Aluminium alloy large-sized superplastic gas bulging forming die

A technology for forming molds and aluminum alloys, which is applied in the direction of forming tools, manufacturing tools, metal processing equipment, etc., can solve the problem that the sealing structure cannot meet the sealing requirements of the forming process of large workpieces, and achieve continuous sealing and avoid gas leakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

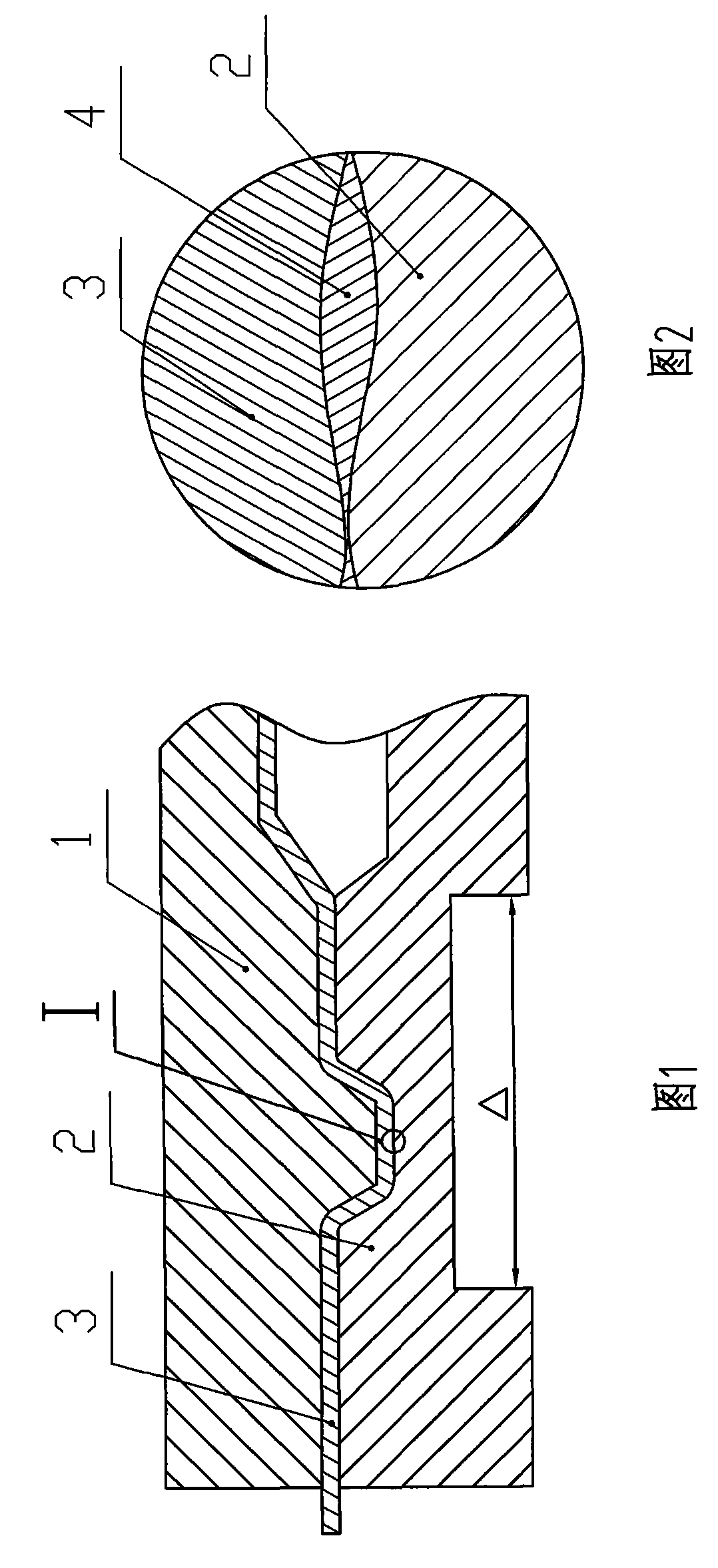

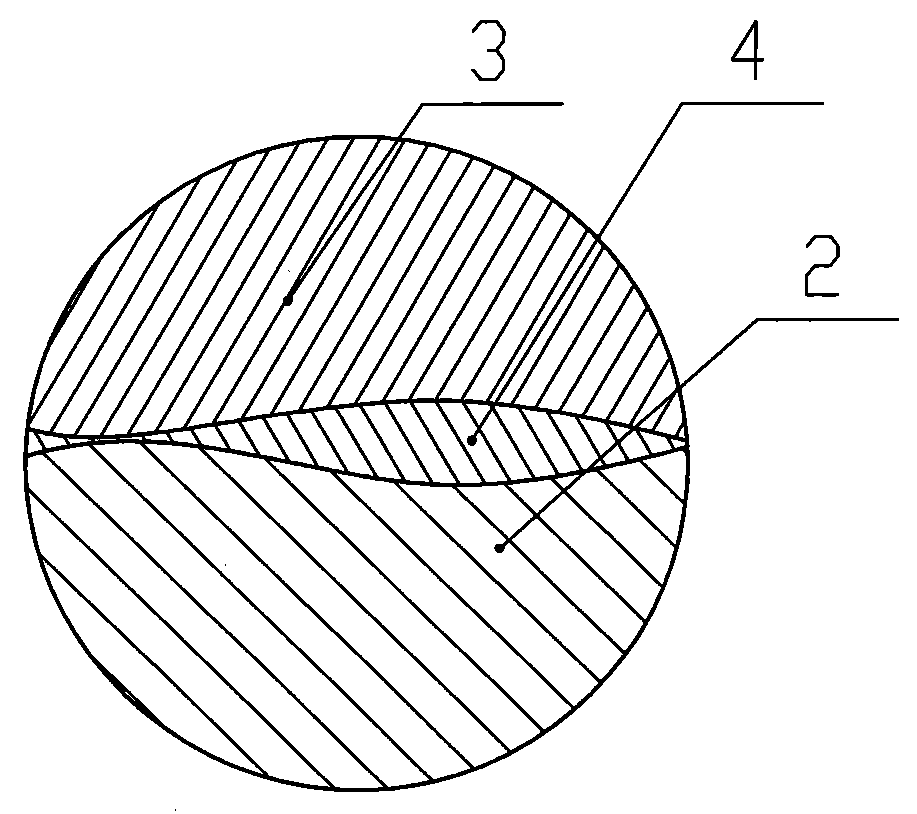

[0010] Such as figure 1 and 2 The embodiment of the aluminum alloy large-scale superplastic inflation forming mold shown in the present invention has movable mold 1 and static mold 2, is provided with one deck metal sealing layer 4 on the sealing surface of static mold 2, and this metal sealing layer 4 is in The workpiece is semi-solid during the forming process.

[0011] The trapezoidal mold sealing groove in the present embodiment, even if its structural design is ideal under the situation of processing, owing to being in the position of different size (x, y, z direction), affected by the high temperature zone, the rate of temperature rise (heat conduction) The situation is different, which affects the gap of the groove, so that the local pressure of the formed metal is different, especially in the Δ area, although the design tolerance requirement is small, but in the case of heating, a temperature change occurs, which increases the tolerance range of the gap. Since the me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com