Tiny pulsation pressure generator

A pressure generator and dynamic pressure technology, applied in the direction of measuring fluid pressure, instruments, measuring devices, etc., can solve the problems that the frequency range cannot cover infrasound, single frequency, etc., to achieve calibration, reduce distortion, and ensure accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

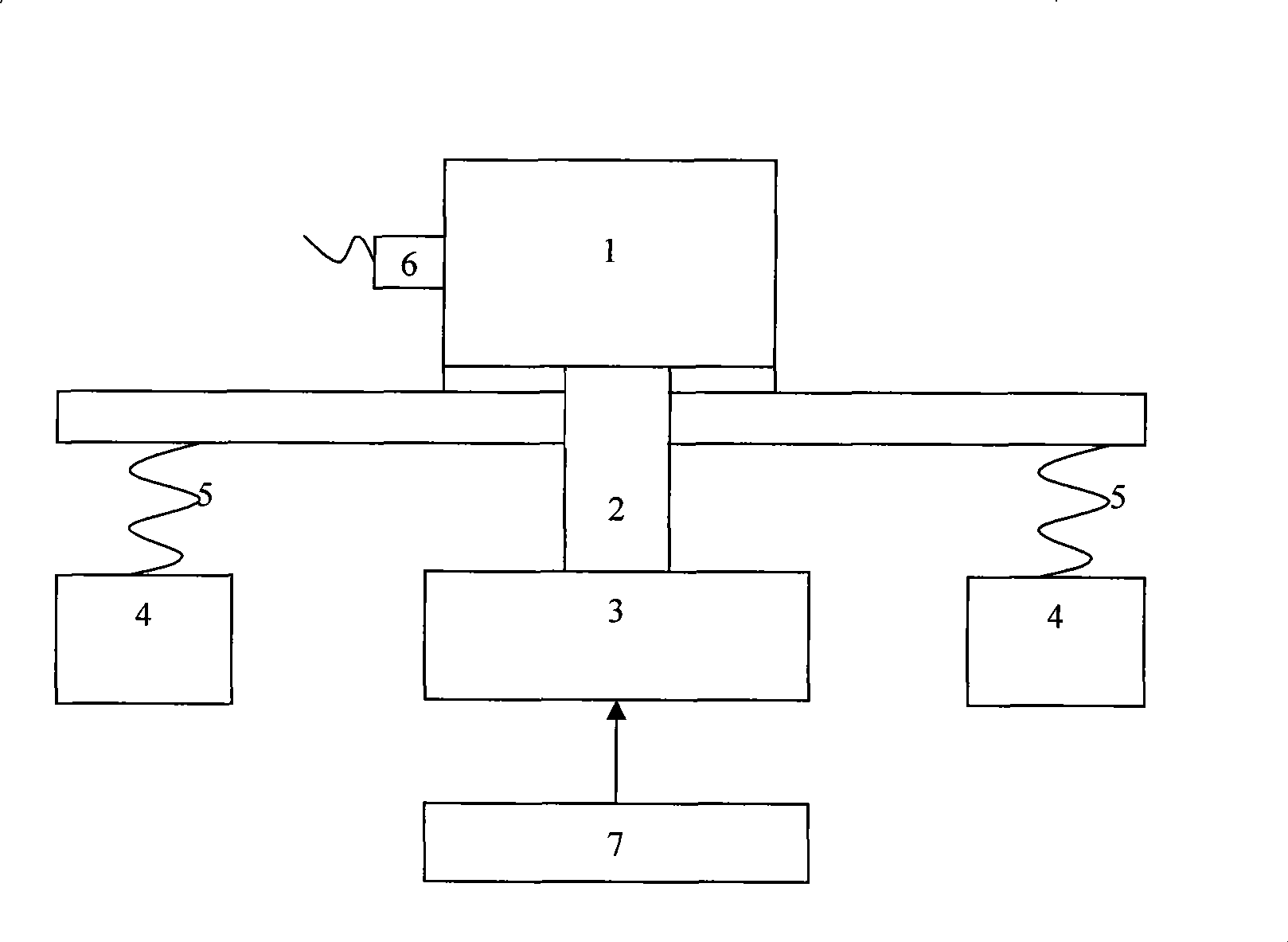

[0018] The micro-pulsation pressure generator includes a closed cavity 1, a piston 2, a vibration table 3, a vibration isolation table 4 and an adjustment spring 5, the cavity 1 is a positive cylindrical cavity, and the diameter of the cavity 1 is equal to the length of the cavity 1; The piston 2 is placed between the cavity 1 and the vibrating table 3 and fixed on the vibrating table 3; a vibration isolating table 4 is installed at each end of the vibrating table 3, and the cavity 1 is installed on the vibration isolating table 4, and by adjusting the spring 5 Adjust the coaxiality with the piston 2.

[0019] The cavity 1 is a positive cylinder, the diameter of the cavity is equal to the length, and the center of the side wall of the cavity is provided with a mounting hole for installing the microphone 6 to be calibrated, and the mounting hole and the microphone 6 to be calibrated are sealed by an O-ring .

[0020] The piston 2 is circular, and the moving direction of the pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com