Novel piezoelectric sensor and preparation thereof

A production method and technology of piezoelectric ceramics, applied in the direction of sensors, sensor types, piezoelectric/electrostrictive transducers, etc., can solve problems such as difficult to realize and troublesome operation, and achieve large connection area, strong practicability, and electric Reliable Effects of Sexual Connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

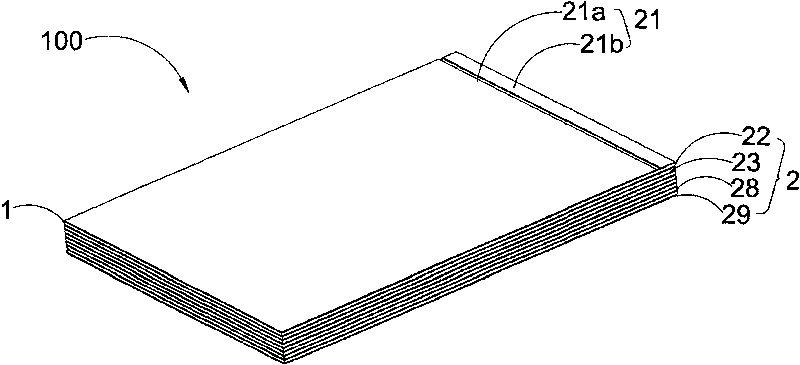

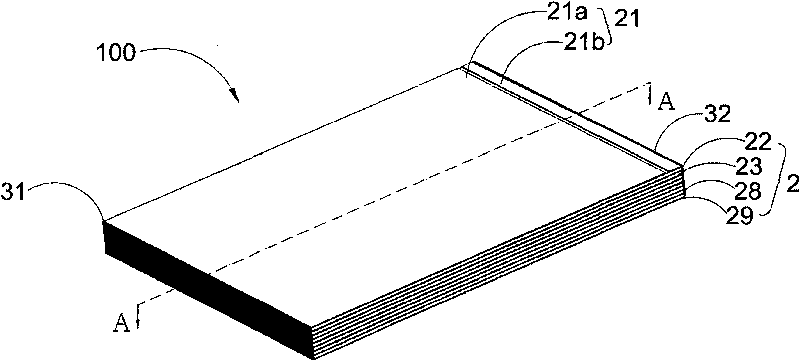

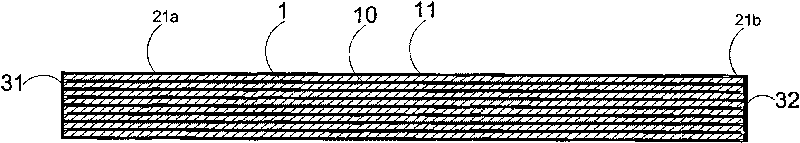

[0024] The nine-layer electrode 2 includes a first-layer external electrode 21 , a second-layer electrode 22 , a third-layer electrode 23 . . . an eighth-layer electrode 28 , and a ninth-layer electrode 29 . The length of the electrodes of each layer is less than that of the ceramic sheet, wherein the adjacent electrodes are respectively aligned with the left end and the right end of the ceramic sheet. That is, as an embodiment of the present invention: the second layer electrode, the fourth layer electrode, the sixth layer electrode, and the eighth layer electrode are aligned with the left end of the ceramic sheet, and the third layer electrode, the fifth layer electrode, the seventh layer electrode, The ninth electrode is aligned with the right end of the ceramic sheet. Because the length of each electrode is less than the length of the ceramic sheet, so the second layer electrode, the fourth layer electrode, the sixth layer electrode, and the eighth layer electrode only exp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com