Piezoelectric ceramics sensor and preparation method thereof

A technology of piezoelectric ceramics and manufacturing methods, applied in the manufacture/assembly of piezoelectric/electrostrictive devices, piezoelectric/electrostrictive/magnetostrictive devices, circuits, etc., which can solve problems such as difficult realization and troublesome operation , to achieve the effect of strong practicability and unique design of electrical connection structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

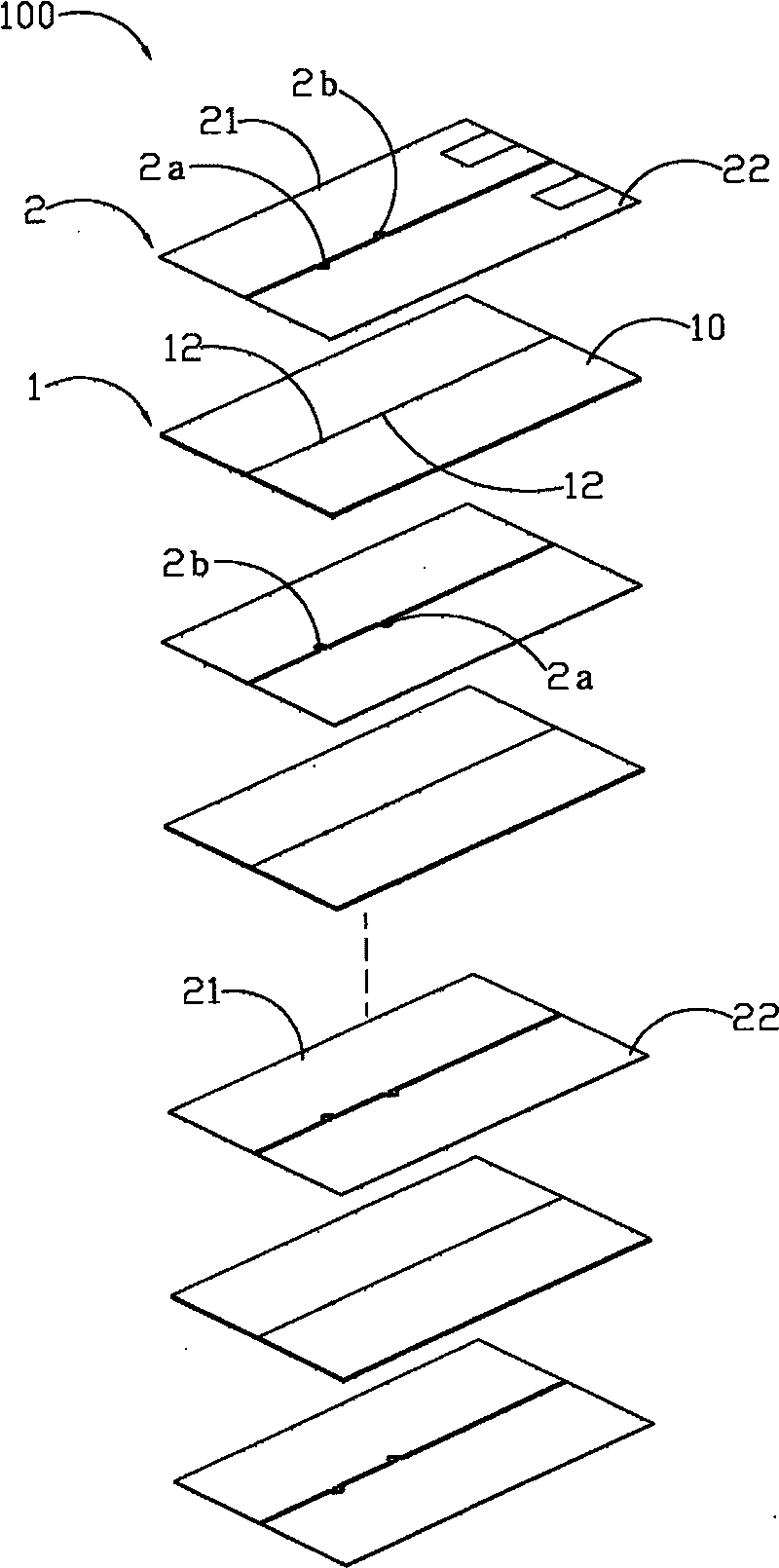

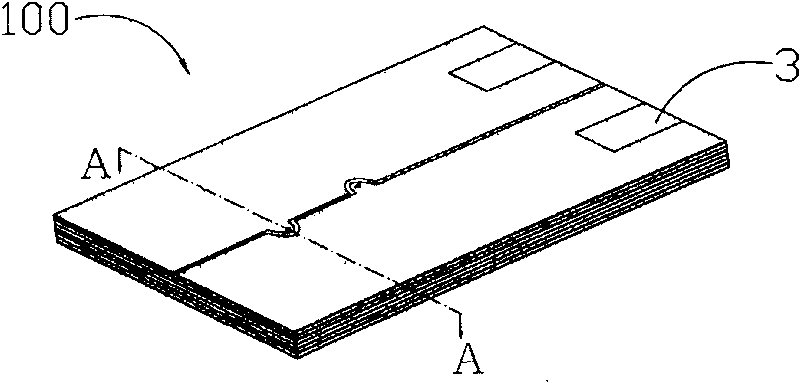

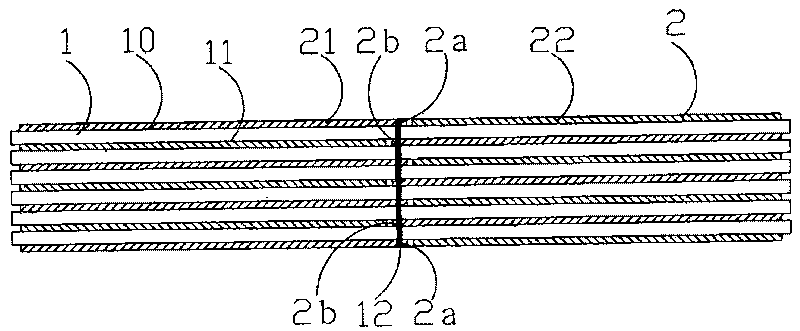

[0022] Such as figure 1 and figure 2 As shown, the piezoelectric ceramic sensor 100 according to the embodiment of the present invention includes 6 layers of rectangular ceramic sheets 1 and 7 layers of electrodes 2 stacked alternately.

[0023] Each ceramic sheet 1 has the same shape and size, including a front surface 10 and a reverse surface 11 opposite to the front surface. Each layer of ceramic sheets is divided into two parts with opposite polarization directions by its center line. Two through holes 12 are arranged on the top, and the two through holes of each ceramic sheet are respectively aligned.

[0024] Each layer of electrodes 2 includes a left electrode 21 and a right electrode 22, and the left electrode 21 and the right electrode 22 are separated in half relative to the surface of the ceramic sheet 1, that is, separated from the cente...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com