frame module is fixedly connected to the left side of the adjustable inner support, the L-shaped plate is connected to the right side and the outer side of the adjustable inner support, the adjustable inner support comprises a left inner support module and a right inner support module, a gap is formed between the right inner support module and the left inner support module, and the gap is adjustable. Through the implementation of the modular bamboo door frame and the assembling method, most of the workload which originally needs to be processed on expensive four-side planing equipment is transferred to common plate cutting and planing equipment to be processed into flat bamboo plates with different widths, so that the production efficiency is greatly improved, the process management difficulty is simplified, the investment requirements on equipment, cutters and tools are reduced, the production period is shortened, and the rework and repair rate is reduced.

Owner:SHANGHAI ALTPLUS ENVIRONMENTAL TECH CO LTD

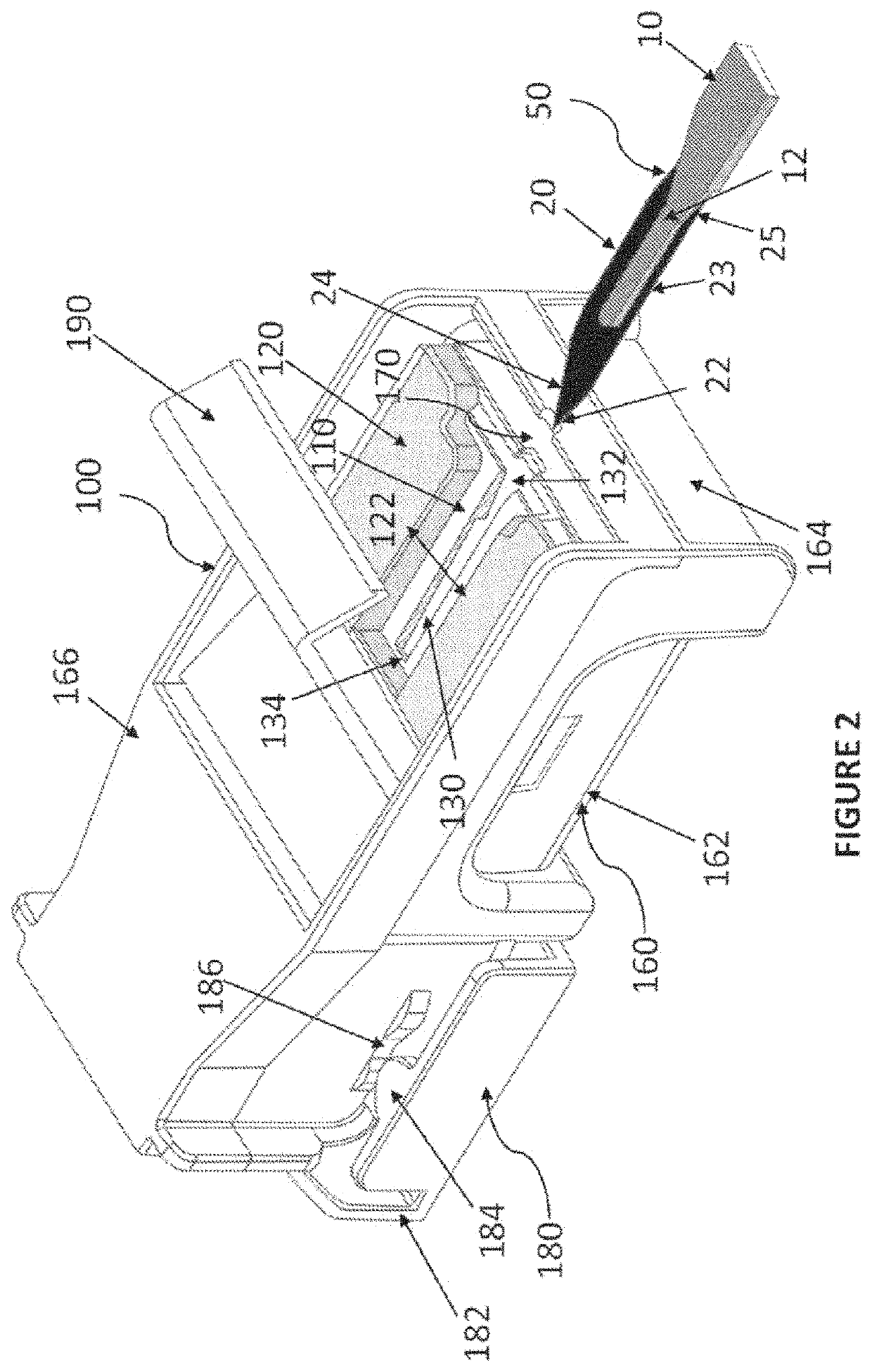

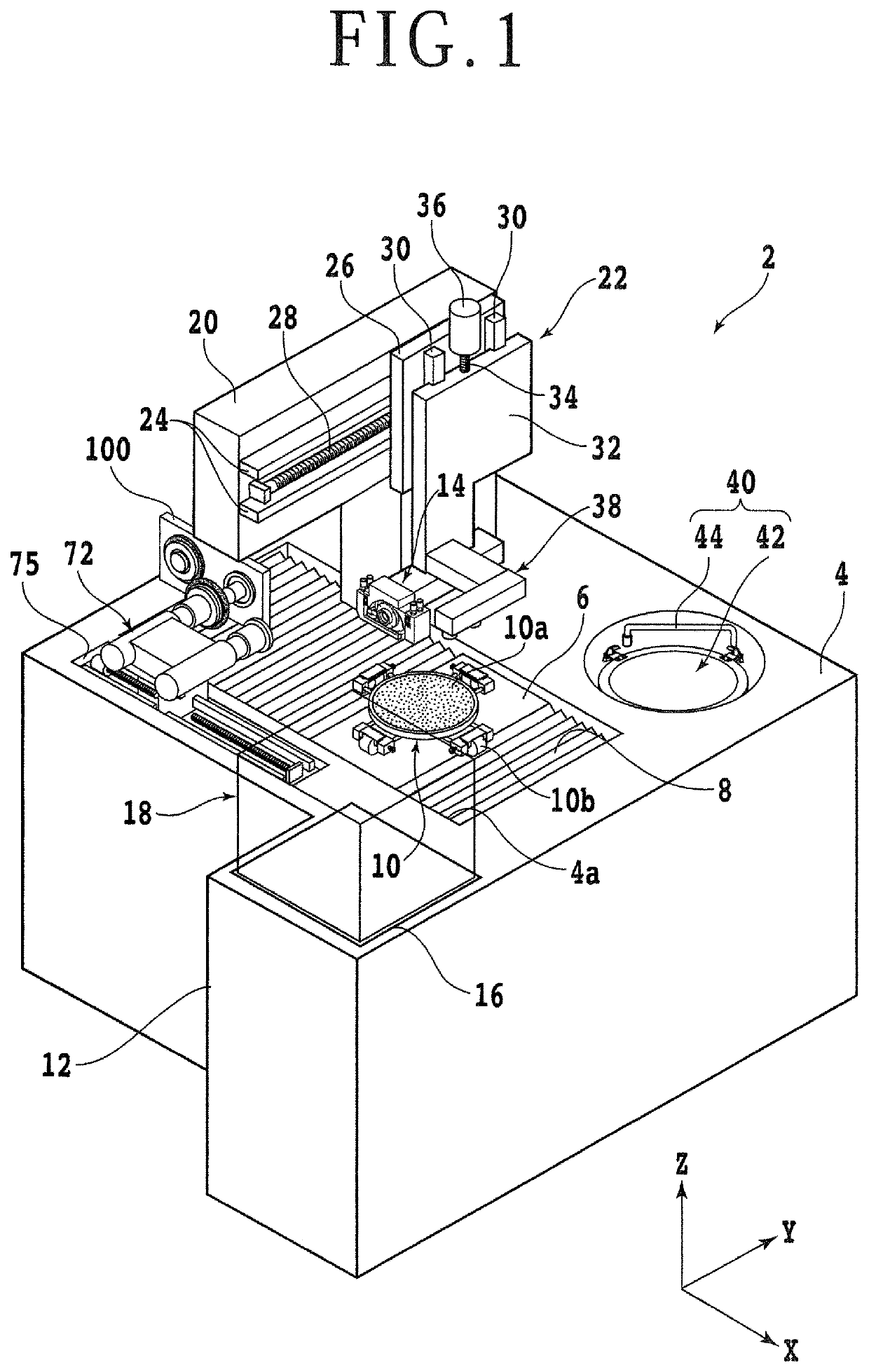

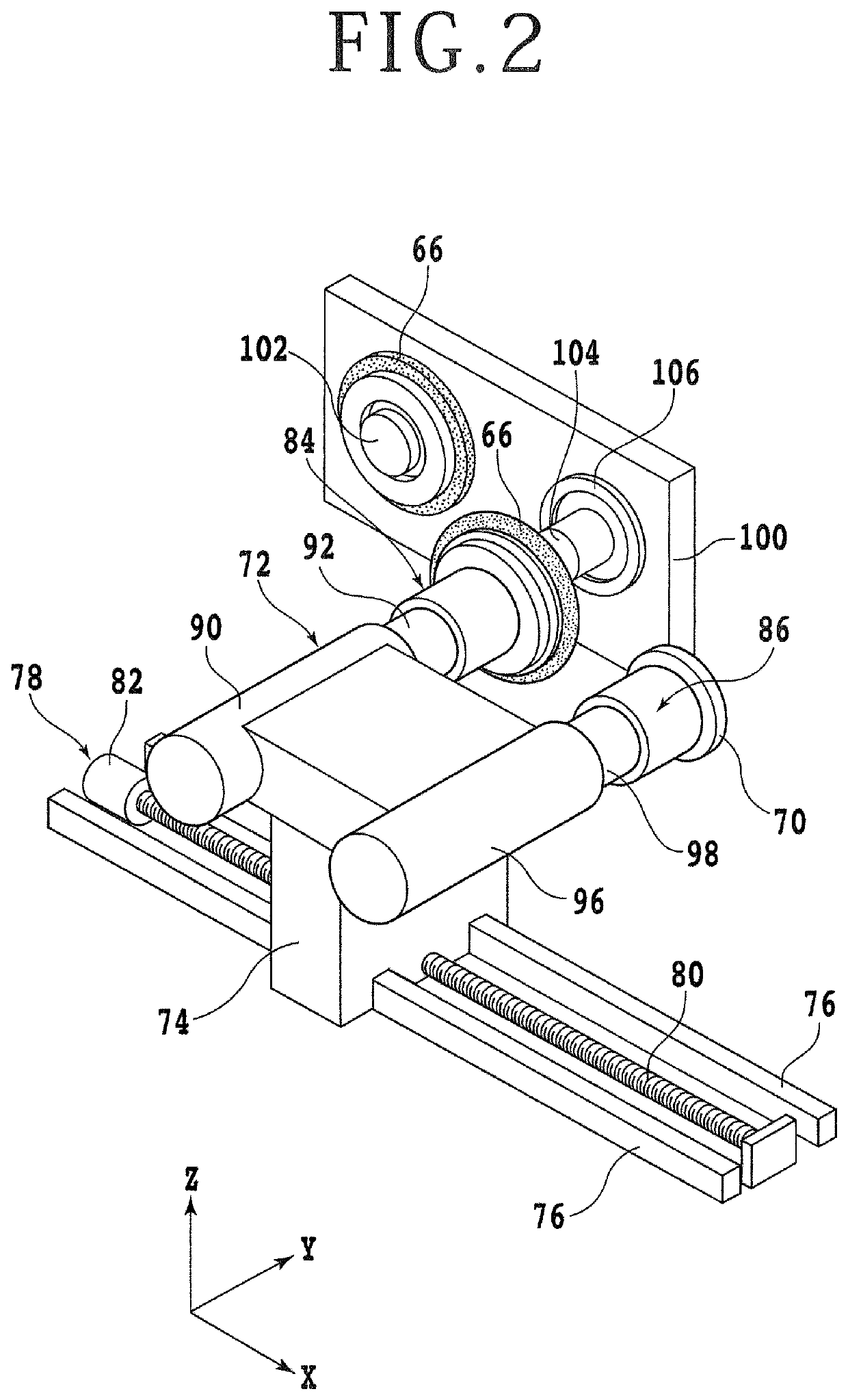

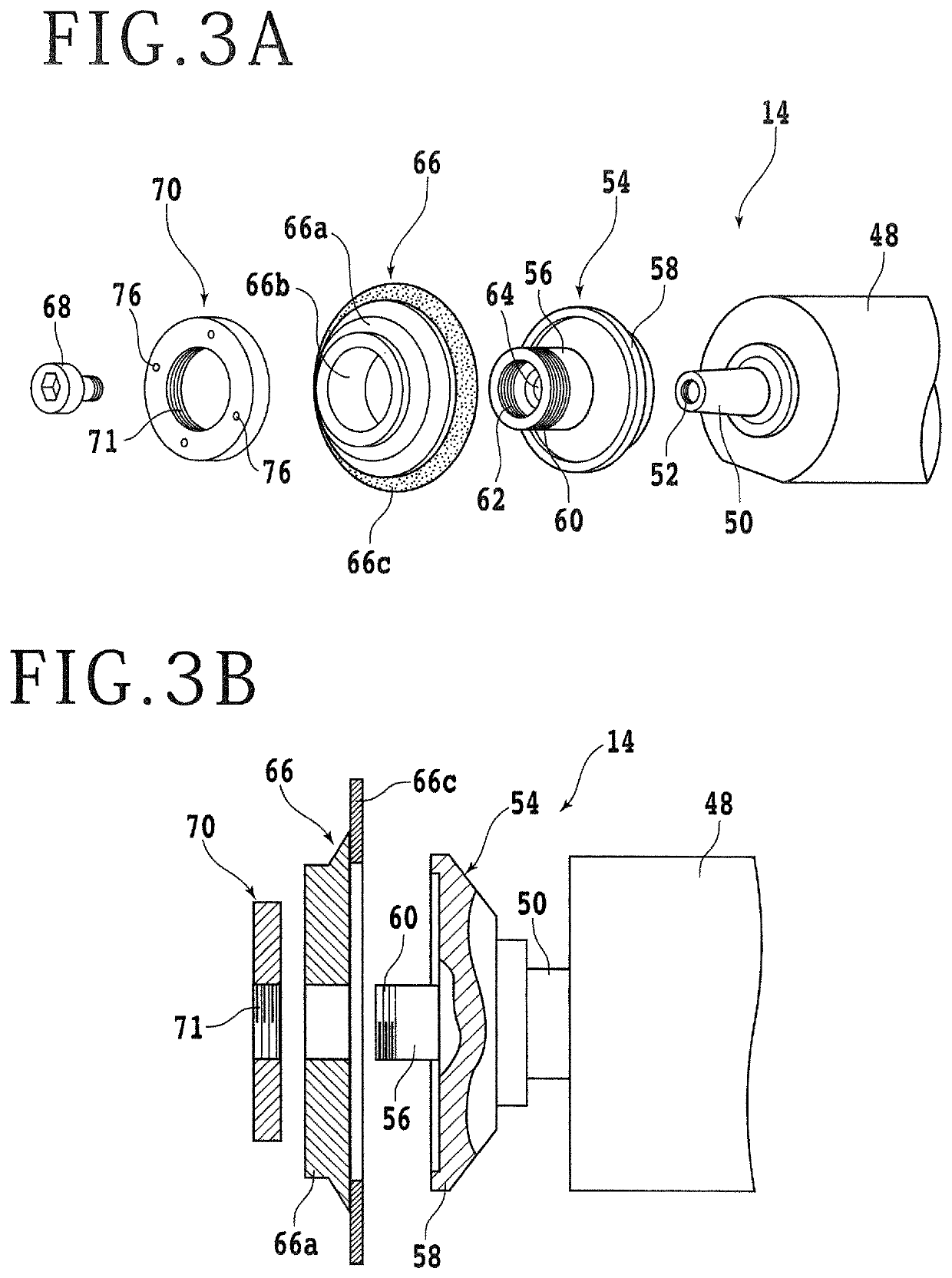

Cutting apparatus

ActiveUS11311976B2Mount and quickly and reliablyRemove quickly and reliablyMetal sawing devicesSemiconductor/solid-state device manufacturingClassical mechanicsStructural engineering

A cutting apparatus includes a blade changing apparatus. The blade changing apparatus includes a blade mounting and removal portion, which in turn includes: a holding portion that removably holds a circular base of a cutting blade; a moving support portion that supports the holding portion and moves the holding portion to a removal and mounting position at which an insertion hole in the blade faces a boss of a blade mount; and a coupling mechanism that couples the holding portion with the moving support portion such that the holding portion is freely tiltable with respect to the moving support portion. The coupling mechanism includes a plurality of elastic member pairs, each pair, while tensioning the holding portion in opposite directions, fixing the holding portion to the moving support portion. Forces acting from the elastic member pairs balance each other to thereby support the holding portion tiltably and aerially.

Owner:DISCO CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com