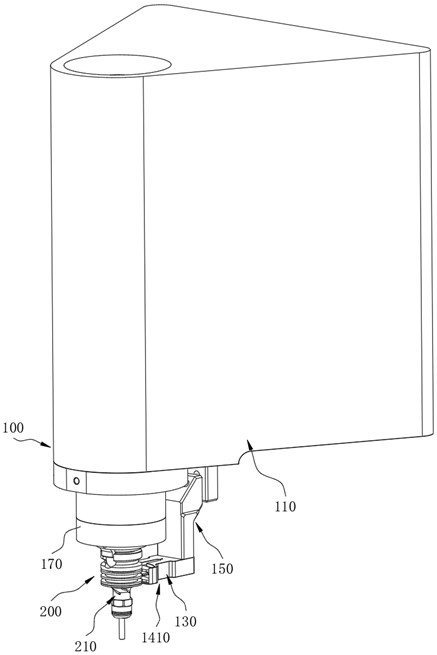

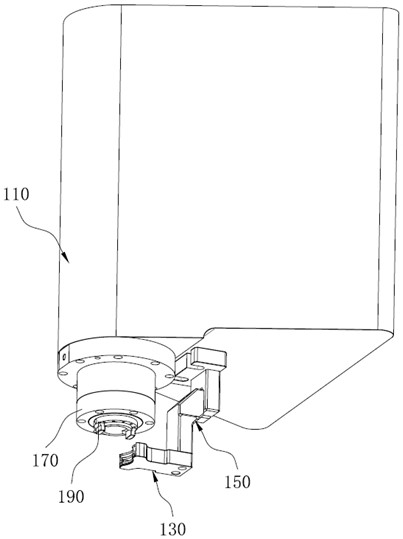

Ultrasonic spindle, ultrasonic tool holder and ultrasonic processing equipment

An ultrasonic and spindle technology, which is applied in metal processing equipment, turning equipment, metal processing machinery parts, etc., can solve the problems of inability to realize the versatility of the tool magazine of the equipment, the inability to change tools automatically, and the increase in cost, and achieve good wireless transmission stability and processing effect, convenient for automatic tool change, and realize the effect of wireless transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

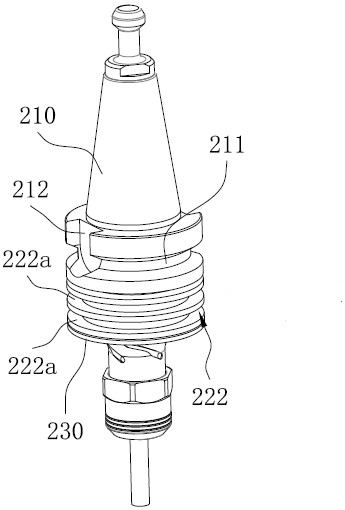

[0115] In the ultrasonic device in the present embodiment, the model of the ultrasonic tool handle 200 is BT30, and correspondingly, the specific structural parameters of the transmitting part 131 and the ultrasonic wireless transmitting unit 140 are:

[0116] α=1.868, V=7176.14, D 1 =46.5,D 2 =67,D 3 =0.35, N=144.

Embodiment 2

[0118] In the ultrasonic device in this embodiment, the model of the ultrasonic knife handle 200 is BT40, and correspondingly, the specific structural parameter values of the transmitting part 131 and the ultrasonic wireless transmitting unit 140 are:

[0119] α=1.888, V=13602.39, D 1 =65,D 2 =89,D 3 =0.45, N=120.

Embodiment 3

[0121] In the ultrasonic device in the present embodiment, the model of the ultrasonic knife handle 200 is BT50, and correspondingly, the specific structural parameter values of the transmitting part 131 and the ultrasonic wireless transmitting unit 140 are:

[0122] α=1.632, V=19223.93, D 1 =101,D 2 =125,D 3 =0.5, N=130.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com