Safe guarding cage vertical ladder

A straight ladder, safe technology, applied in the direction of ladders, buildings, building structures, etc., can solve the problem of straight ladders without a rest platform cage, and achieve the effect of saving measures and materials, simple production and convenient installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

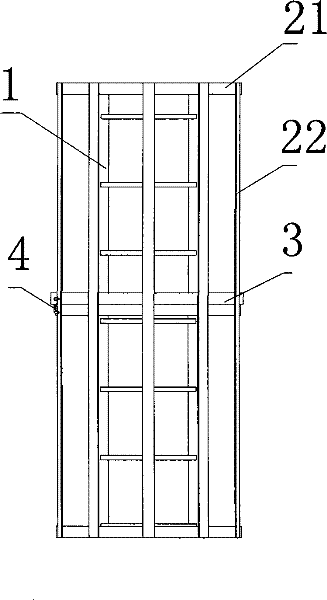

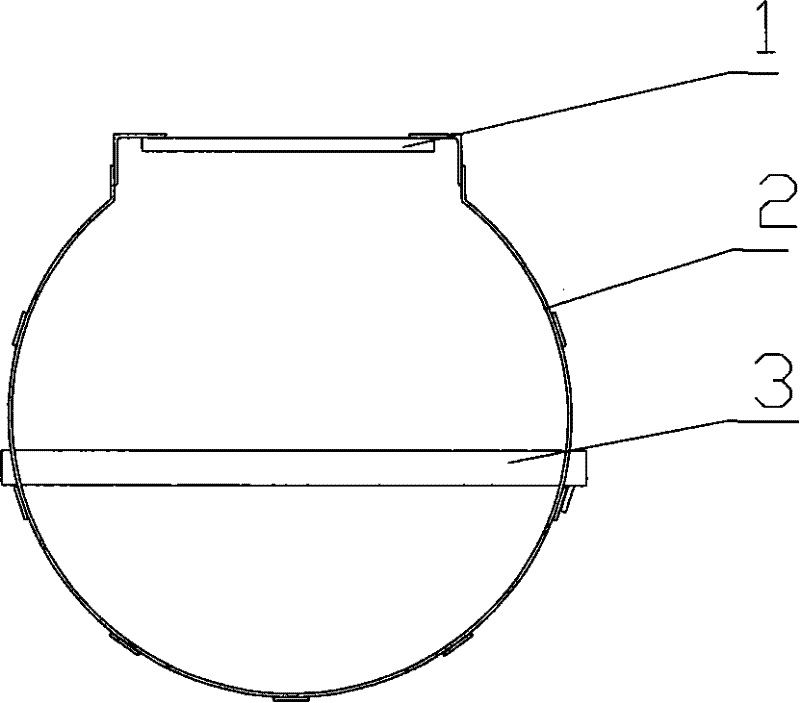

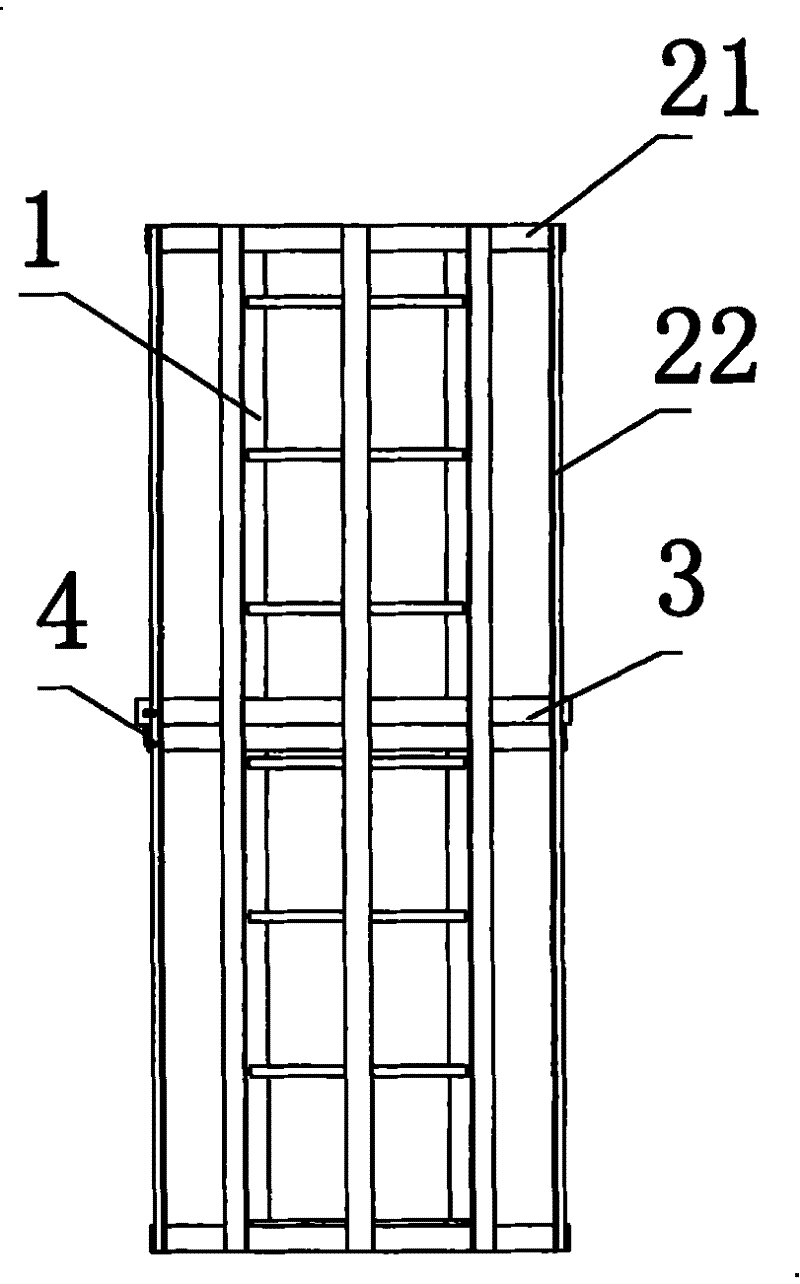

[0012] Such as figure 1 with figure 2 As shown, a safety cage straight climbing ladder, it includes a straight climbing ladder 1 and a cage 2, the cage 2 is composed of transverse circular flat steel 21 and longitudinal flat steel 22 interlaced, it also includes a number of transverse supports 3, each One end of each transverse support 3 is rotatably connected to the transverse annular flat steel 21 and the longitudinal flat steel 22 of the cage 2 at the alternate positions with a connecting piece 4 , and the other end is lapped on the transverse annular flat steel 21 .

[0013] The connecting piece 4 is a U-shaped part, one end of which is welded and fixed to the longitudinal flat steel 22, and the other end is overlapped and fixed to the horizontal circular flat steel 21 of the cage 2, and one end of the lateral support 3 can be flipped up and down to connect the U-shaped part 4.

[0014] Described transverse support 3 is a section steel, and its length matches with cage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com