Grinding mechanism common to cylindrical roller modules and face grinding wheel modules

A grinding mechanism and cylindrical grinding technology, applied in machine tools suitable for grinding the plane of the workpiece, machine tools designed for grinding the rotating surface of the workpiece, grinding machines, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

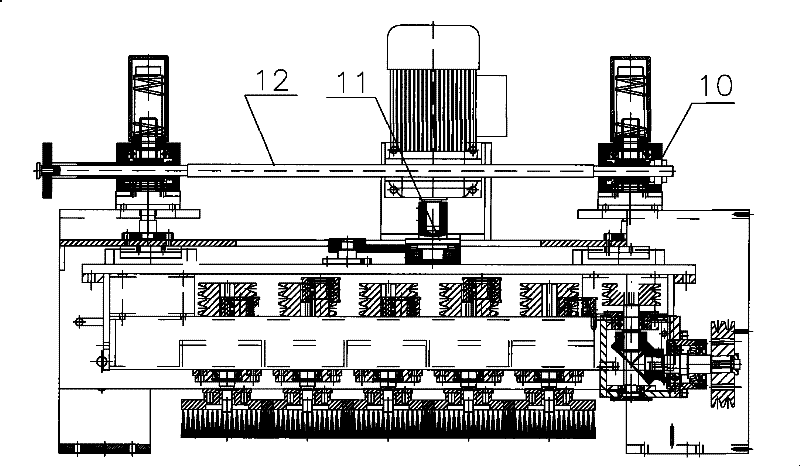

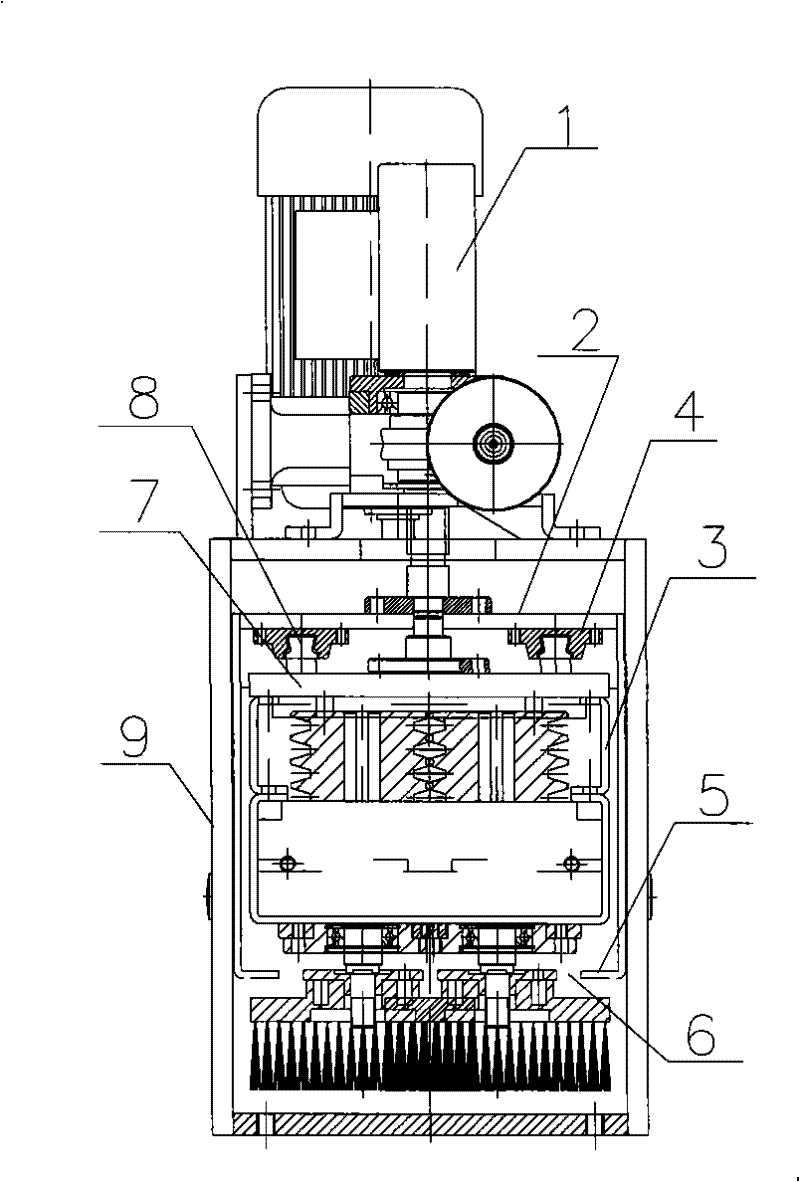

[0012] Embodiment 1: with reference to attached figure 1 and 2 . A universal grinding mechanism for cylindrical grinding roller modules and end surface grinding wheel modules. The worm gear mechanism 10 in the grinding mechanism is located on the upper end of the support 9 and is driven by the motor 1. The lifting mold frame 2 is located in the support 9 and on both sides of the lifting mold frame 2. It is in precise sliding fit with the inner wall of the bracket 9, driven by the worm gear mechanism 10 to rise or fall, and the worm gear box on the upper end surface of the bracket 9 adopts a rigid connecting rod 12 to act synchronously. The frame bottom of the lifting mold frame 2 is an open slide rail structure 6 , that is to say, the horizontal edges on both sides of the opening are slide rails 5 . The upper end surface of the transition plate 7 is provided with (several pieces) sliders 8 in parallel, and the sliders 8 are located at the top (four sets) of linear guide rai...

Embodiment 2

[0013] Embodiment 2: On the basis of Embodiment 1, a method for working and exchanging the universal grinding mechanism of the cylindrical grinding roller module and the end face grinding wheel module, the worm gear mechanism 10 in the grinding mechanism is driven by a motor, and the lifting mold frame 2 is driven by The worm gear mechanism 10 drives it up or down, and the eccentric mechanism drives the transition plate 7 connected with the movement mechanism 3 to move left and right along the linear guide rail, thereby driving the movement mechanism 3 to move left and right; the outer cylindrical grinding roller module or the end face grinding wheel module is replaced When removing the power belt on the rear side and the four front and rear connecting screws, the outer cylindrical grinding roller module or end face grinding wheel module can fall onto the slide rail at the bottom of the lifting mold frame, and the outer cylindrical grinding roller module or end face grinding whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com