Gold thread break detection apparatus of full-automatic lead bonding machine

A technology for wire bonding and wire breakage detection, which can be used in measuring devices, measuring electricity, measuring electrical variables, etc., and can solve problems such as poor bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

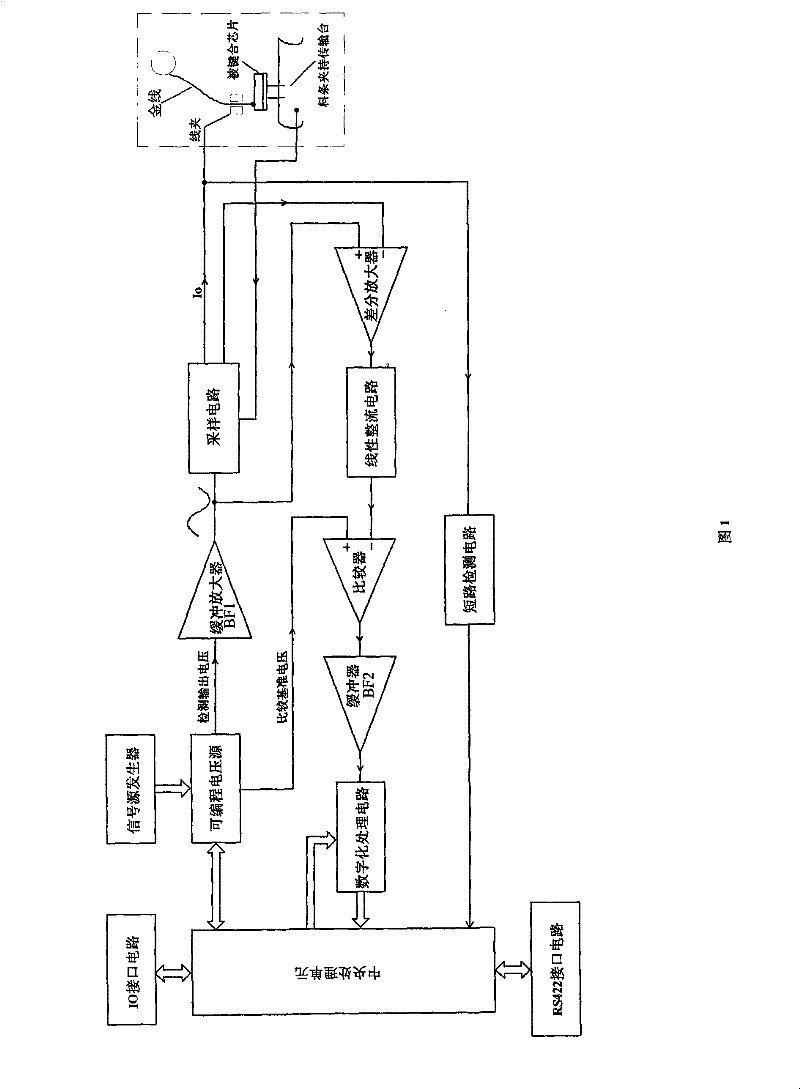

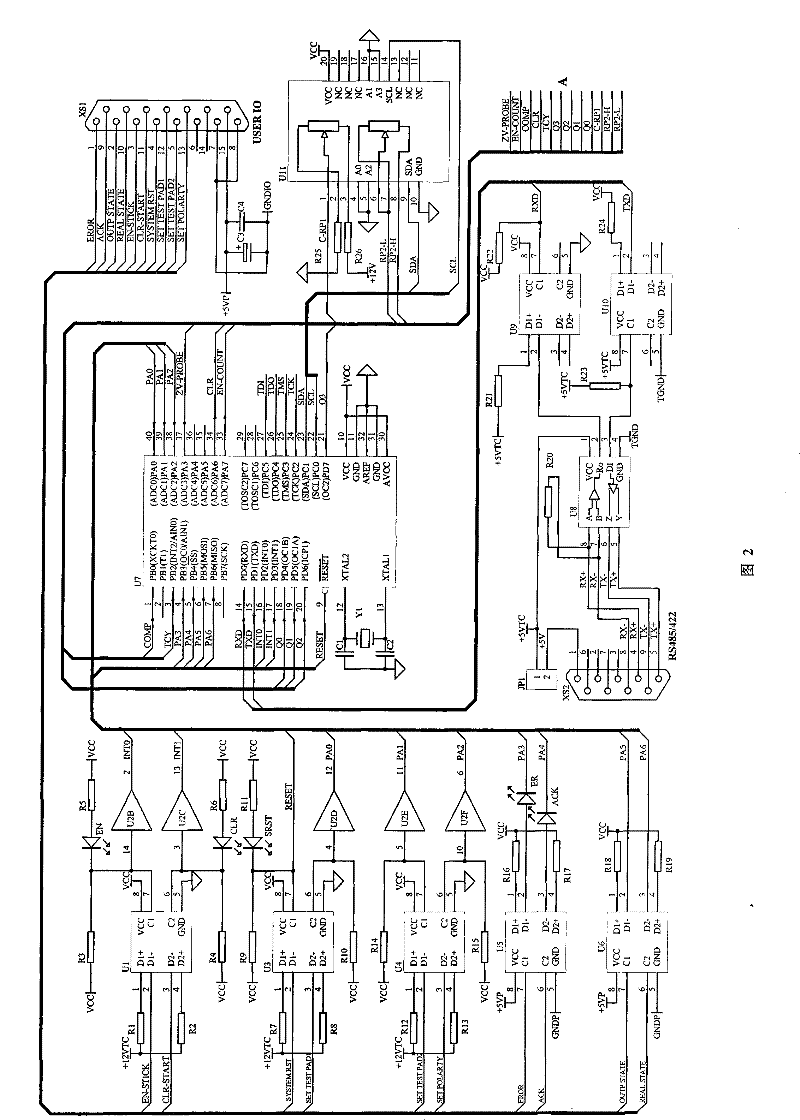

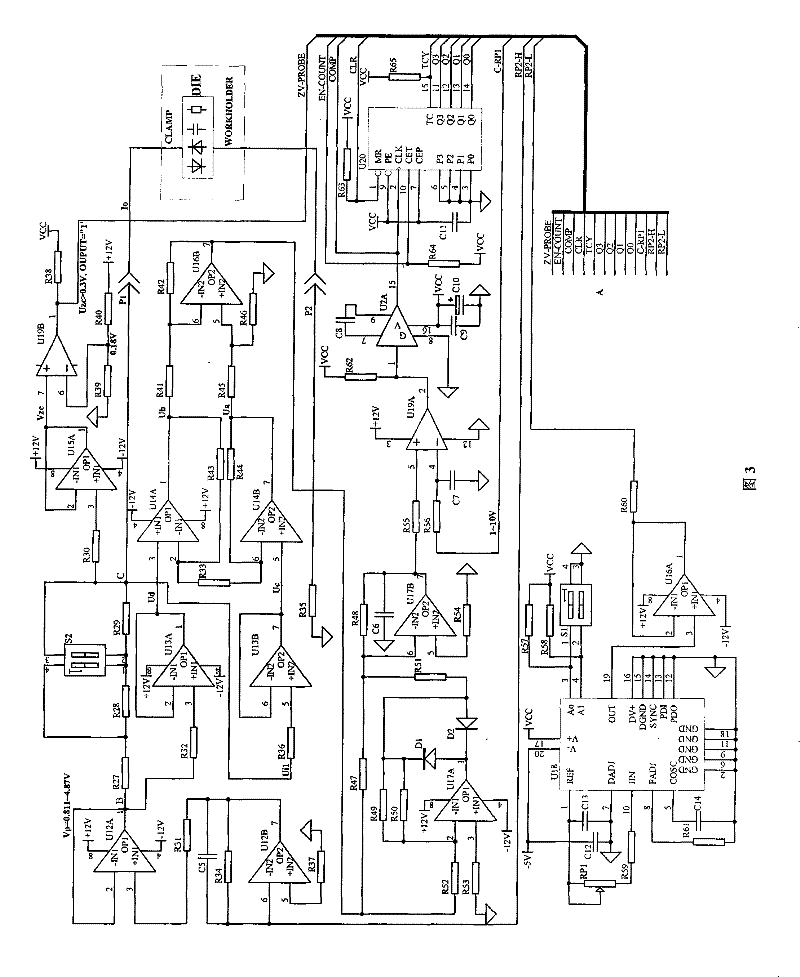

[0017] Depend on Figure 1-3 It can be known from the shown embodiment that this embodiment consists of a central processing unit, an IO interface circuit, an RS422 interface circuit, a signal source generator, a programmable voltage source, a buffer amplifier BF1, a sampling circuit, a differential amplifier, a linear rectification circuit, a comparator, Buffer BF2, a digital processing circuit, and a short circuit detection circuit; the central processing unit is bidirectionally connected to the IO interface circuit and the RS422 interface circuit, and the output terminal of the signal source generator is connected to the input terminal of the programmable voltage source, which can be programmed The voltage source is bidirectionally connected to the central processing unit. The first output of the programmable voltage source, that is, the AC signal voltage, is connected to the input end of the buffer amplifier BF1. One output of the buffer amplifier BF1 is connected to an inp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com