Electricity driving operation/exit apparatus for protection pressing board

A technology to protect the pressure plate and electric power, applied in substation/switch layout details, electrical components, etc., can solve the problems that the power system cannot be safely used, cannot provide mechanical disconnection points, manpower and material resources consumption, etc., to save manpower and operate. Convenience, reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with accompanying drawing:

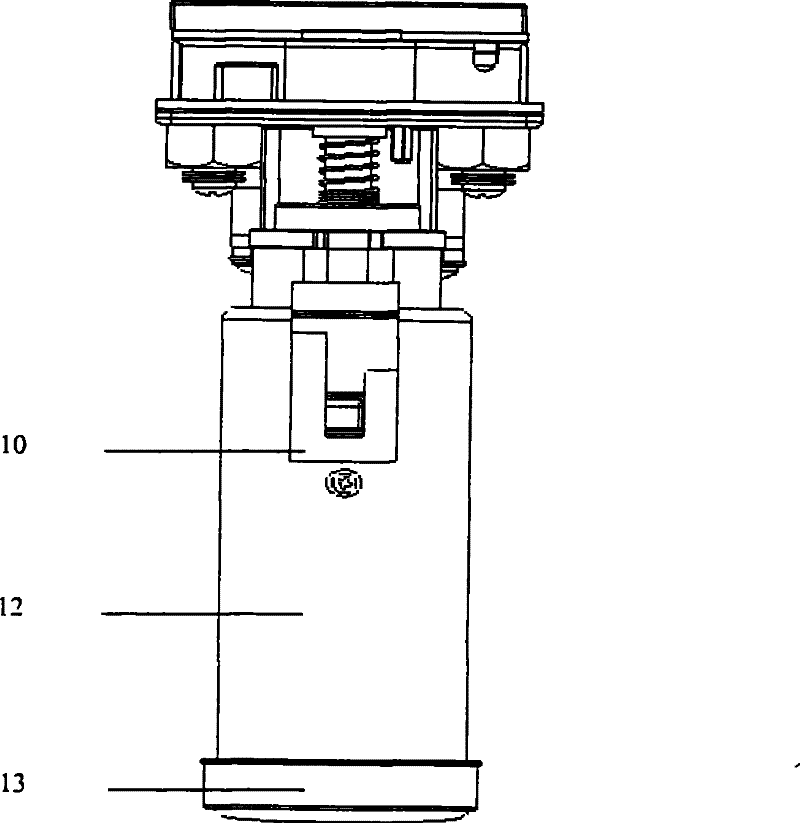

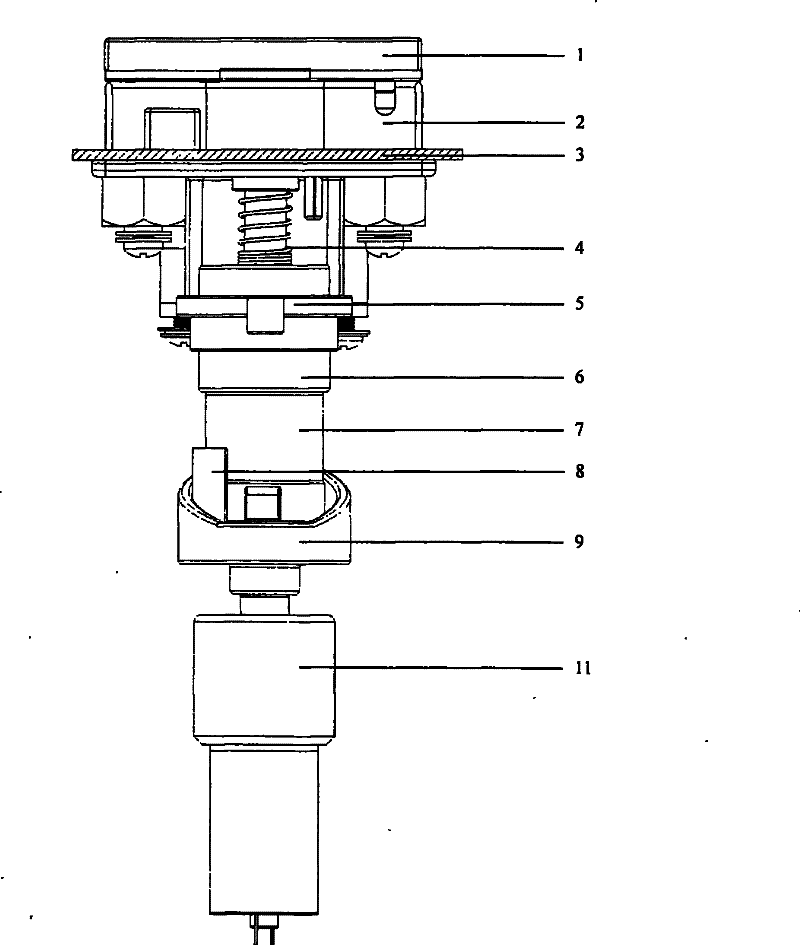

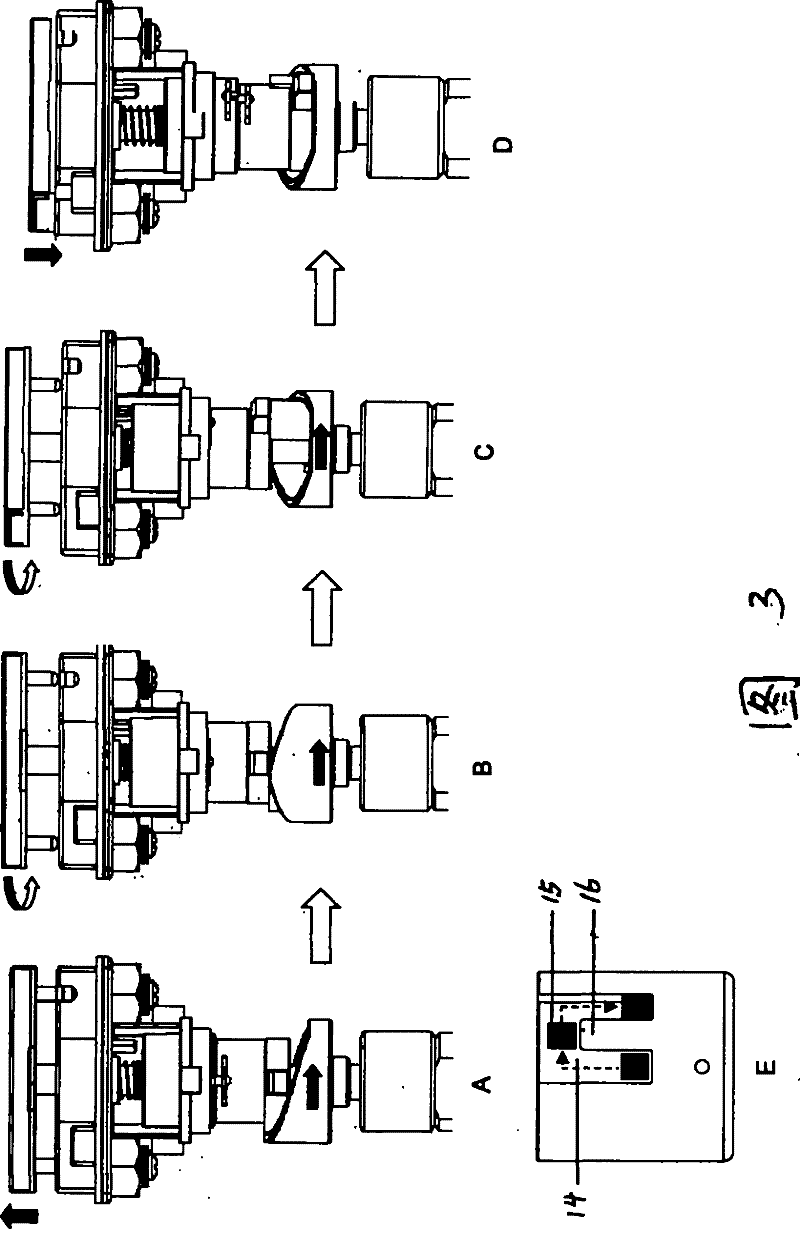

[0012] Such as figure 1 and figure 2 As shown, the installation screen 3 is to install the protective screen screen of the present invention, and a plurality of throwing and withdrawing devices can be installed on it. The plate connecting piece 1 of the device is plugged on the plate base 2 and electrically connected with the plate base 2. The fixing column of the plate base 2 passes through the round holes on both sides of the installation screen 3, and the top of the detection bracket 5 is fixed by a nut. both sides of the face. The fixing rod of the pressure plate connecting piece 1 passes through the pressure plate seat 2, the middle hole of the installation screen 3, the inner circle cavity of the position detection bracket 5 and the magnetic steel column 6 in order downwards, and the magnetic steel column 6 is connected with the magnetic steel column 6 below it. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com