Stacker crane body node-pin shaft connection mode and connection pin shaft

A technology of tower cranes and connection methods, applied to cranes and other directions, can solve the problems of inconvenient disassembly of tower body sections, difficult work intensity, and poor foothold for workers, and achieve saving of high-strength metal materials, large working space, and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

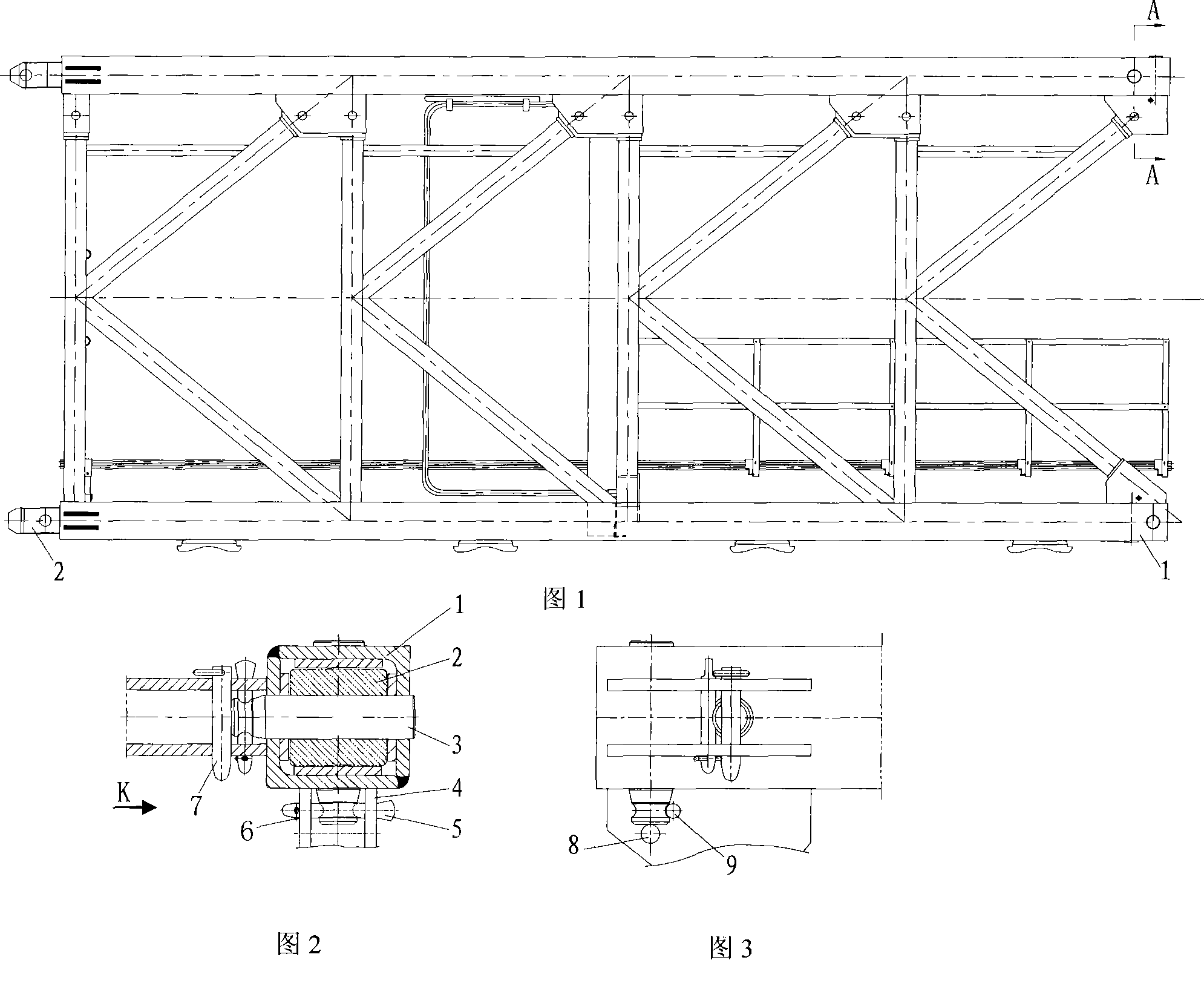

[0025] As shown in Fig. 1-Fig. 3, it is a schematic structural diagram of a tower crane adopting the tower body joint pin shaft connection method of the present invention, including the following steps:

[0026] 1. After putting the tenon 2 of the tower body into the inner hole at the end of the main branch 1, put the retaining pin 7 into the retaining pin hole 8 on the ear plate 4, and the position of the retaining pin hole 8 can be installed according to the needs. Depending on the length of pin shaft 3;

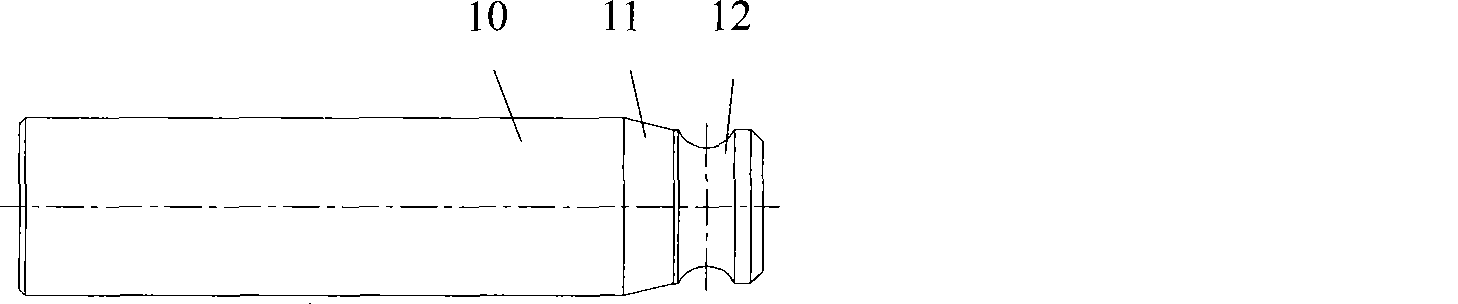

[0027] 2. Put the end of the connecting pin shaft 3 with the lock pin groove into the connecting hole of the main branch of the tower body section, and make the end of the locking pin part 12 of the connecting pin shaft 3 contact with the stop pin 7; The pin shaft 3 is driven to the predetermined position, and the lock pin groove on the connecting pin shaft 3 just matches the position of the lock pin hole 9 on the ear plate 4 at the end of the tower body section;

[0028]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com