Method for producing a tampon wrapped in a protective cover

A protective sleeve and plug technology, which can be used in tampons, medical science, absorbent pads, etc., can solve problems such as equipment consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

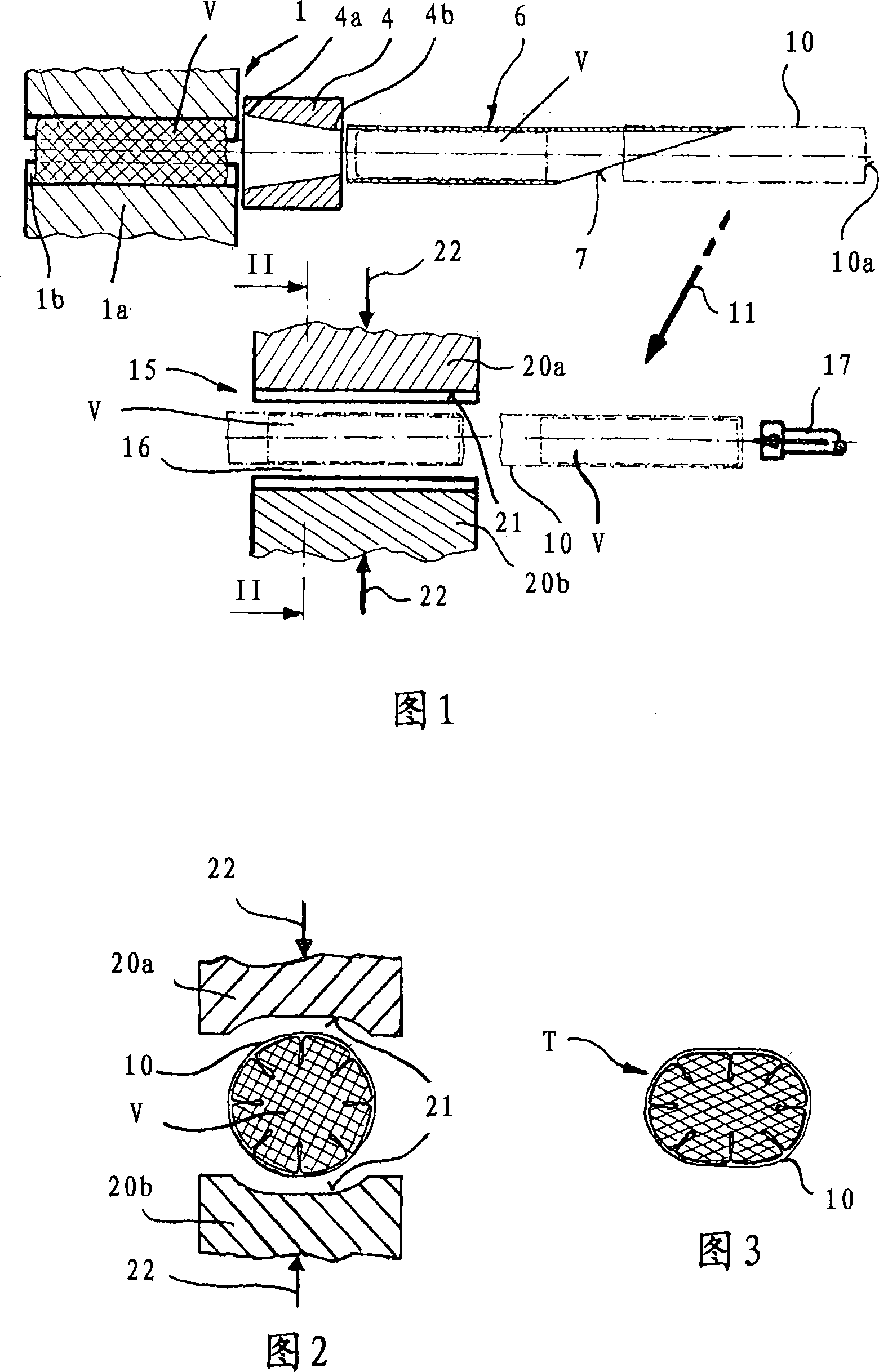

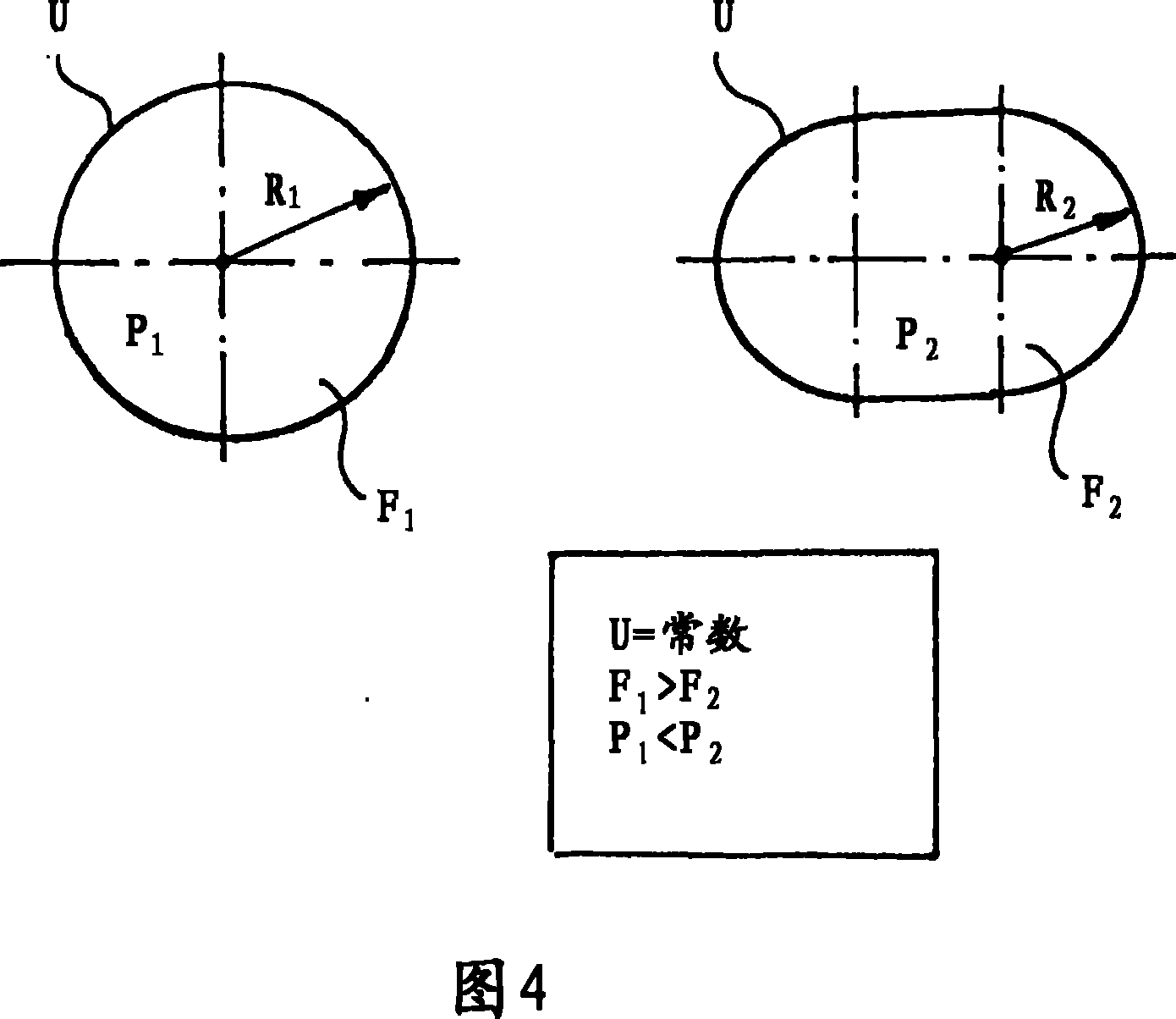

[0015] pass figure 1 The device described in simplified form can carry out the method according to the invention. A pressing tool is referenced 1 and in this exemplary embodiment consists of eight radially movable pressing jaws 1a. The pressing jaws 1a are provided with pressing surfaces and additionally each have a pressing blade 1b that projects further in the radial direction. If the pressing jaws 1a of the pressing tool are closed after introducing a blank V of any cross-sectional shape made of absorbent fibers, the resulting preform V has a relatively compressed core and consists of axially extending ribs. The formed edge regions and the longitudinal grooves extending between the ribs improve the absorbency of the subsequent finished stopper.

[0016] The preform V is axially ejected from the pressing tool 1 by means of an ejection rod (not shown in the drawing). Arranged behind the pressing tool 1 in the ejection direction is a forming tool 4 with a conical inner cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com