Embroidery paste stripping machine

An embroidery peeling machine, the technology of the peeling machine, which is applied to the embroidery machine, the mechanism of the embroidery machine, textiles and papermaking, etc., can solve the problems of continuous and fast use, high labor intensity, waste of time, etc., and improve productivity , Personnel operation is simple and easy, the effect of saving human resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

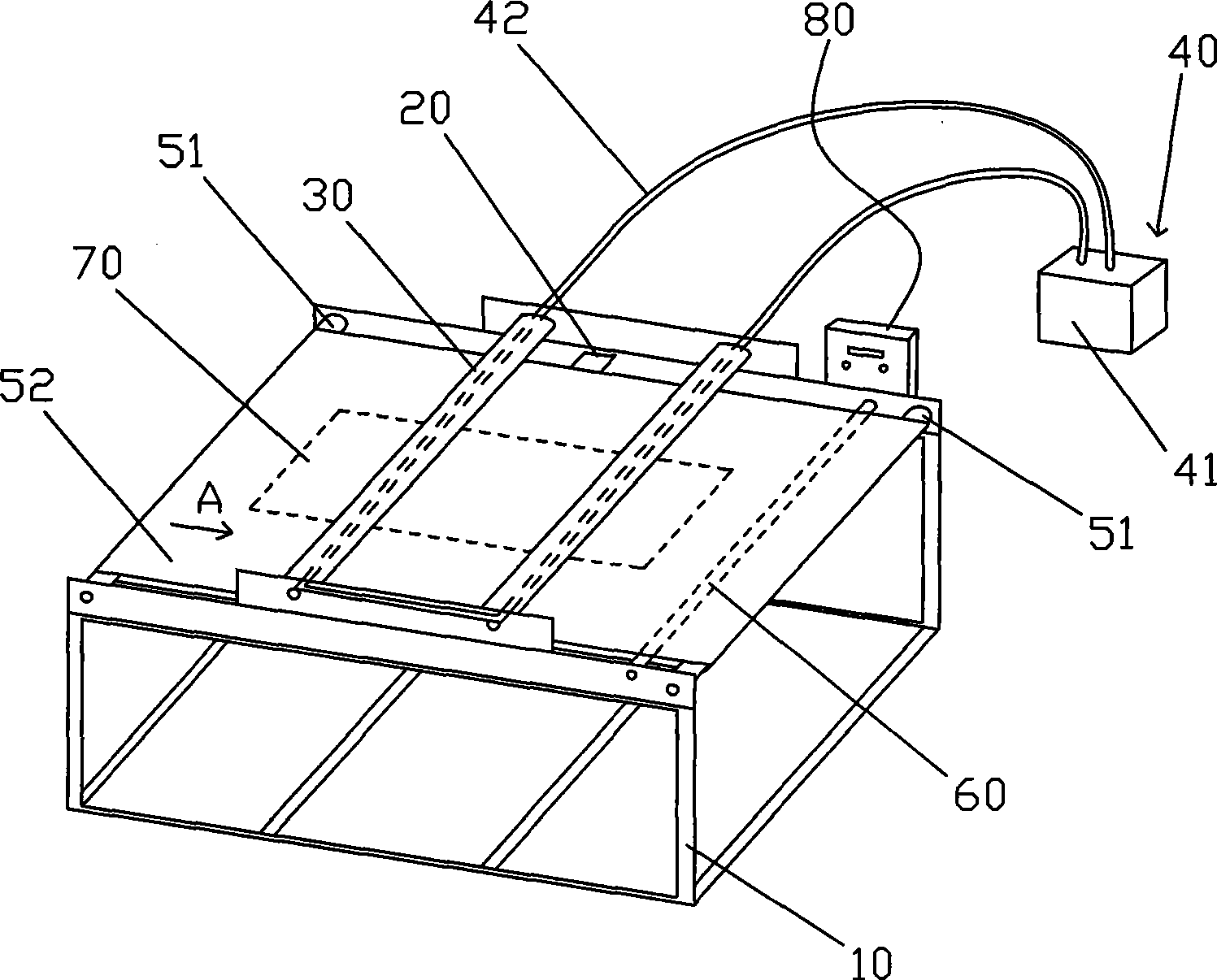

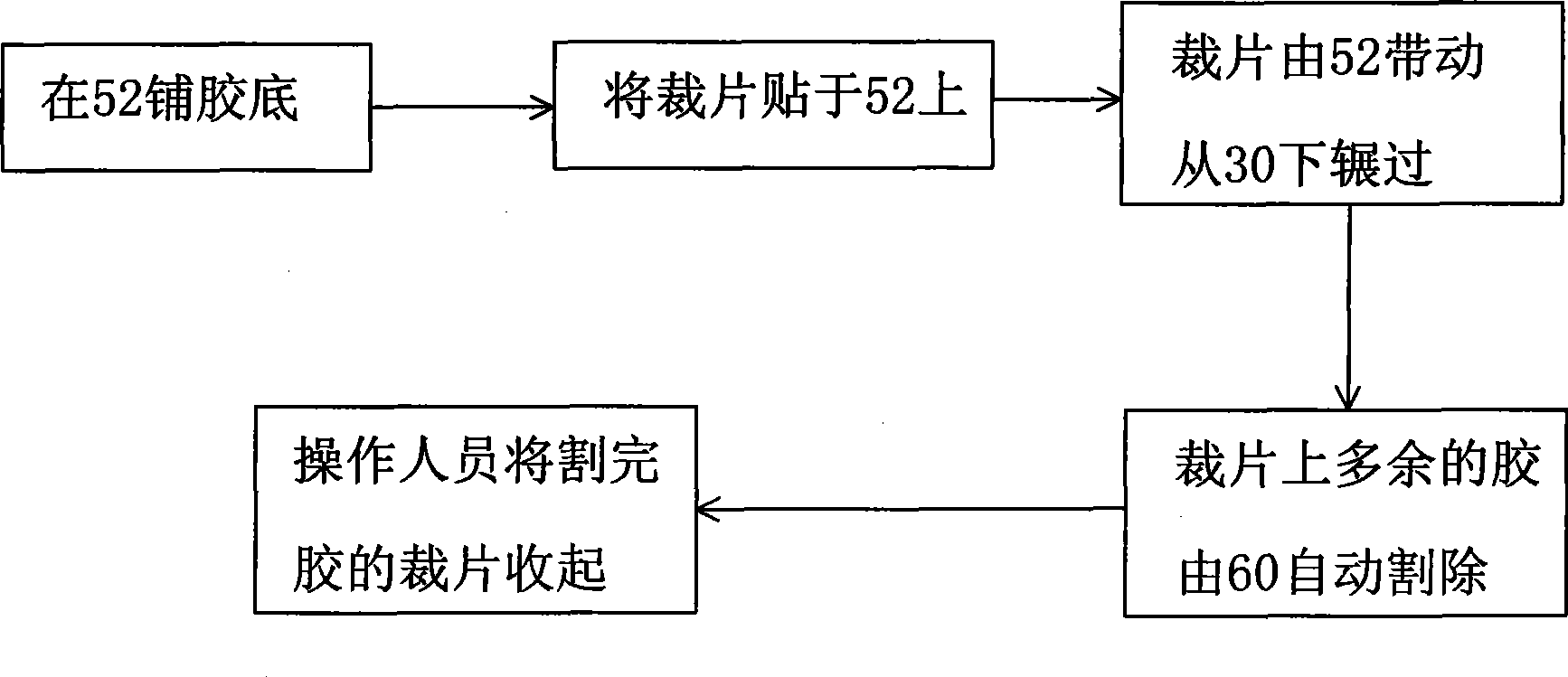

[0022] refer to Figure 1 to Figure 2 , the present invention is implemented like this:

[0023] exist figure 1 Among them, an embroidery peeling machine includes a base frame 10, a rolling and circulating stainless steel belt platform is arranged above the base frame 10, and the stainless steel belt platform is composed of a rotating device 51 and a roll of stainless steel belt 52 arranged on the outside of the rotating device 51 , the outside of the stainless steel belt 52 is provided with an automatic anti-edge device 20 for ensuring that the stainless steel belt platform is always in one position, and two pressure rollers 30 for flattening embroidery products are arranged above the stainless steel belt platform. The inside of the platform is provided with a heating device 70 .

[0024] The embroidery stripping machine is provided with a water cooling circulation system 40 for ensuring that the pressure roller 30 and the glue will not stick to each other. The water coolin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com