Small terminal and material belt integral built-in injection mold

An injection mold and embedded technology, which is applied in household appliances, other household appliances, household components, etc., can solve the problems of long putting time of small terminals, long injection molding cycle, and high production cost, so as to shorten the injection molding cycle and improve performance Reliable, cost-effective production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

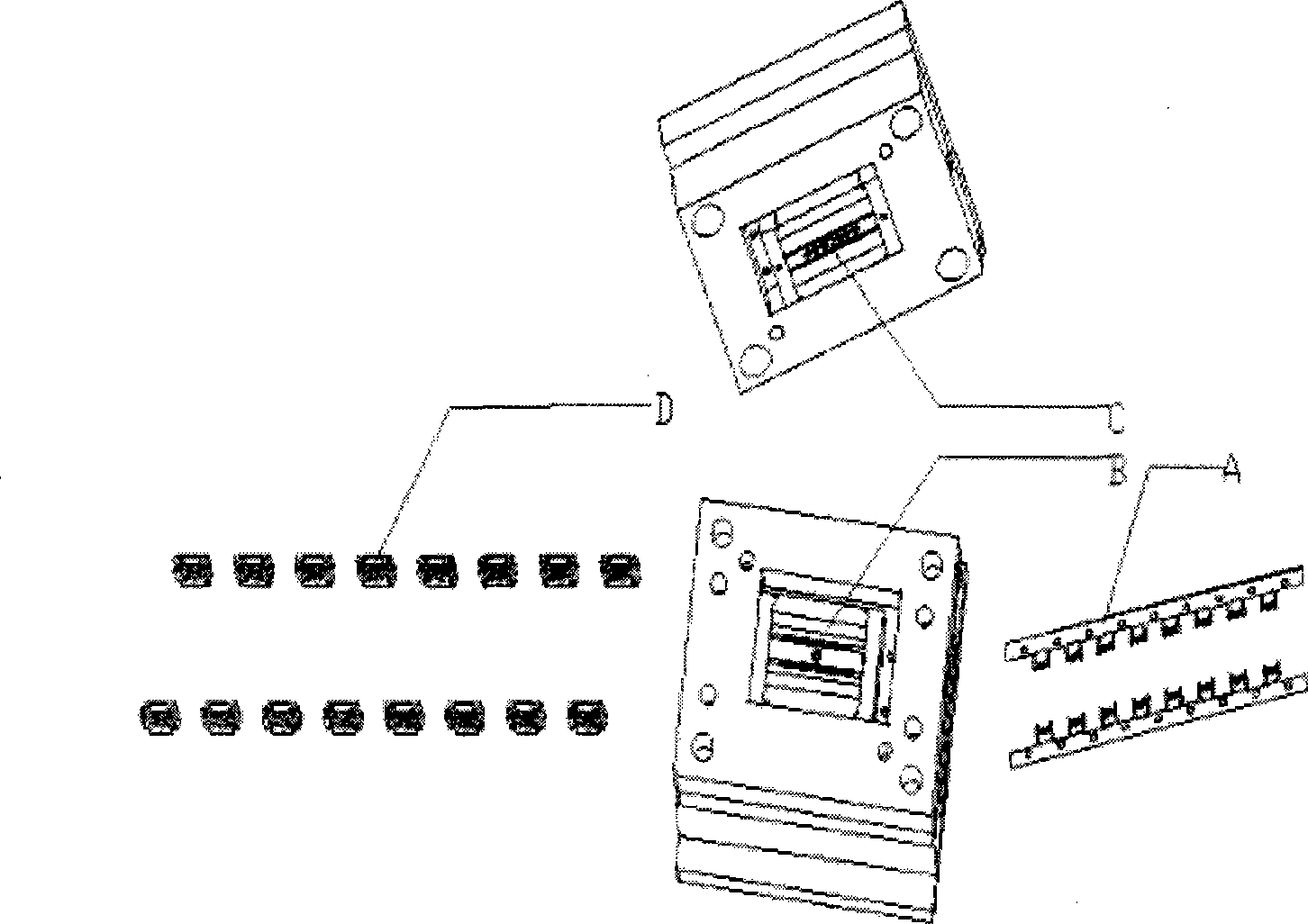

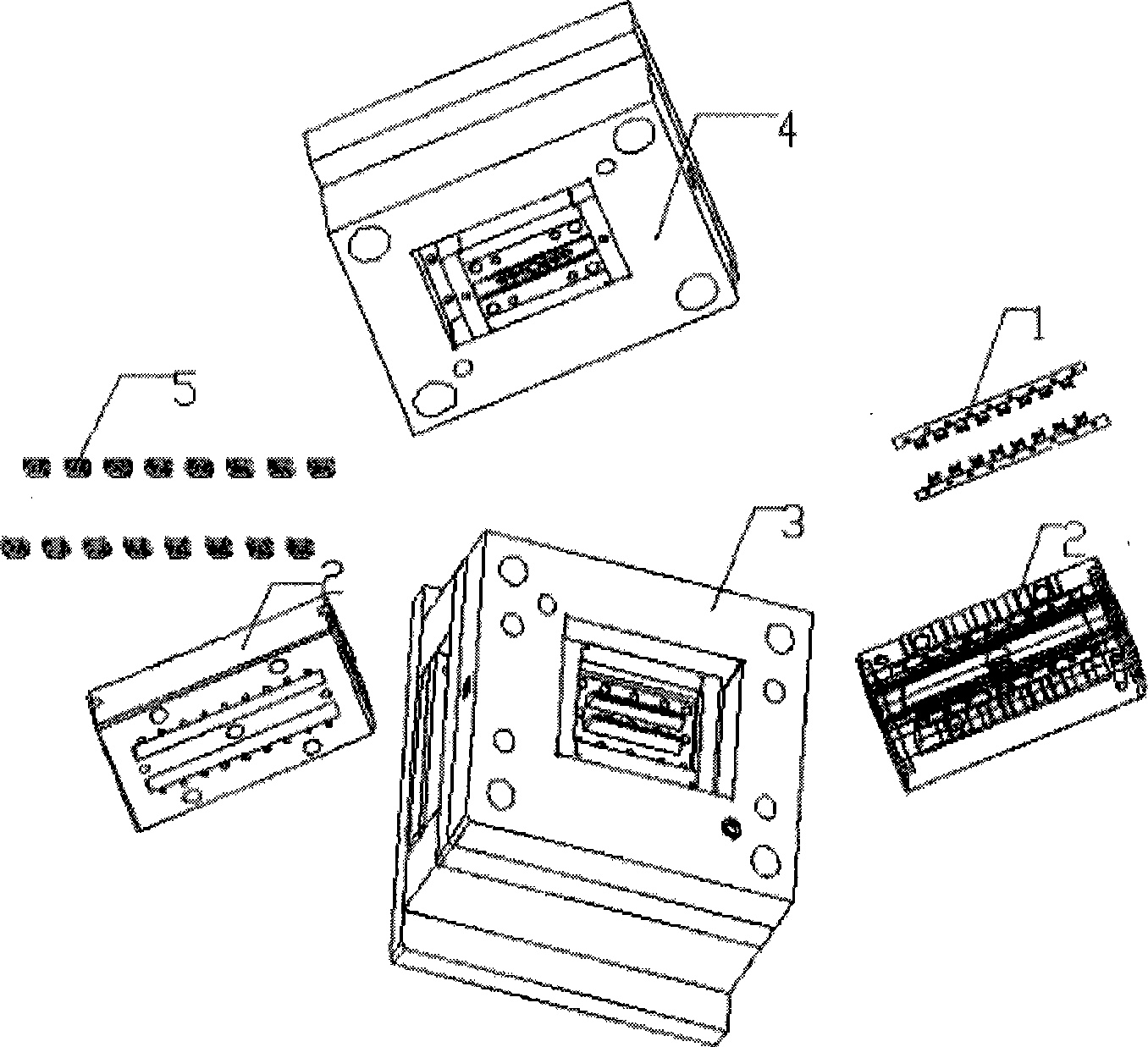

[0022] see figure 2 , the present invention discloses an integral embedded injection mold for a small terminal with a material strip, as shown in the figure: it includes a plurality of movable plates 2 placed on a small metal terminal 1 with a material strip, and an injection mold male mold 3 embedded in the movable plate , and the injection mold master mold 4 for mold clamping injection molding.

[0023] The integral embedded injection mold of the small terminal connecting material strip mainly adopts the method of first placing the small metal terminal 1 of the connecting material belt on a plurality of movable plates 2, and then putting one movable plate 2 into the male mold 3 of the injection mold, and then The product 5 is molded by injection molding the female mold 4 of the injection mold, and the movable plate 2 can be ejected out of the male mold 3 of the injection mold through the injection molding machine along with the product, and the movable plate 2 with the meta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com