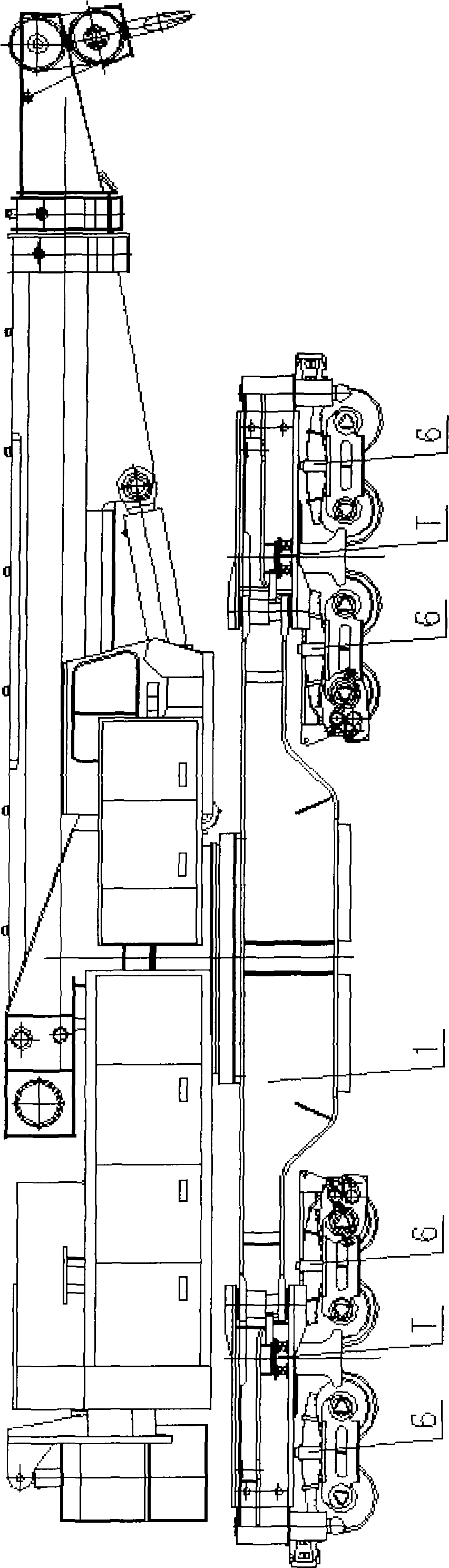

Railway crane with outer rail superelevation levelling function

A leveling function, crane technology, applied in cranes and other directions, can solve problems such as cumbersome operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

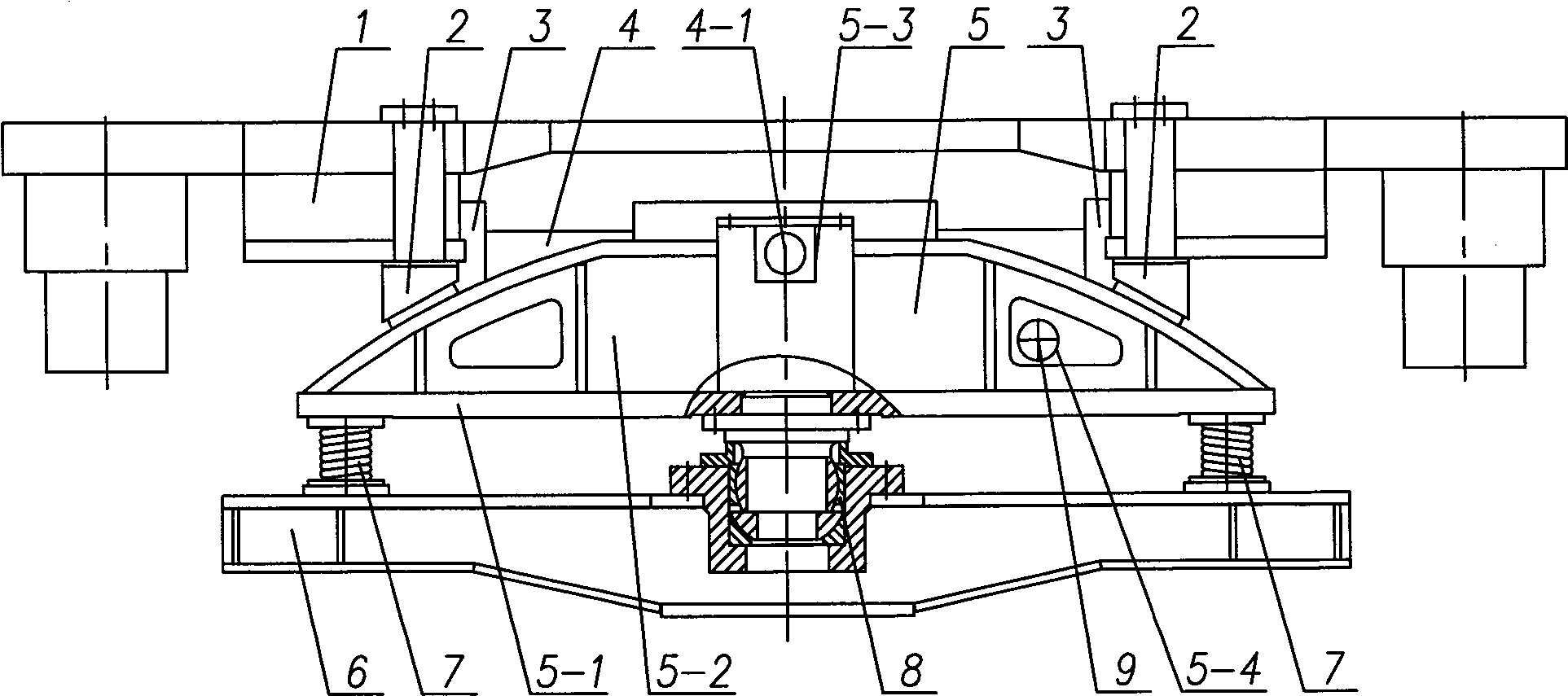

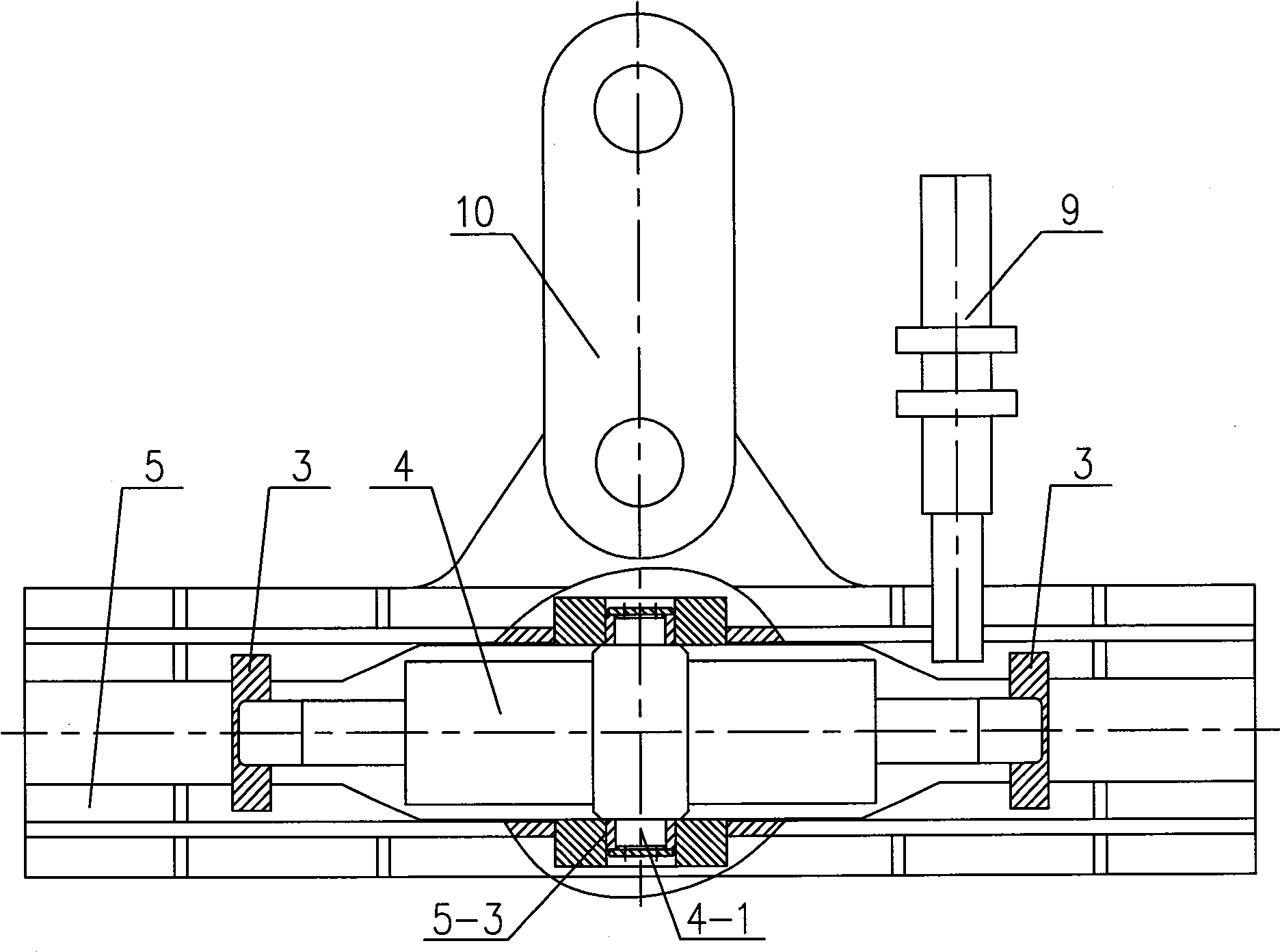

[0022] Now further illustrate how the present invention is implemented in conjunction with accompanying drawings:

[0023] The curved beam 5 of the curved beam leveling device T in this design is composed of a lower bottom plate 5-1 and an upper curved plate, and the upper curved plate is composed of two parallel curved plates 5-2, and the curved plate 5-2 The outer cylindrical surface of each arc-shaped plate faces upwards, and a sliding shoe 2 is arranged on the left and right sides above each arc-shaped plate. The outer cylindrical surface of -2 fits and can slide along it. The double extension rod oil cylinder 4 is arranged in parallel between the two arc-shaped plates 5-2, and the short shafts 4-1 on both sides of the cylinder are installed in the corresponding recesses of the arc-shaped plates respectively. In the groove 5-3, the groove opening is closed with clamps and bolts. The axis direction of the minor axis is perpendicular to the axis direction of the cylinder. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com