Rotary cutting method of foaming sponge

A foaming sponge and sponge technology, applied in the direction of shearing devices, shearing machine control devices, metal processing equipment, etc., can solve problems such as poor index values, large fluctuations in physical properties, and large differences in the structure of sponge longitudinal pores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

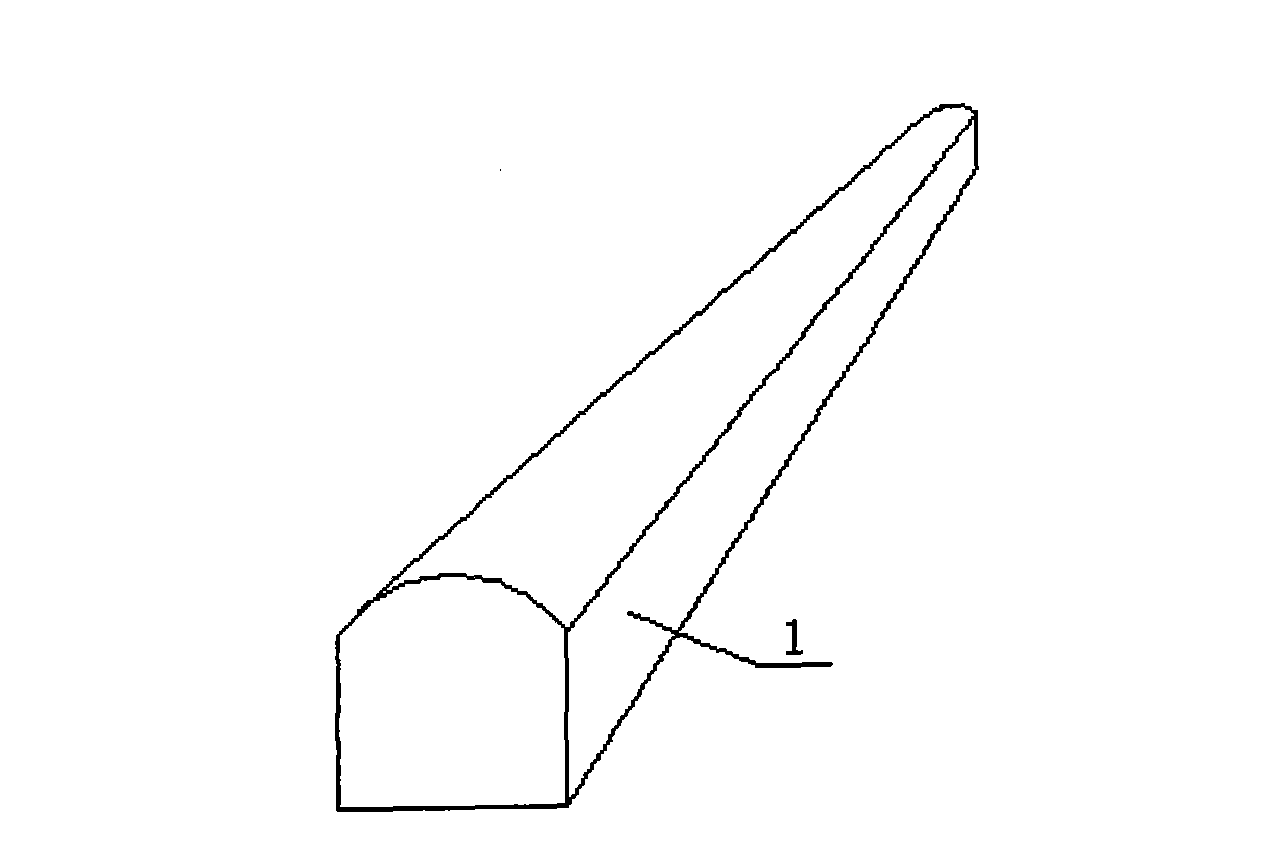

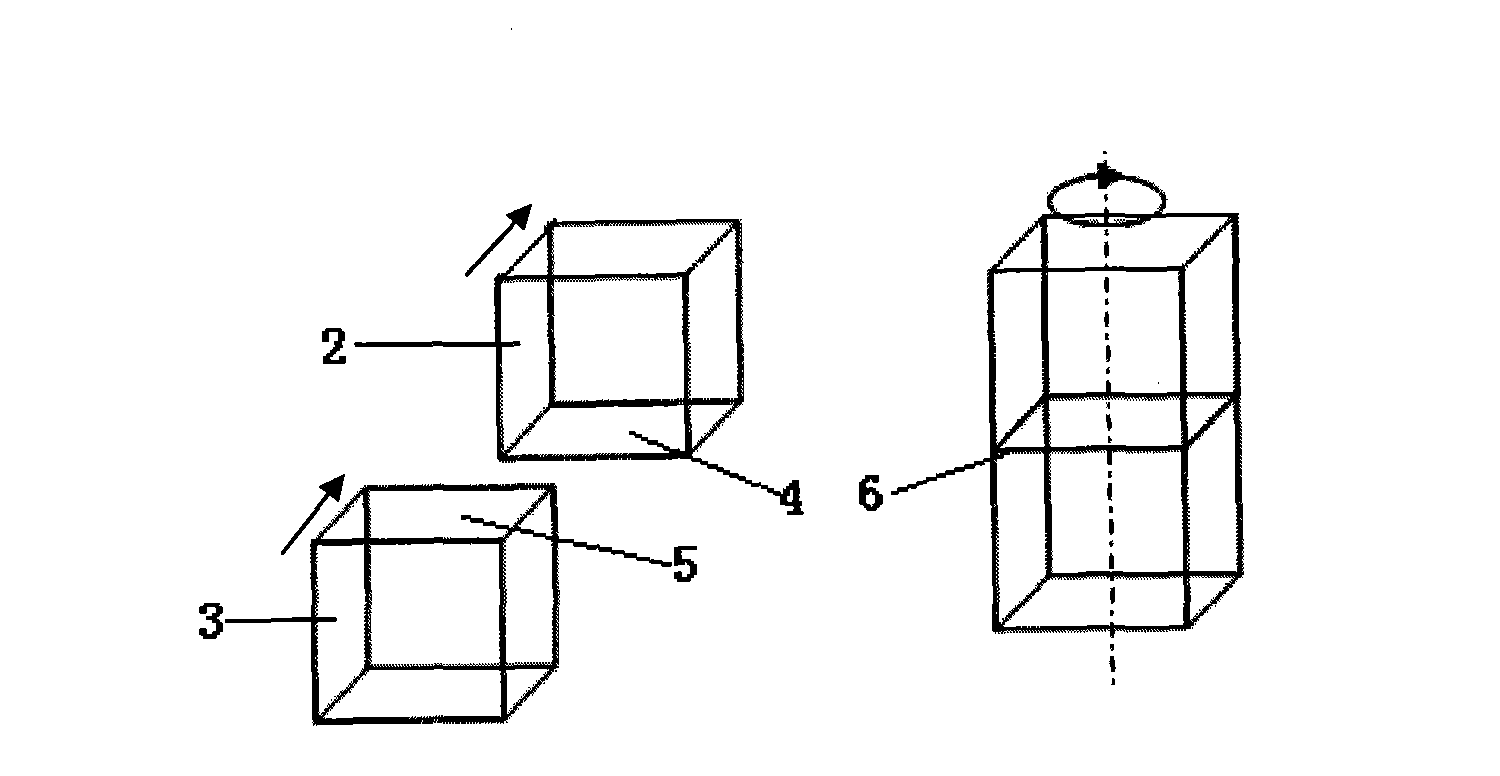

[0013] Refer to figure 1 , (1) Cut the top and bottom of the sponge body 1 to a thickness of 20cm; (2) Cut at least 2 pieces of the sponge body with the top and bottom away along the direction of movement of the foam body (Note: figure 1 The straight arrow in the middle indicates the direction of movement of the foam body) The vertical upper and lower surfaces are bonded, see the bonding process figure 2 , The bonding interface 6, is formed by the bottom surface 4 of one foam body 2 on the top surface 5 of the other foam body 3; (3) along the vertical axis ( figure 2 The dotted line shows the upper and lower axis) parallel to the direction of the rotary cut into a sheet of sponge ( figure 2 The direction of the middle rotating arrow indicates the direction of rotary cutting, and the straight arrow indicates the direction of bubble movement, that is, the upper and lower axis perpendicular to the direction of bubble movement is the central axis of rotary cutting).

[0014] Perf...

Embodiment 2

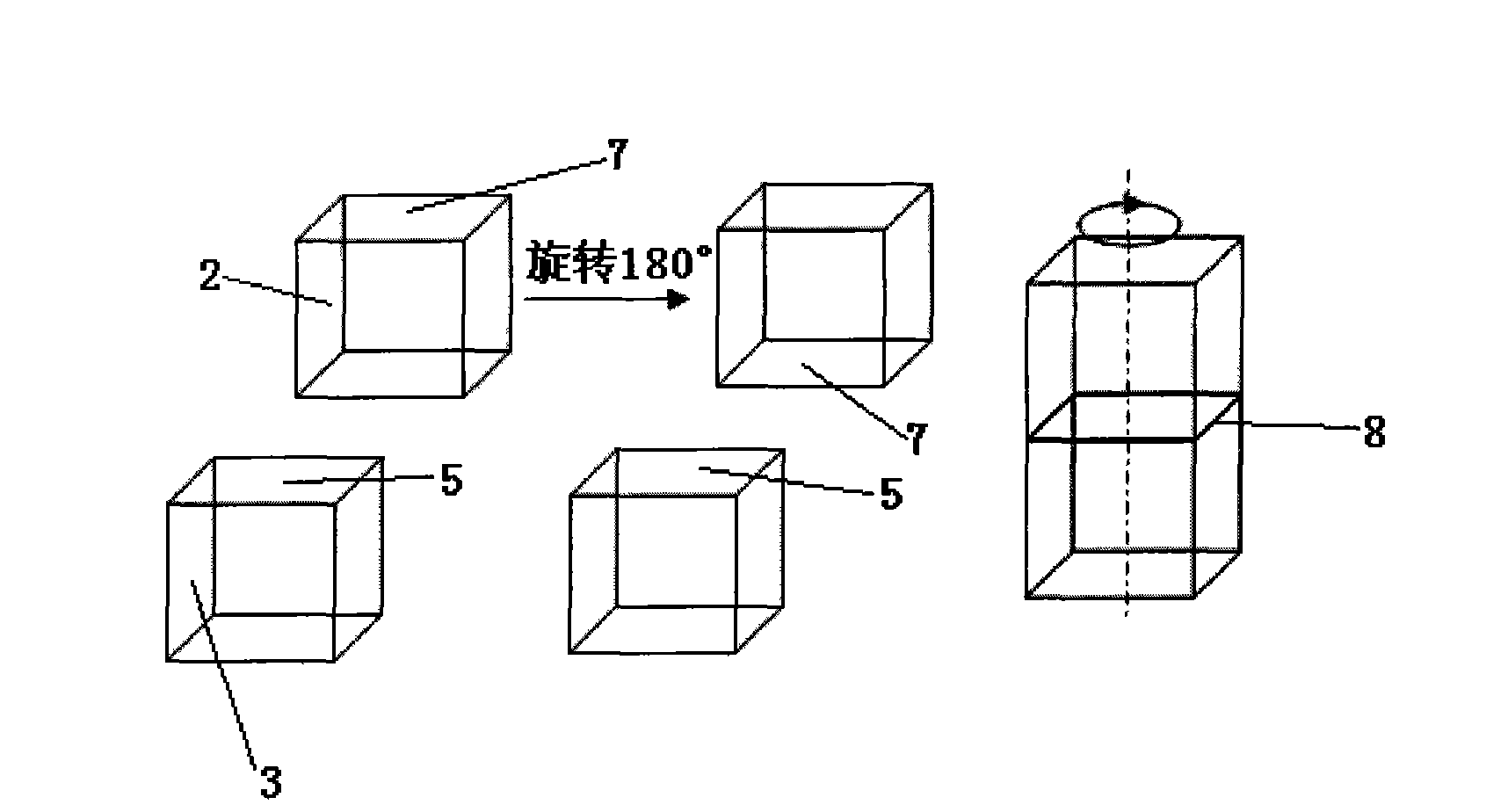

[0022] (1) Cut off the convex part and the bottom of the sponge foam body 1 to a thickness of 15 cm; (2) At least 2 pieces of the foam body) 2 and 3 are bonded along the upper and lower surfaces perpendicular to the direction of movement of the foam body ( See image 3 ), the bonded interface 8 is formed by the top surfaces 7 and 5 of the two foam bodies facing each other, that is, the foam body 2 is rotated 180° so that the top surface 7 is opposite to the top surface 5 of the foam body 3; (3) Then along the vertical axis ( image 3 The dotted line shows the upper and lower axis) parallel to the direction of the rotary cut into a sheet of sponge ( image 3 The direction of the middle rotating arrow indicates the direction of rotary cutting, and the straight arrow indicates the direction of bubble movement, that is, the upper and lower axis perpendicular to the direction of bubble movement is the central axis of rotary cutting).

Embodiment 3

[0024] (1) Cut off the convex part and bottom surface of the sponge foam body 1 by 25cm; (2) Then at least two pieces of the foam body 2 and 3 are bonded along the upper and lower surfaces, and the bonding interface is composed of two bubbles The bottom surface of the body is formed oppositely, that is, the foam body 3 is rotated 180° so that the bottom surface is opposite to the bottom surface of the foam body 2; (3) Then, it is cut into slices along the direction parallel to the vertical axis perpendicular to the movement direction of the foam body. Sponge (upper and lower axis perpendicular to the direction of bubble movement is the central axis of the rotary cutting).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com