Manifold system for the ventilated storage of high level waste and a method of using the same to store high level waste in a below-grade environment

一种高放废物、通风系统的技术,应用在加防护的小室、核工程解决方案、轻便的防护容器等方向,能够解决笨重等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

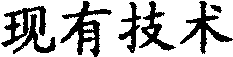

[0041] See first figure 2 , The figure shows a manifold storage system 100 according to an embodiment of the present invention. Such as figure 2 As shown, the manifold storage system 100 is taken out of the ground. However, as will be described in detail below, the manifold storage system 100 is specifically designed to achieve dry storage of multiple sealed waste tanks containing spent nuclear fuel in an underground environment.

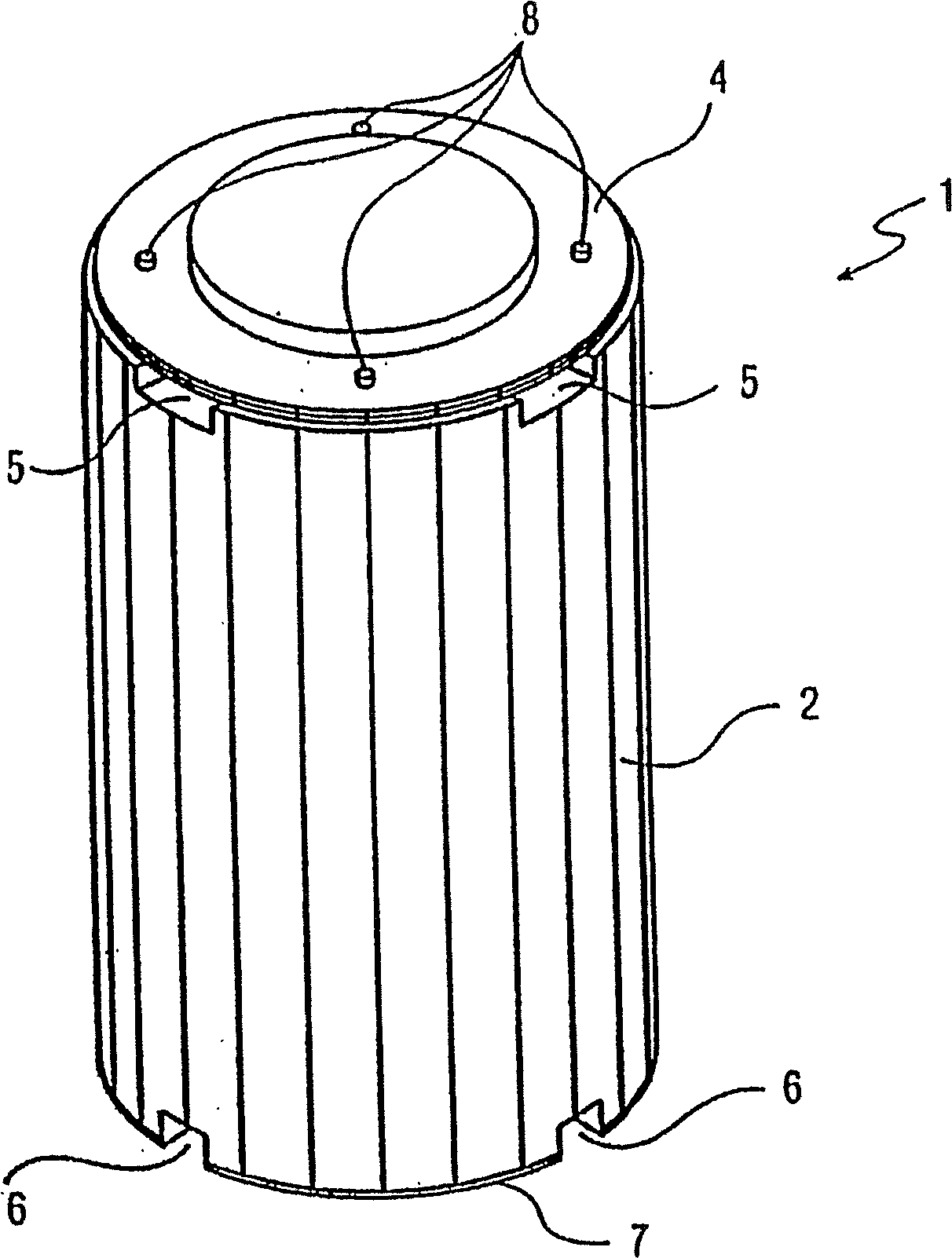

[0042] The manifold storage system 100 is a vertical, ventilated, dry spent fuel storage system, which is fully compatible with 100-ton and 125-ton transfer shielded tanks used for spent fuel waste tank transfer operations. The manifold storage system 100 can be modified / designed to be compatible with transfer shielding tanks of any size or form. The manifold storage system 100 is designed to replace an on-ground packaging structure (e.g. figure 1 The Independent Spent Fuel Storage Installation ("ISFSI") of the prior art (VVO1) shown in the prior art...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com