Method for loading and carrying object and transportation vehicle thereof

A technology for objects and vehicles, applied in the field of transport vehicles, loading and handling objects, can solve the problem of high manufacturing and production costs, and achieve the effect of saving time and speeding up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

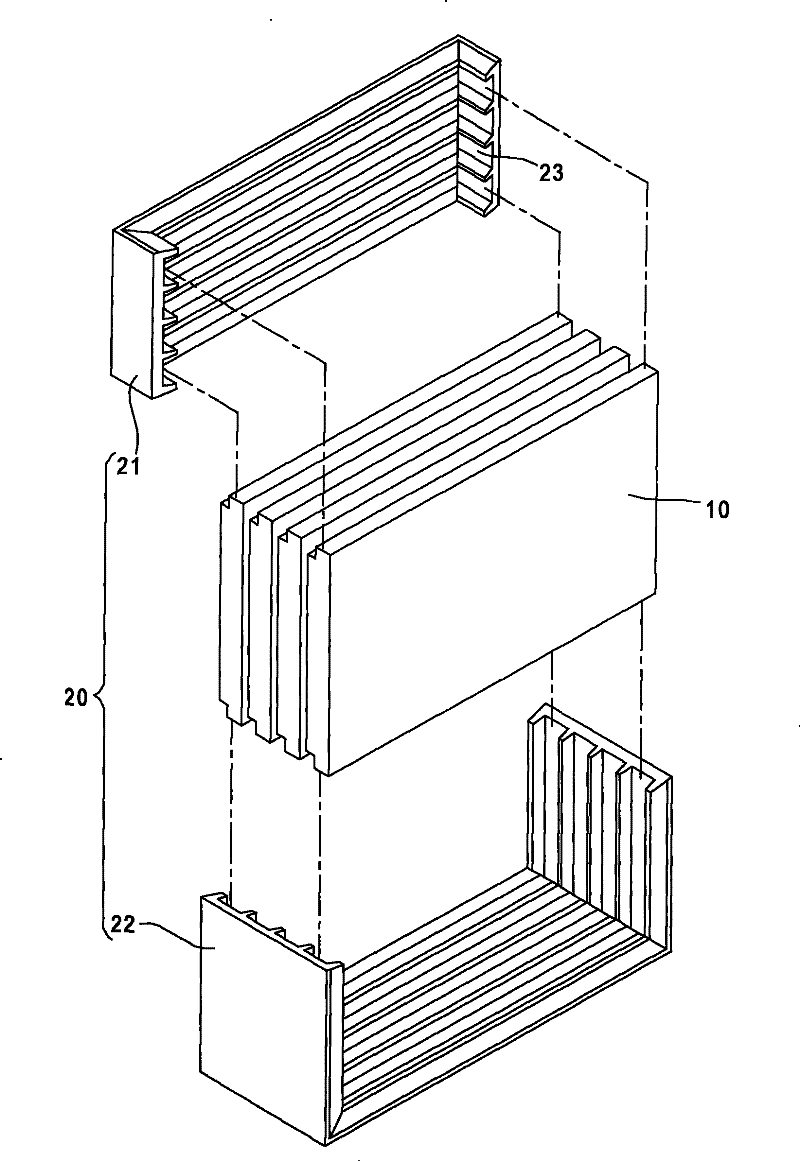

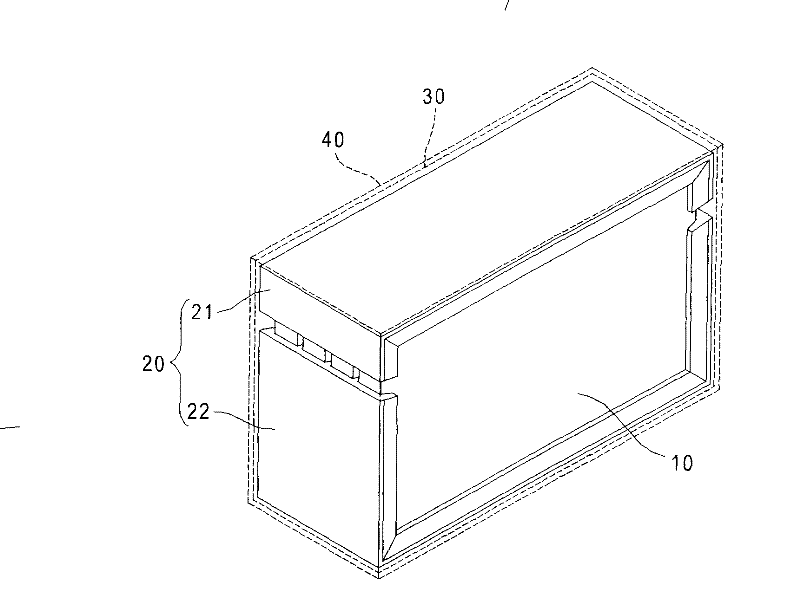

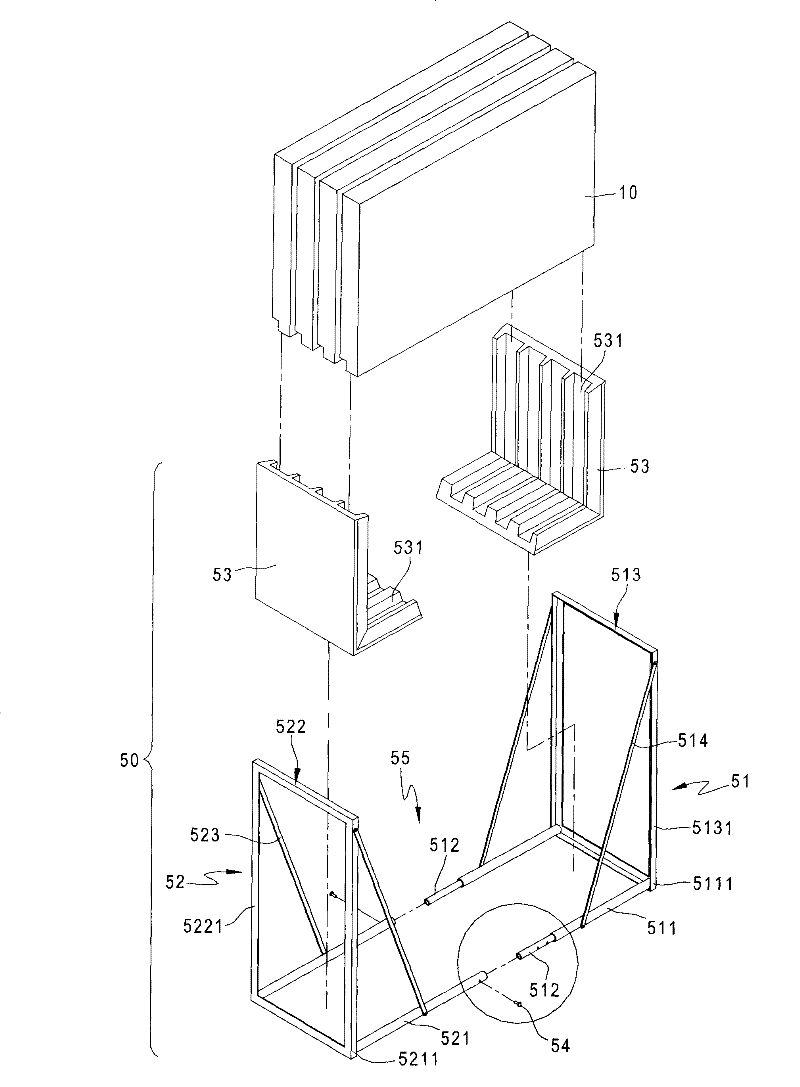

[0048] Figure 3A with Figure 4Shown is an exploded and assembled schematic diagram of an embodiment of the transportation vehicle of the present invention. The transportation carrier 50 disclosed in this embodiment includes a first frame body 51 , a second frame body 52 , a pair of trays 53 and a pair of fixing components 54 . The first frame body 51 is made of metal material (such as iron, steel, alloy and other metals), and the first frame body 51 includes a pair of horizontal brackets 511, a pair of movable components 512, a rectangular bracket 513 and a pair of oblique brackets 514 . The two horizontal supports 511 have a corresponding end 5111 respectively, and the opposite end of the corresponding end 5111 is connected with the movable assembly 512 respectively, and the movable assembly 512 has a fixing hole 5121 (such as Figure 3B shown); two rectangular supports 513 include a pair of vertical supports 5131, and the rectangular supports 513 are connected to the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com