Arch pre-carding device

An arc-shaped, pre-divided technology, applied in deburring devices, textiles and papermaking, fiber processing, etc., can solve the problems of easily damaged needle teeth, insufficient carding degree, etc., to reduce noil rate, improve carding quality, and soft carding. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

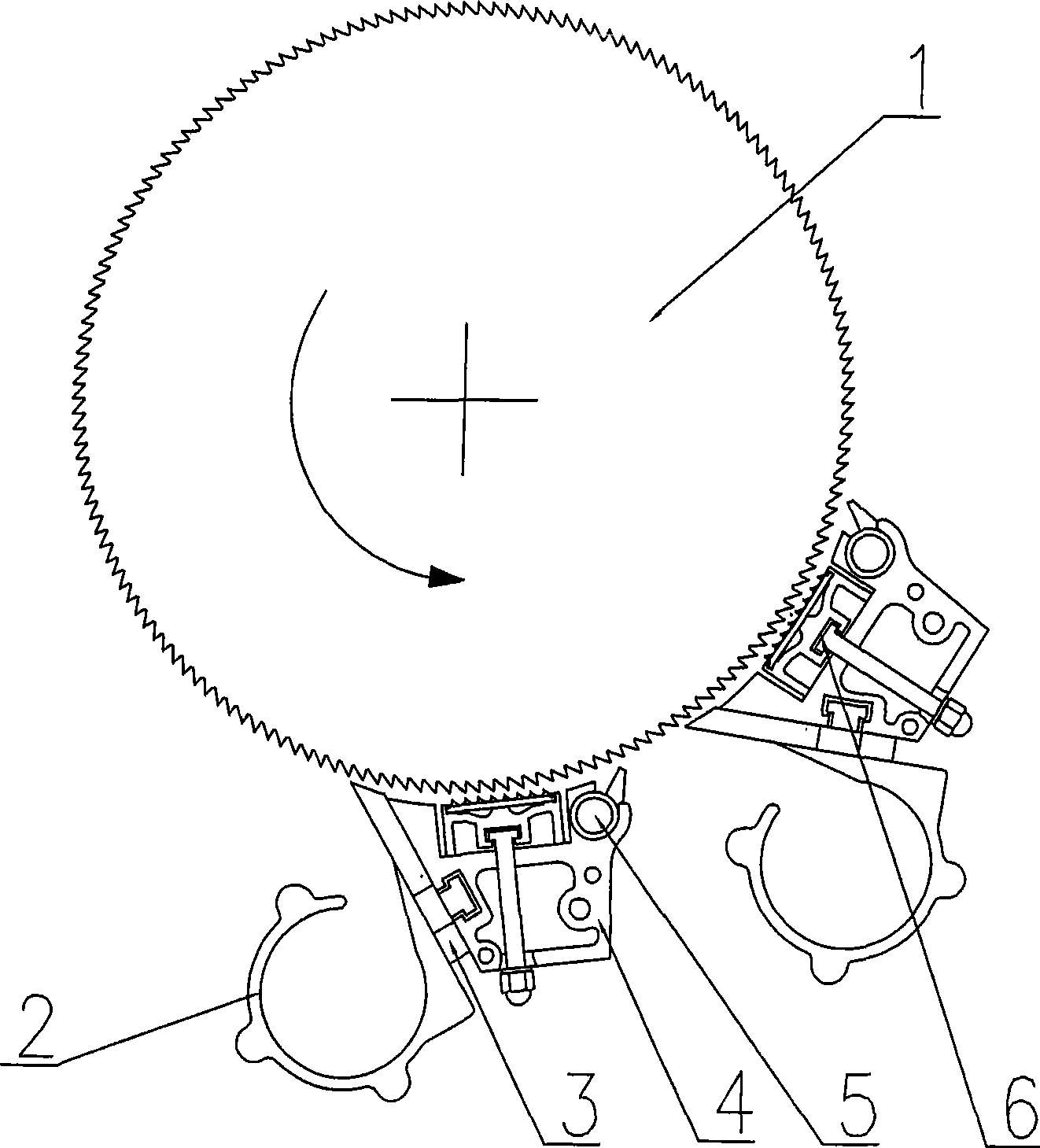

[0012] Such as figure 1 The arc-shaped pre-carding device shown includes a licker-in roller 1, a suction and impurity removal unit 2, a dust removal knife 3, a carding plate seat 4 and a cotton support adjustment plate 5, and an arc-shaped carding plate is installed on the carding plate seat 2. The arc-shaped pre-combing rack 6 formed by the combination of tooth pieces, the length of the tooth surface of the arc-shaped pre-combing rack 6 is 30mm-36mm, and the tooth tip direction is opposite to the rack tooth tip direction of the licker-in roller 1 .

[0013] In practice, one or two sets of arc-shaped pre-carding devices can be installed according to different types of carding. For example, a small drain bottom can be installed in the place where the second set of arc-shaped pre-carding devices is installed behind one set of arc-shaped pre-carding devices. Instead, be flexible. According to the running direction of the lap, there are licker-in roller 1, air suction and impurit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com