Continuous flow micro-pump

A micropump and pump body technology, applied in the field of continuous flow micropumps, can solve the problems of difficult continuous and stable fluid transmission, difficult gas transmission, small flow rate, etc., and achieve the effect of small volume, large pump flow rate and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

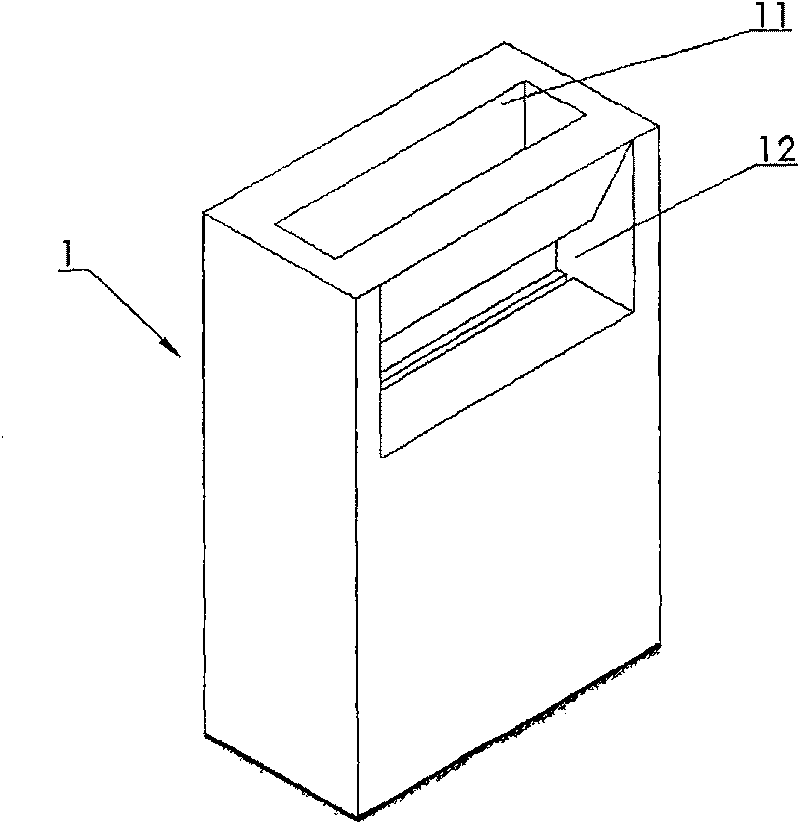

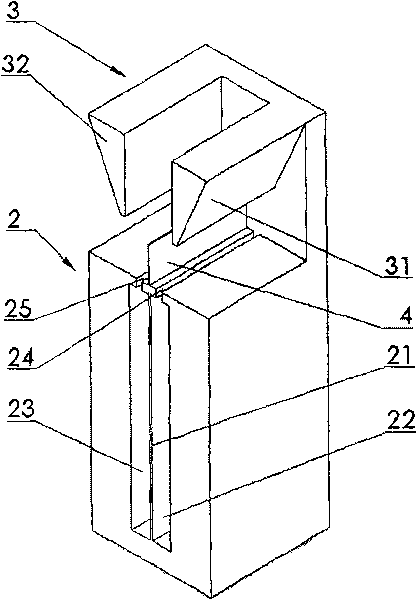

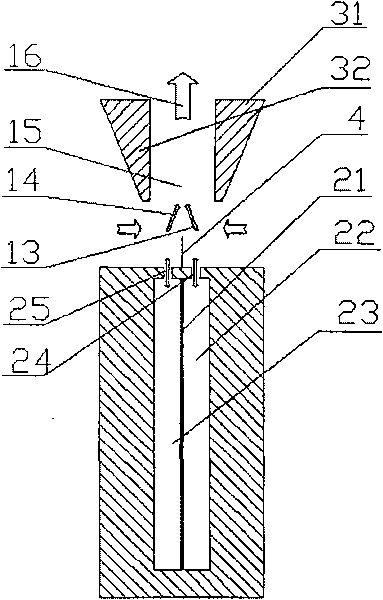

[0037] See attached Figure 1~2 , the pump body 1 of this embodiment of a continuous flow micropump of the present invention, its external dimensions are 20 × 50 × 70mm 3 , the shell is made of non-flexible hard aluminum alloy material; the vibration film 21 is made of rubber film material with good elasticity and flexibility, which is rectangular and driven by piezoelectric vibration; the guide baffle 4 is made of aluminum alloy sheet profile, with a size of 0.2 ×40×6mm 3 ; The cavity depth of the first cavity 22 and the second cavity 23 match the length of the vibrating membrane 21, both of which are 5mm; the first outlet 24 and the second outlet 25 are in the same shape as a narrow slit, and the cross-sectional size of the outlet is 40mm 2 ; And the outlet 11 can generally be made into a nozzle with a horn-shaped section, and the cross-sectional size of the outlet of the outlet 11 in the present embodiment is 10 * 40mm 2 , the entrance 12 is a frustum-shaped channel that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com