Electric-controlled micro valve implemented by shape memory alloy

A technology of memory alloy and electronic control, which is applied in the direction of lifting valve, valve detail, multi-way valve, etc., can solve the problems of difficult modification and complex structure, and achieve the effect of small size, reduced volume and weight, and easy manufacturing and production

Inactive Publication Date: 2010-12-01

TONGJI UNIV

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, this traditional valve is difficult to meet these needs because of its precise structure and complex structure, and it is not easy to be refitted.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

specific Embodiment approach 1

specific Embodiment approach 2

Embodiment approach

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

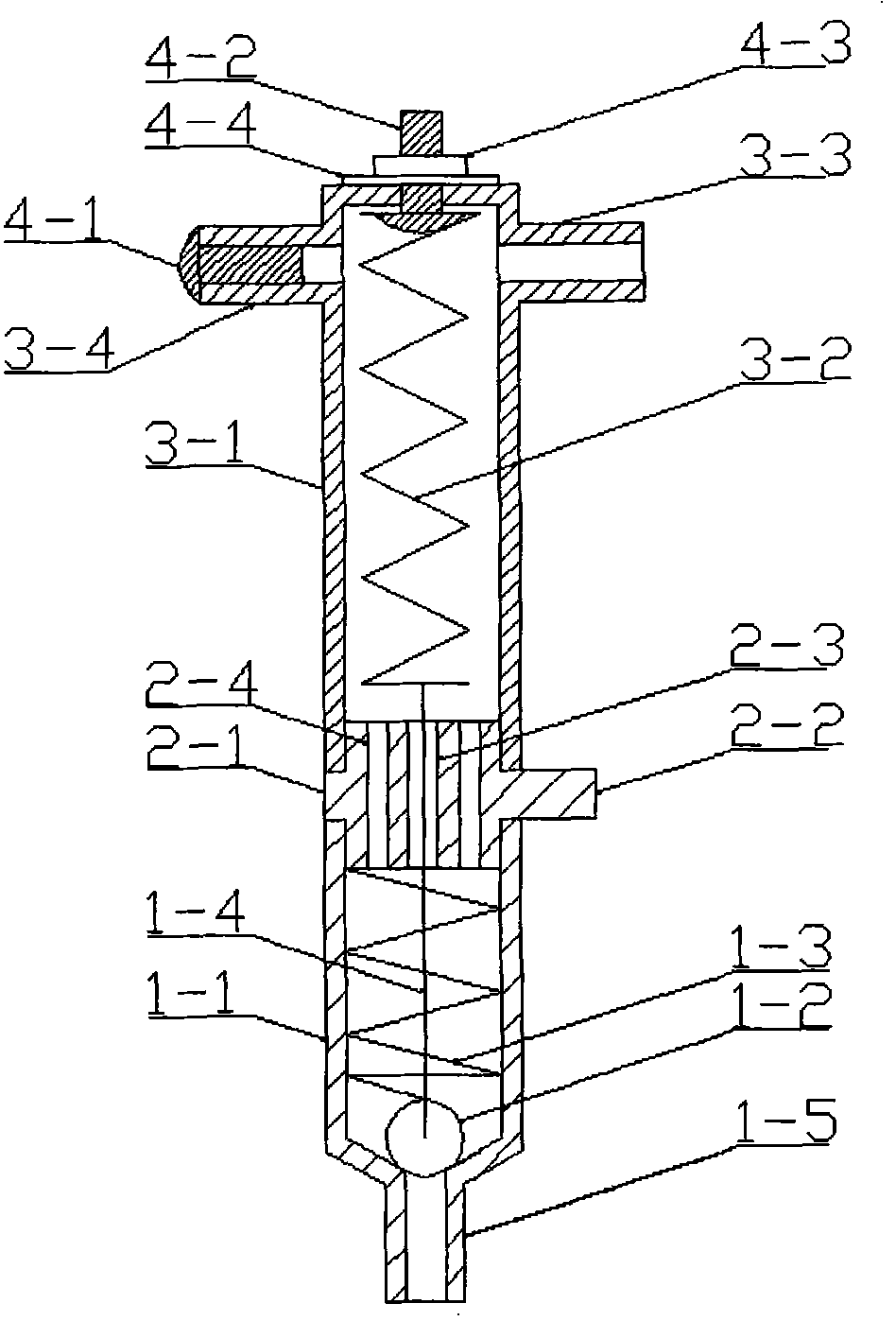

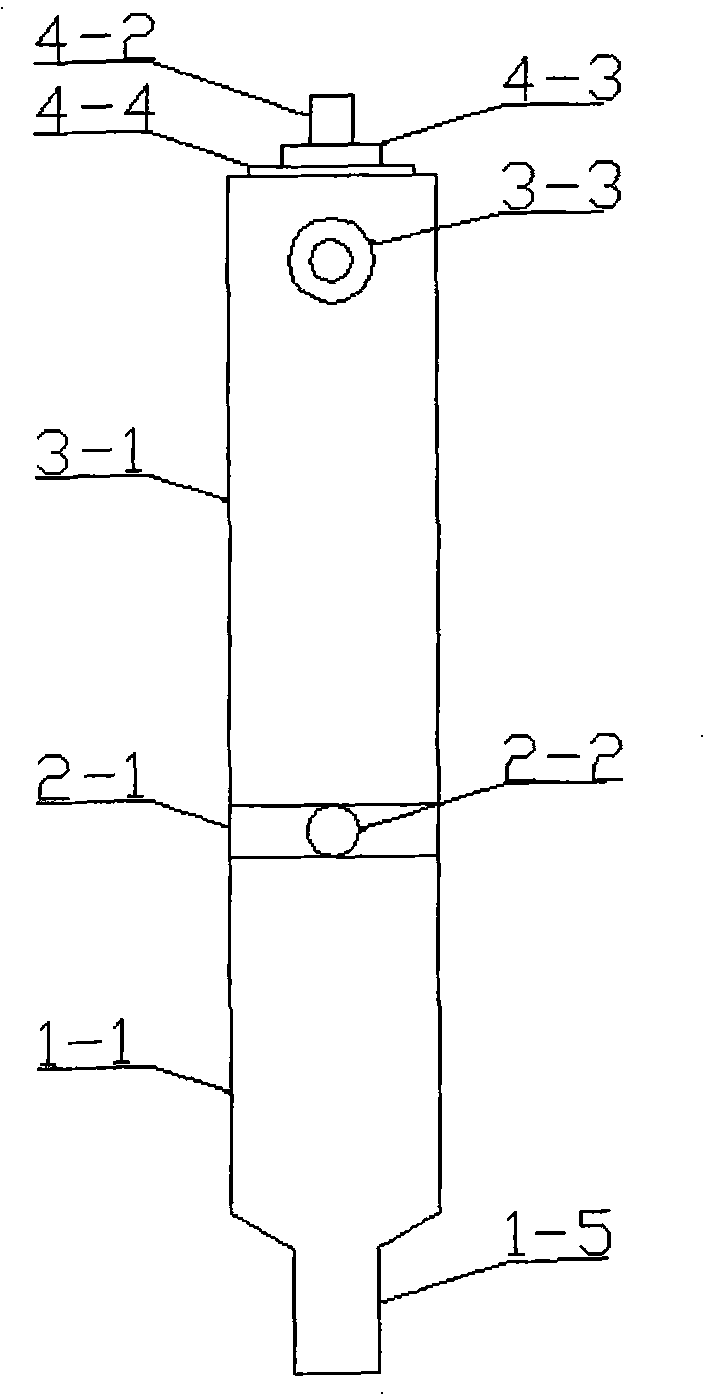

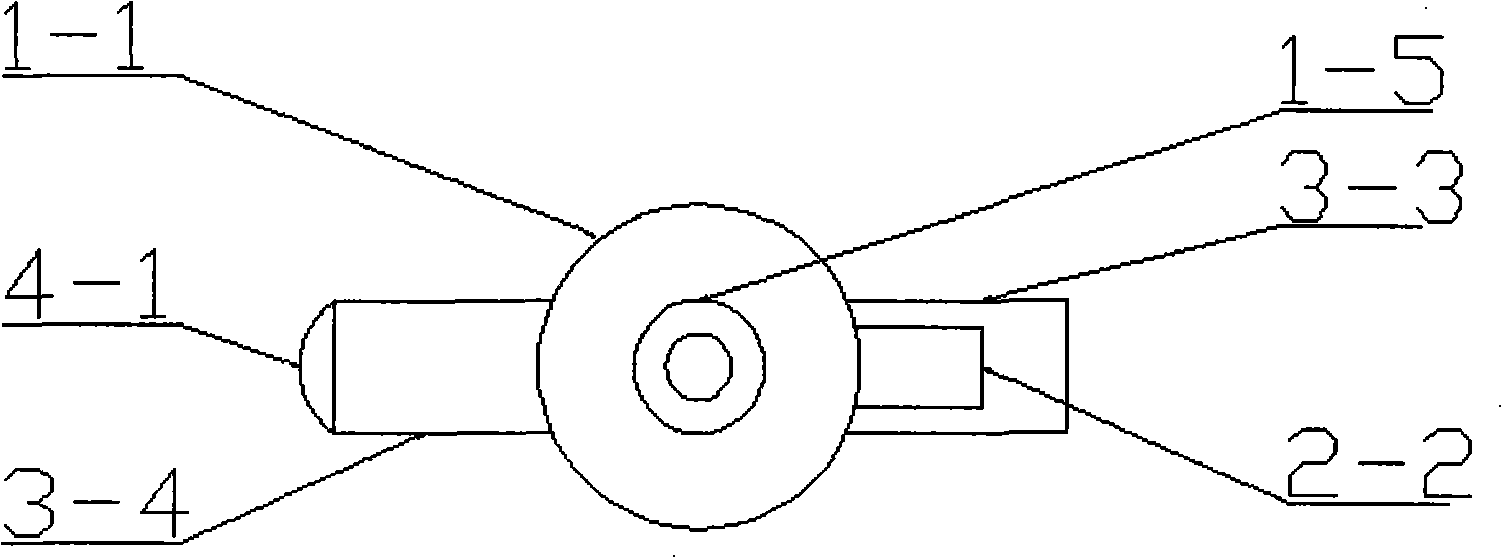

Login to View More Abstract

An electronic control micro valve realized by shape memory alloy comprises a liquid inlet tube, a spacer layer, a sparge pipe, a shape memory alloy drive, a linkage piece, a valve ball and a bias pressure spring; wherein, the liquid inlet tube and the sparge pipe are connected by being respectively connected and fixed with the spacer layer; the valve ball is positioned in the sparge pipe and is over against a jet pipe; one side of the valve ball far away from the jet pipe is connected with the linkage piece; the other end of the linkage piece is connected with the shape memory alloy drive by passing through the spacer layer; the other end of the shape memory alloy drive is fixed at the top of the liquid inlet tube; one end of the bias pressure spring is against the spacer layer and the other end thereof is connected with the valve ball; under certain pressure state, the bias pressure spring presses the valve ball against the jet pipe to cause the jet pipe to close; the electric energycontrols the shape memory alloy drive to act to drive the valve ball to further open and close the valve. The micro valve has low manufacturing cost, small volume, light weight, simple structure and simple and convenient assembly and disassembly and is easily suitable for certain specific industry and agriculture and life automation requirements by improving structures.

Description

Electronically Controlled Micro-valve Realized by Shape Memory Alloy technical field The invention relates to a controllable valve element device, in particular to an electric energy control valve realized by shape memory alloy. Background technique Traditional micro valves are usually controlled electromagnetically. This kind of micro-valve realizes the opening and closing of the valve through the magnetic force generated by the electromagnetic coil to drive the valve core and the clutch valve port. Usually this kind of valve has high cost, small flow coefficient, and is easily damaged by voltage shock. Moreover, its control voltage is usually 12V or 24V and above, which is not suitable for some applications that require a lower voltage drive. In addition, in some practical application scenarios, it is necessary to use the valve for some specific signal output to precisely control the flow of water to meet the needs of automatic control. However, this traditional valve...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): F16K1/14F16K31/64F16K11/044

Inventor 何斌刘振黎明和

Owner TONGJI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com