Railway crane with outer rail superelevation levelling function

A leveling function, crane technology, applied in the direction of cranes, etc., can solve problems such as cumbersome operation, and achieve the effect of solving the overall tilt problem

Active Publication Date: 2010-11-10

WUHAN BRIDGE INDUSTRIAL EQUIPMENT COMPANY LTD

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, this method needs to add a suitable independent oil cylinder and install it under the turntable of the crane, and there are also requirements for the road surface where the oil cylinder base is placed, that is, it is flat and the foundation has sufficient strength. It retracts and turns to be placed horizontally so that it will not affect the rotation of the turntable or collide with other things around it, and the operation is relatively cumbersome

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

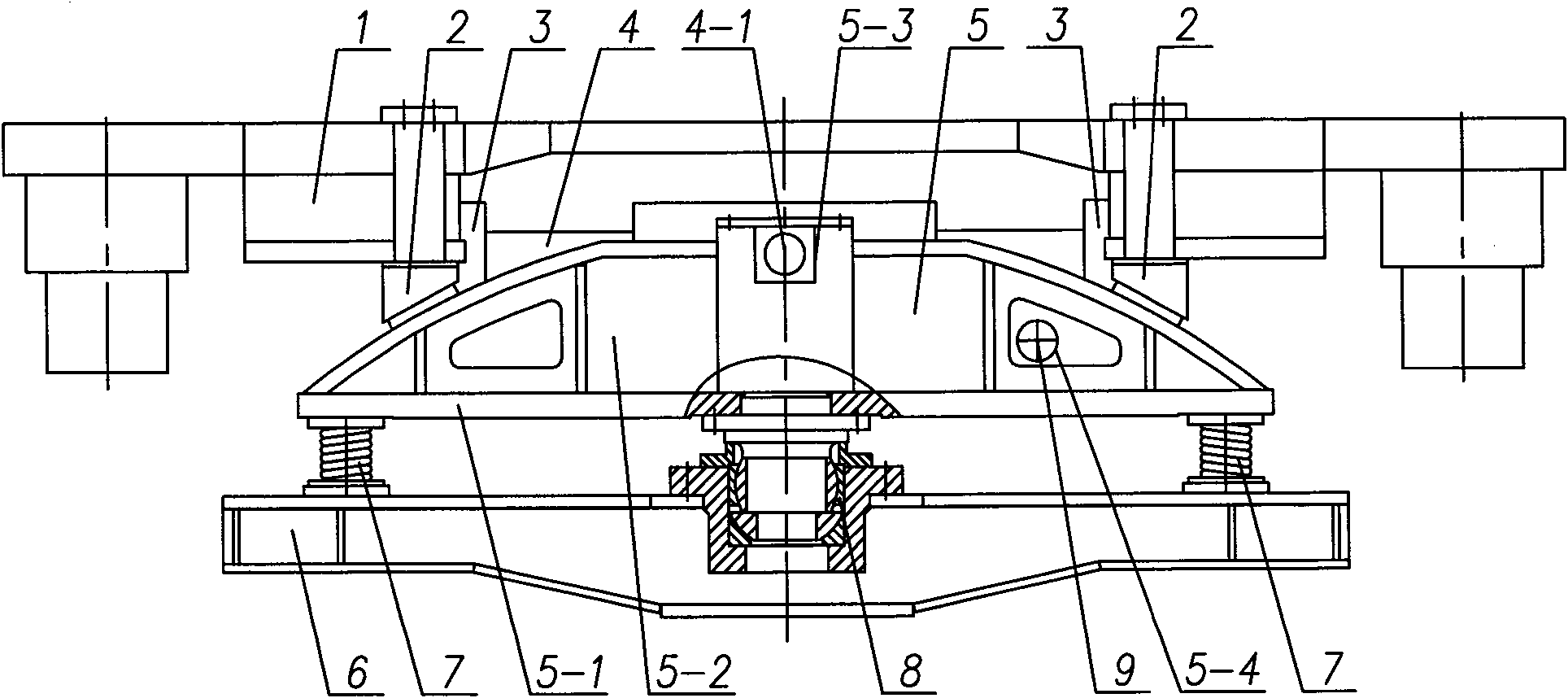

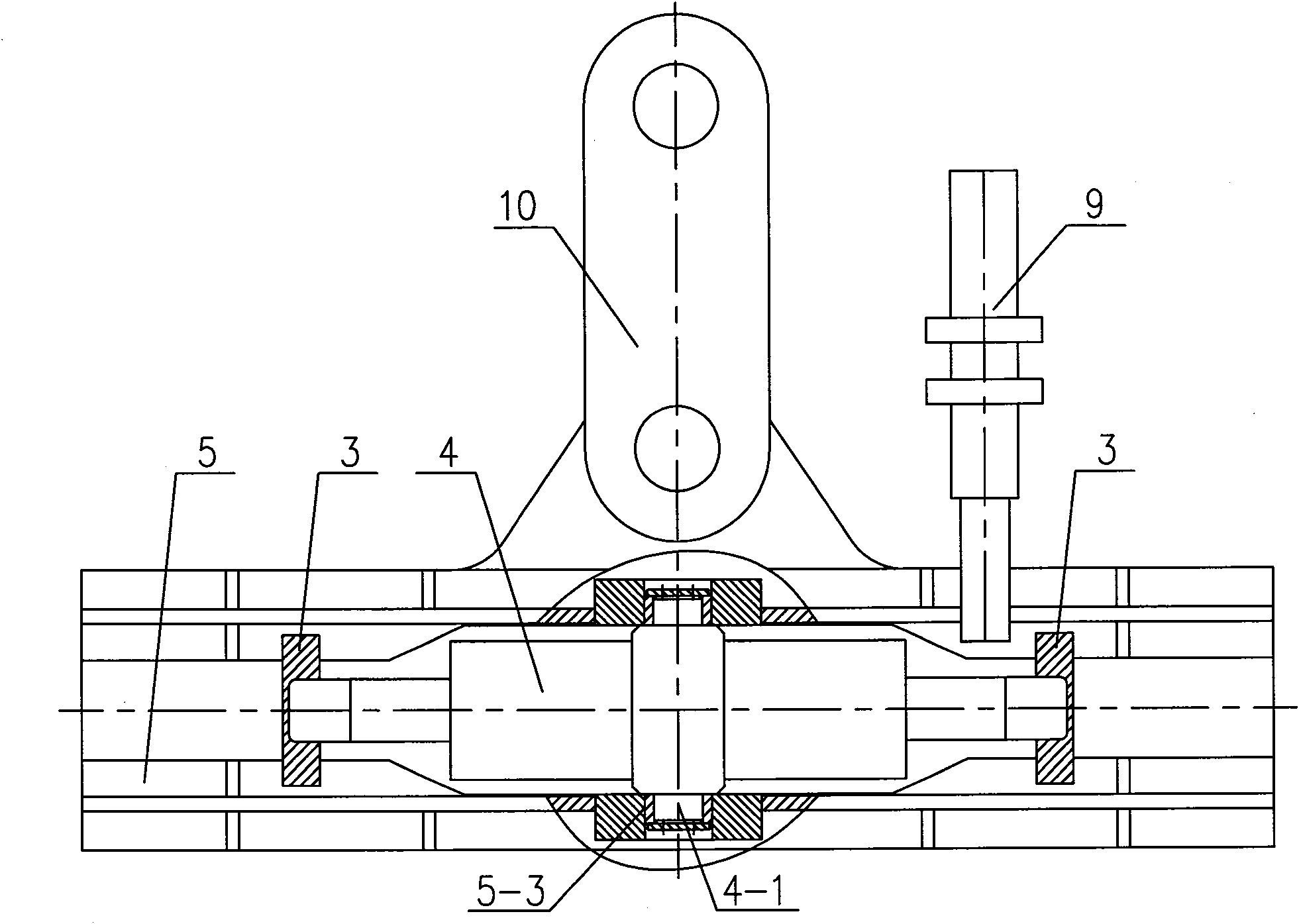

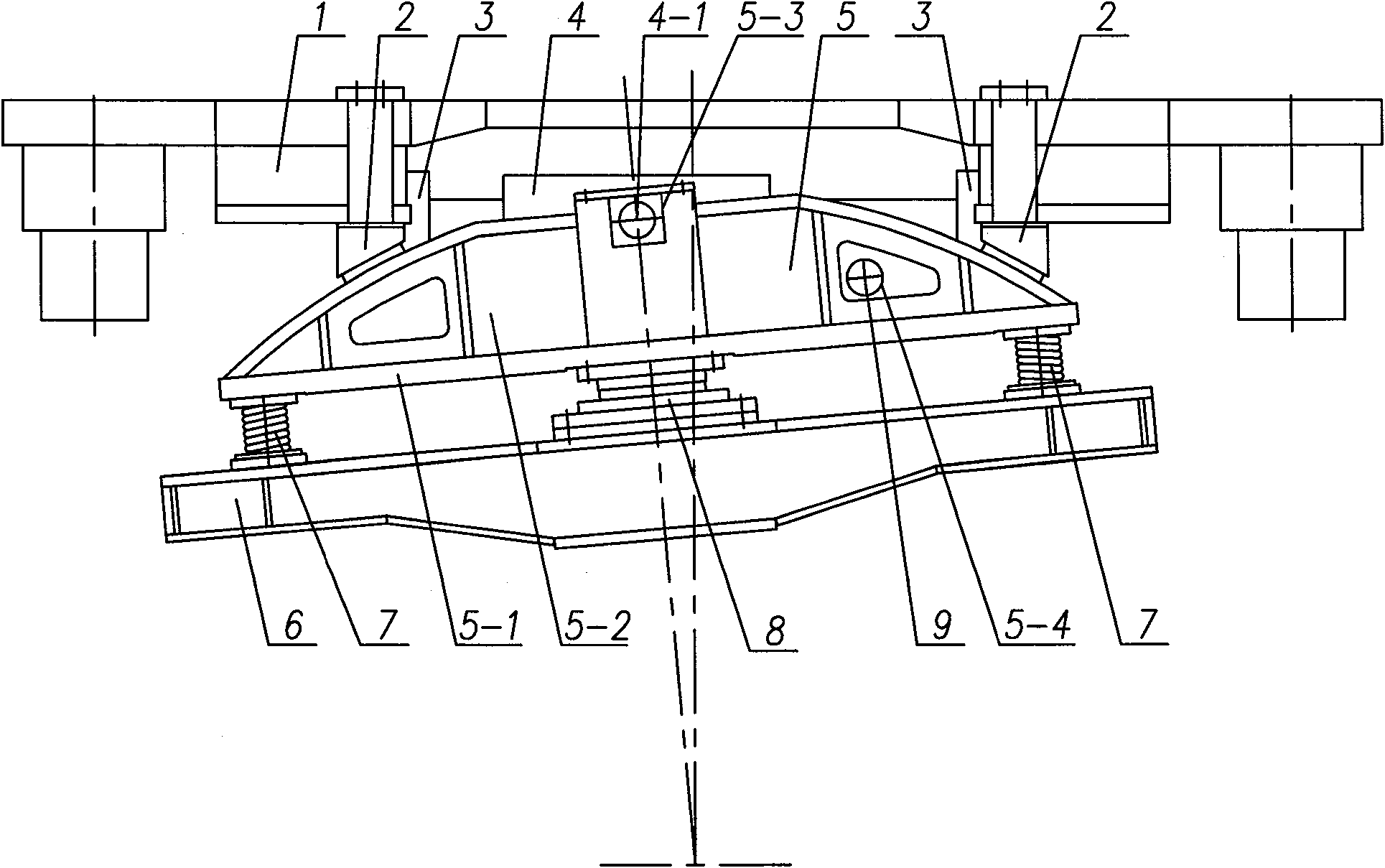

The invention provides a railway crane with outer rail superelevation levelling function and belongs to the crane field. The crane realizes levelling by arranging an arched beam levelling device between an upper vehicle frame and a lower steering frame. The device pushes the vehicle frame by a piston rod base matched with a double-boom oil cylinder such that the vehicle frame relatively slides along an arched beam matched therewith through skid shoes so as to gradually reduce the inclination degree of the vehicle frame above the arched beam to realize levelling; synchronously, as the double-boom oil cylinder can rotate with certain angle around the short shafts at the two sides of a cylinder with respect to the arched beam and the arched beam base plate can also slightly rotate with respect to the steering frame, the vehicle frame and the upper components can be levelled to be horizontal even though the arched beam and the steering frame connected to the lower portion of the arched beam are inclined. The invention solves the problem that the crane integrally inclines when the crane works at a railway curve by an integrated levelling device and ensures the rated hoisting performance and working safety when the crane works at a railway curve.

Description

A railway crane with super high leveling function of outer rail technical field The invention relates to a railway crane with an outer rail super-high leveling function, which belongs to the field of cranes. Background technique Railway cranes are mainly used for railway rescue, and are also suitable for loading and unloading of large cargo, equipment installation, railway construction, laying rail rows, replacing turnouts, erecting bridges and other engineering operations. When the railway crane is working on the curve, the whole crane is in a tilted state due to the super high outer rail, which not only makes the crane overturn easily and cannot reach the rated lifting capacity, but also may It will cause part of the outline of the crane to exceed the prescribed railway rolling stock limit, which will affect the operation of adjacent line vehicles and bring great safety hazards. Therefore, it is necessary to adjust the inclined crane to a level state in order to guaran...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B66C23/50B66C23/80

Inventor 杜斌武许俊张建辉冯俊莲操建丽张真

Owner WUHAN BRIDGE INDUSTRIAL EQUIPMENT COMPANY LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com