Control method of beam, light lump, light line, curve surface pattern ceramic brick polisher

A control method and surface pattern technology, applied in surface polishing machine tools, grinding/polishing equipment, manufacturing tools, etc., can solve problems such as low revolution and rotation speed, lack of flexibility, and inability to form gloss differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in further detail below in conjunction with accompanying drawing:

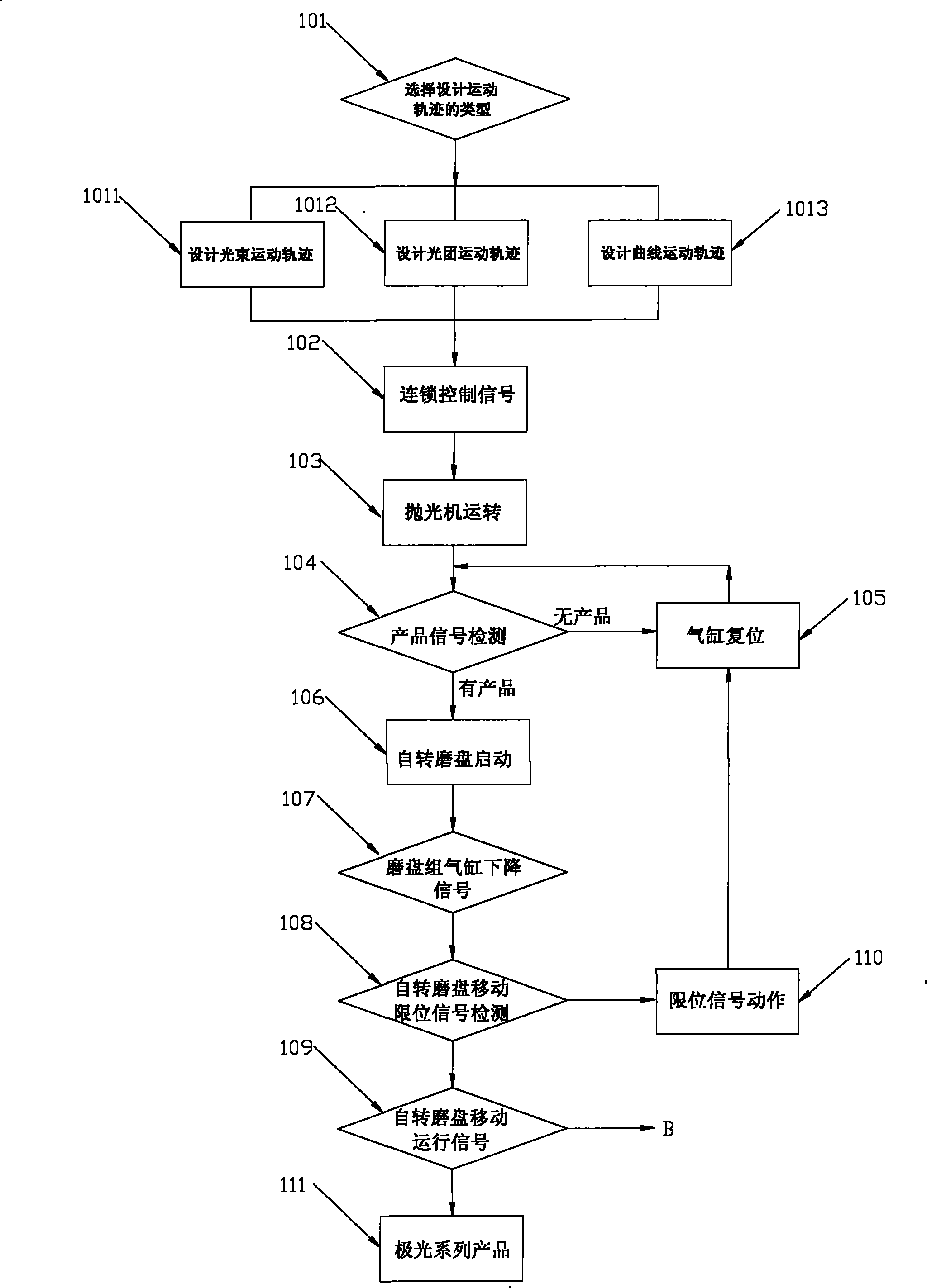

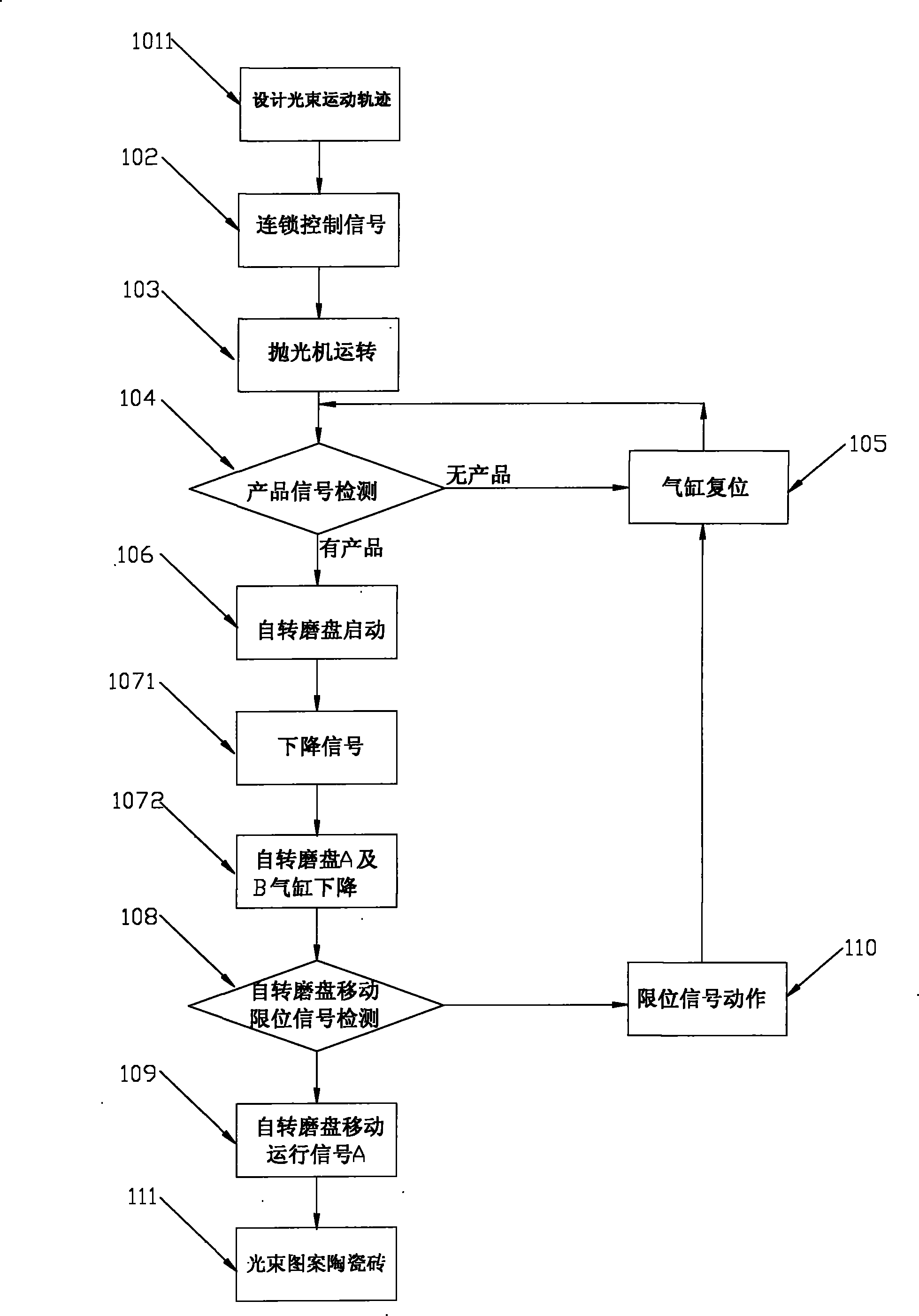

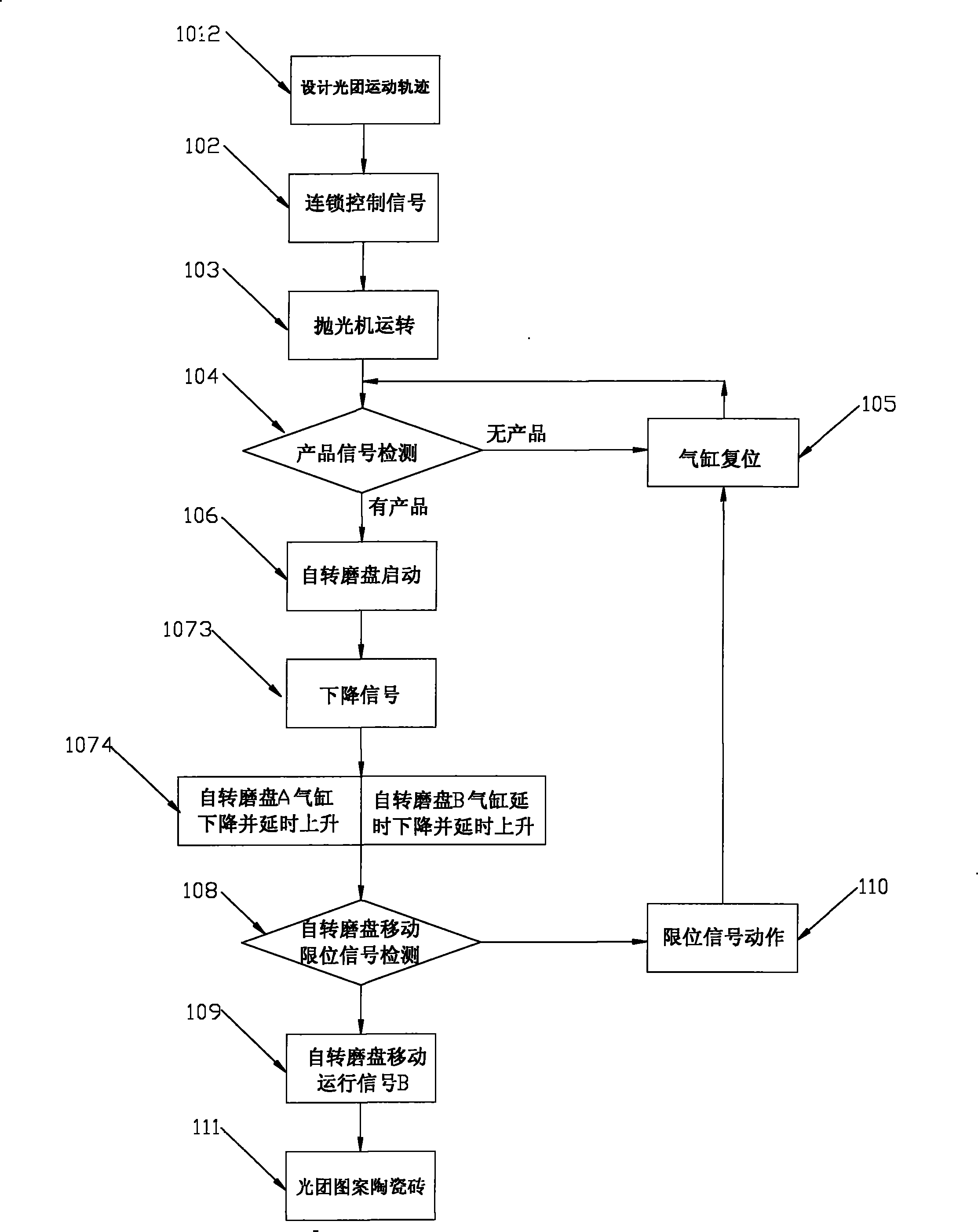

[0040] see figure 1 As shown, in this embodiment, the control method of the ceramic tile polishing machine that produces a natural aurora effect pattern on the surface includes the following steps:

[0041] (1) select the type of design motion track (step 101);

[0042] (2) Design beam trajectory (step 1011);

[0043] (3) Design light cluster motion trajectory (step 1012);

[0044] (4) design curve motion track (step 1013);

[0045] (5) chain control signal (step 102);

[0046] (6) polishing machine operation (step 103);

[0047] (7) Detect whether there is a product signal (step 104);

[0048] (8) If the detection result of step 104 is none, then through "cylinder reset" (step 105), return to step 104;

[0049] (9) if the detection result of step 104 is to have, then start the self-rotating grinding disc (step 106);

[0050] (10) Detect whether there is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com