with tensioner

A technology of tensioner and belt roll, which is applied in the direction of belt tensioner, etc., can solve the problems of increased gear wear, deformation of supporting position, deformation of belt tensioner or shell, etc., and achieves the effect of less power transmission and guaranteed loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

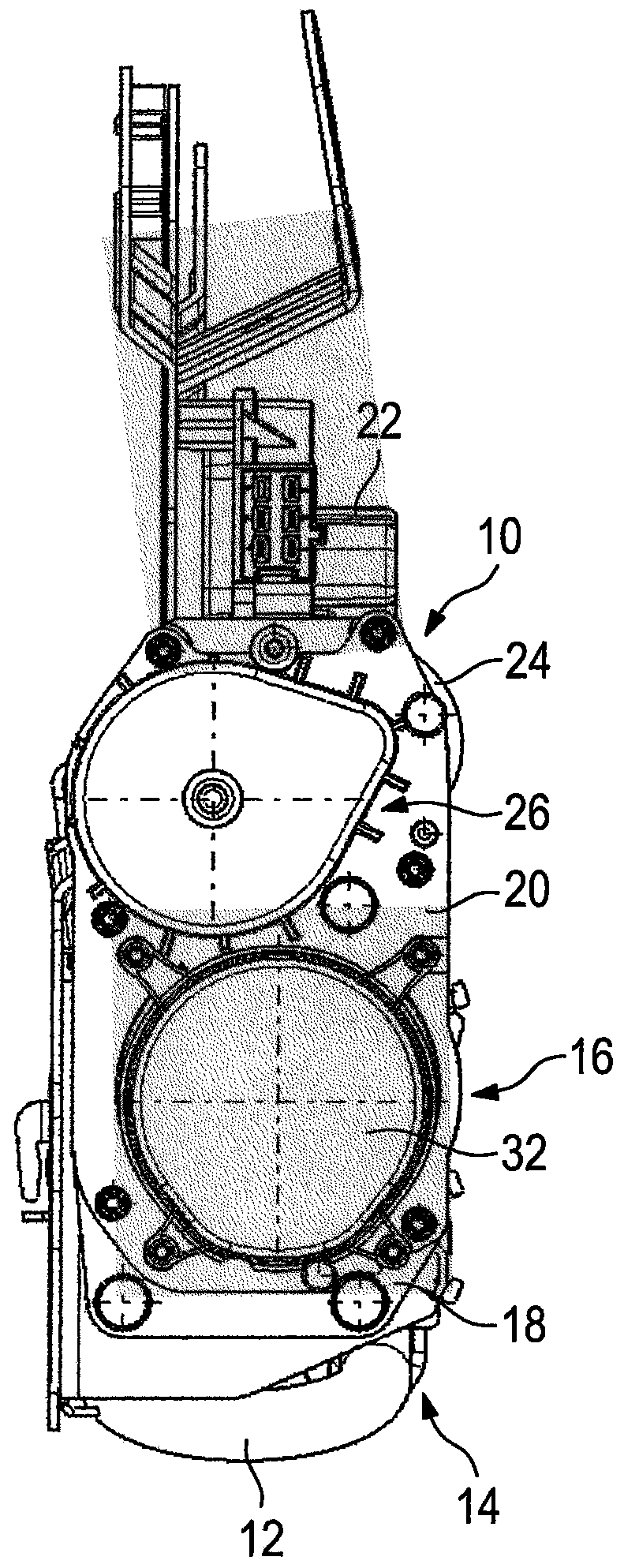

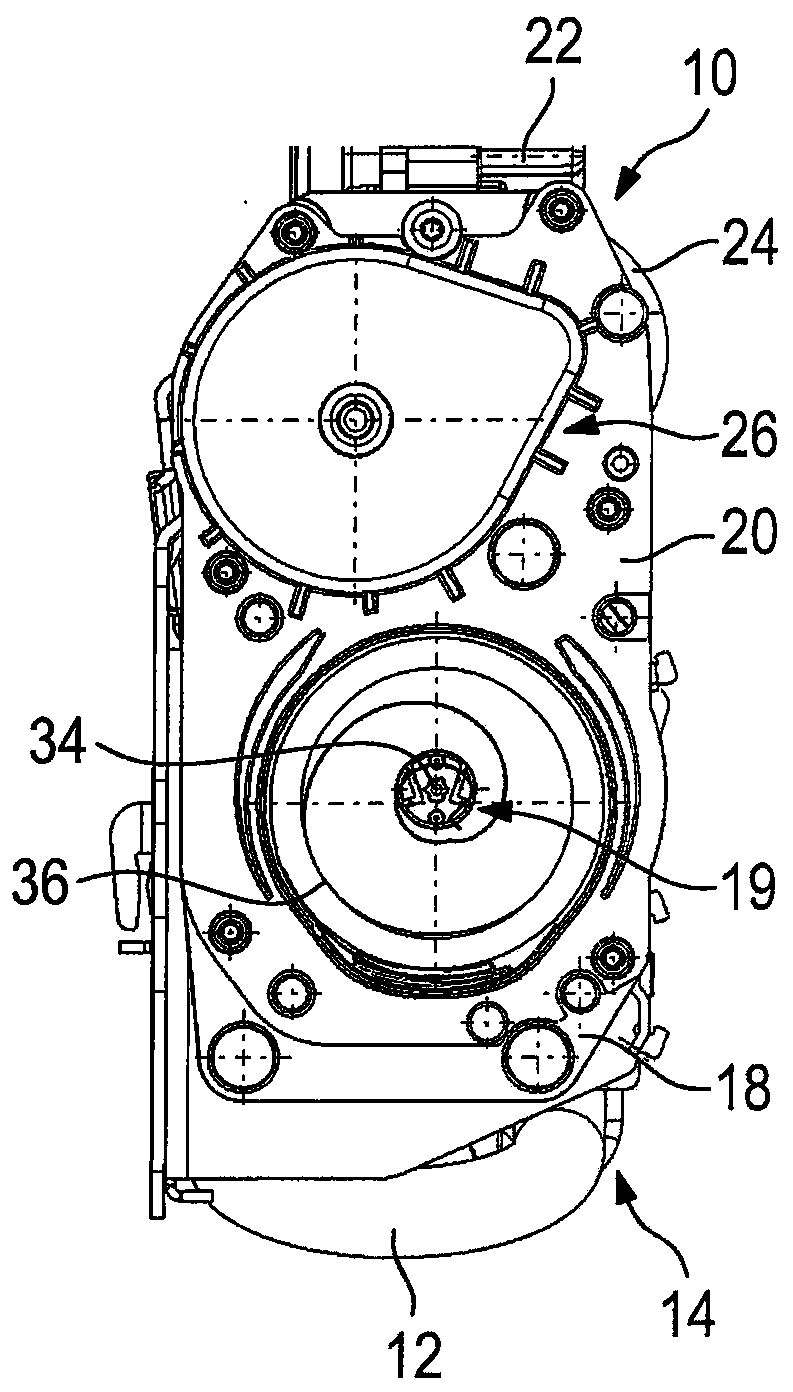

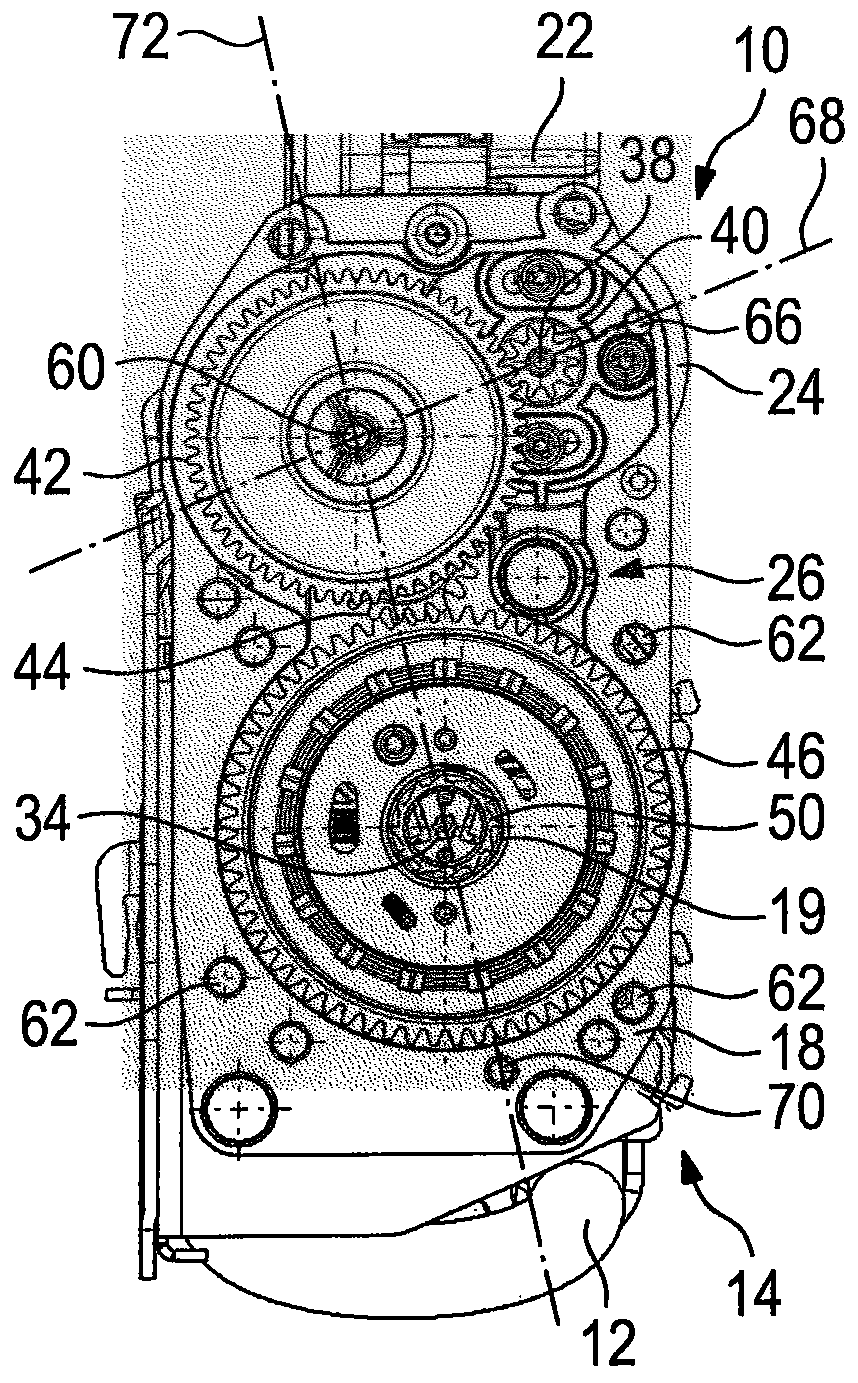

[0021] exist figure 1 A belt tensioner 10 in a vehicle safety belt is shown in . The belt tensioner 10 is mounted on a frame 12 of a belt retractor 14 in which a belt reel 16 is rotatably supported (see also image 3 ). In the tensioned situation, the belt tensioner 10 can exert a force acting in the winding direction A on the belt reel 16 , so that the safety belt can be wound on the belt reel 16 and the belt slack can be eliminated.

[0022] The belt tensioner 10 has a transmission housing 18 (see also figure 2 ), in which a receptacle 19 for the axial end 34 of the tape reel 16 is provided. An electronic control unit 22 , a drive motor 24 , a transmission 26 and a clutch 28 are also arranged in the transmission housing 18 .

[0023] as in figure 1 As can also be seen in the figure, a housing cover 20 and a cover 32 for the receptacle 19 of the tape reel 16 are provided on the transmission housing 18 .

[0024] as in figure 2 As can be seen in , the tape reel 16 pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com