Automatic baking device of general aluminum casting machine mould

A technology of baking device and casting machine, applied in foundry, foundry equipment, pig iron foundry and other directions, can solve the problems of easy explosion, failure to overcome, unable to meet the production process, etc., and achieve the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

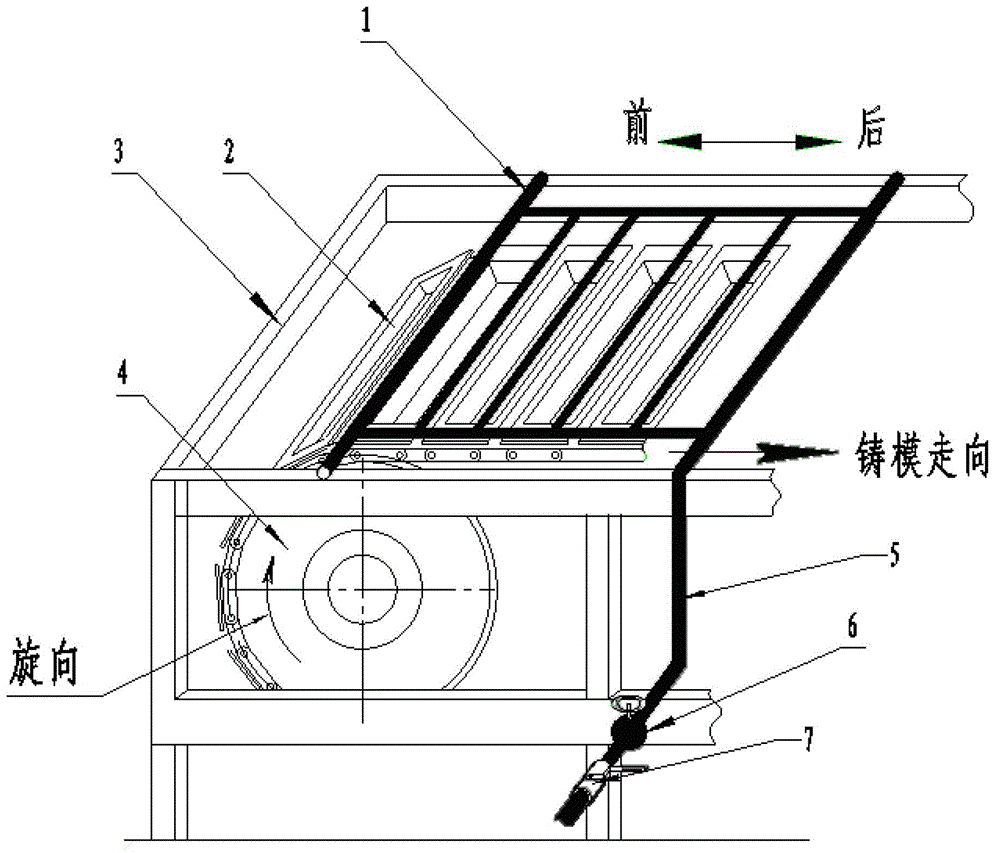

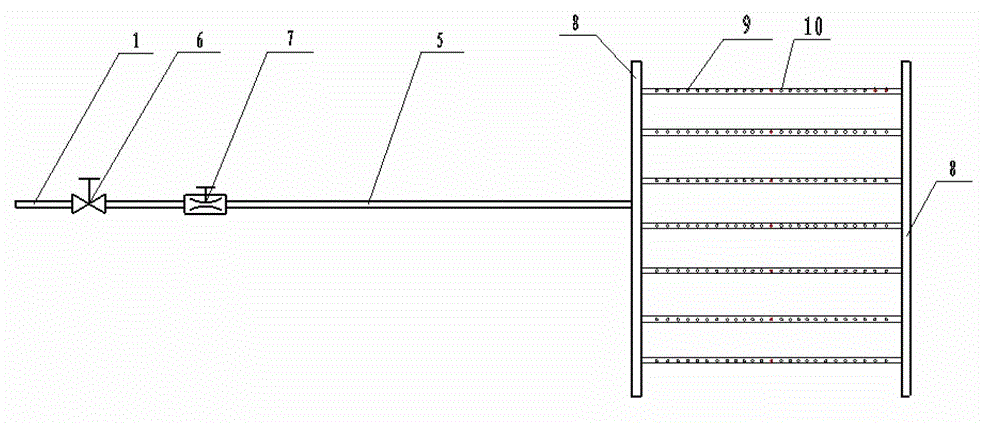

[0014] An automatic mold baking device for a common aluminum casting machine, which includes a casting frame 3, a casting mold 2 matched in the casting frame 3 and a rear sprocket 4 of the casting mold, such as figure 1 Shown: on the upper horizontal frame of the above-mentioned casting frame 3, there is a casting mold baking frame 1 fixed left and right and slidable front and back. valve 7;

[0015] As shown in Figure 2: the mold baking rack 1 is assembled by two vertical main pipes 8 and branch pipes 9 connected therebetween, and the branch pipes 9 are evenly distributed with fire holes 10;

[0016] The fire hole 10 on the mold baking rack 1 faces figure 1 The mold 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com