Oil liquid abrasive grain on-line monitoring method and system

A technology of oil abrasive particles and abrasive particles, which is used in measurement devices, particle suspension analysis, suspension and porous material analysis, etc., can solve problems such as high cost, hysteresis of analysis results, and inability to determine the specific type of abrasive particles.

Inactive Publication Date: 2010-09-08

NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

View PDF0 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, offline detection requires sampling, the analysis period is long, the cost is high, and the analysis results have a certain lag

The existing online monitoring sensors for oil wear particles are generally only suitable for large wear particle detection. For example, the oil wear particle monitor MetalSCAN produced by GasTops in Canada is only suitable for the monitoring of wear particles with a size above 70um, and the price is very expensive.

In addition, the wear particle on-line monitoring sensor generally can only give the information of the wear particle concentration in the oil, and provide an early warning signal of the wear state. It can only distinguish between ferromagnetic particles and non-ferromagnetic particles, and cannot determine the specific type of wear particles. It is difficult to determine accurately Wear degree and wear mechanism analysis and wear location

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

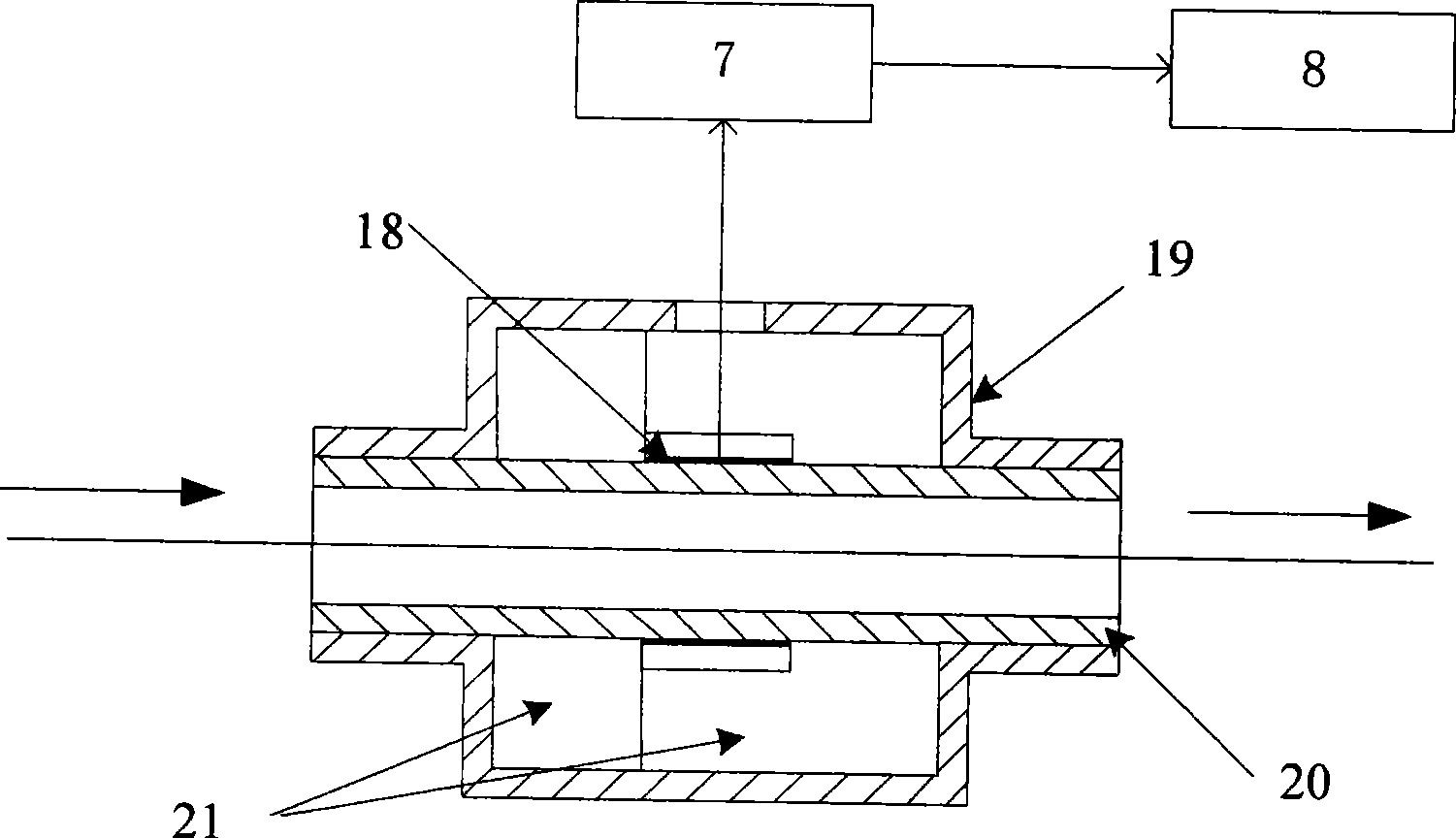

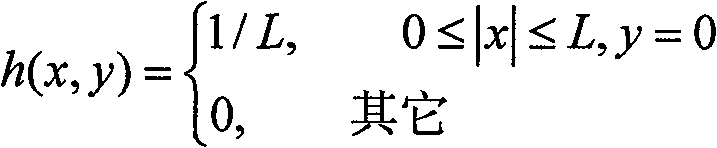

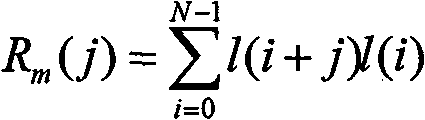

The invention relates to an online monitoring method and an online monitoring system for oil abrasive particles of a machine, which belong to the field of monitoring of the wear condition and failure diagnosis of a machine. The method monitors the wear condition of the machine by utilization of the principle that the oil abrasive particles are provided with net charges and the static signals are stronger when the concentration of the charged abrasive particles is high. The system comprises an abrasive particle online monitoring subsystem, wherein the subsystem is formed by a static sensor (1), a charge amplifier (7) and a dynamic signal test analysis instrument (8) in turn. The invention designs the abrasive particle online monitoring system on the basis of combination of static images and microscopic images aiming at the defects of the oil abrasive particle offline monitoring technology and the prior online monitoring technology. The system is suitable for online monitoring of abrasive particles with the thickness of more than 5 micrometers, and has low cost.

Description

technical field The oil abrasive particle online monitoring system of the present invention monitors the abrasive particle concentration, abrasive particle size, quantity and type in the machine oil in real time, provides a theoretical basis for wear state judgment, fault diagnosis and condition-based maintenance, and belongs to machine wear state monitoring and field of fault diagnosis. Background technique Oil wear particle analysis is an important means of wear state monitoring. At present, the off-line detection technology of oil wear particles has been developed relatively mature, including ferrography analysis technology, spectral analysis technology, particle counter, etc., which respectively provide oil samples from the aspects of wear particle type, composition, size and wear particle number statistics. Information on abrasive grains. However, offline detection requires sampling, the analysis period is long, the cost is high, and the analysis results have a certai...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): G01N15/06G01N15/00G01N27/60

Inventor 左洪福李绍成文振华卞利

Owner NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com