Protrudent toothed belt groove longitudinal bending mode conversion dual-rotor ultrasonic motor

An ultrasonic motor and mode conversion technology, which is applied in the direction of piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, electrical components, etc., can solve problems such as complex processing technology, and save bearings, The effect of high torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

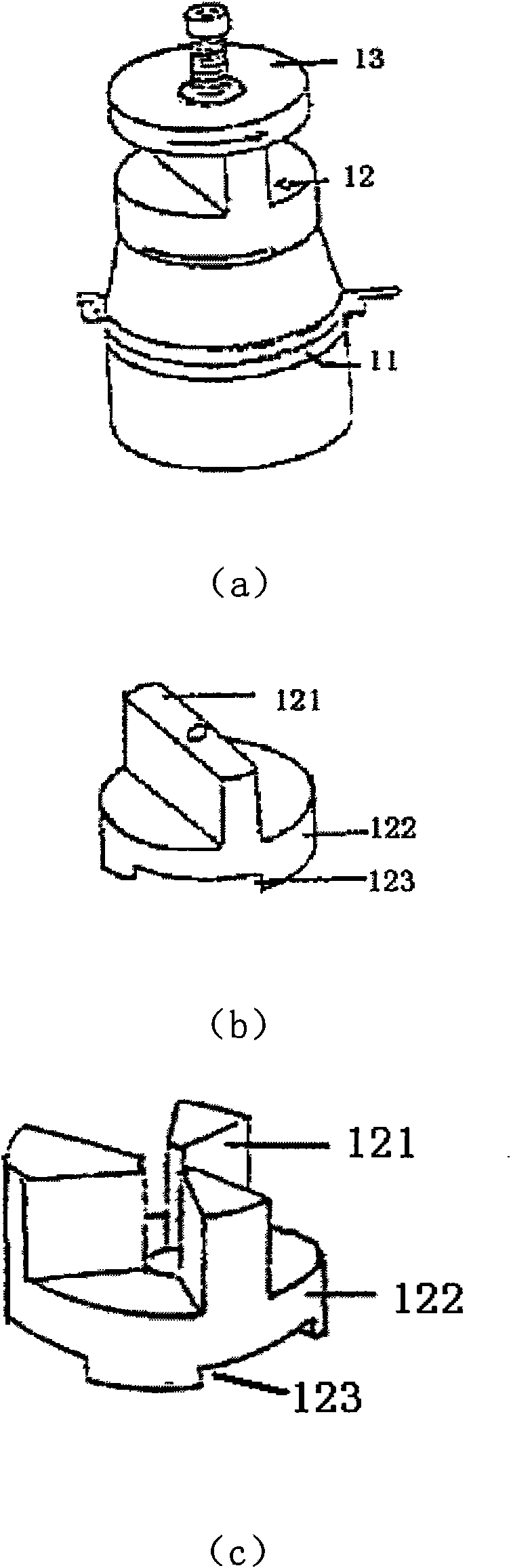

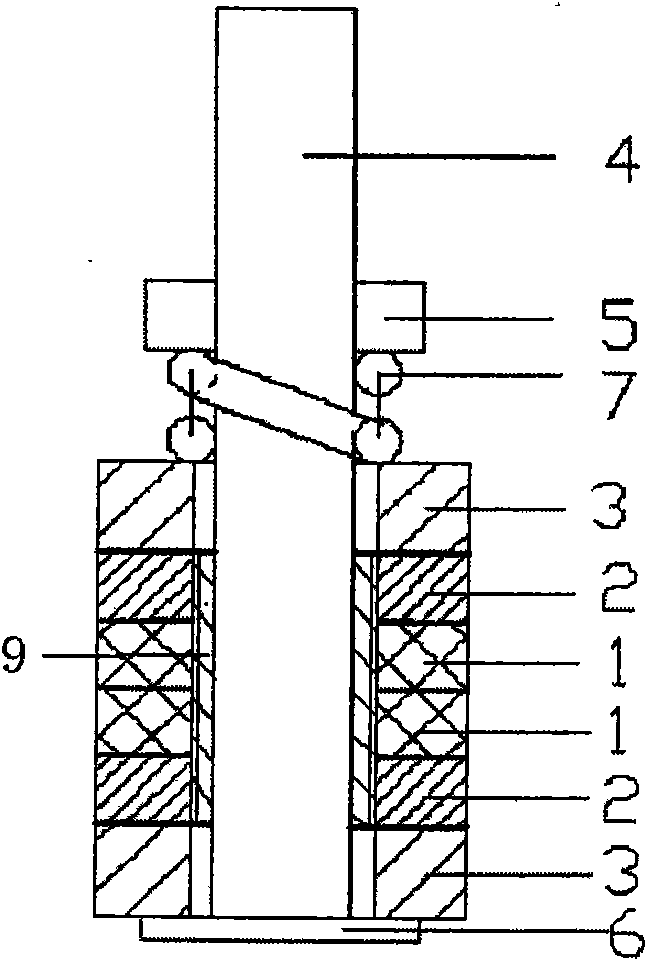

[0015] The longitudinal-bending mode conversion double-rotor ultrasonic motor with protruding teeth and grooves proposed by the present invention has a structure such as figure 2 Said, including the first rotor 3 , the second rotor 3 , the stator, the rotating shaft 4 , the chassis 6 and the solenoid 9 . The first rotor 3 , the solenoid tube 9 and the second rotor 3 are sequentially fitted on the rotating shaft 4 from top to bottom and then placed on the chassis 6 . The stator is screwed on the screw tube 9 through the stator cap, and the stator is composed of the first stator cap 2, the first piezoelectric sheet 1, the second piezoelectric sheet 1 and the second stator cap 2 which are stacked in sequence. The nut 5 applies a preload to the first rotor 3 and the second rotor 3 through the spring 7 .

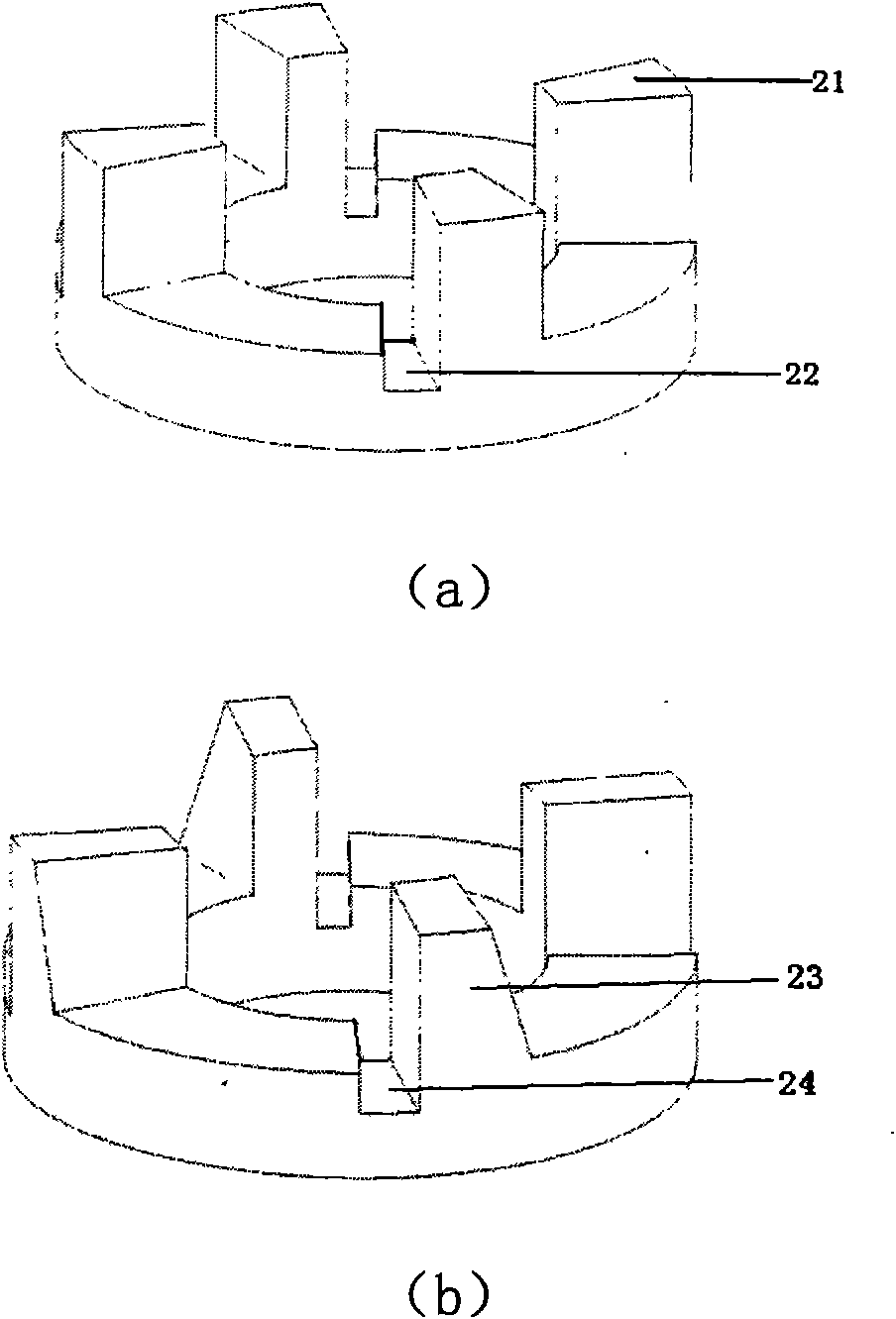

[0016] In the above ultrasonic motor, the structures of the first stator cap and the second stator cap are frustum-shaped, such as image 3 As shown in (a), in one embodiment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com