Electromagnetic vibration pump with non-return ventilation valve

A vibrating pump and ventilation valve technology, which is applied to components of pumping devices for elastic fluids, pump elements, variable displacement pump components, etc., can solve problems such as inability to pump water, inability to overcome pressure, and insufficient self-priming capacity, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

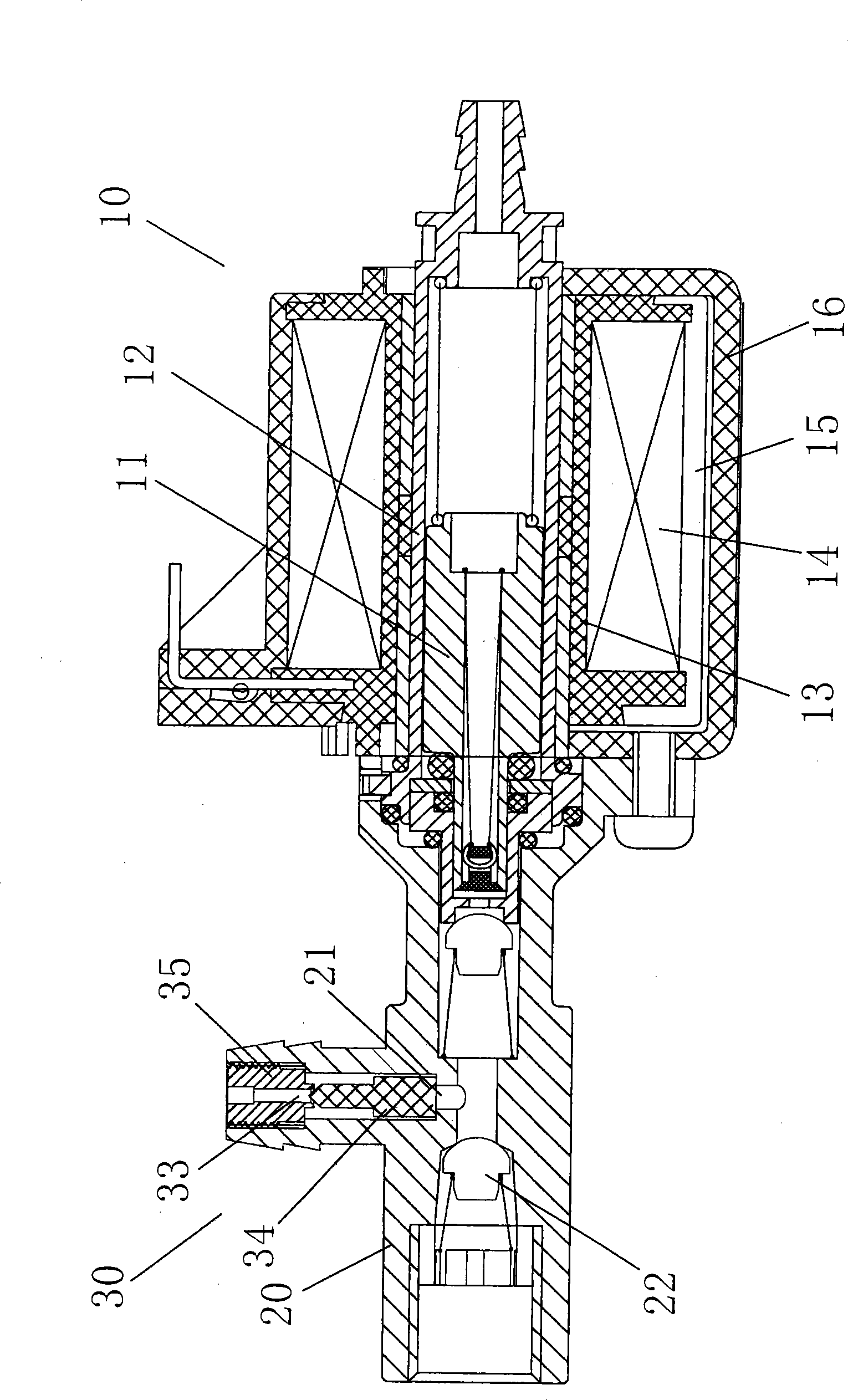

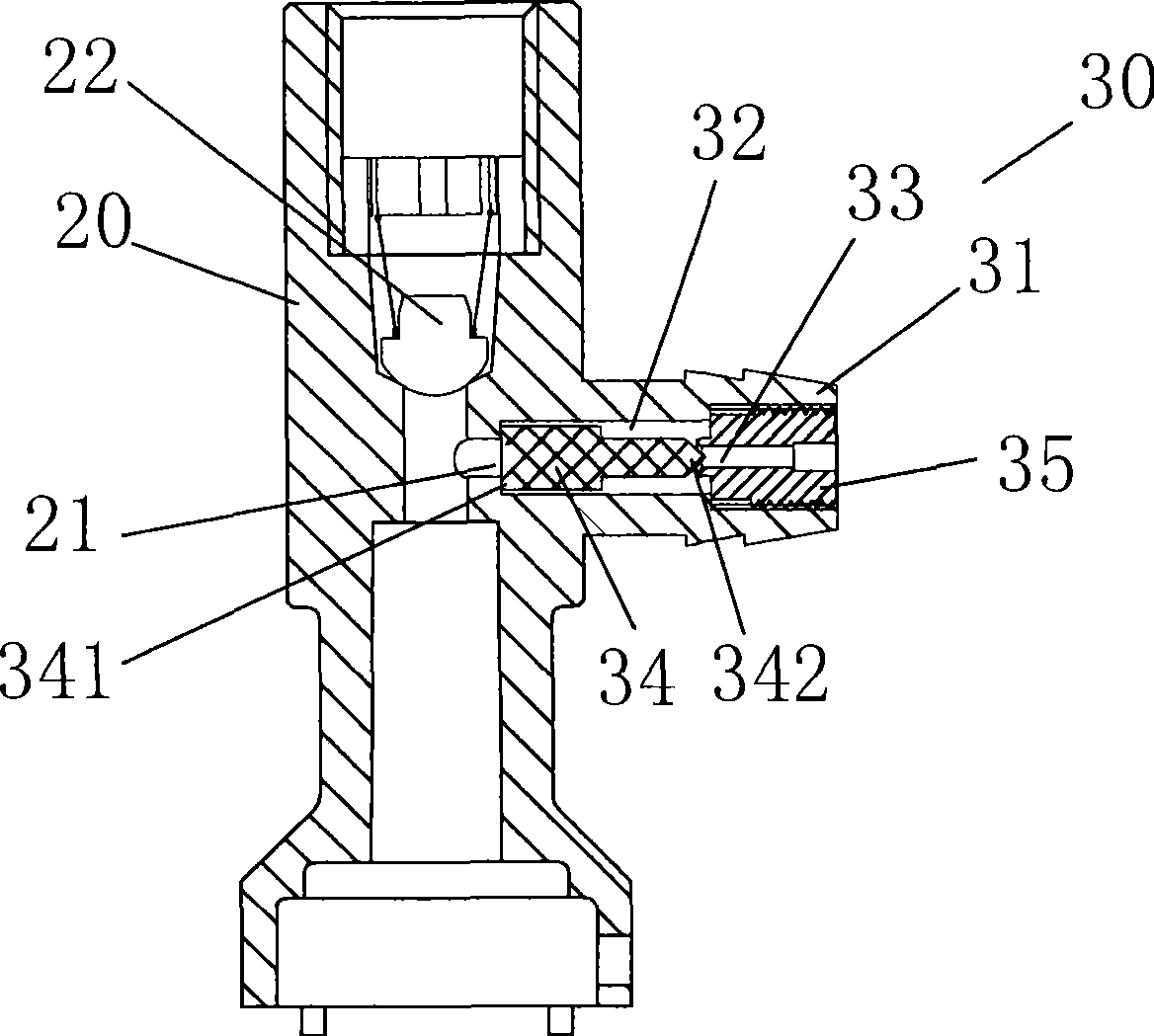

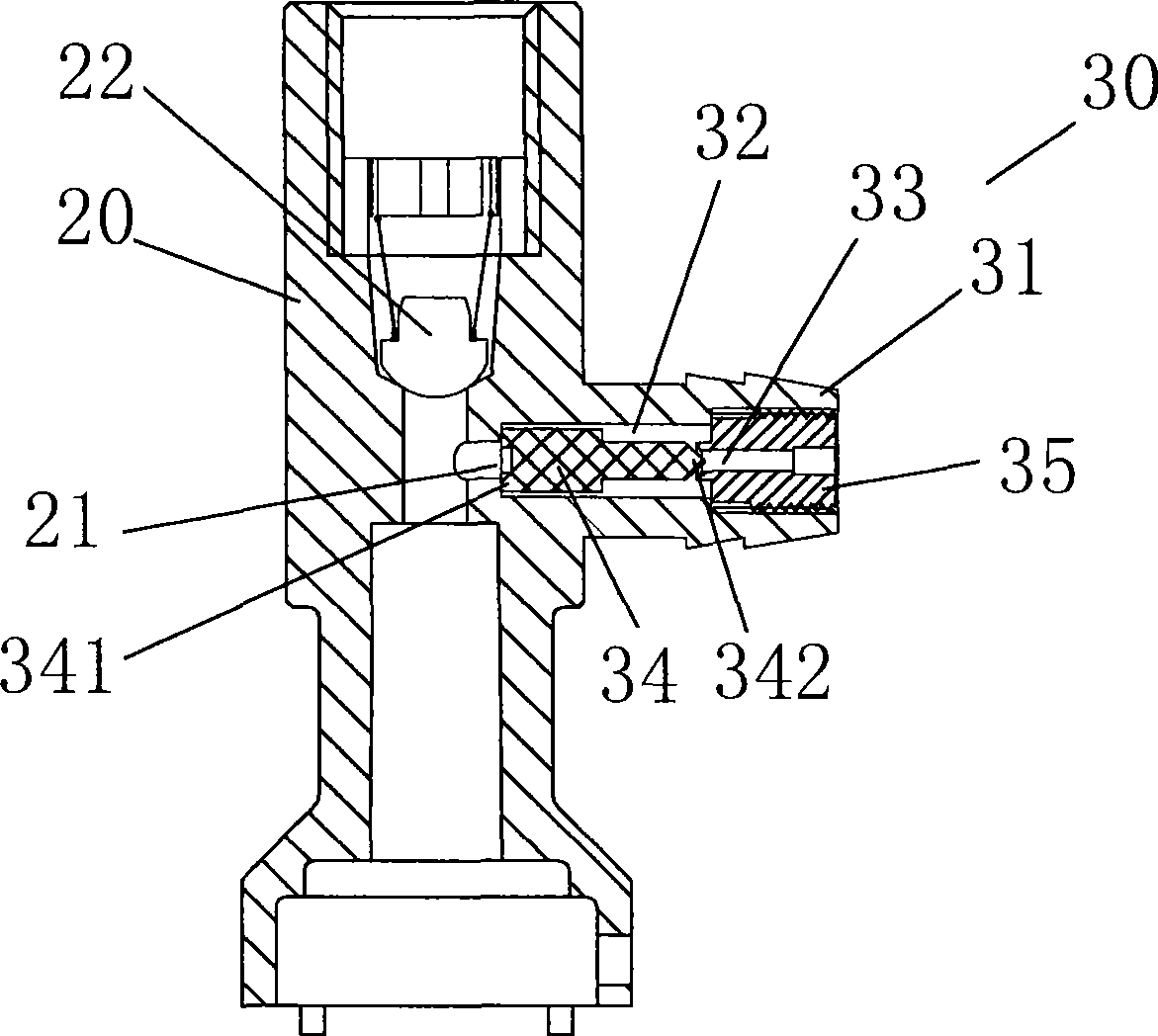

[0017] Such as figure 1 As shown, the present invention includes an electromagnetic vibration pump body 10, the water outlet end of the electromagnetic vibration pump body 10 is connected with a water outlet connection pipe 20, and a water outlet end position of the water outlet connection pipe 20 connected to a high-pressure device is provided to prevent high-pressure gas The backflow check valve 22 is provided with a vent valve 30 on the body of the water outlet connecting pipe 20, and the electromagnetic vibration pump body 10 is a pump body that vibrates by pumping water through electromagnetic action; the valve body 31 of the vent valve 30 There is a chamber 32, one end of the chamber 31 communicates with the lumen communication port 21 of the water outlet connecting pipe 20, and the other end of the chamber 32 communicates with the vent hole 33 communicating with the outside air, and the cross-sectional size of the vent hole 33 is smaller than that of the cavity. The siz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com