Oil liquid abrasive grain on-line monitoring method and system

A technology of oil abrasive particle monitoring system, applied in measurement device, particle suspension analysis, suspension and porous material analysis, etc., can solve the problems of inability to determine the specific type of abrasive particles, high price, and hysteresis of analysis results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

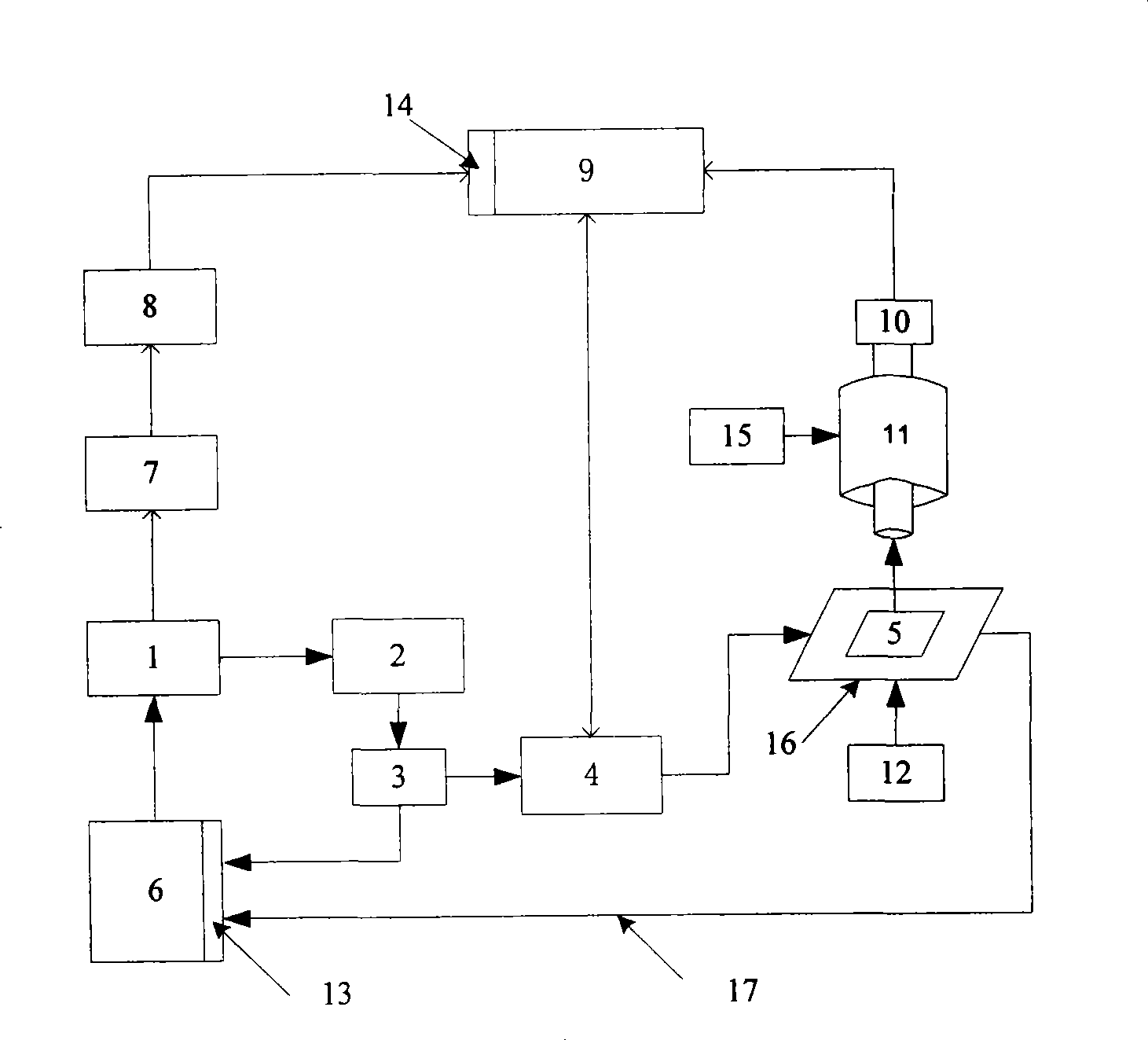

[0016] 1. System structure

[0017] The system consists of figure 1 As shown, the on-line wear particle electrostatic monitoring subsystem (including electrostatic sensor 1, charge amplifier 7 and dynamic signal test analyzer 8) wear particle image online acquisition and analysis subsystem (including oil analysis chip 5, microscope 11, light source 12) And 15, industrial digital camera 10), oil intake system (including pump 2, micro pump 4, diverter device 3, oil pipeline 17).

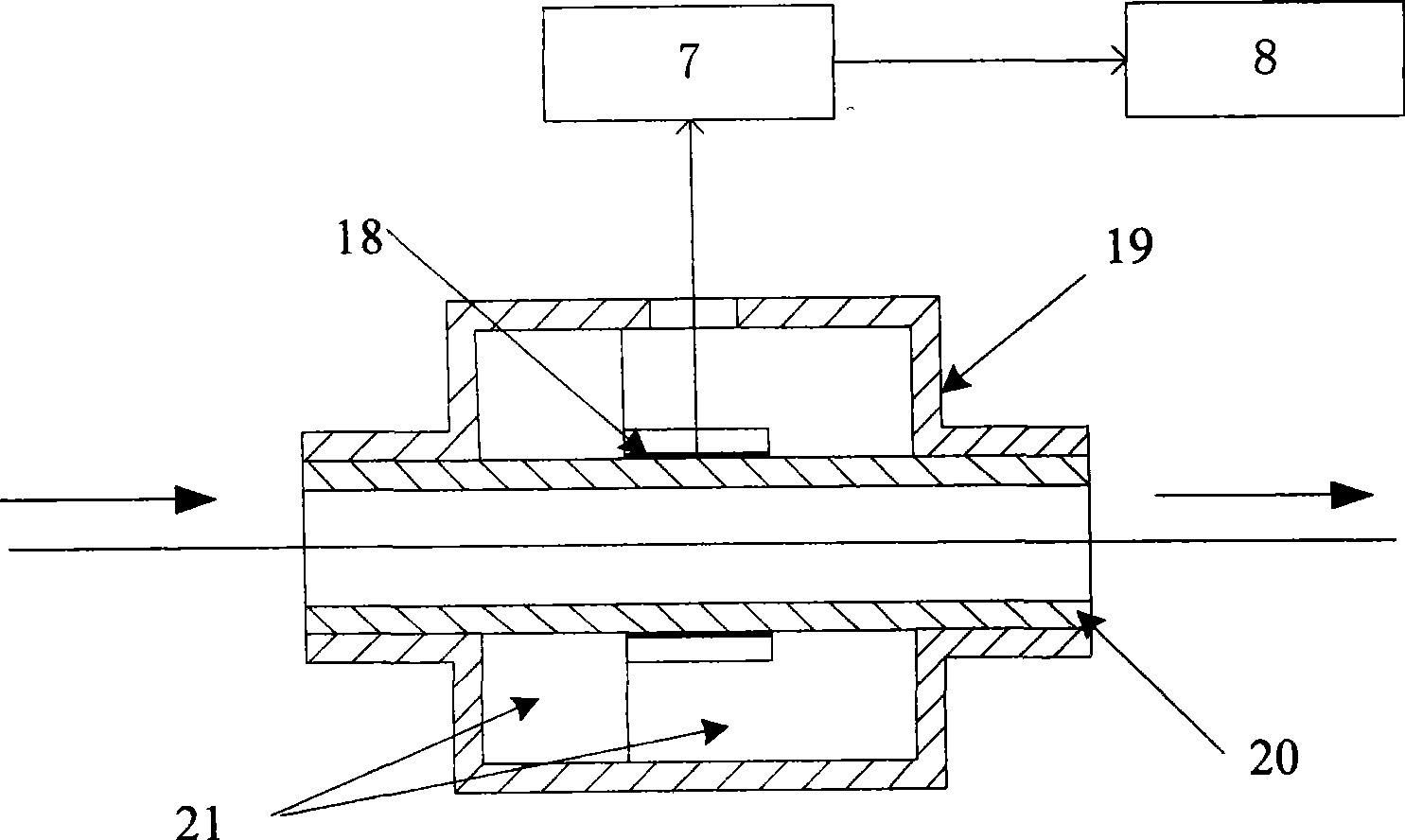

[0018] Electrostatic sensor structure such as figure 2 As shown, it is composed of an electrode 18, a shielding cover 19, an insulating tube 20, and an insulator 21. The materials of the electrode, shielding cover, insulating tube and insulator in the sensor are copper, brass, quartz glass and polytetrafluoroethylene respectively. The specific structural dimensions are optimized based on the theoretical model of the sensor's electrostatic field and through finite element analysis. In this example, the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com