Fuel supply module

A fuel supply and fuel technology, applied in the direction of liquid fuel feeder, charging system, filtration and separation, etc., can solve the problems of long longitudinal fuel passage, hindering the installation of base components and electric pumps close to each other, so as to avoid interference , to achieve miniaturization and improve space efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

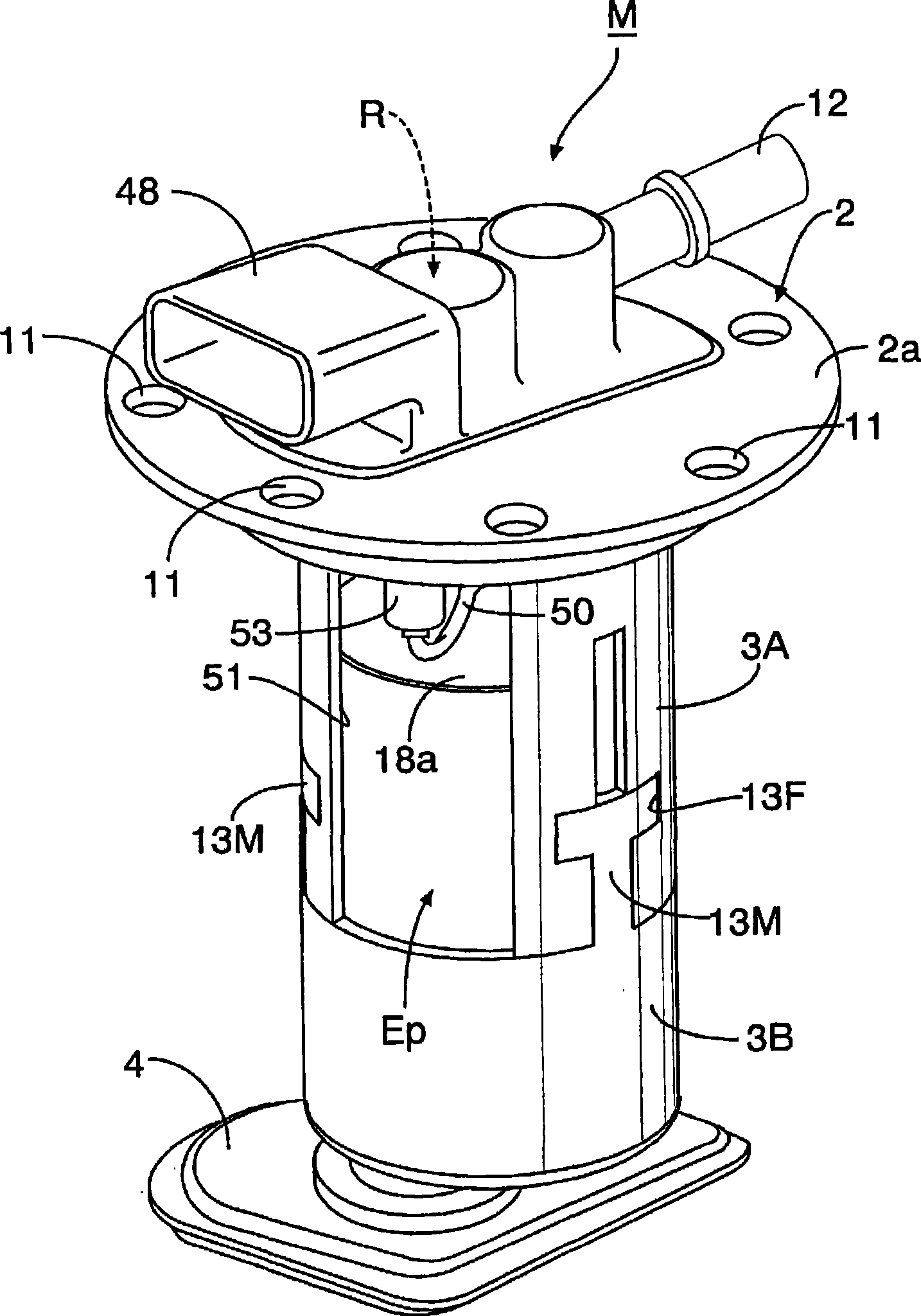

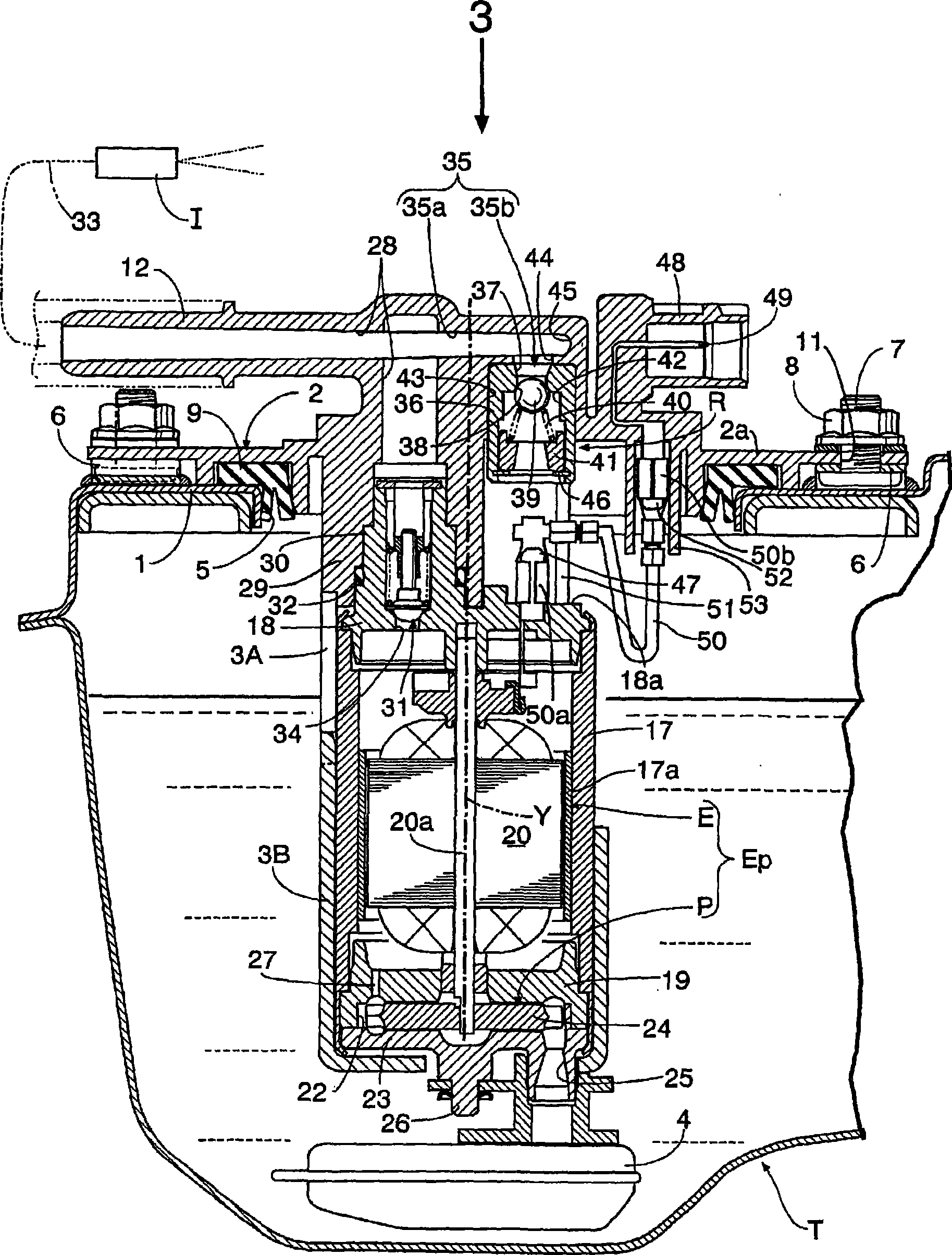

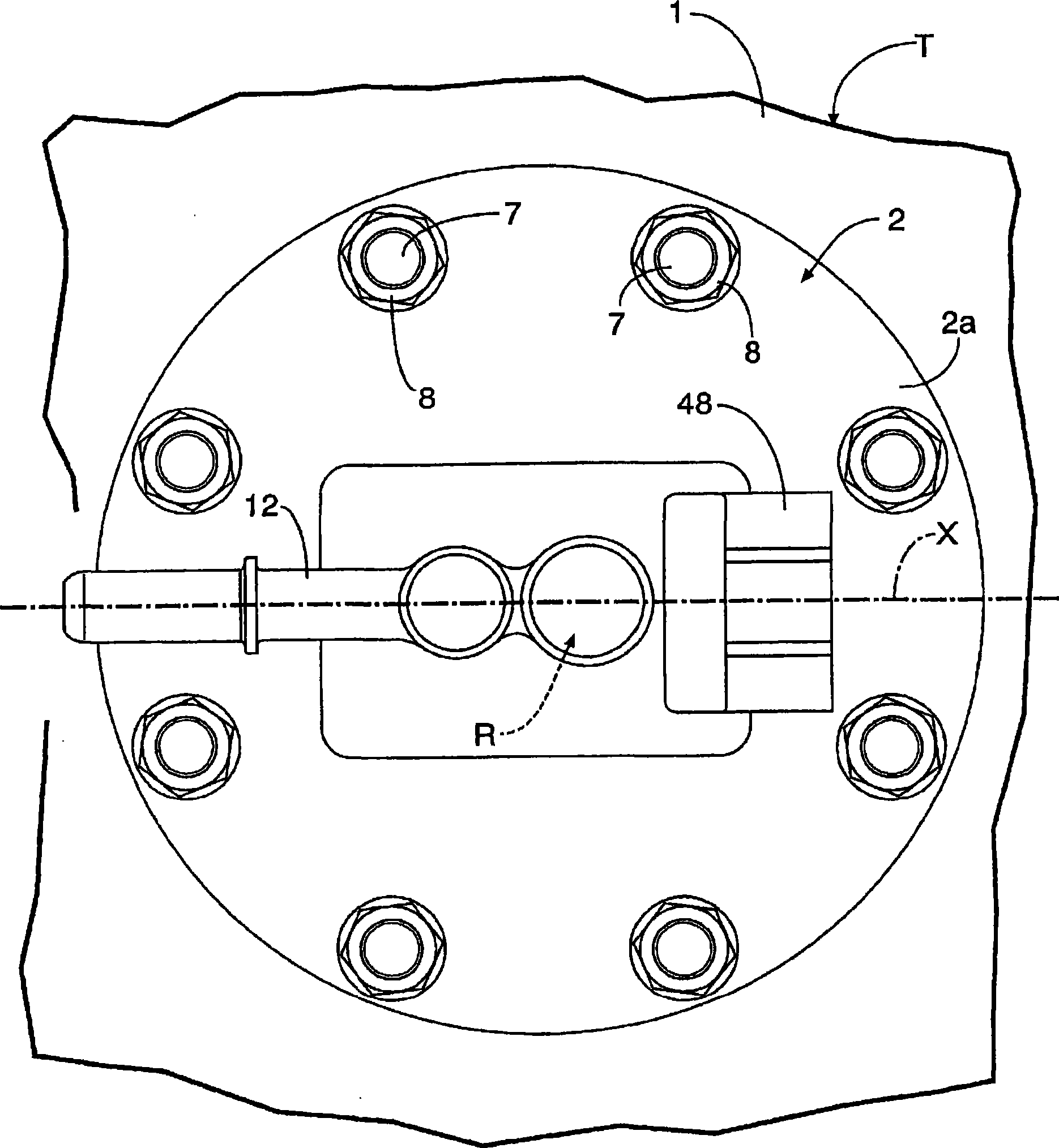

[0041] First, in Figure 1 ~ Figure 3 Among them, the fuel supply module M of the present invention is mounted on the top wall 1 of the fuel tank T mounted on a vehicle such as a motorcycle, and the fuel supply module M supplies fuel in the fuel tank T to the fuel injection valve I of the engine.

[0042] The fuel supply module M has: a mounting base member 2; an electric pump Ep disposed directly below the mounting base member 2 with the axial direction vertical; and an upper pump holder 3A. 3A is integrally formed on the installation base part 2; the lower pump holder 3B, which is detachably combined with the upper pump holder 3A, and is linked with the installation base part 2 to accommodate and hold the motor pump Ep; and a fuel filter 4 installed at the lower end of the electric pump Ep.

[0043] Inside the ceiling wall 1 of the fuel tank T is provided an opening 5 into which the electric pump Ep is inserted, and a mounting ring 6 surrounding the opening 5 is fixedly pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com