Cable side electric connector

An electrical connector and connector technology, applied in the direction of connection, parts and circuits of connecting devices, can solve the problems of difficulty in ensuring elasticity, small deflection and displacement, and high rigidity, and achieve an increase in the number of parts, easy locking, The effect of large displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

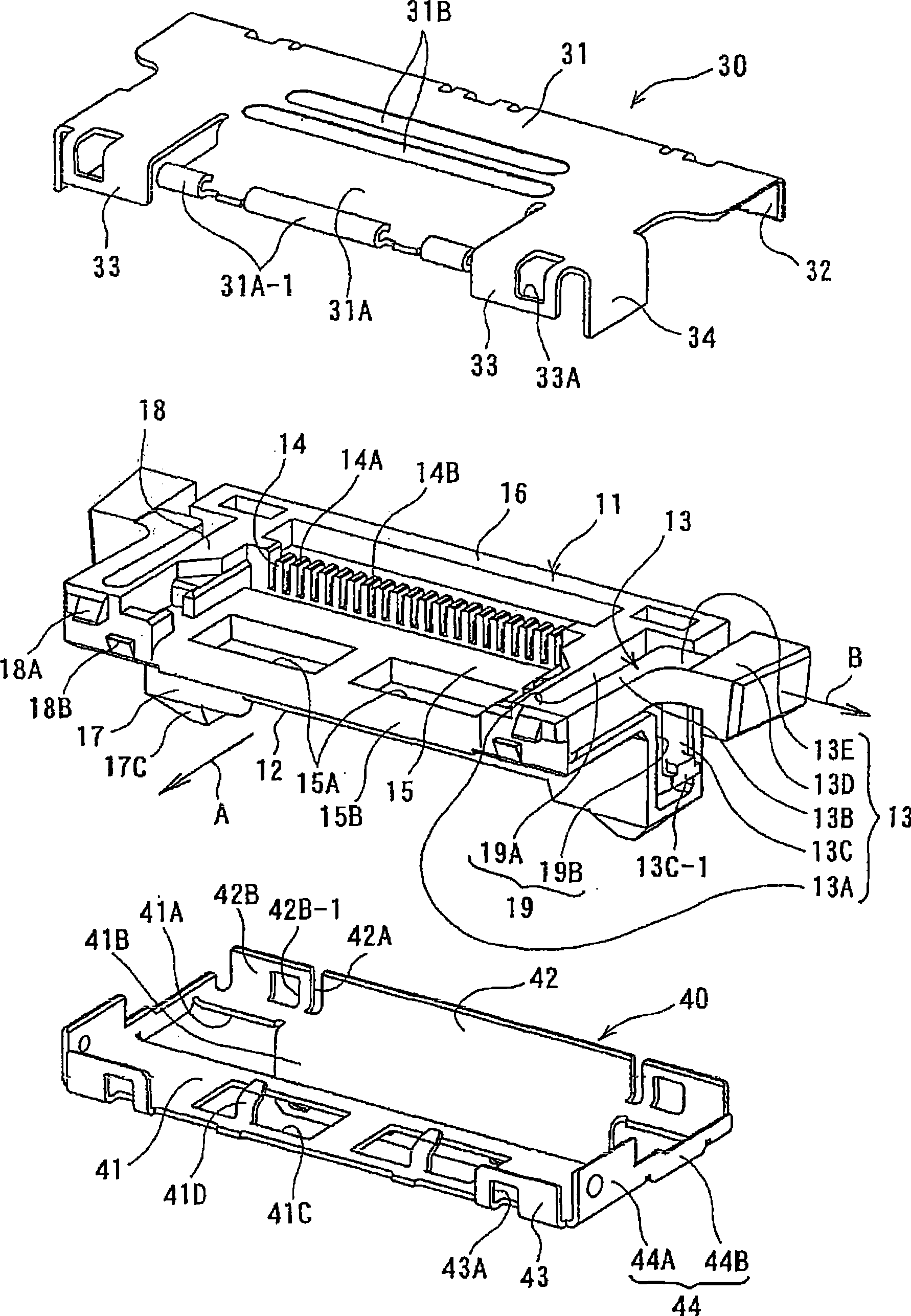

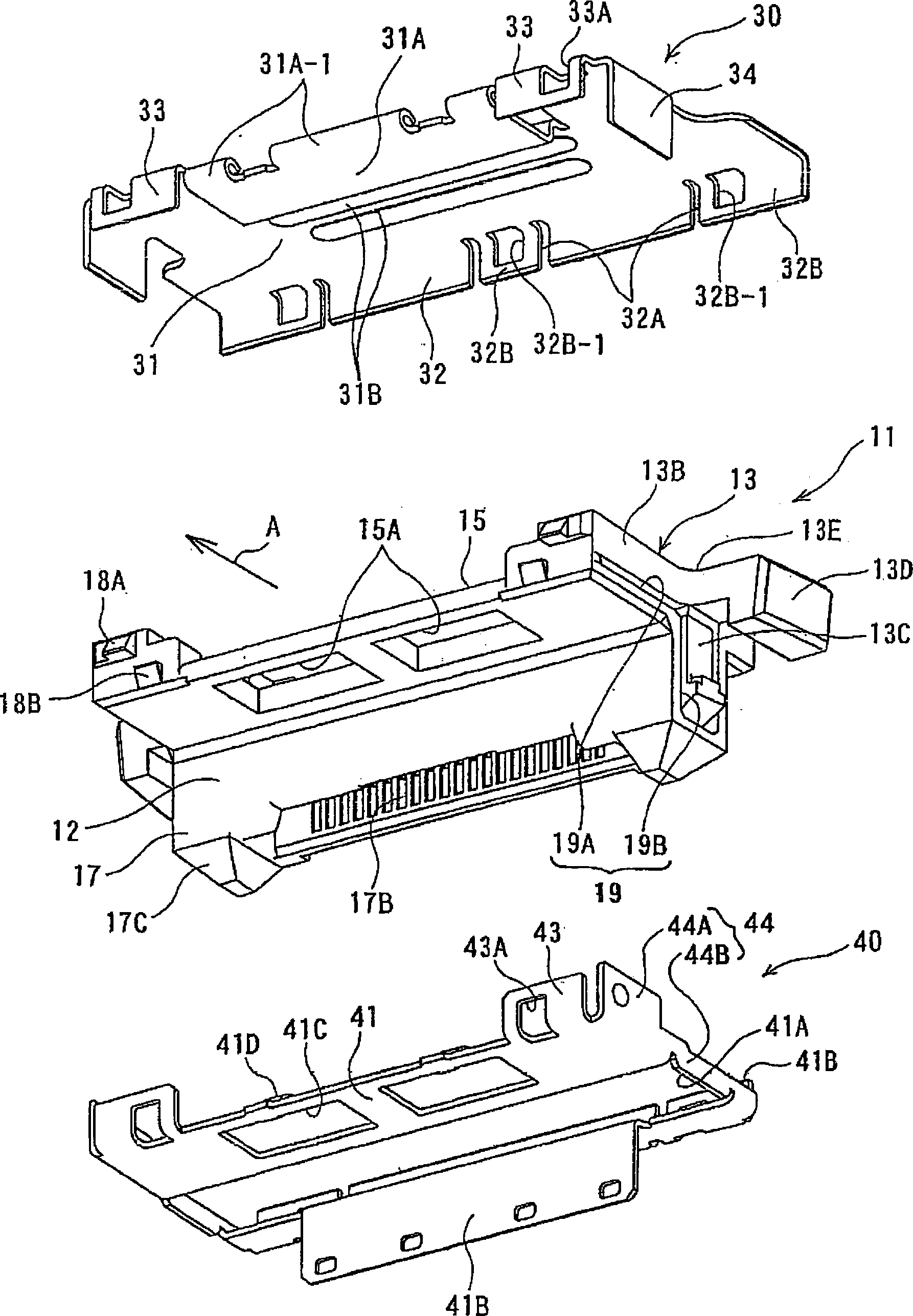

[0032] An embodiment of the present invention will be described below with reference to the drawings.

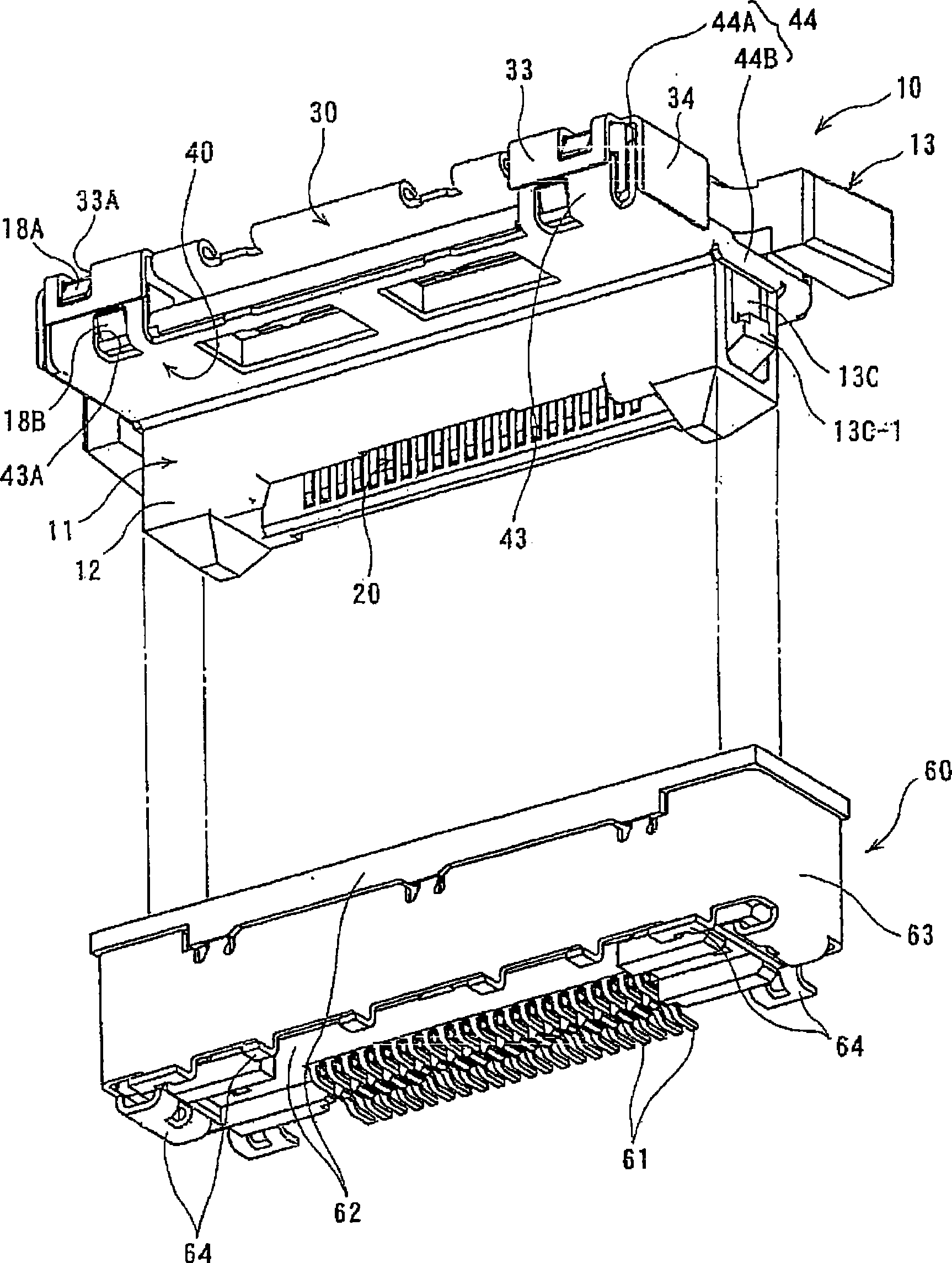

[0033] figure 1 It is a state before fitting the connector 10 of this embodiment and the mating connector 60, and is an overall perspective view seen from below. In this figure, the circuit board mounted at the bottom surface side of the object connector 60 is omitted.

[0034] On the object connector 60, an L-shaped connection portion 61 extending from the bottom surface of a plurality of terminals, when the object connector 60 is arranged on a circuit board (not shown), the connection portion 61 and the corresponding circuit of the circuit board welding. The object connector 60 is equipped with a metal case 63 for shielding on the peripheral surface of the housing 62 used to hold the above-mentioned terminals, and an L-shaped fixing foot 64 extends from the lower end of the metal case 63, and is fixed by welding. on the above circuit substrate. The mating connector 60 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com