Leveling system of railway electrification working vehicle

A work vehicle and work platform technology, applied in the field of leveling systems, can solve the problems of instability of workpiece placement, difficulty in standing for construction workers, and deflection of the vehicle body and work platform, and achieves safe and convenient work, convenient work, and elimination of deflection. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

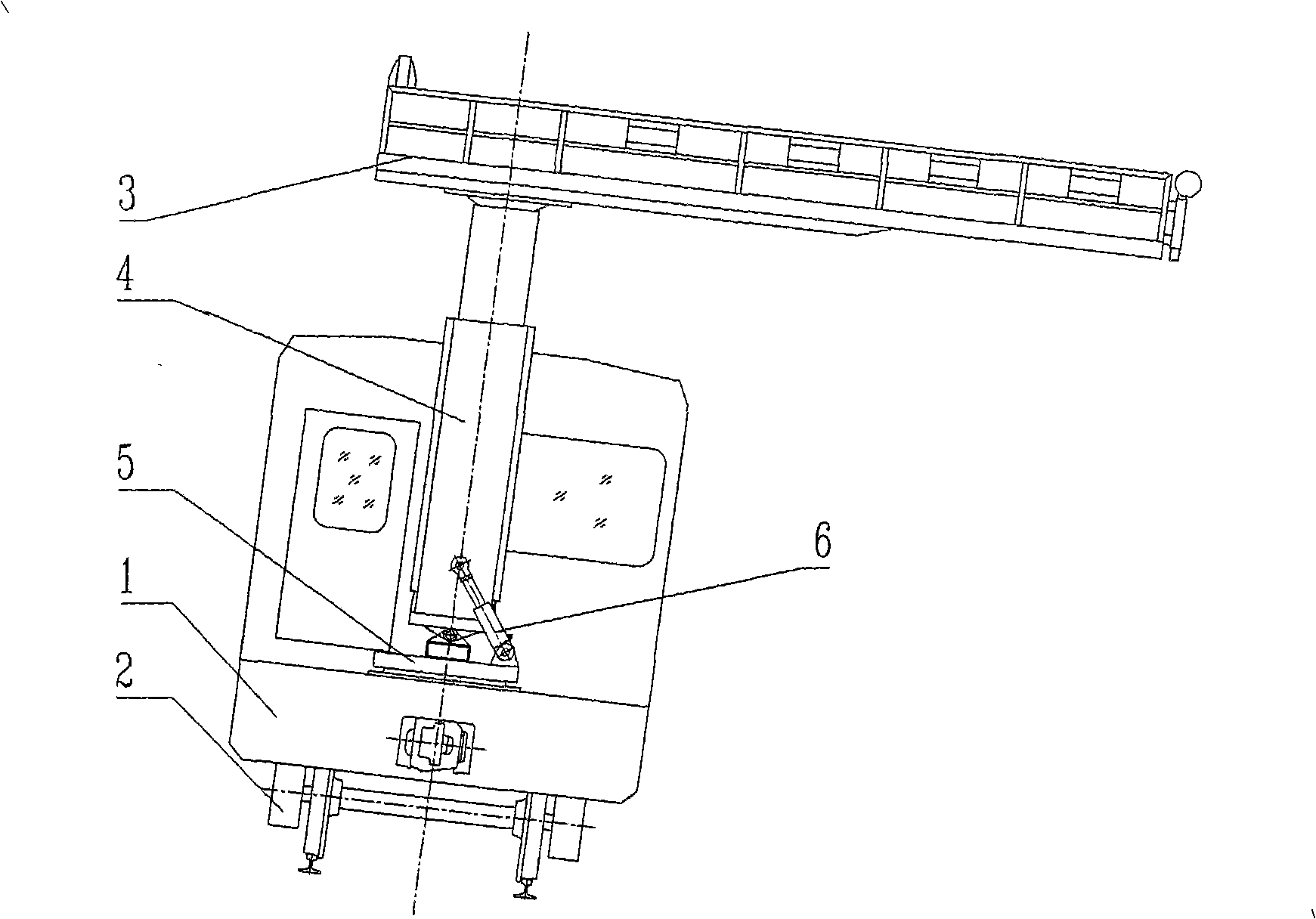

[0016] figure 1 Among them, (1) is the main frame, (2) is the bogie, (3) is the work platform, (4) is the lifting column, (5) is the slewing support, and (6) is the adjustable extension. The slewing support (5) is fixedly installed on the main vehicle frame (1), the operating platform (3) is fixedly installed with the lifting column (4), and the lifting column (4) and the slewing support (5) are hingedly installed and rotatable. Now the adjustable extension (6) is retracted, and the main frame (1), operating platform (3), lifting column (4), slewing support (5) remain in the tilted position together with the bogie (2).

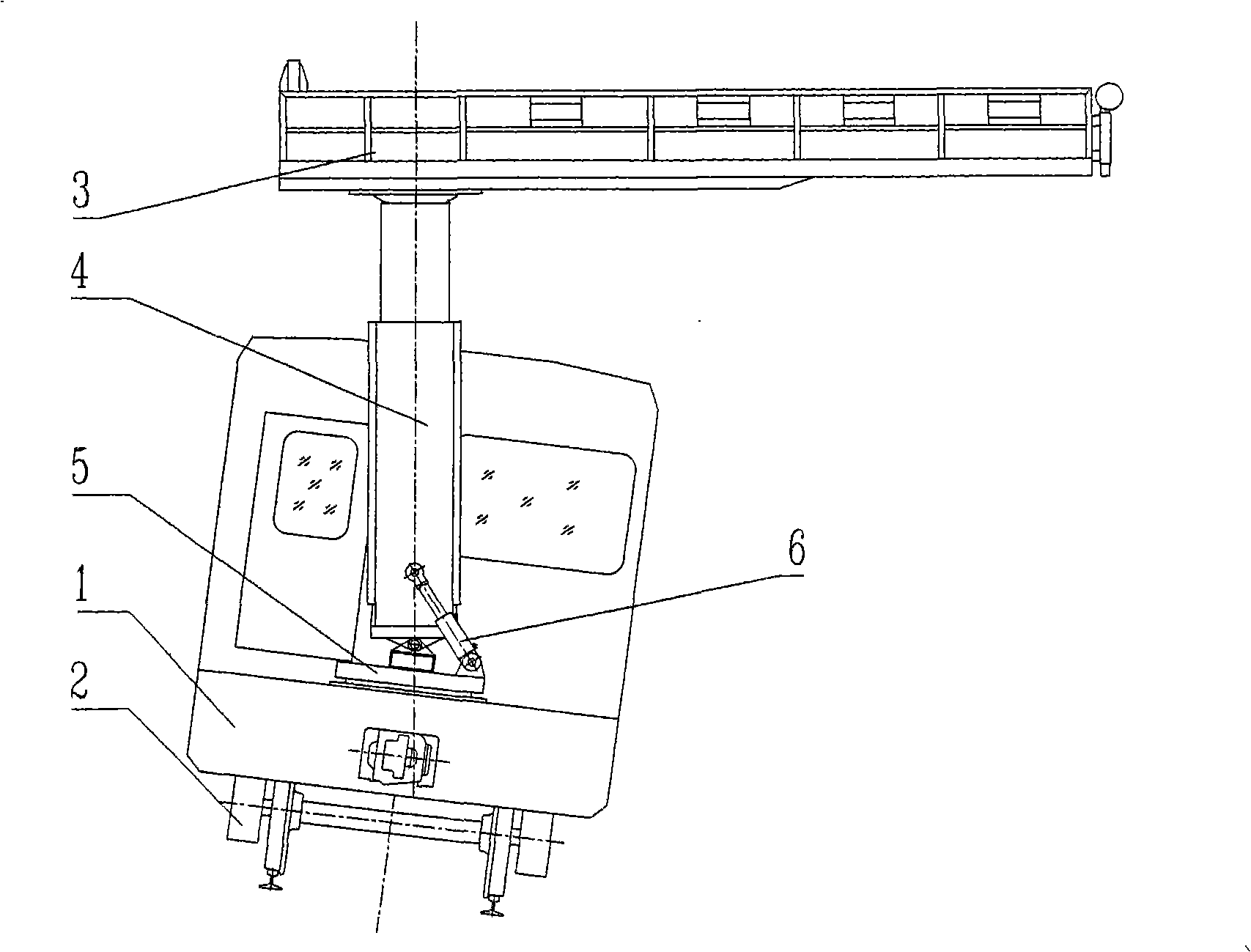

[0017] figure 2 At this time, the adjustable extension (6) is stretched out, the working platform (3) and the lifting column (4) are adjusted to the horizontal position, and the main frame (1), slewing support (5) and the bogie (2) are still maintained in inclined position.

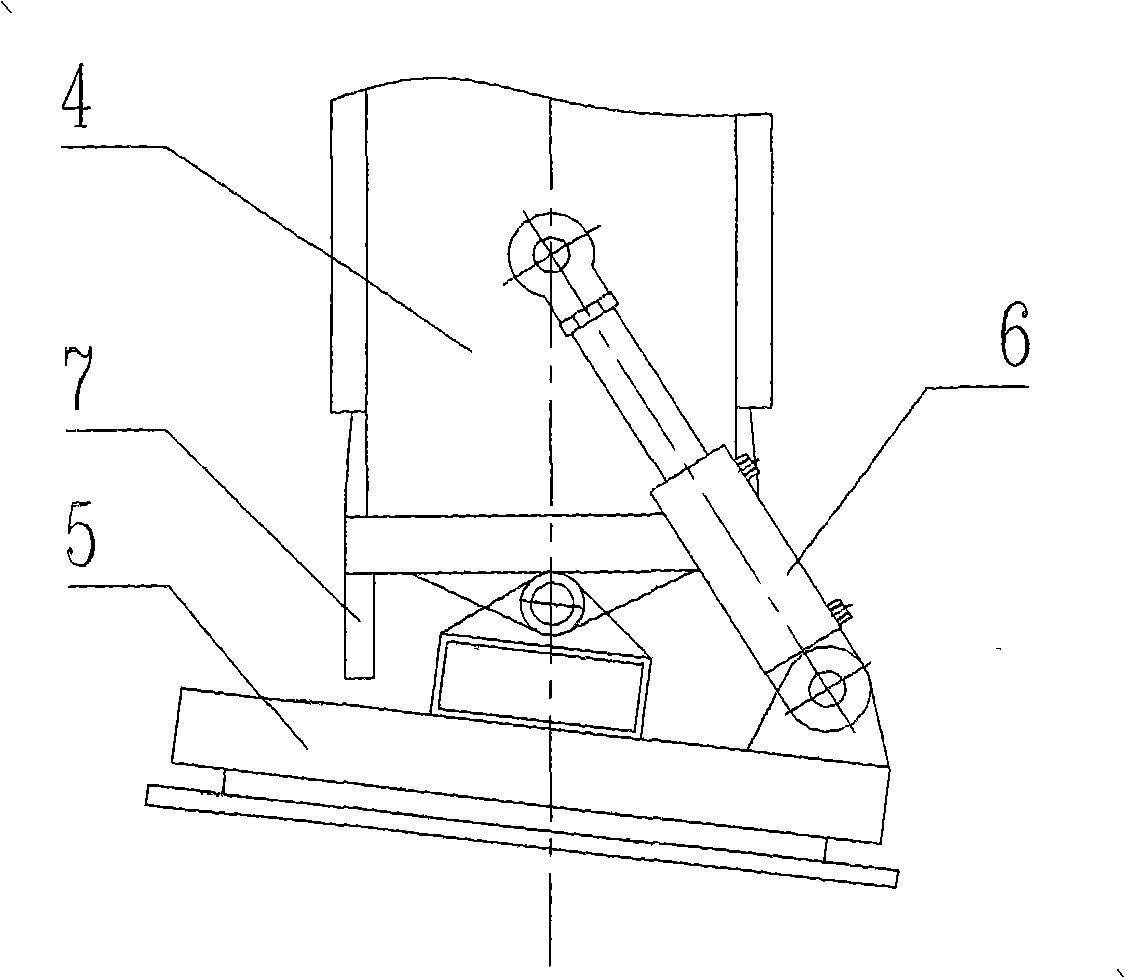

[0018] image 3 Among them, an adjustable extension (6) is installed between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com