Improved roller-type discharging structure

A technology of roller type and silo, which is applied in the field of improved roller unloading structure, which can solve the problems of difficult control of unloading, reduction of work efficiency, winding, etc., and achieve the effect of preventing material winding and improving unloading work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

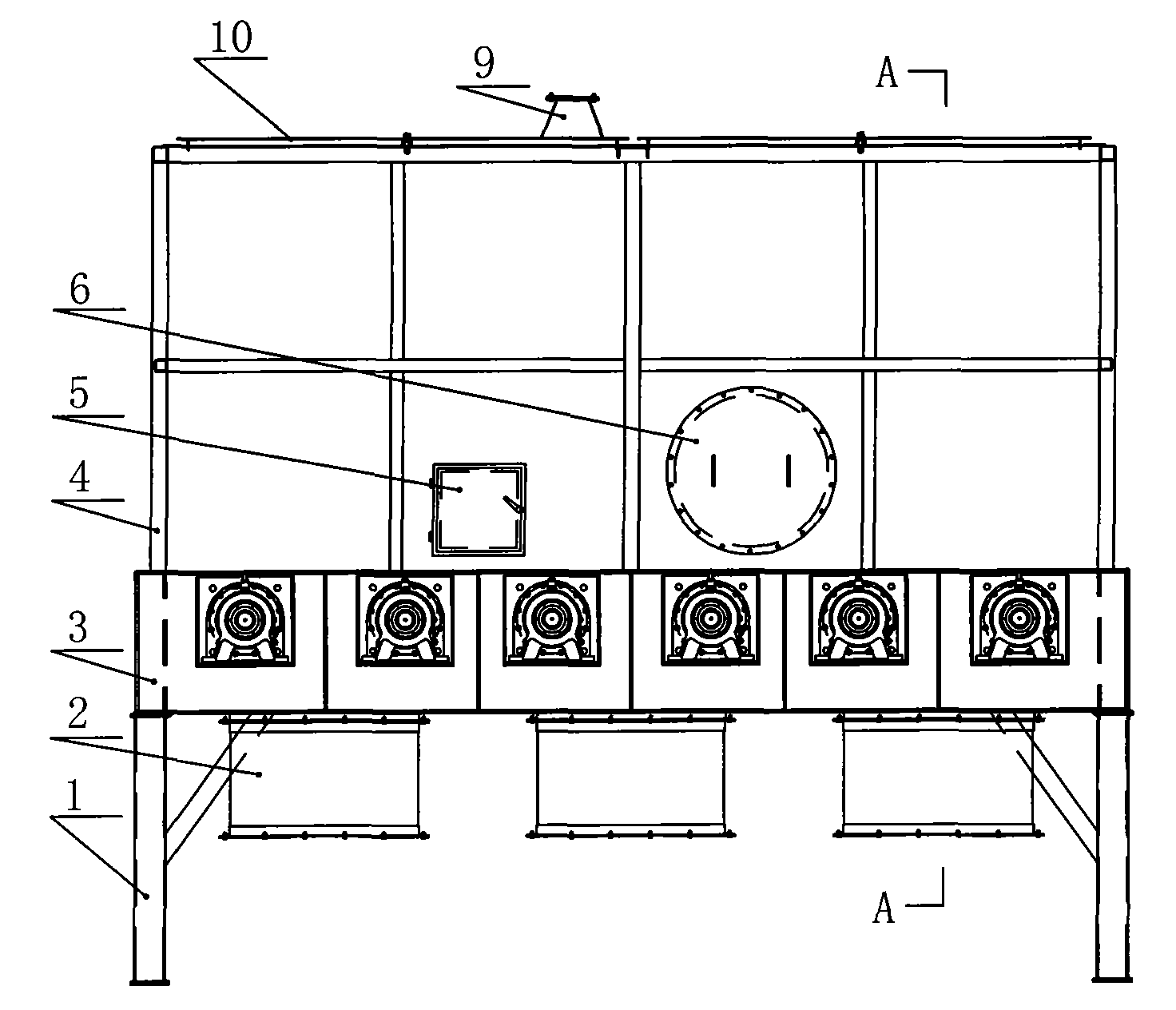

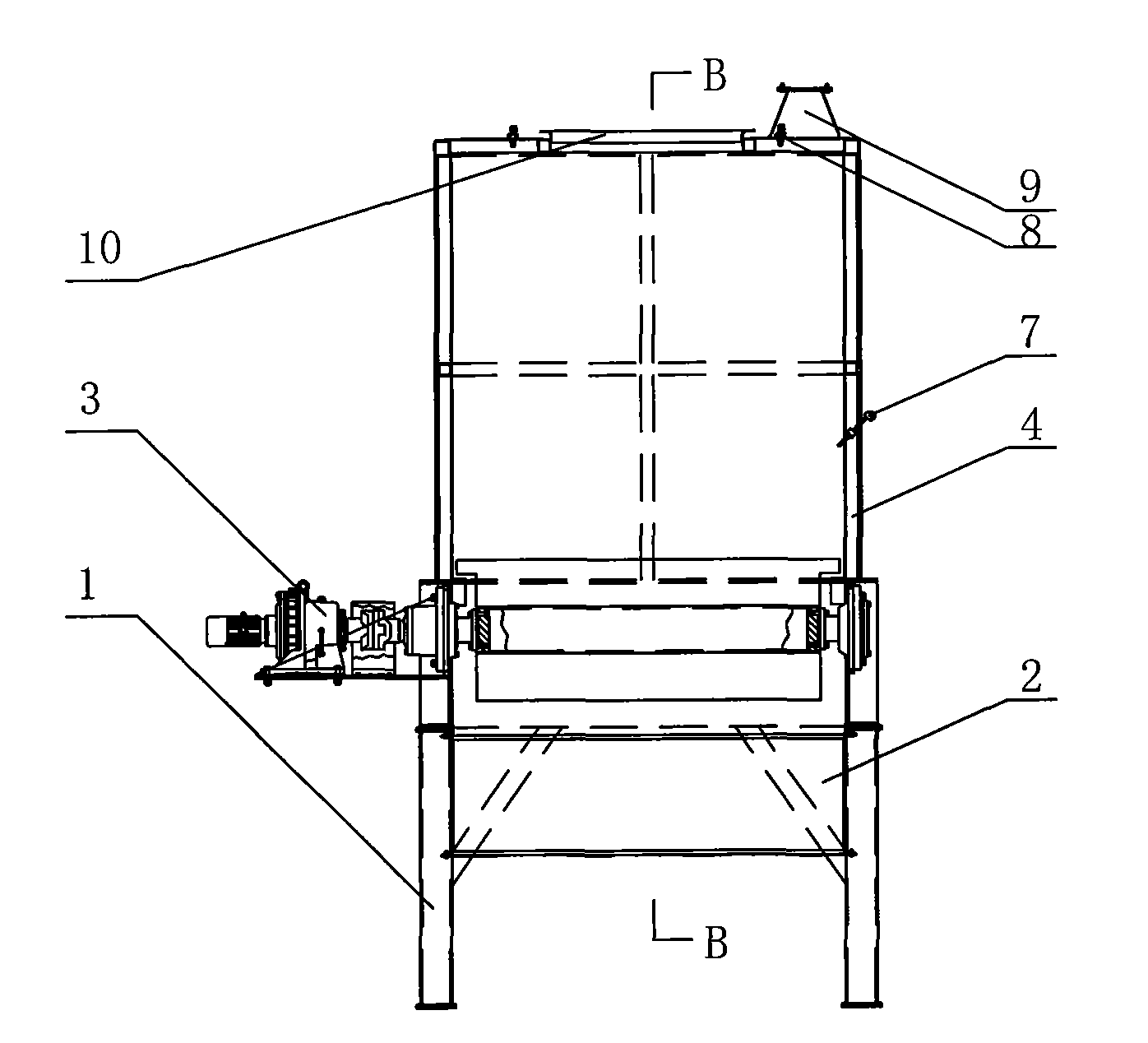

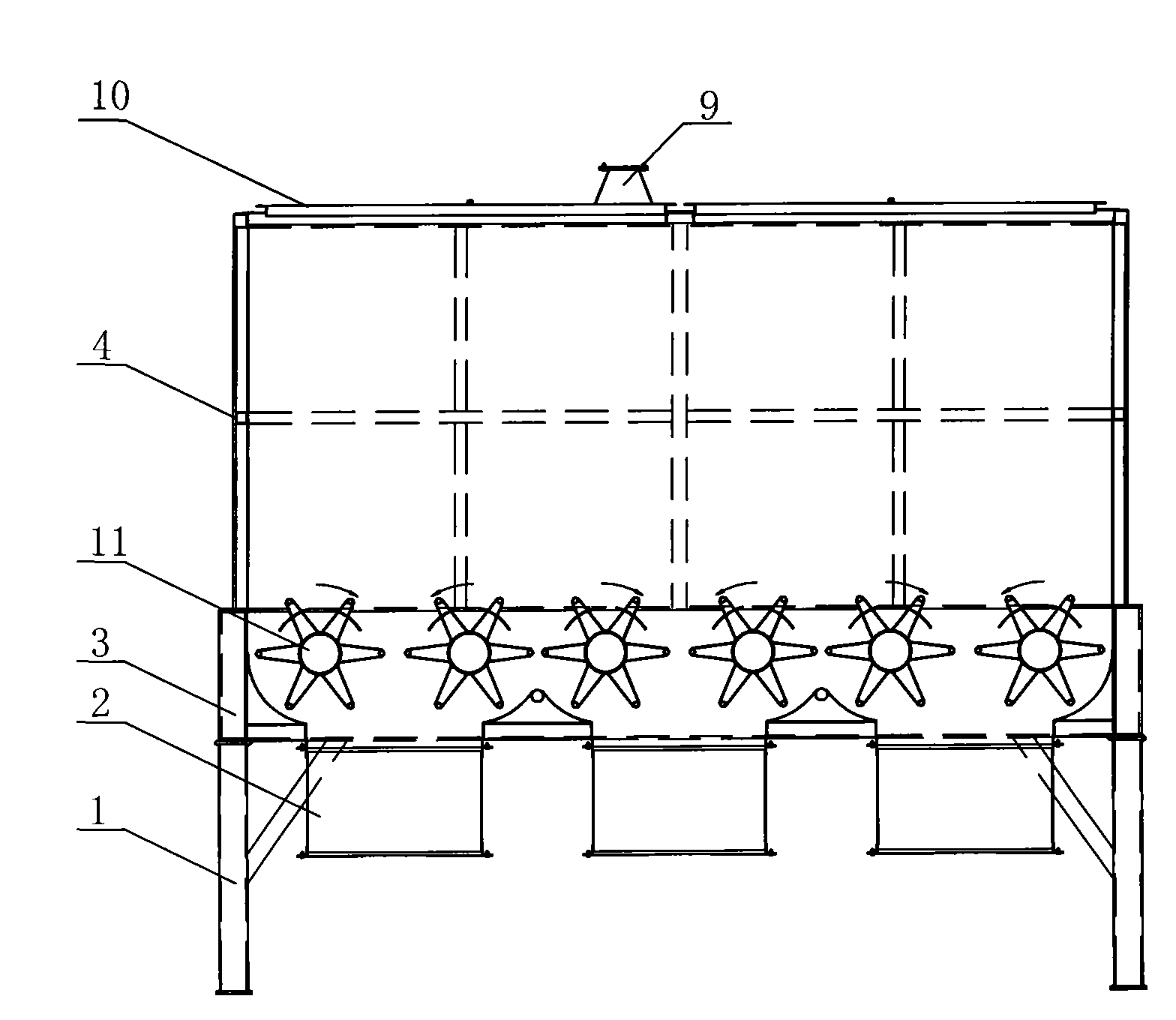

[0010] See figure 1 , figure 2 , image 3 , the present invention comprises feed bin 4, support 1, unloading driving device 3, feed port 10 is installed on feed bin 4 upper part, unloading driving device 3 is installed on bracket 1, feed bin 4 is installed on unloading driving device 3 , The blanking opening 2 is installed on the lower part of the blanking drive device 3 . Wherein, the blanking driving device 3 is a rotating roller 11 with blades; it is provided with three groups; there are three blanking ports 2; the three blanking ports 2 are correspondingly installed under the three groups of blanking driving devices 3; The material driving device 3 is provided with a pair of rotating rollers; the rotating direction of the pair of rotating rollers is opposite; the top of the material bin 4 is also equipped with a dust suction device 9 and a fire extinguishing nozzle device 8 . figure 1 Among them, 5 is the inspection door, 6 is the inspection door, and 7 is the thermoco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com