Corrugated tube and installation method

A technology of bellows and locking protrusions, applied in the direction of hose connection devices, hoses, pipes, etc., can solve problems such as gripping of installation components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

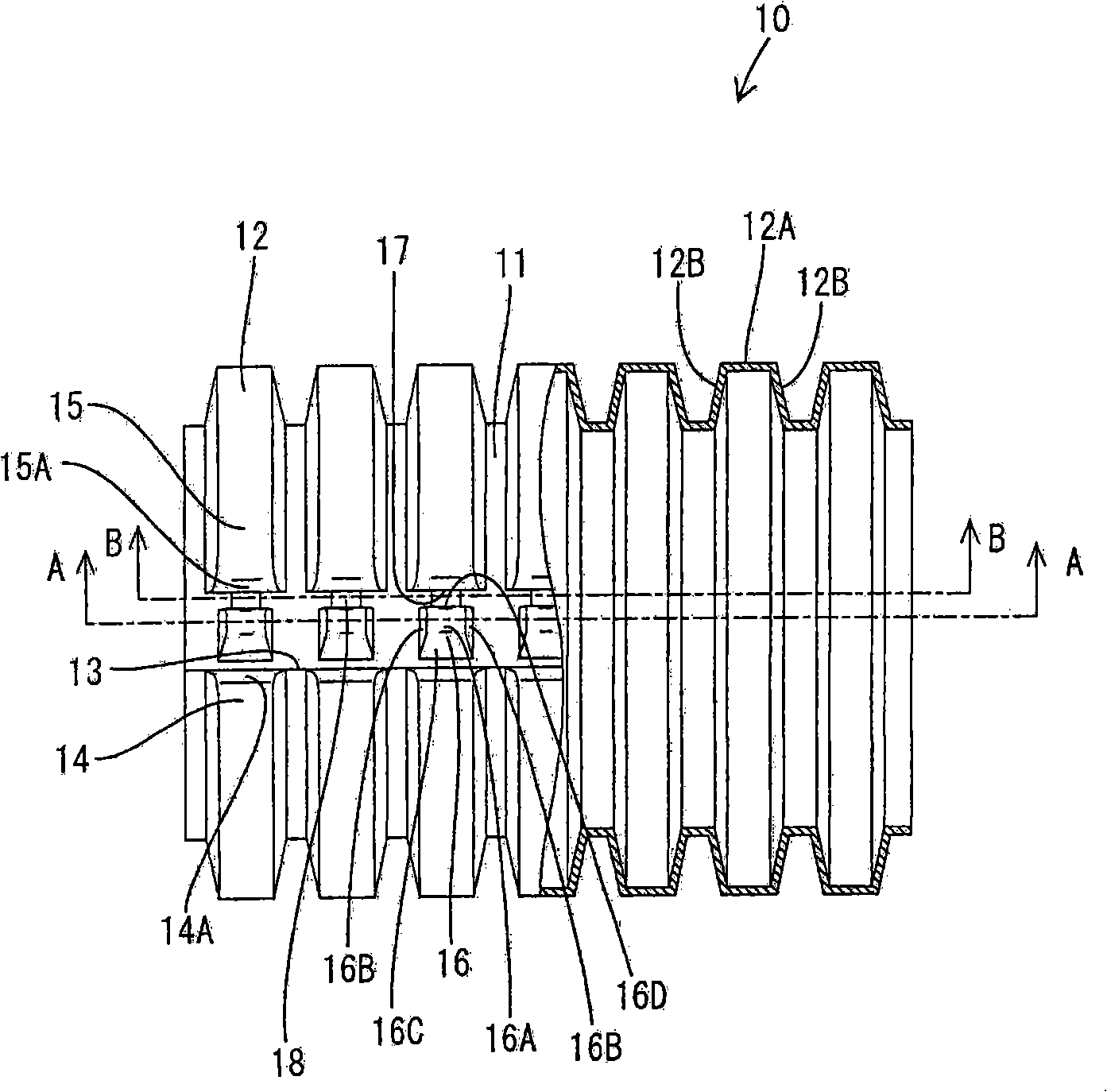

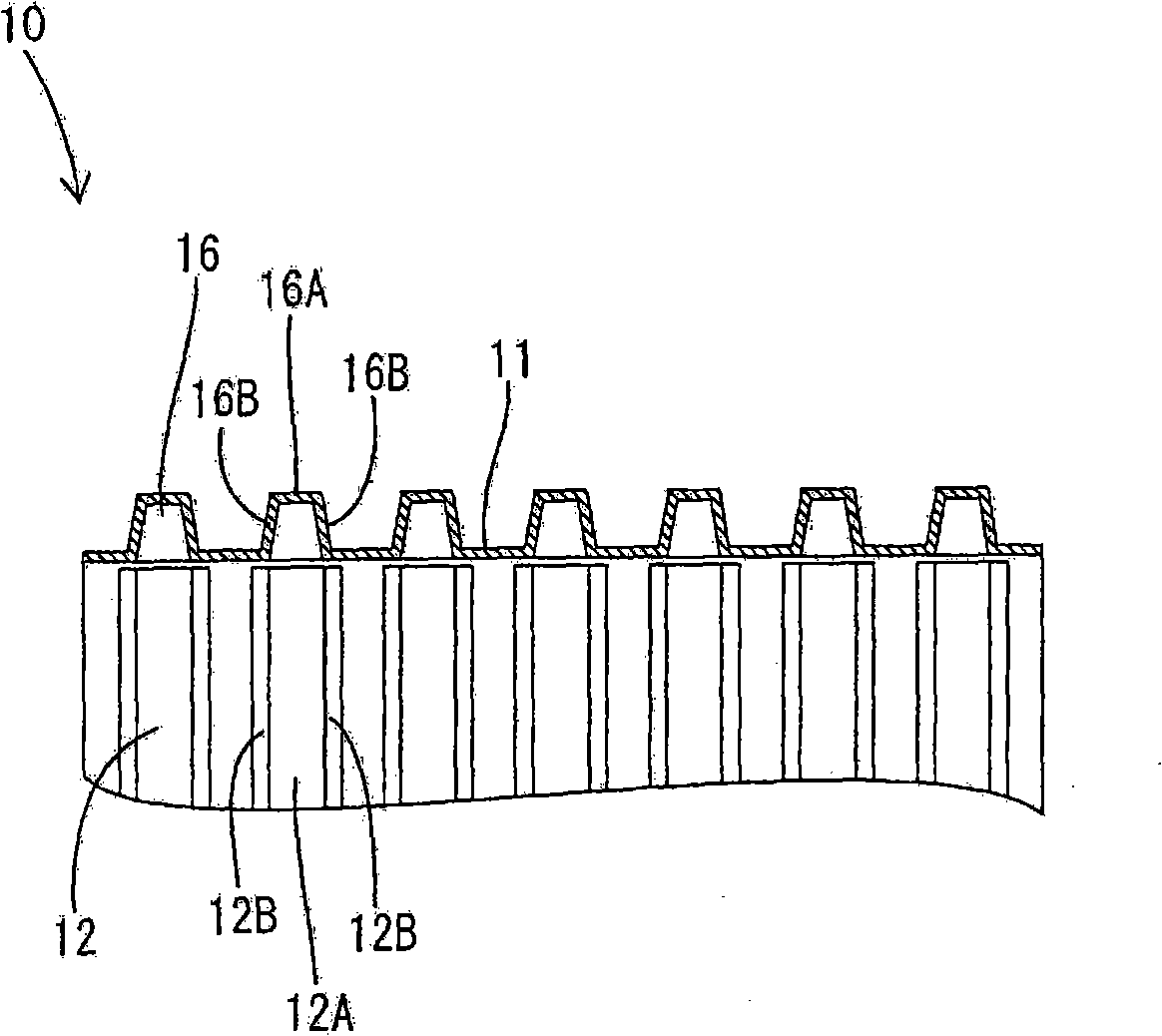

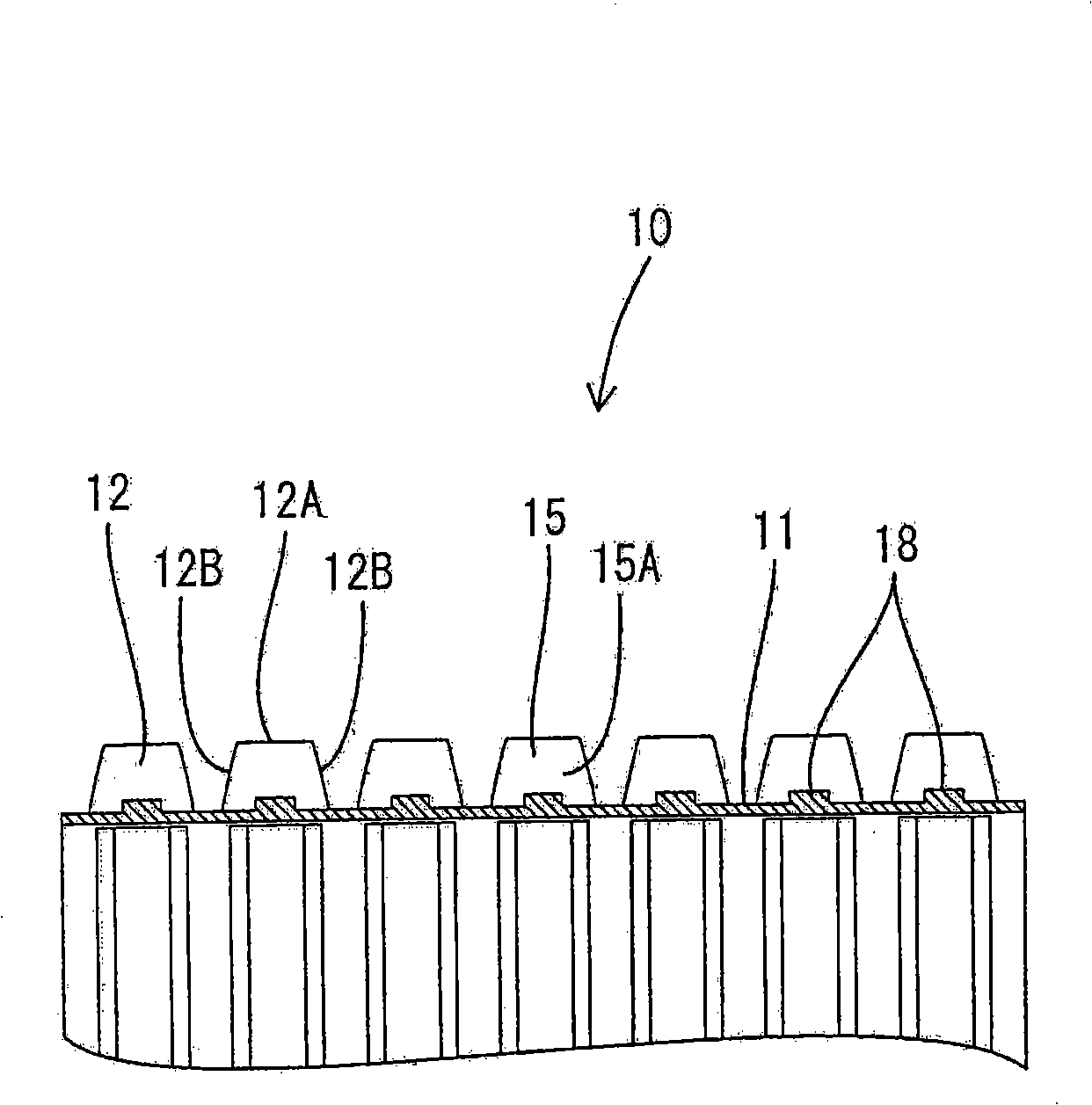

[0056] In the following, refer to the attached Figures 1 to 6 A preferred embodiment of the present invention is described.

[0057] The corrugated tube 10 in this embodiment is to be mounted to a specific (preset or pre-determinable) location of an unspecified wire group or to the wire group to protect the wire group by at least partially surrounding it. The bellows 10 is made of, for example, synthetic resin, and has a bellow or corrugated shape in which several substantially annular protrusions 12 emerge from (preferably substantially cylindrical) at specific (preset or predeterminable) intervals Shaped) the inner wall 11 protrudes and has such flexibility that it is preferably able to flexibly advance along the laying path of the wire group. The bellows 10 is formed with (preferably substantially straight) slits 13 over its entire length in its longitudinal direction.

[0058] The annular protrusion 12 extends circumferentially from a position in contact with the slit 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com