Scissors

A scissors and blade technology, applied in the field of new scissors, can solve problems such as inconvenient use of handles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

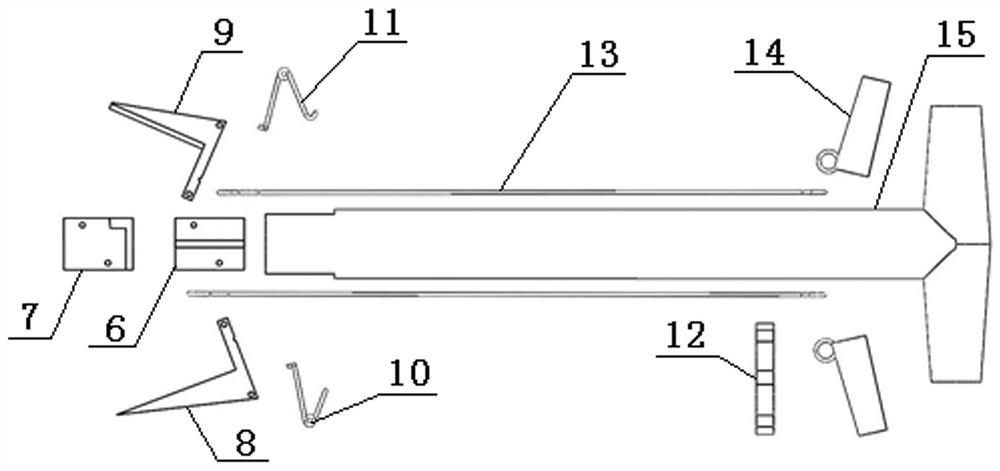

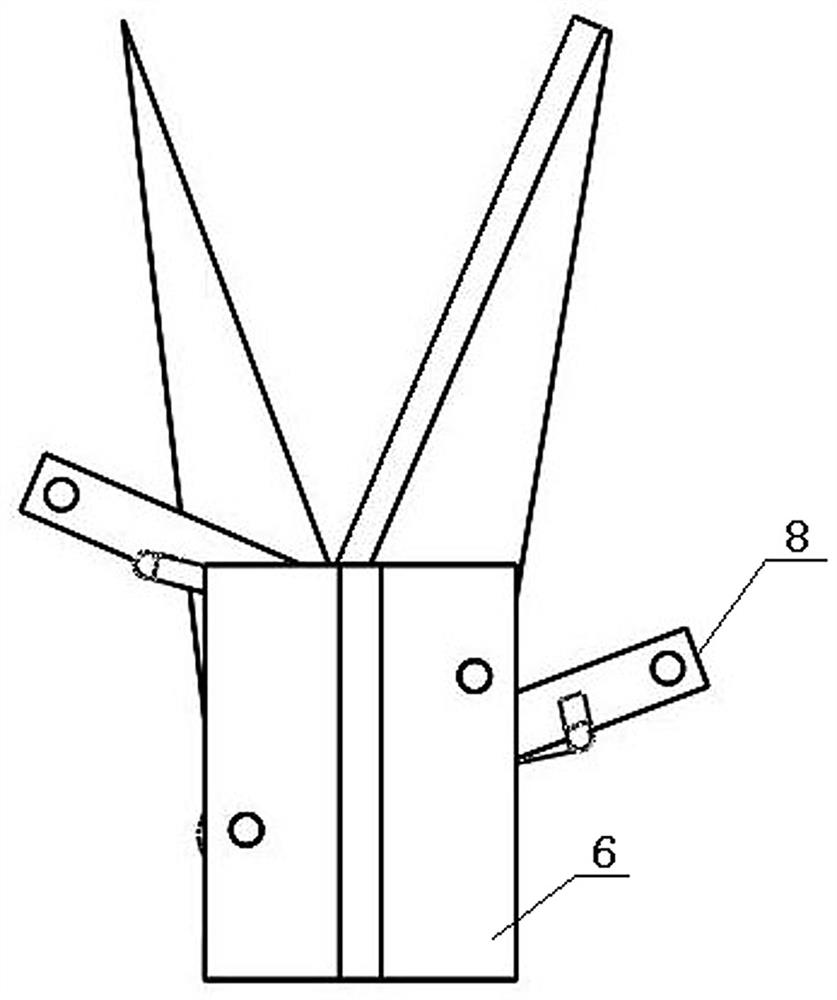

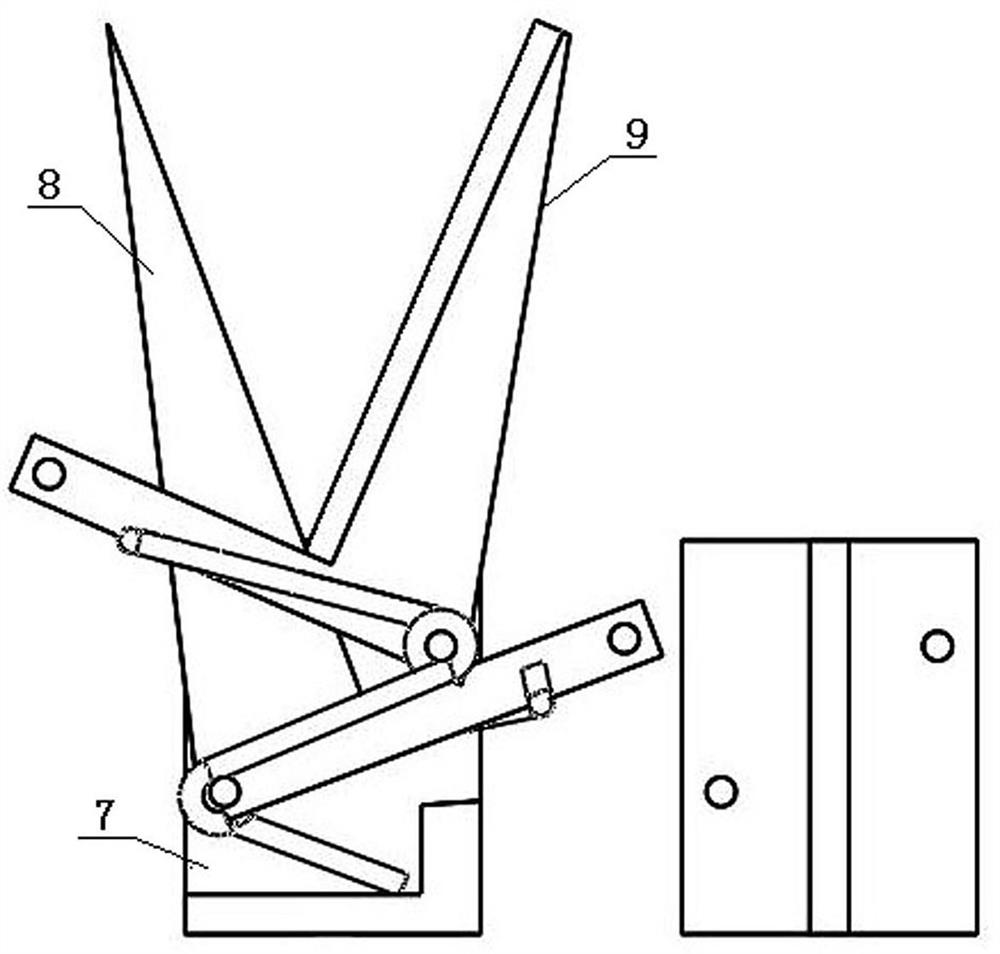

[0033] The left end of handle 15 has groove to cooperate with cutter head, and the right end has the vertical inline handle with handle, and cutter head comprises pointed blade 8, flat blade 9 and the 1st, 2 blade seats 6,7, and flat blade, pointed blade are The L-shape formed by the blade shank and the blade, the blade mounting surfaces of the 1st and 2nd blade holders face each other, the 1st shaft is located on the lower left of the 2nd blade holder 7, the 2nd shaft is located on the upper right of the 2nd blade holder, and the 1st shaft Go through the hole on the L-shaped corner of the 1st torsion spring 10, pointed blade 8 successively and be connected with the 1st hole on the 1st blade seat 6, the 2nd shaft passes successively the hole on the L-shaped corner of flat-headed blade 9, The 2nd torsion spring 11, is connected with the 2nd hole on the 1st blade seat, and the outer end of the 1st, 2nd blade holder has hole to be connected with one end of the 1st, 2 connecting ax...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com