Pneumatic tire

A technology of pneumatic tires and tires, which is applied to tire parts, tire tread/tread pattern, transportation and packaging, etc., and can solve problems such as reduction of ground contact area, uneven wear of ground pressure growth, and residual height of tire shoulder ground , to ease the ground pressure and suppress uneven wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

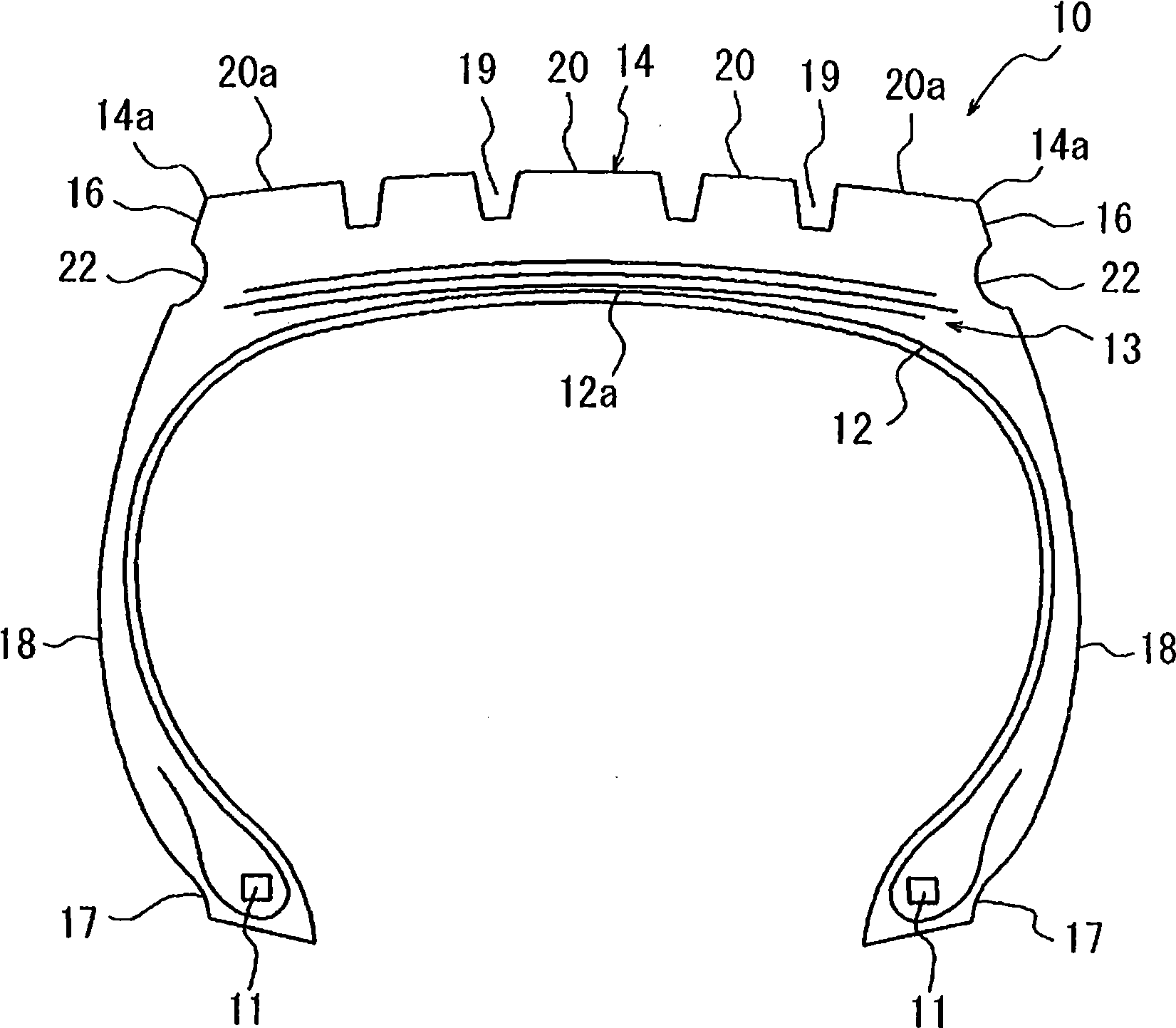

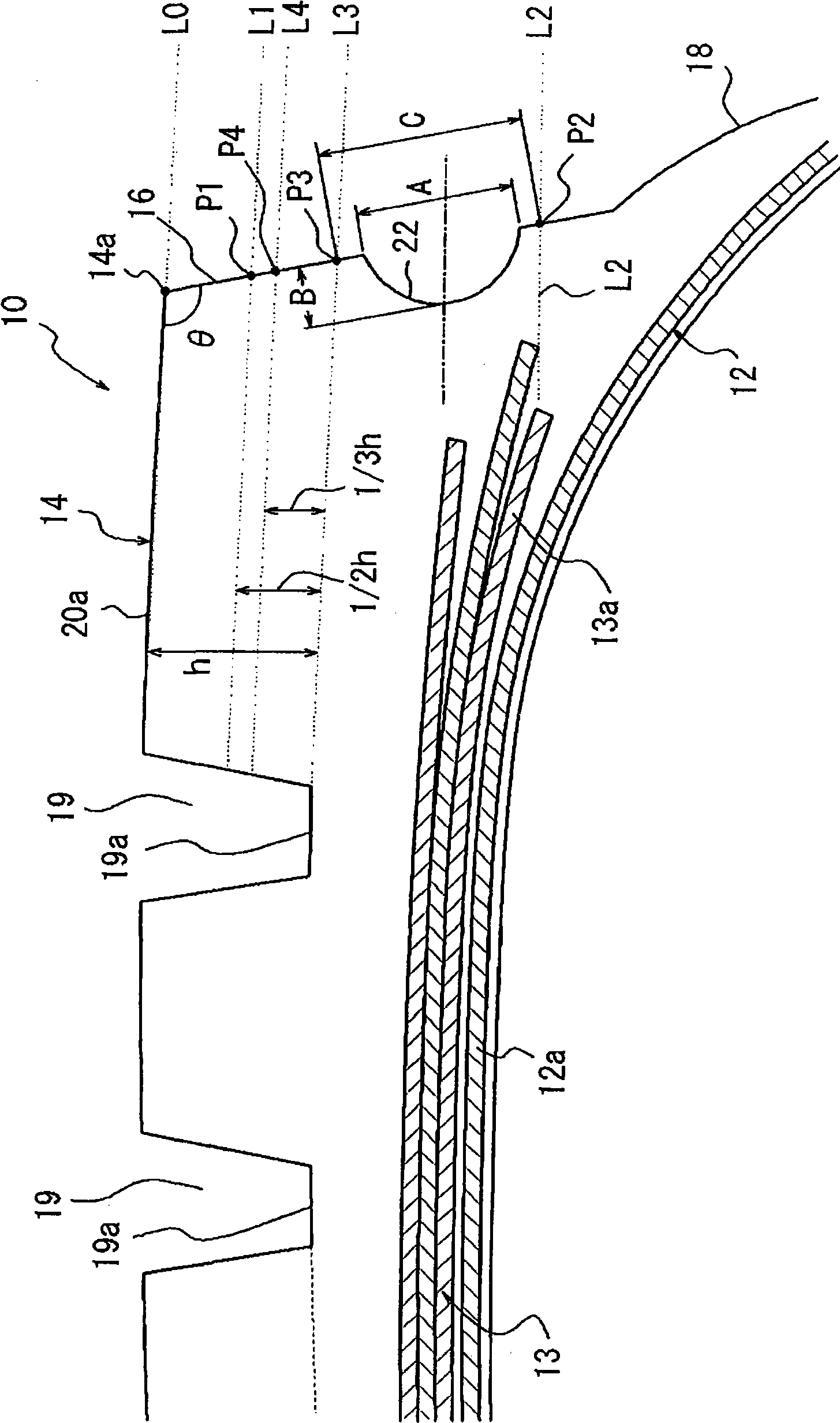

[0046] Below, refer to figure 1 as well as figure 2 One embodiment of the pneumatic tire of the present invention will be described.

[0047] figure 1 It is a cross-sectional view showing a pneumatic tire 10 along the tire width direction, and a belt layer 13 and a belt layer 13 are provided in this order on the outer side in the tire radial direction of the crown portion 12a of the carcass layer 12 extending annularly between a pair of left and right beads 11. The tread contact surface 14. In addition, in the illustrated example, the belt layer 13 has multiple layers.

[0048] In addition, in the present embodiment, the pneumatic tire 10 includes a shoulder reinforcement portion 16, a bead portion 17, and a sidewall portion 18; the shoulder reinforcement portion 16 is directed radially inward from both ends 14a in the width direction of the tread contact surface 14, respectively. Extension; the bead portion 17 is formed by embedding the bead 11 inside; the sidewall porti...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap