Integrated measuring instrument

A technology of a comprehensive measuring instrument and a comprehensive testing instrument, applied in the field of comprehensive measuring instruments, can solve the problems of inconvenient adjustment, poor versatility, and difficulty in meeting the needs of debugging and calibration of different medical equipment at the same time, and achieves the effect of improving the versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

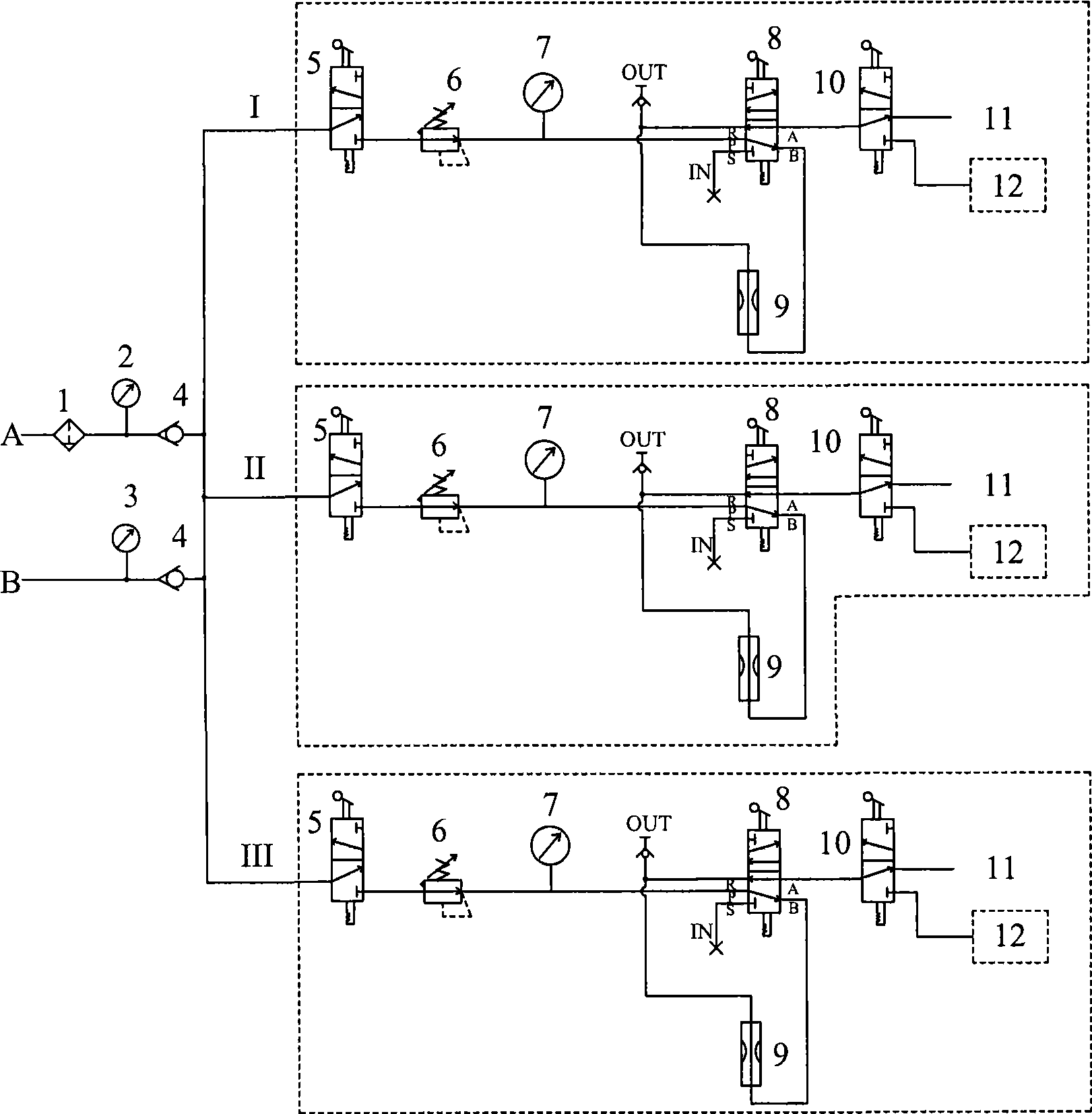

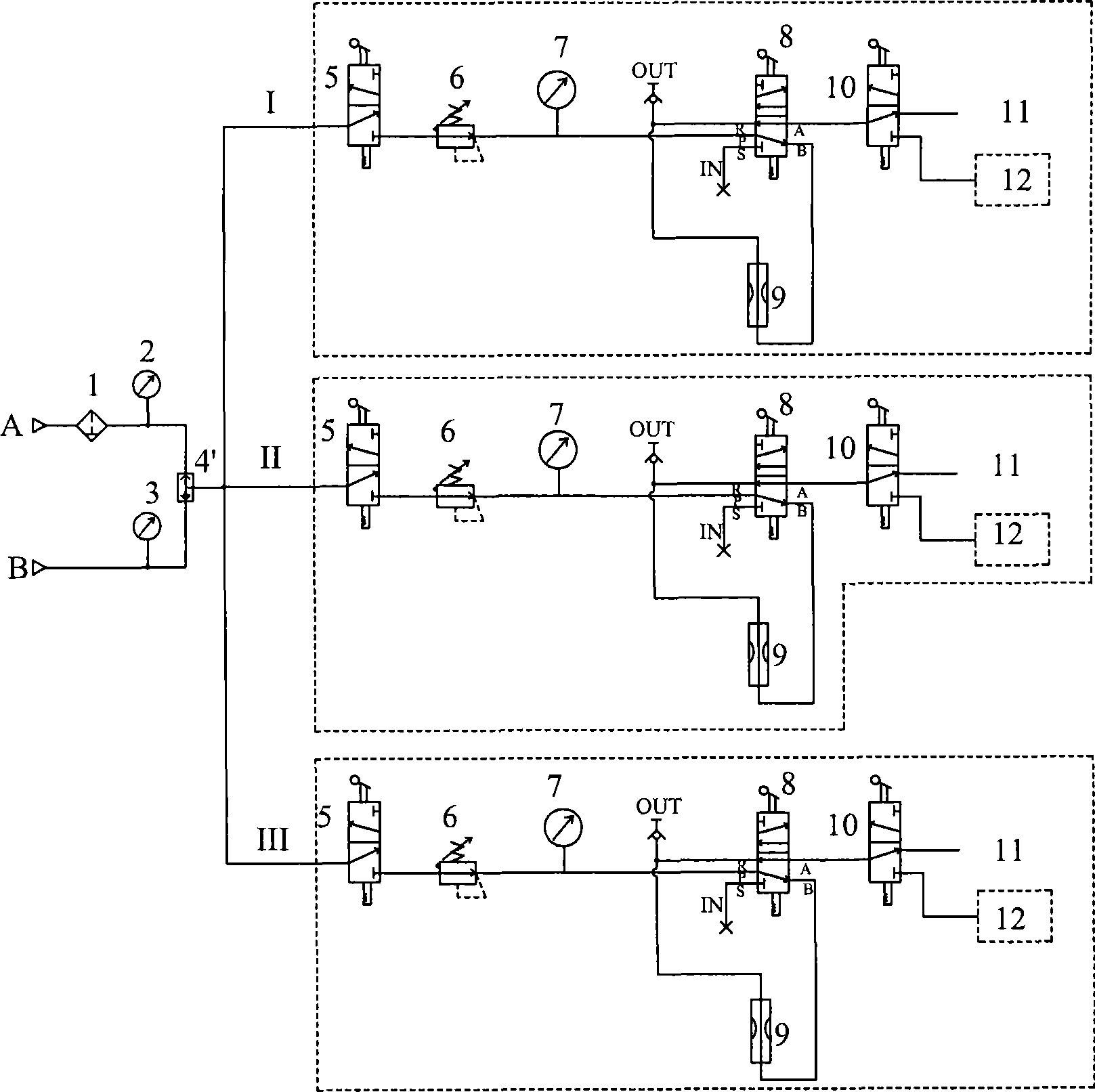

[0024] refer to figure 1 , shows a schematic block diagram of the gas path structure of the comprehensive measuring instrument according to a preferred embodiment of the present invention. Among them, according to the preferred embodiment of the present invention, there are two air source input interfaces - air interface (first air source interface) A and oxygen interface (second air source interface) B, these two interfaces are connected to the corresponding debugging equipment air The source pipeline is used to input the source gas into the comprehensive tester. Specifically, the air interface A is used for inputting an air source, and it is a self-sealing plug-in interface; the oxygen interface B is used for inputting an oxygen source, and it is a self-sealing threaded interface. Preferably, a filter 1 is connected after the air port A, which is used...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com