Zoom optic lens

A technology of optical zoom and lens, applied in the field of optical zoom lens, can solve problems such as difficult to meet high resolution and large resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

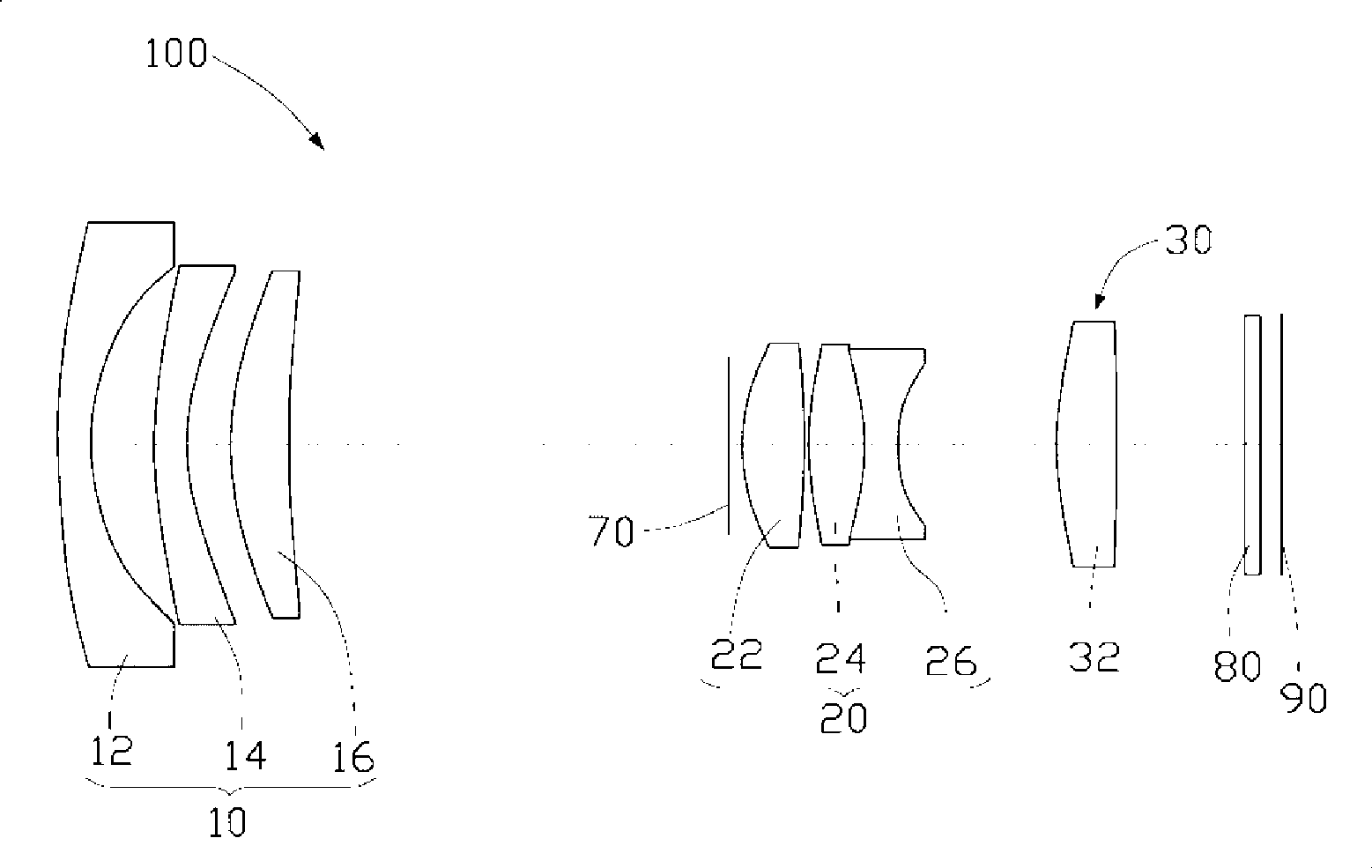

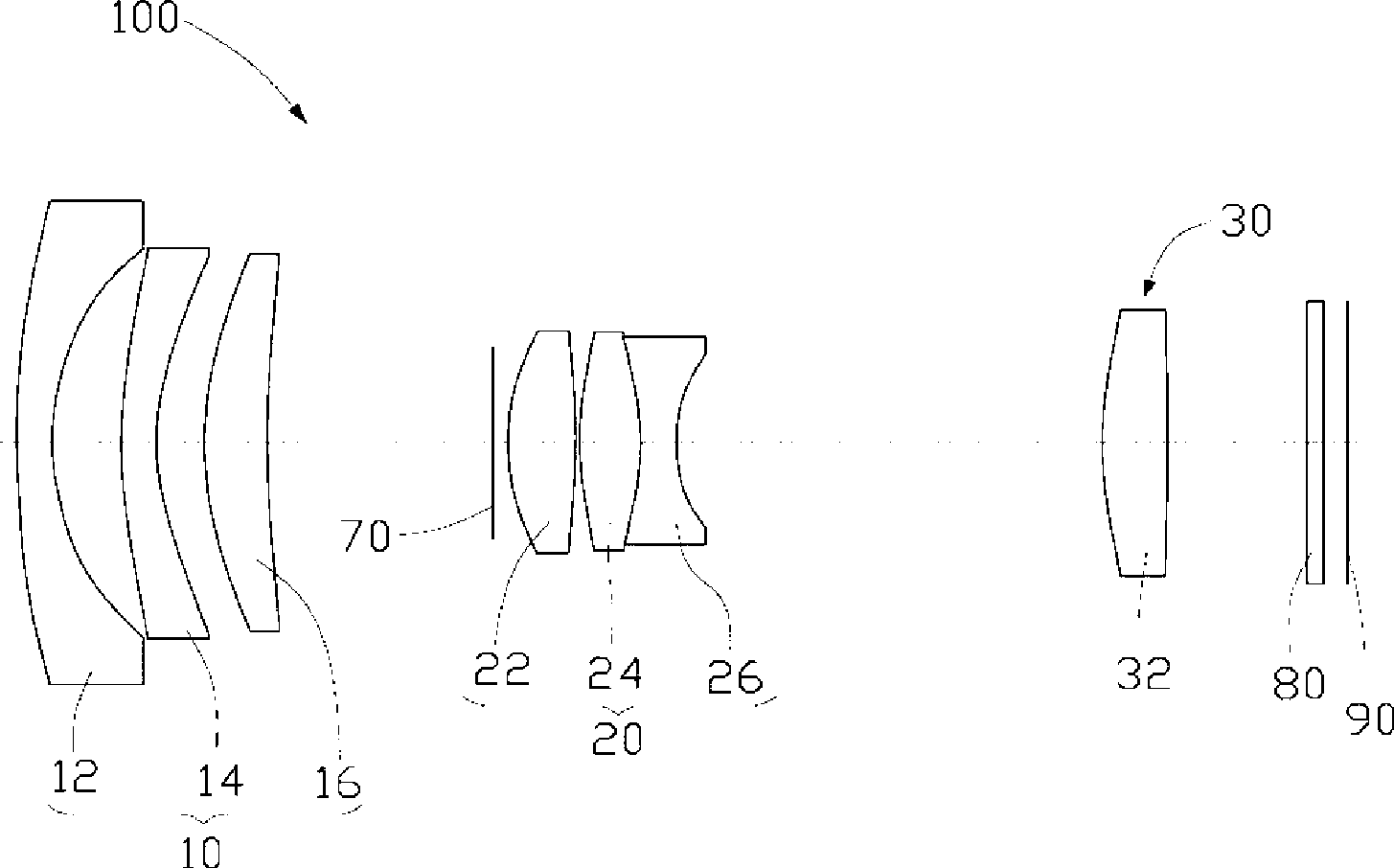

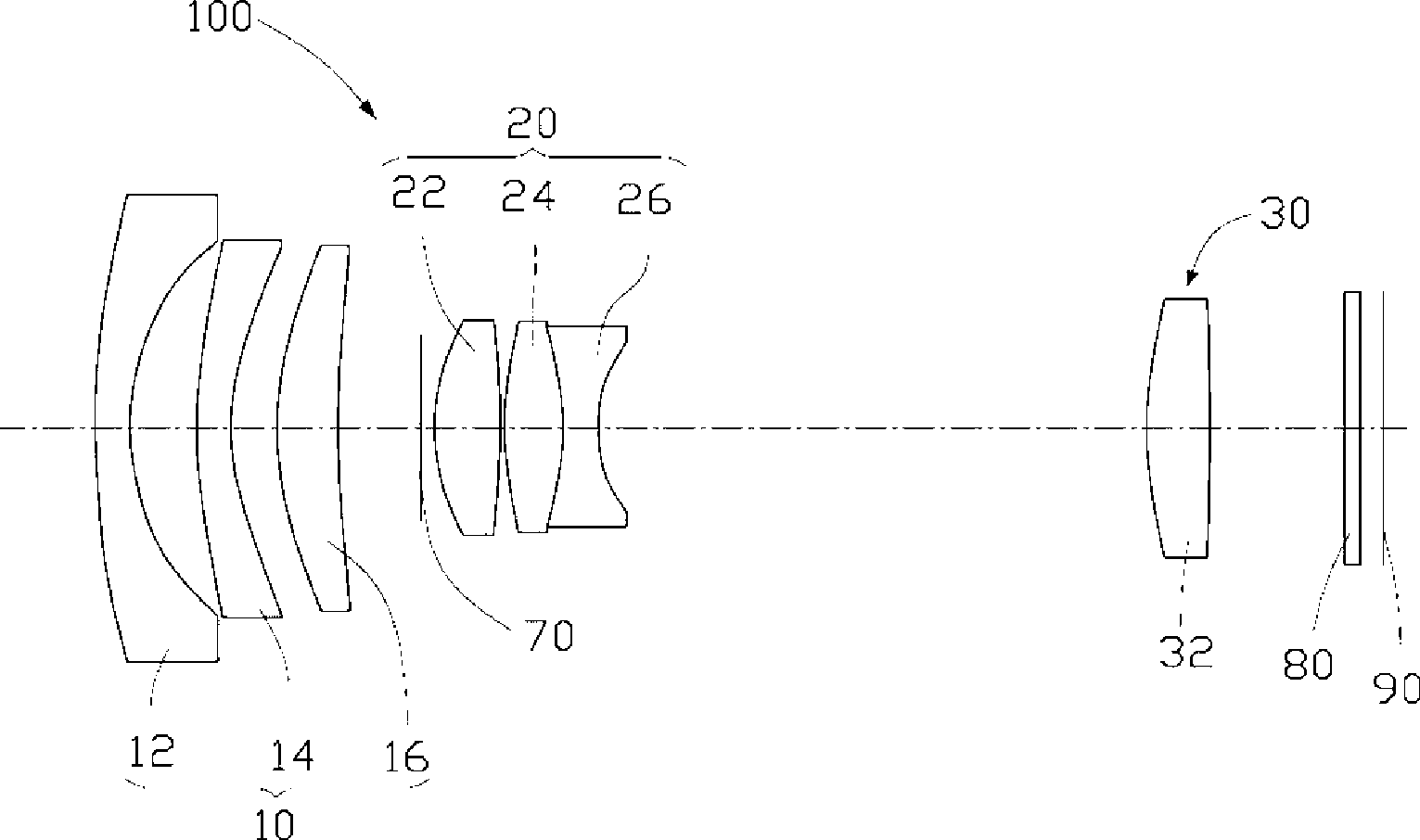

Image

Examples

Embodiment 1

[0049] Each optical element of the optical zoom lens 100 satisfies the conditions in Table 1 to Table 3, and its f=6.27~17.9mm; F W =6.27mm; F No =2.9~4.9; 2ω=59°~22°.

[0050] Table 1

[0051] surface Radius of curvature (mm) Thickness (mm) Refractive index Abbe number

[0052] The surface of the first lens 12 on the object side 24.41 1 1.69 48.5 The image-side surface of the first lens 12 6.5 1.76 --- --- The second lens 14 is on the object side surface 11.16 1 1.531 56.04 The surface of the second lens 14 on the image side 5.41 1.23 --- --- The surface of the third lens 16 on the object side 8.25 1.86 1.6 26.64 The surface of the third lens 16 on the image side 29.64 D6 (variable) --- --- Aperture surface gigantic 0.3 --- --- The fourth lens 22 is on the object side surface 5.45 1.909 1.531 56.04 The surface of the fourth lens 22 on the image side -16.27 0.1 --- --...

Embodiment 2

[0060] Each optical element of the optical zoom lens 100 meets the conditions of Table 4~Table 6, and its f=6.85~19.6mm; F W =6.85mm; F No =2.9~4.9; 2ω=59°~22°.

[0061] Table 4

[0062] surface Radius of curvature (mm) Thickness (mm) Refractive index Abbe number The surface of the first lens 12 on the object side 23.59 1 1.69 48.5 The image-side surface of the first lens 12 6.23 1.87 --- --- The second lens 14 is on the object side surface 8.99 1 1.531 56.04 The surface of the second lens 14 on the image side 5.58 1.09 --- --- The surface of the third lens 16 on the object side 8.86 1.84 1.6 26.64 The surface of the third lens 16 on the image side 28.84 D6 (variable) --- --- Aperture surface gigantic 0.3 --- ---

[0063] The fourth lens 22 is on the object side surface 5.76 2.03 1.531 56.04 The surface of the fourth lens 22 on the image side -18.1 0.1 --- --- Th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap