Holding jig

A technology of jigs and baffles, applied in the direction of manufacturing tools, grinding workpiece supports, grinding machines, etc., can solve problems such as flying out and loosening, and achieve the effect of convenient use and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

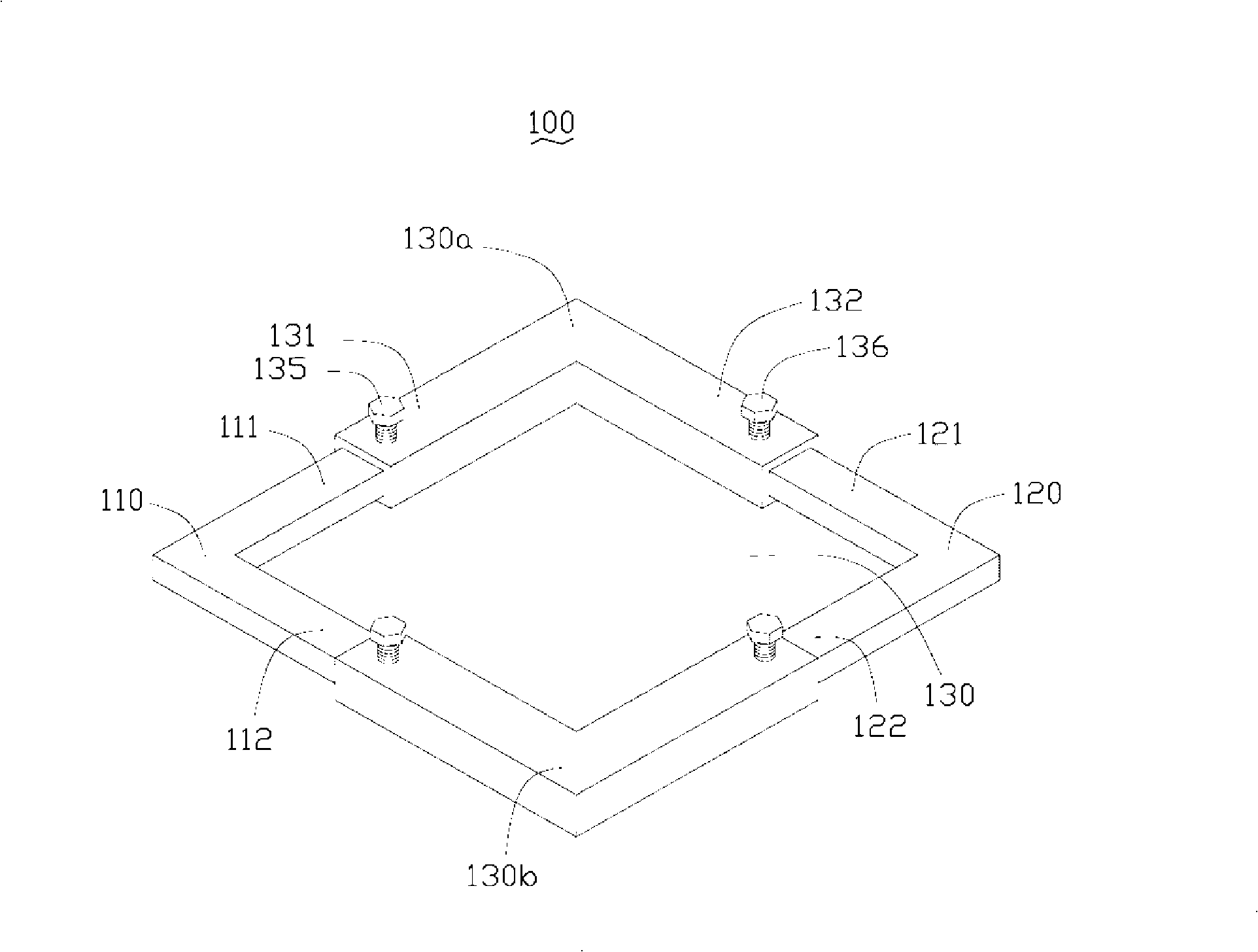

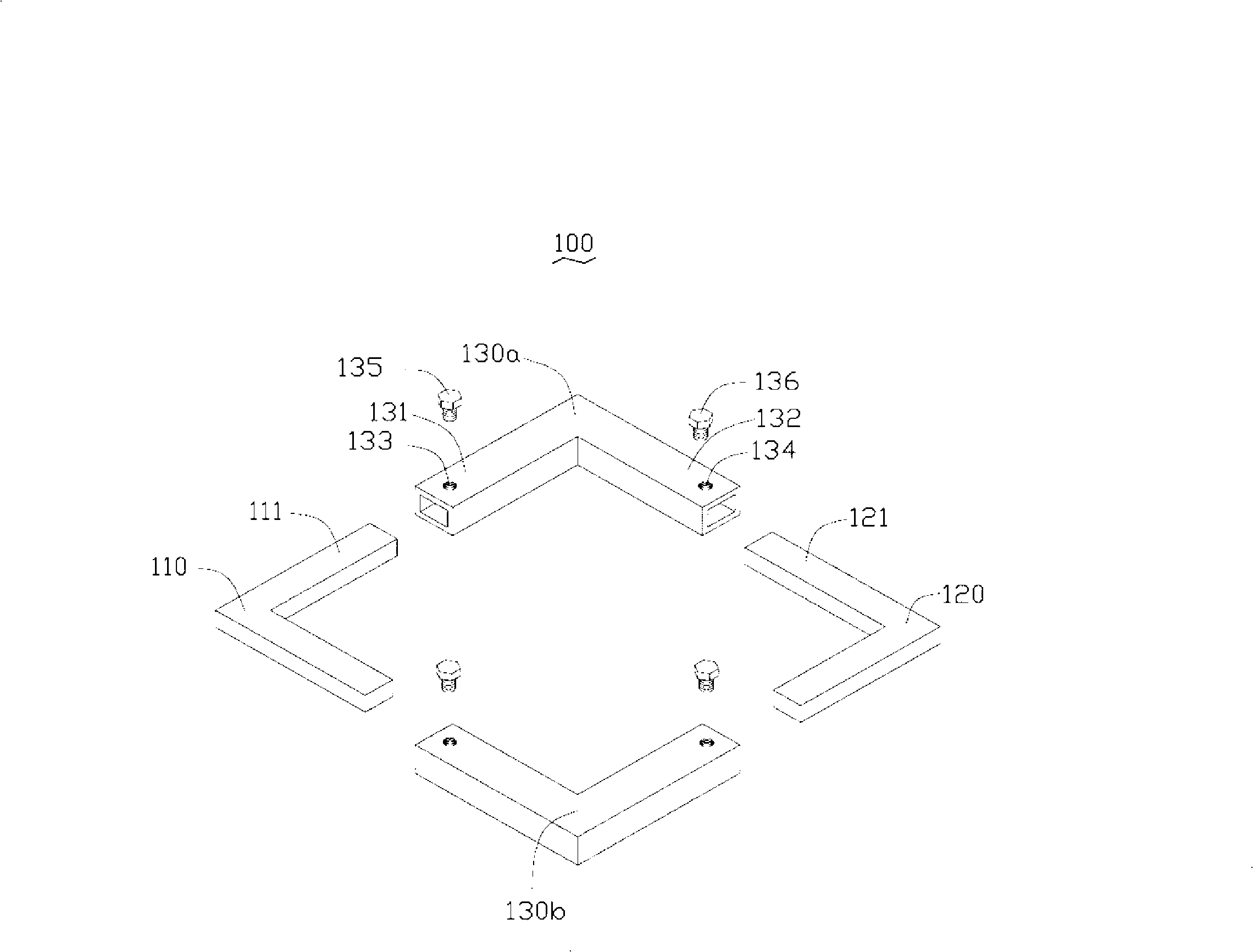

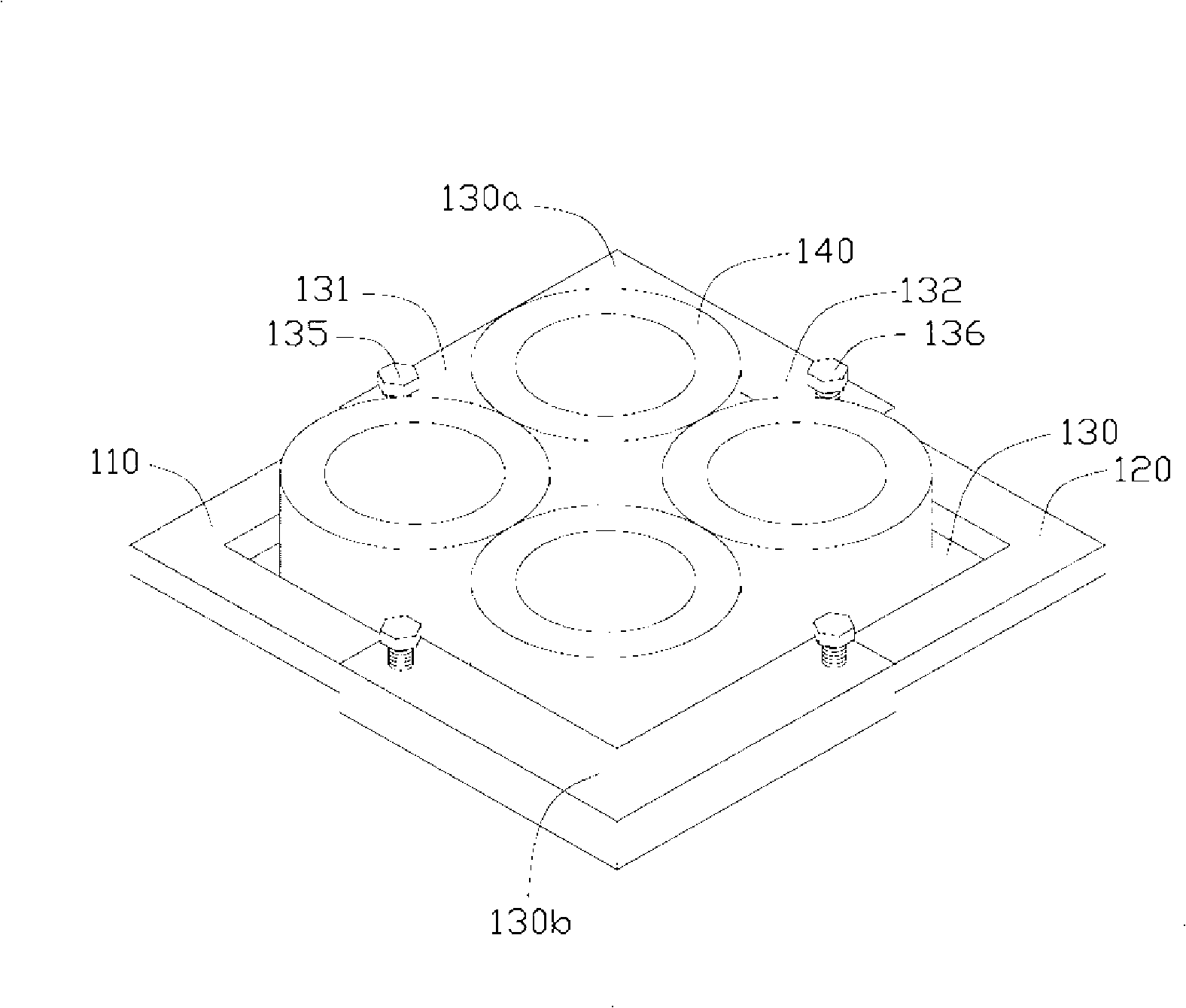

[0018] see figure 1 and figure 2 , is the holding jig 100 provided in the first embodiment of the present invention, which includes a first baffle 110 and a second baffle 120 . The holding fixture 100 also includes two hollow connectors 130a and 130b sleeved between the first baffle 110 and the second baffle 120, and the hollow connectors 130a and 130b are used to connect the The first baffle 110 and the second baffle 120 are described above. The first baffle plate 110, the second baffle plate 120 and the two hollow connectors 130a and 130b are connected to each other to form a continuous ring structure, and the ring structure encloses an accommodating space 130 for accommodating at least one object 140 And fix it in the accommodating space 130 .

[0019] The first baffle 110 and the second baffle 120 have the same shape. In this embo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com