Cap assembly having storage chamber for secondary material with movable working member

An auxiliary material and storage room technology, which is applied in the directions of caps with auxiliary devices, sealing parts with auxiliary devices, and parts of bottles/cans, etc., which can solve the problem that the neck is not suitable for containers, and achieve the effect of convenient drinking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0076] The operation examples of the present invention recommended according to the figures or accompanying drawings are as follows:

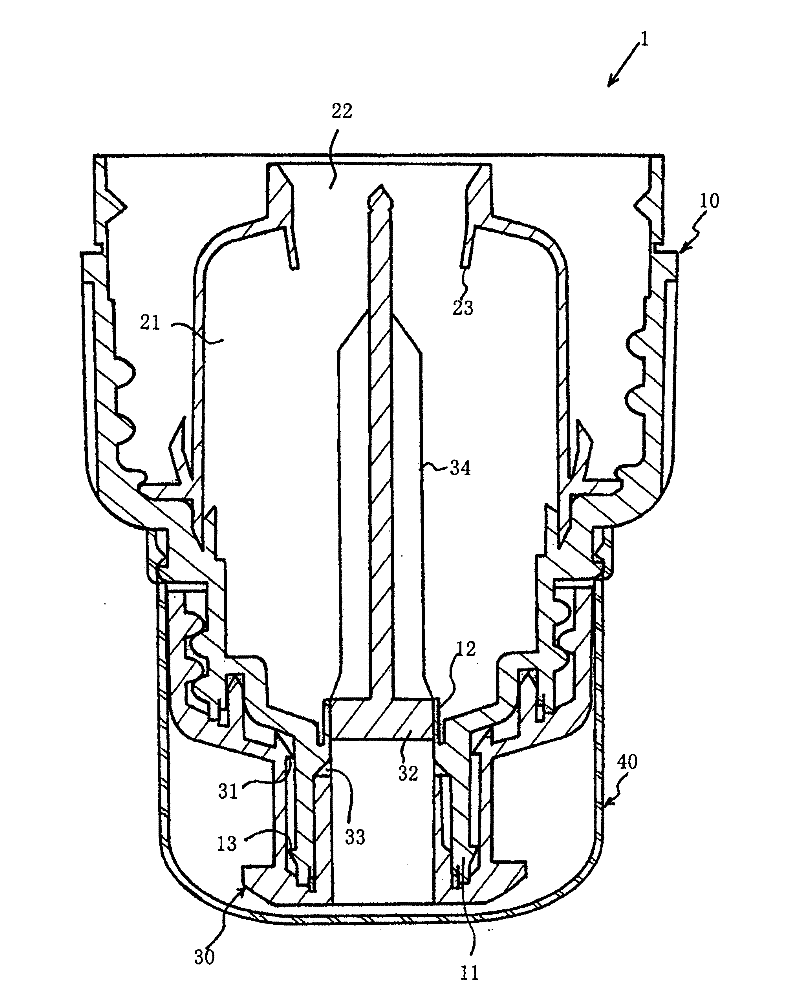

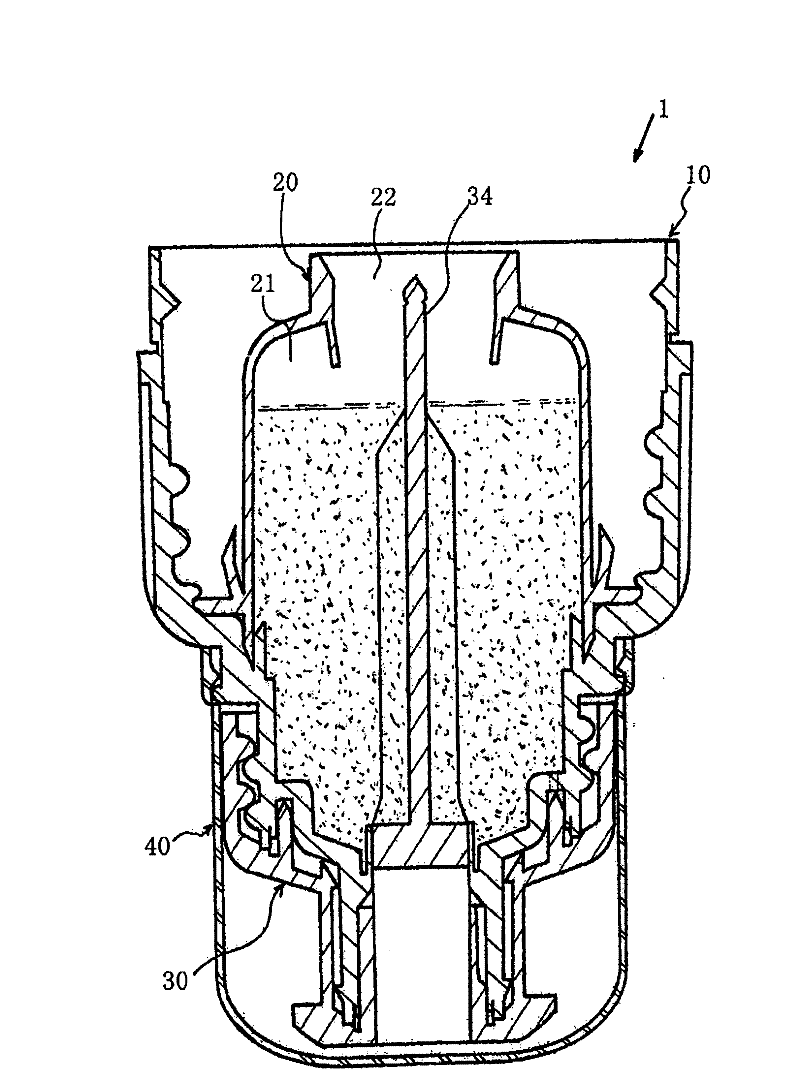

[0077] figure 1 An example of operation recommended by the present invention is shown. The reservoir (1) of the invention is integrated into the container by screws or one-touch method or adhesive. The reservoir (1) can be selectively detached from the container (100).

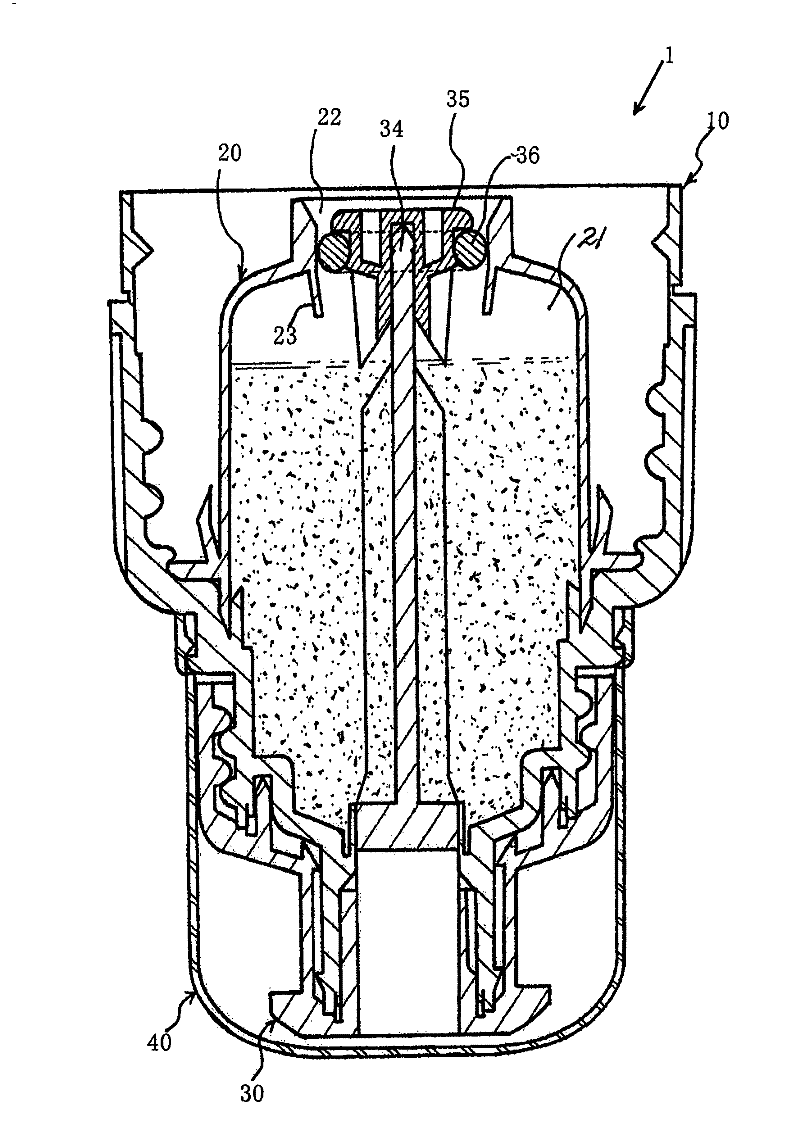

[0078] The receiving part (20) with the storage space (21) and the opening and closing holes (22) is fixed to the body (10) through the assembly process, and the spherical cover (11) and the closing part (12) are fixed to the body ( 10), and then assemble the operating part (30) that surrounds the spherical cover (11) and plays the role of closing the opening and closing hole (22) of the receiving part (20).

[0079] The operation part (30) is selectively opened and closed by turning or lifting on the dome cover (11). figure 1 Shows examples of recommended on and off when...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com